Gob-side entry retaining and sectional coal seam gas pre-extracting method for single low-permeability outburst coal seam

A technology for protruding coal seam and permeability, applied in gas discharge, earth-moving drilling, safety devices, etc., can solve the problems of large construction and high pressure of mine transportation and lifting system, so as to improve production, save gas extraction time, and prolong gas The effect of draining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]

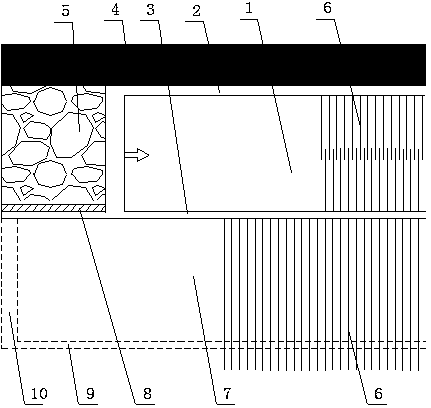

[0016] Such as figure 1 As shown, the single low-permeability protruding coal seam gobside entry retaining and pre-pumping section coal seam gas method of the present invention includes digging out the wind-inflow groove 3 and the wind-return groove 2 in the coal mining area to form the working face 1, And excavate the cut hole behind the working face 1 to form a U-shaped working face, in which the side of the wind trough 3 of the working face 1 is the unmined area 4, and the side of the return air trough 2 of the working face 1 is the adjacent working face 7; also includes the following steps:

[0017] a. On both sides of the air inlet trough 3 and the return air trough 2 in front of the coal mining face 1, drill multiple rows of overlapping bedding holes 6 in parallel along the coal seam inclination, and use the sealing pipe to align the bedding Borehole 6 is sealed and connected to the gas drainage pipe network for gas drainage;

[0018] b. Under the wind troug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com