Roots atmosphere direct-exhausting smart machine unit

An intelligent unit, straight row technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problems of large unit energy consumption and Roots pump damage caused by power grid impact, so as to reduce the impact of power grid, The effect of improving service life and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

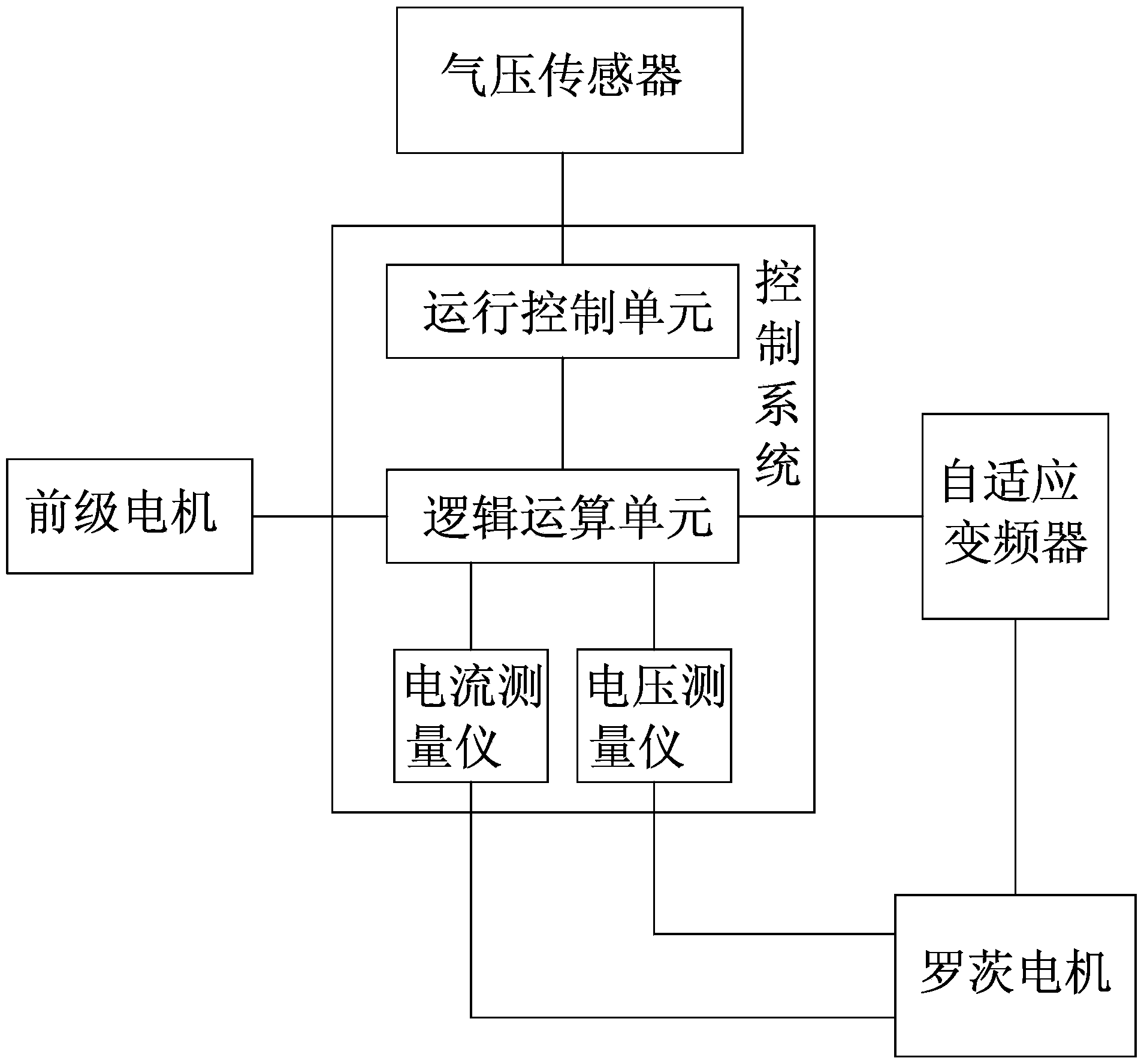

[0029] This Roots atmospheric direct exhaust intelligent unit includes Roots vacuum pump, backing pump, negative pressure sensor and control system.

[0030] The Roots vacuum pump consists of a pump body and a Roots motor. The pump body has an intake pipe, a pump chamber and an exhaust pipe.

[0031] The backing pump is a slide valve vacuum pump or a rotary vane vacuum pump, a liquid ring vacuum pump or a dry vacuum pump. The backing pump includes the backing motor.

