Equipment for averagely distributing separated ore pulp

A technology for equal distribution and pulp distribution, applied in liquid distribution, distribution devices, special distribution devices, etc., can solve the problems of few pulp equalization devices, low pulp distribution efficiency, and inability to achieve equal distribution effects, achieving strong practicability, preventing Clogging, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

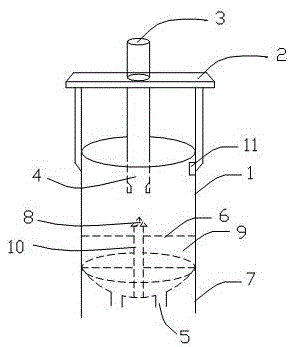

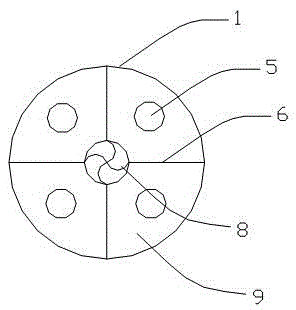

[0023] like Figure 1~2 As shown, this embodiment is a device for evenly distributing ore dressing pulp, including a pulp inlet pipe 3, a bucket rack 2, a slurry bucket 1, a necking funnel 4, a slurry separation head 8, a slurry separation column 10, and a liquid level detection device 11 And the pulp outlet pipe 5, wherein, the barrel upper frame 2 is located above the pulp barrel 1, and is fixedly connected with the barrel wall of the pulp barrel 1, one end of the pulp inlet pipe 3 is fixedly connected to the barrel upper frame 2, and the other end is suspended vertically on the pulp barrel 1, and is located on the vertical center line of the pulp tank 1, the outlet of the pulp inlet pipe 3 communicates with the necking funnel 4, and the pulp enters the pulp tank 1 from the necking funnel 4, and the slurry separating column 10 is set at the center of the bottom wall of the pulp tank 1 At the position, the slurry head 8 is arranged on the top of the slurry column 10, and is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com