Water-stopping deep foundation pit excavation method and structure thereof

A deep foundation pit and water blocking technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of unstable people's livelihood, increased cost input, resource loss and waste, etc., and achieve low-carbon environmental protection and resource availability. The effect of sustainable development, compact and reasonable process arrangement, and prevention of water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

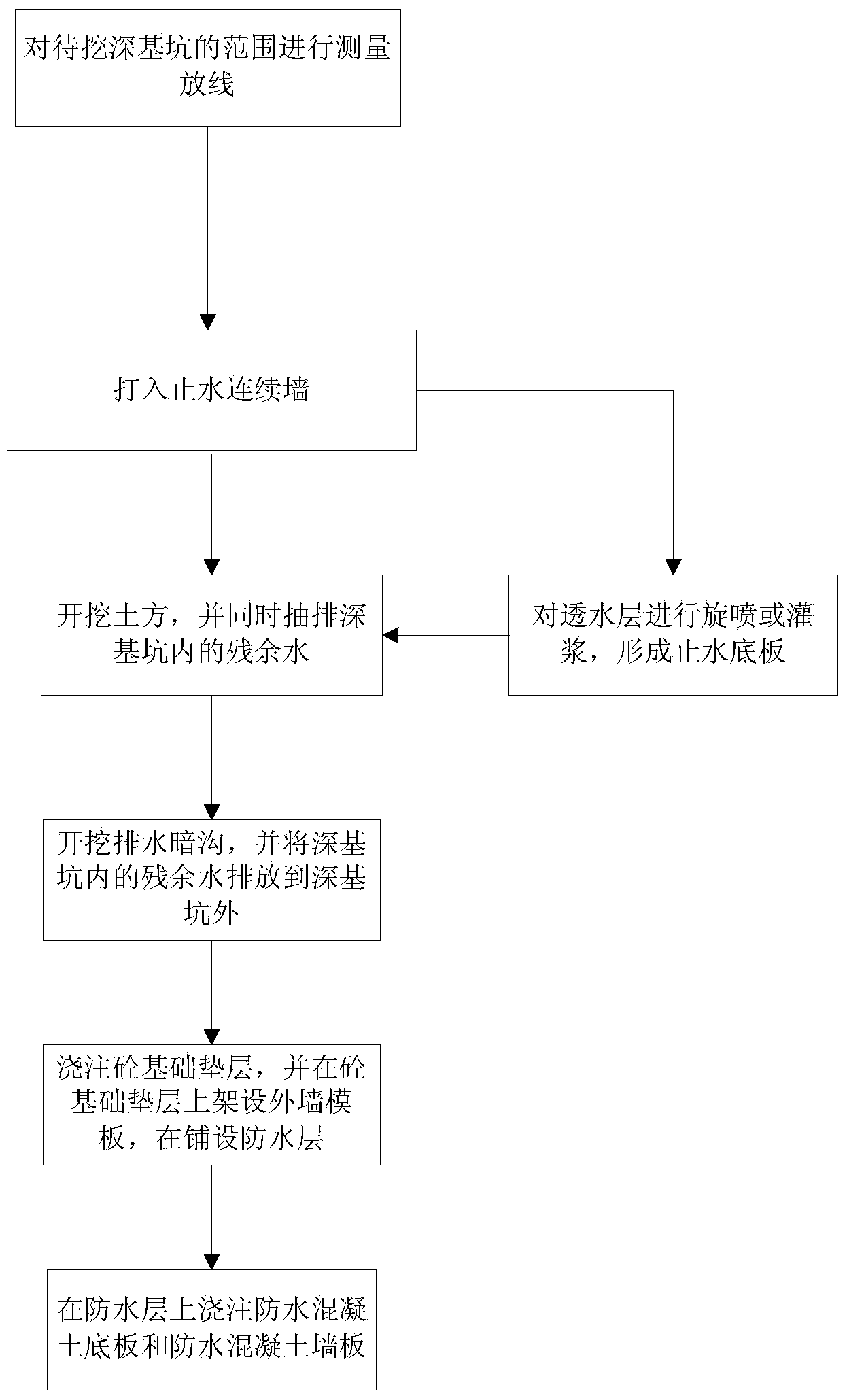

[0057] Such as figure 1 with Figure 5 As shown, a deep foundation pit water stop excavation method comprises the following steps:

