Porous multi-site provided reactor for water treatment

A reaction device and a water treatment technology are applied in the field of devices for improving the efficiency of oxidizing organic matter in water by an oxidant, and can solve the problems of poor mixing effect of ozone and catalyst, large dosage and residual amount of chemicals, affecting the treatment process, etc. The removal rate of organic matter, the effect of reducing the amount of derivatization, and increasing the chance of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

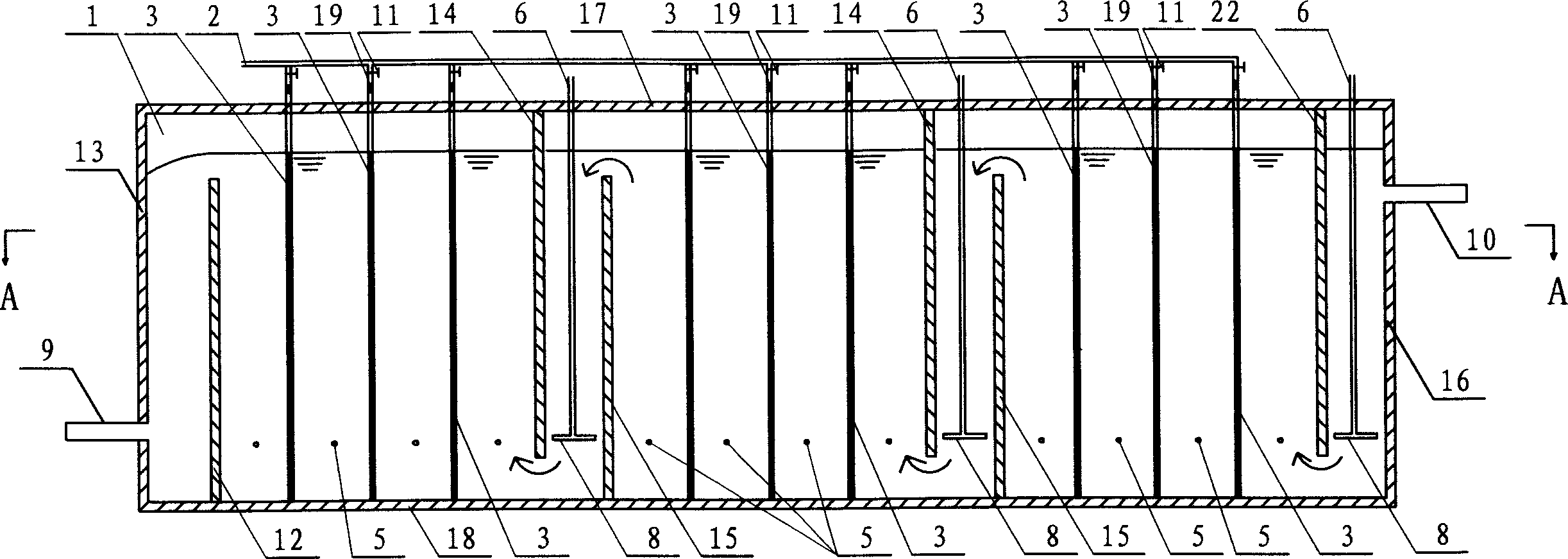

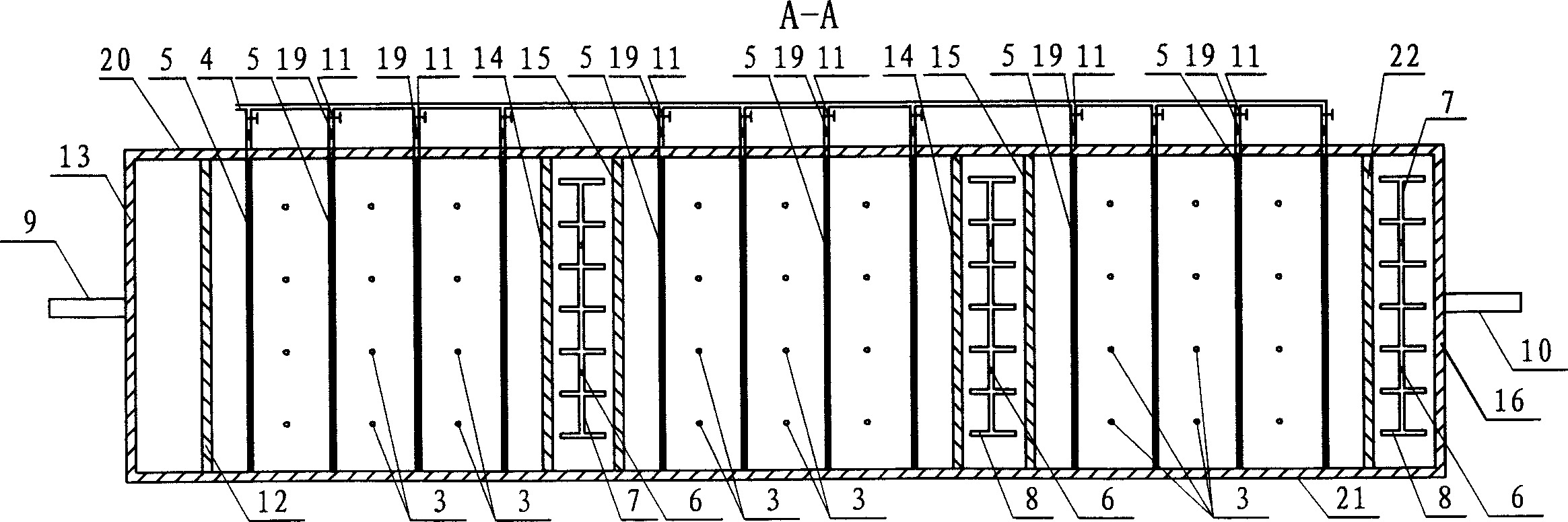

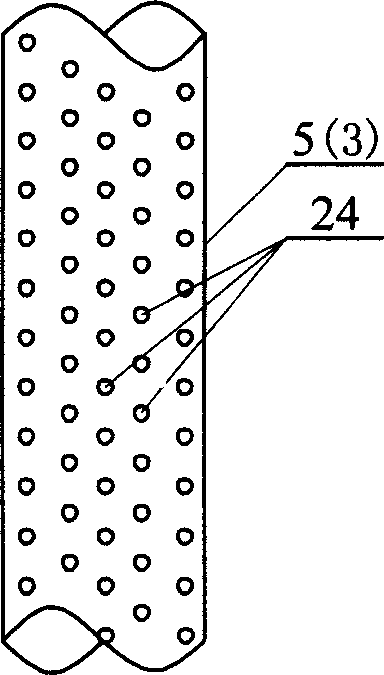

[0022] Specific implementation mode one: (see Figure 1-Figure 2) This embodiment consists of a reaction tank 1, a main chemical pipe 2, a vertical chemical dosing pipe 3, a front side main chemical pipe 4, a horizontal chemical dosing pipe 5, an ozone main pipe 6, an ozone horizontal pipe 7, and an ozone aeration branch pipe 8 , outlet pipe 9, water inlet pipe 10, outlet weir 12, upper partition 14, lower partition 15, upper right partition 22; outlet pipe 9 is fixed on the bottom of the left side wall 13 outside of pool 1, outlet weir 12 and left The side walls 13 are arranged in parallel, the outlet weir 12 is arranged on the left side in the pool 1, the lower end of the outlet weir 12 is fixed on the pool floor 18 in the pool 1, the upper right partition 22 is arranged in parallel with the right side wall 16 of the pool 1, the upper right The dividing plate 22 is arranged on the right side in the pool 1, the upper end of the upper right dividing plate 22 is fixed on the po...

specific Embodiment approach 2

[0023] Specific implementation mode two: (see figure 2 ) The difference between this embodiment and the first embodiment is that a valve 11 and a pressure gauge 19 are added between the horizontal medicament dosing pipe 5 and the front side medicament main pipe 4, and one end of the valve 11 is fixed to one end of the pressure gauge 19 Connection, the other end of the valve 11 is fixedly connected with the front medicine dry pipe 4, and the other end of the pressure gauge 19 is fixedly connected with the horizontal medicine dosing pipe 5. Other compositions and connections are the same as in the first embodiment. The increased valve 11 and pressure gauge 19 are used to adjust the dosage.

specific Embodiment approach 3

[0024] Specific implementation mode three: (see figure 1 ) The difference between this embodiment and specific embodiment 1 or 2 is that a valve 11 and a pressure gauge 19 are added between the vertical medicament dosing pipe 3 and the medicament main pipe 2, and one end of the pressure gauge 19 is connected to the vertical medicament dosing pipe. 3. Fixed connection, the other end of the pressure gauge 19 is fixedly connected to one end of the valve 11, and the other end of the valve 11 is fixedly connected to the medicine main pipe 2. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2. The increased valve 11 and pressure gauge 19 are used to adjust the dosage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com