Single wheat/rice plant threshing device

A threshing device and a single plant technology, applied in threshing equipment, applications, agricultural machinery and tools, etc., can solve the problems of complex design structure, corners, many gaps, inconvenient movement, etc., and achieve low manufacturing cost, high cleaning rate, easy-to-move effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

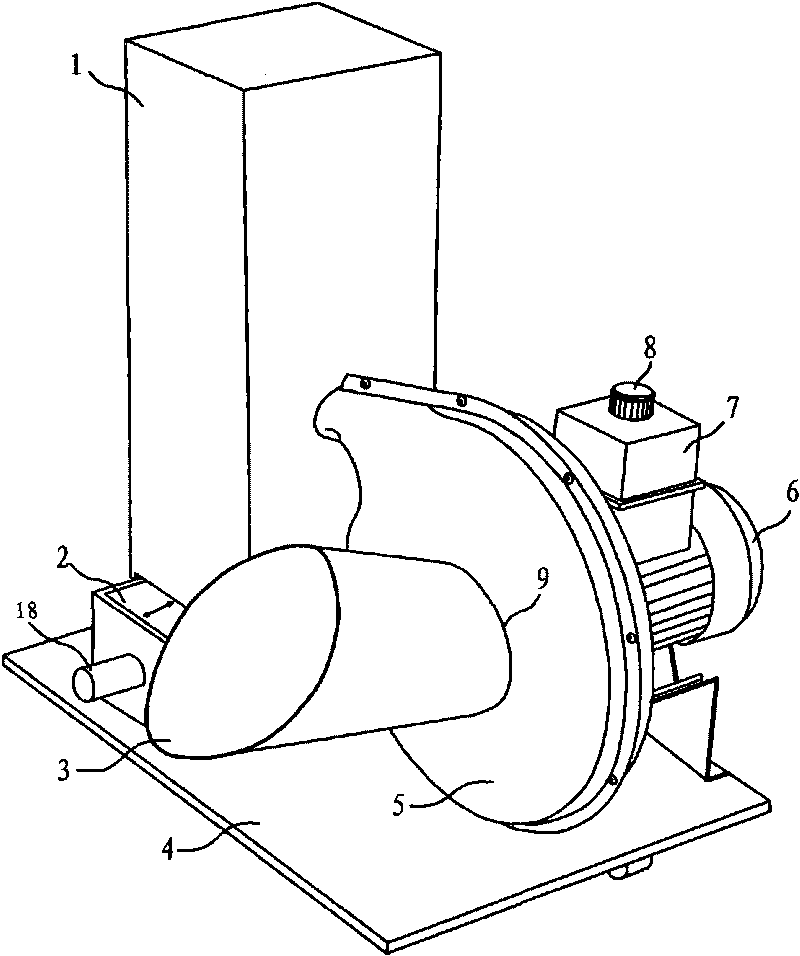

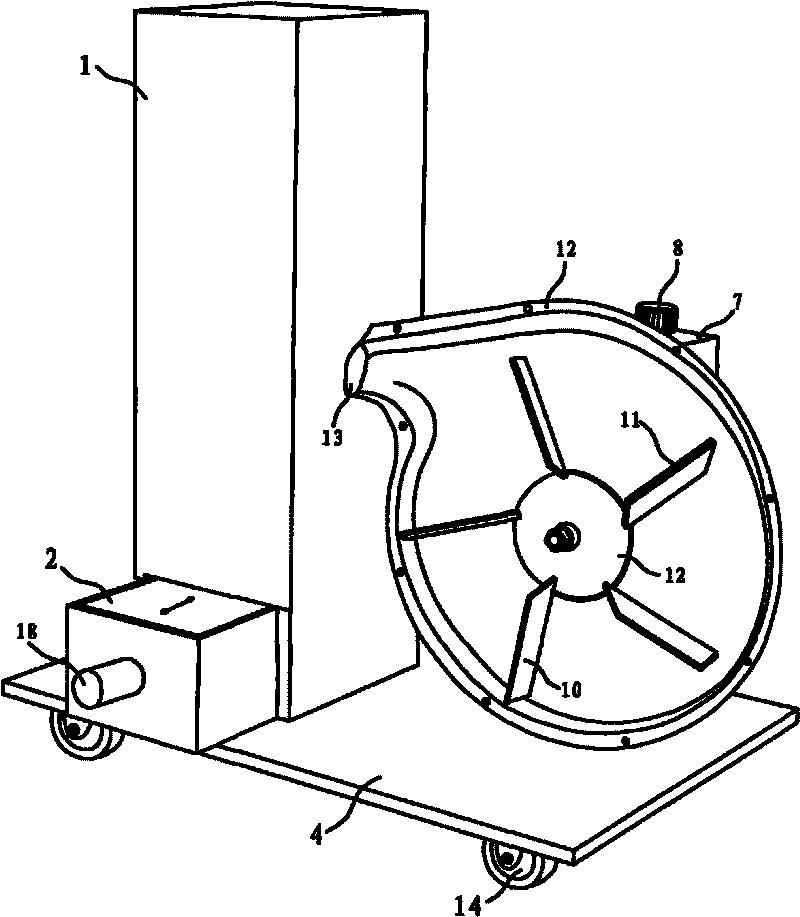

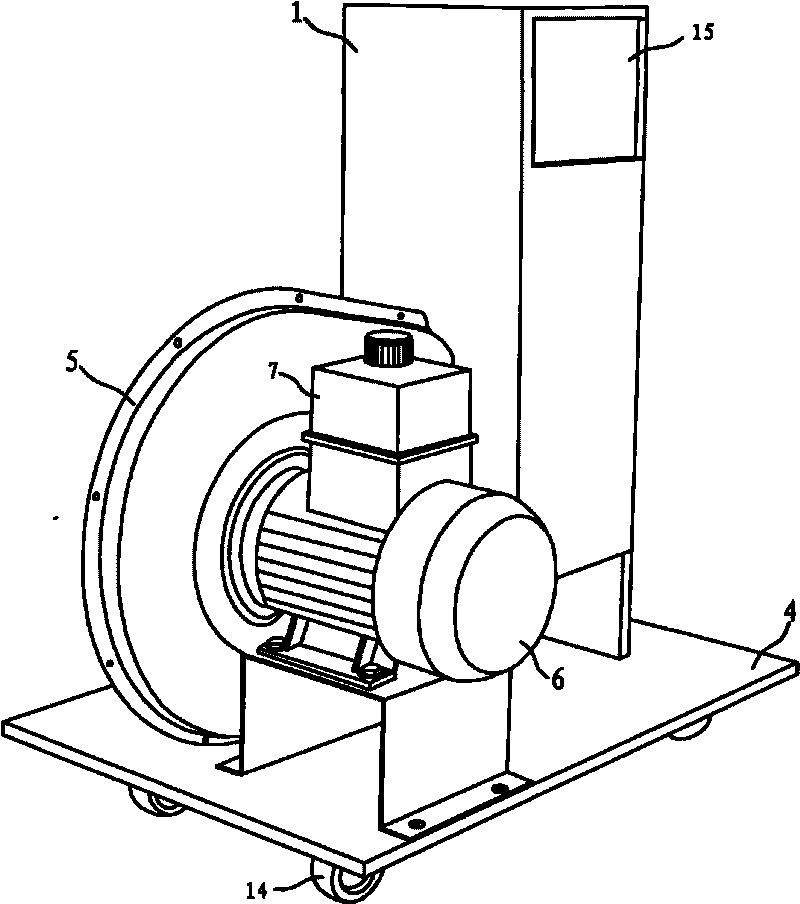

[0025] Example 1 see figure 1 , figure 2 , image 3 , a wheat / rice single-plant threshing device, comprising a centrifugal fan thresher 5, a square prism-shaped separation box 1 and an installation base 4 thereof, universal wheels 14 are installed below the base; the centrifugal fan thresher includes a speed regulating Motor 6, impeller 11, volute housing 12, trumpet-shaped spike bucket 3, the speed of the speed-regulating motor 6 can pass through the current speed controller 7 (just adjust the knob 8 during use), and the impeller 11 is installed in a matching manner In the volute housing 12 and connected to the rotating shaft of the motor 6, five uniformly distributed blades 10 are installed on the impeller 11, each blade is perpendicular to the rotation plane and rotates counterclockwise, and the blades 10 rotate along the The side facing the direction of rotation is wrapped with a wear-resistant rubber layer 11. The volute housing 12 is provided with an air inlet 9 and a...

Embodiment 2

[0039] Embodiment 2 is basically the same as Embodiment 1, except that a carburized layer is provided on the inside of the volute casing to increase the wear resistance, and four uniformly distributed blades are installed on the impeller.

Embodiment 3

[0040] Embodiment 3 see Figure 4 , is basically the same as that of Example 1, the difference is that a ridge-shaped threshing claw 16 is provided on the surface of the blade of the impeller, the impeller includes a wheel for installing the blade, and the side of the wheel facing the side of the ear bucket Ridge-shaped threshing claws 17 are arranged on the disk surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com