[0058] A deep foundation pit water stop excavation method, comprising the following steps:

[0059] (1) Measure and set out the range of the deep foundation pit to be excavated;

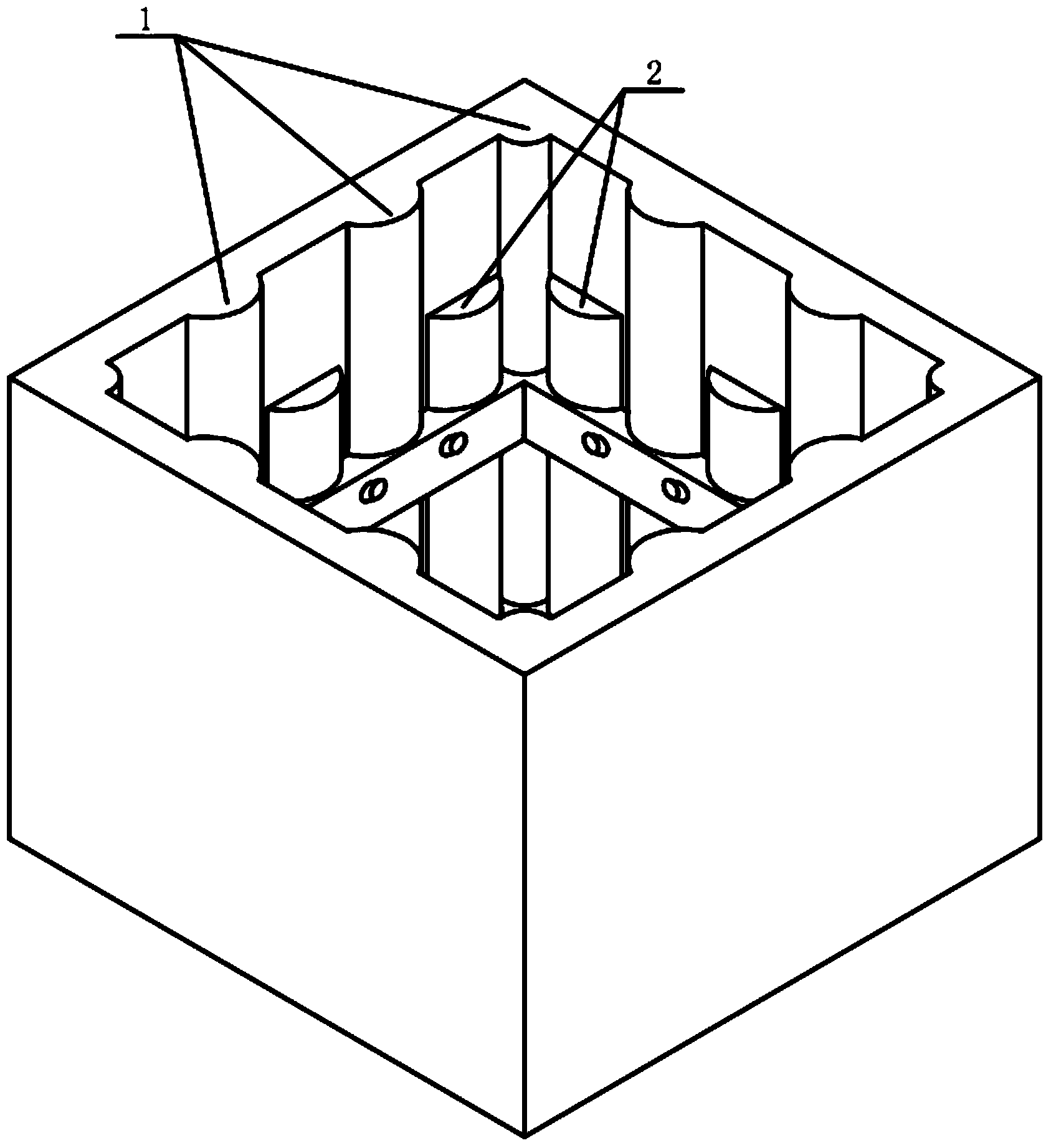

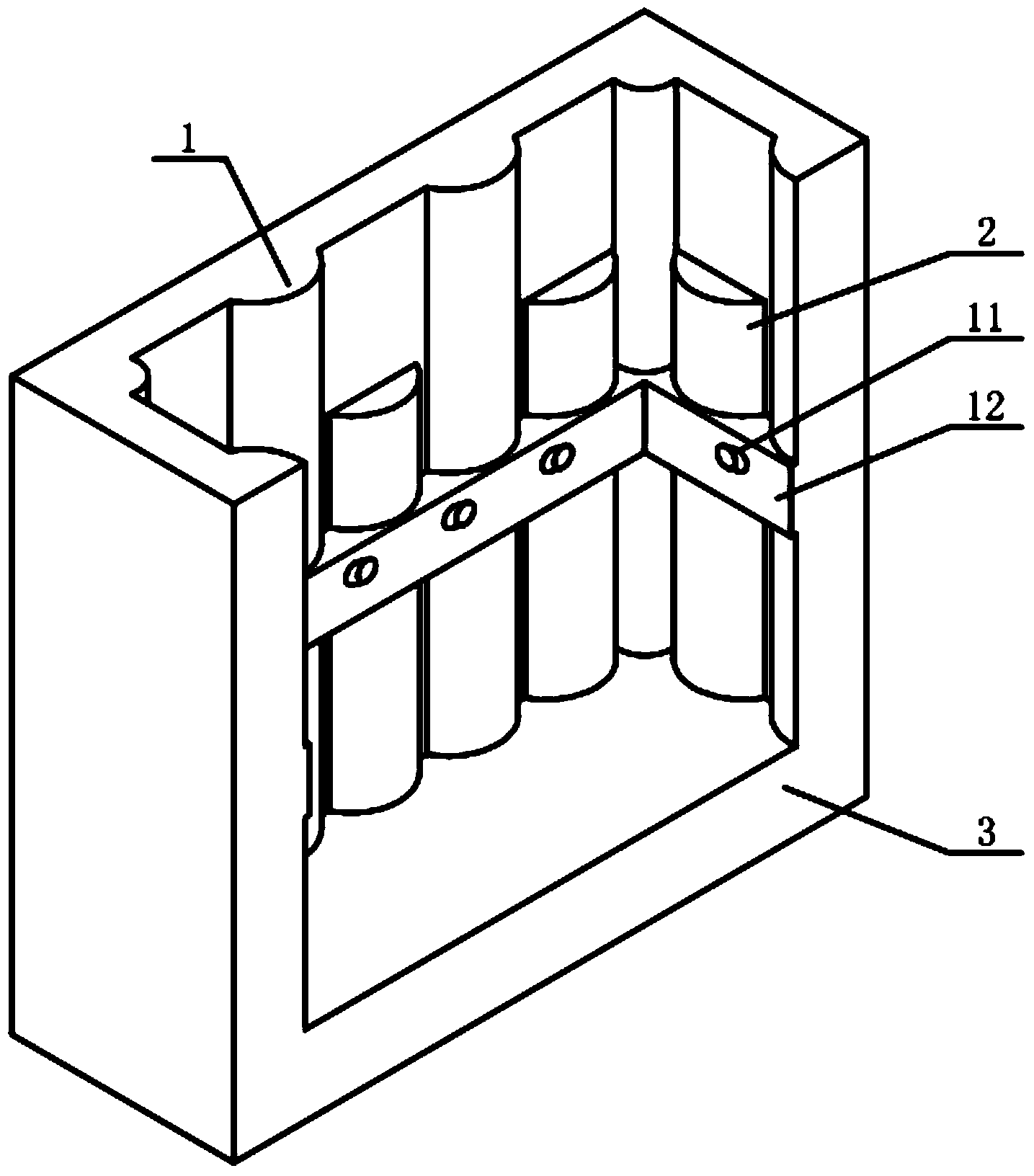

[0060] (2), drive wall retaining piles 1 downward along the side wall of the deep foundation pit to be dug, after the adjacent wall retaining piles 1 are driven in at intervals, drive rotary grouting piles 2 in the intervals of retaining wall piles 1 to form a continuous water stop Wall, the water-stop continuous wall extends into the bearing layer below the foundation design level;

[0061] (3), when the bearing layer under the foundation design elevation is a water-permeable layer, then under the found...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com