Titanium manganese alloy smelting device

A titanium-manganese alloy and smelting furnace technology, which is applied in the field of metal smelting, can solve problems such as difficulty in ejection, cracking, cracked ingot end face, etc., and achieves the effects of saving gas extraction energy consumption, preventing alloys from being oxidized, and reducing gas extraction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

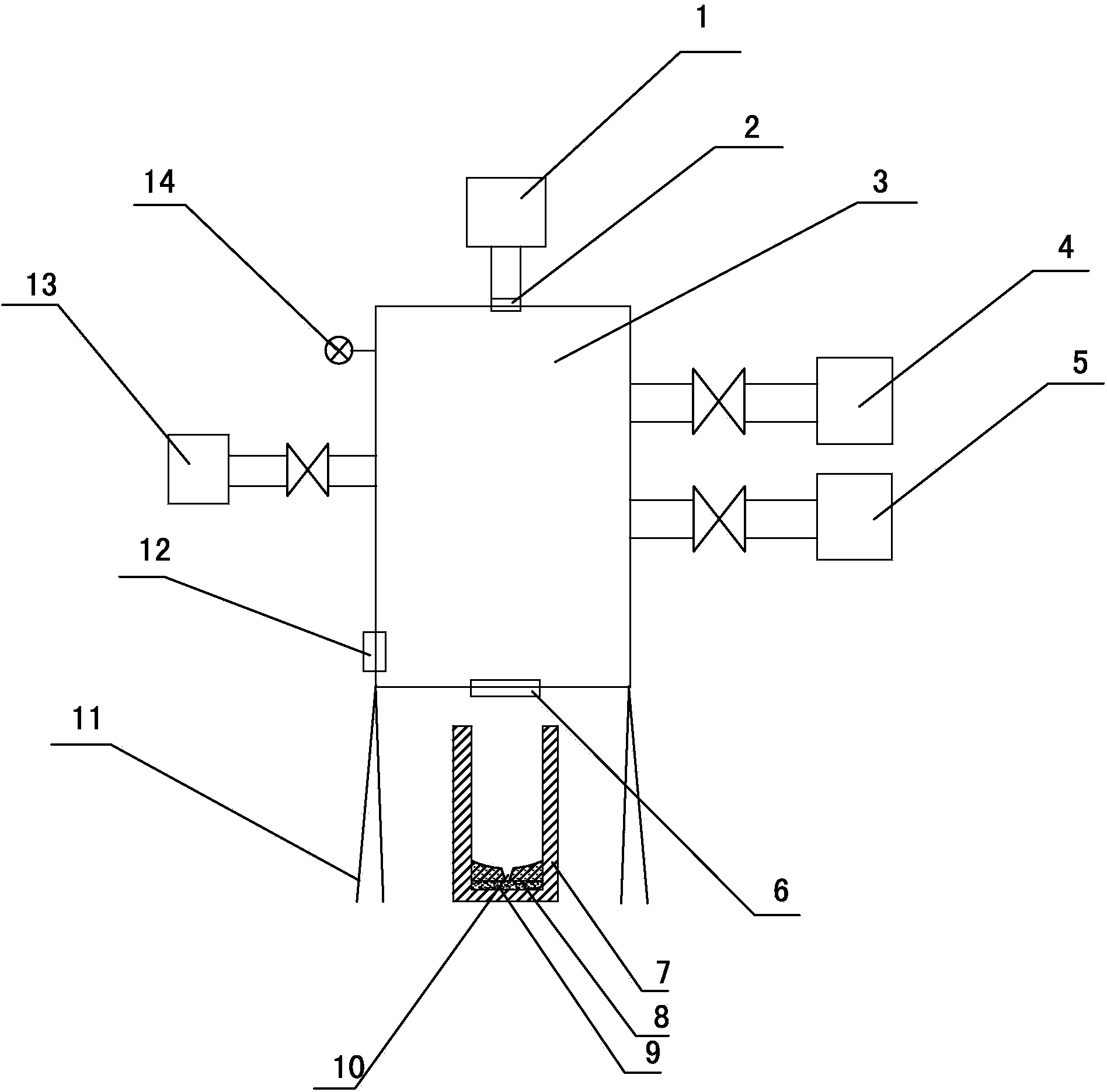

[0016] Such as figure 1 As shown, it includes a smelting furnace 3, a vacuum pump 4, a traction molecular pump 5, a gas distribution device 13, and a pouring mold 7. A feeding device 1 is arranged above the smelting furnace 3, and the feeding device 1 passes through the pipeline and the feeding of the smelting furnace 3 top Port 2 is connected, the vacuum pump 4, traction molecular pump 5, and gas distribution device 13 are respectively connected to the melting furnace 3 through pipelines, and the pipelines between the vacuum pump 4, traction molecular pump 5, gas distribution device 13 and the melting furnace 3 are respectively provided with valves A vacuum gauge 14 and a heating device 12 are arranged on one side of the smelting furnace 3, supports 11 are arranged on both sides of the bottom of the smelting furnace 3, a discharge port 6 is provided in the middle of the bottom of the smelting furnace 3, and a corresponding discharge port 6 is provided at the bottom of the smel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com