[0032] The negative pressure sensor is used to monitor the air pressure in the pump body of the Roots vacuum pump; the negative pressure sensor is arranged in the pump body of the Roots vacuum pump. Specifically, the negative pressure sensor is arranged in the intake pipe of the Roots vacuum pump. According to actual conditions, the negative pressure sensor can also be arranged in the exhaust connection pipe or in the pump cavity of the Roots vacuum pump.

[0033] The negative pressure sensor is preferably a h...

Embodiment 2

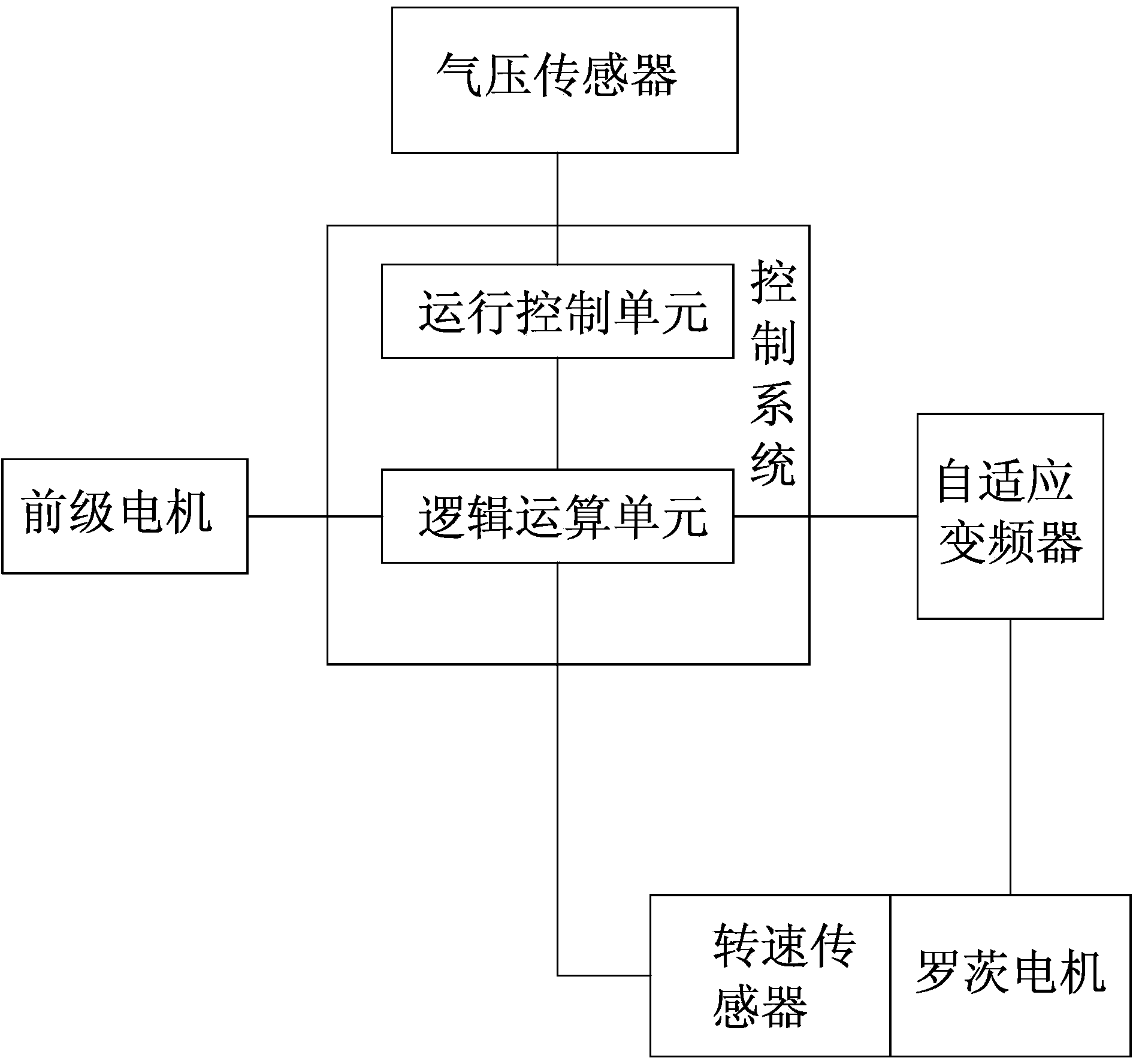

[0060] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: figure 2 As shown, the Roots motor has a motor shaft, and the monitoring unit includes a speed sensor arranged on the Roots motor for detecting the speed of the motor shaft, and the speed sensor is electrically connected to the logic operation unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com