Method for detecting metal magnetic impurities in positive electrode material

A technology of metal magnetism and positive electrode materials, which is applied in the direction of analysis materials, measurement devices, and preparation of test samples, etc., can solve the problems of low reliability and validity of the test, non-uniform magnetic adsorption, and large differences in adsorption effects. Achieve the effects of easy real-time tracking, fast testing speed, and excellent adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

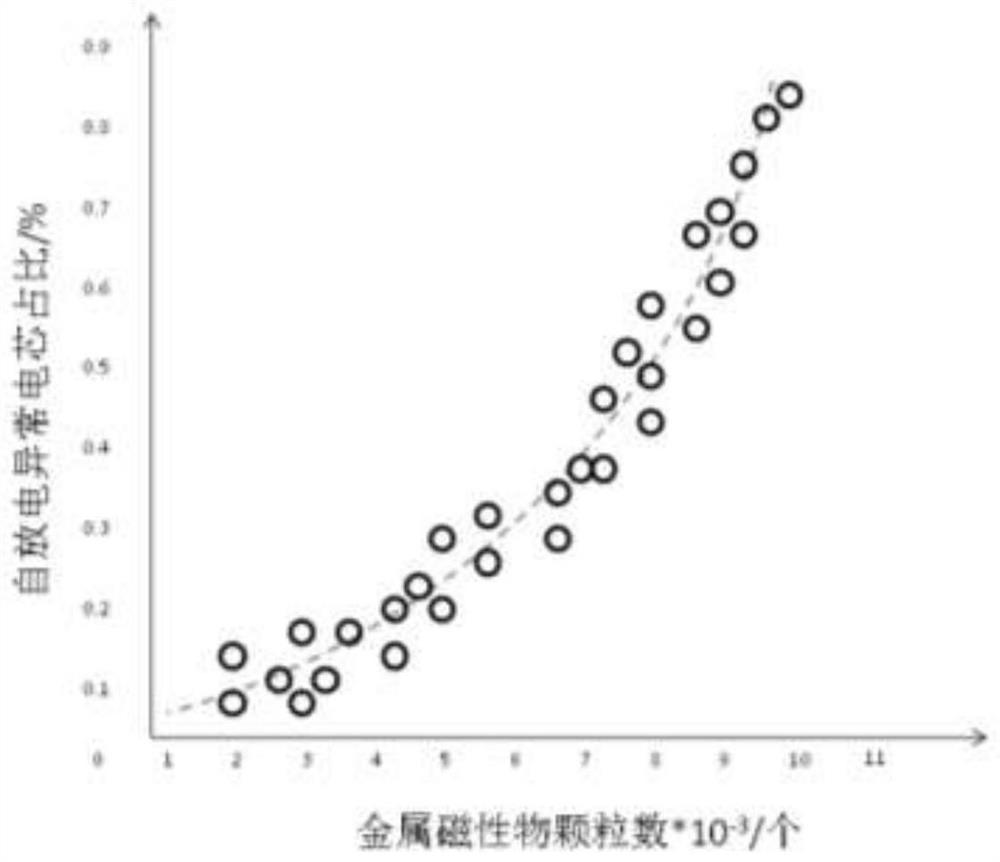

[0044] A method for detecting metallic magnetic impurities in positive electrode materials, comprising the steps of:

[0045] S1. Weigh 2Kg of the positive electrode material sample and disperse it in 4Kg of ethanol, stir magnetically at a speed of 800rpm for 1.5h, and then sonicate for 0.5h to obtain the sample solution;

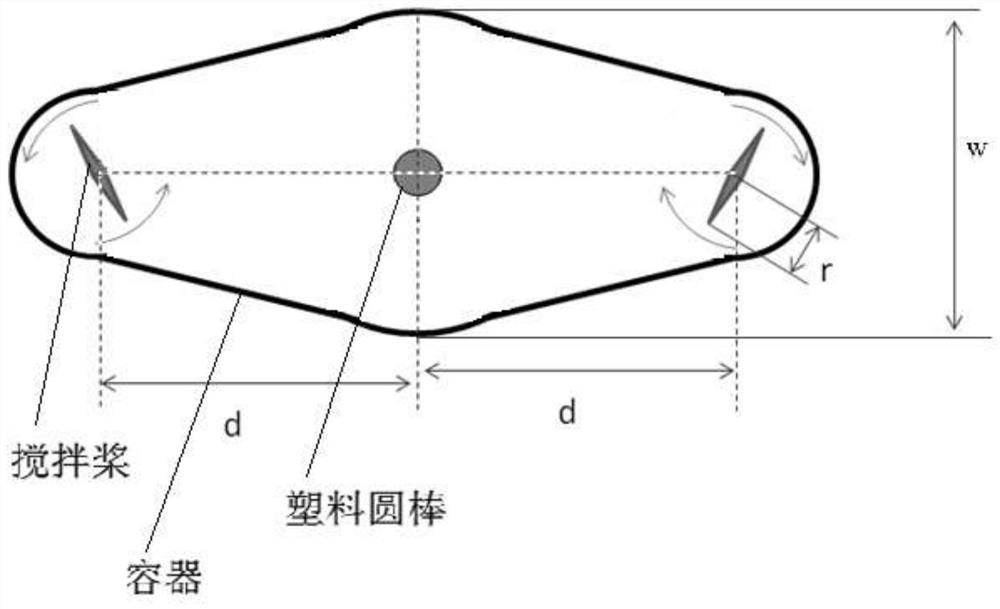

[0046] Put the sample solution in the container, insert a polytetrafluoroethylene round rod equipped with a magnetic rod into the sample solution and fix it, and use a stirrer on both sides of the polytetrafluoroethylene round rod to continuously reverse at a speed of 1000rpm Stir for 3 hours and perform dynamic adsorption, wherein the magnetic force of the magnetic rod is 10000 Gauss, the rotation direction of the two stirrers is changed every 10 minutes at the same time, and the distance between each stirrer and the plastic round rod is the same;

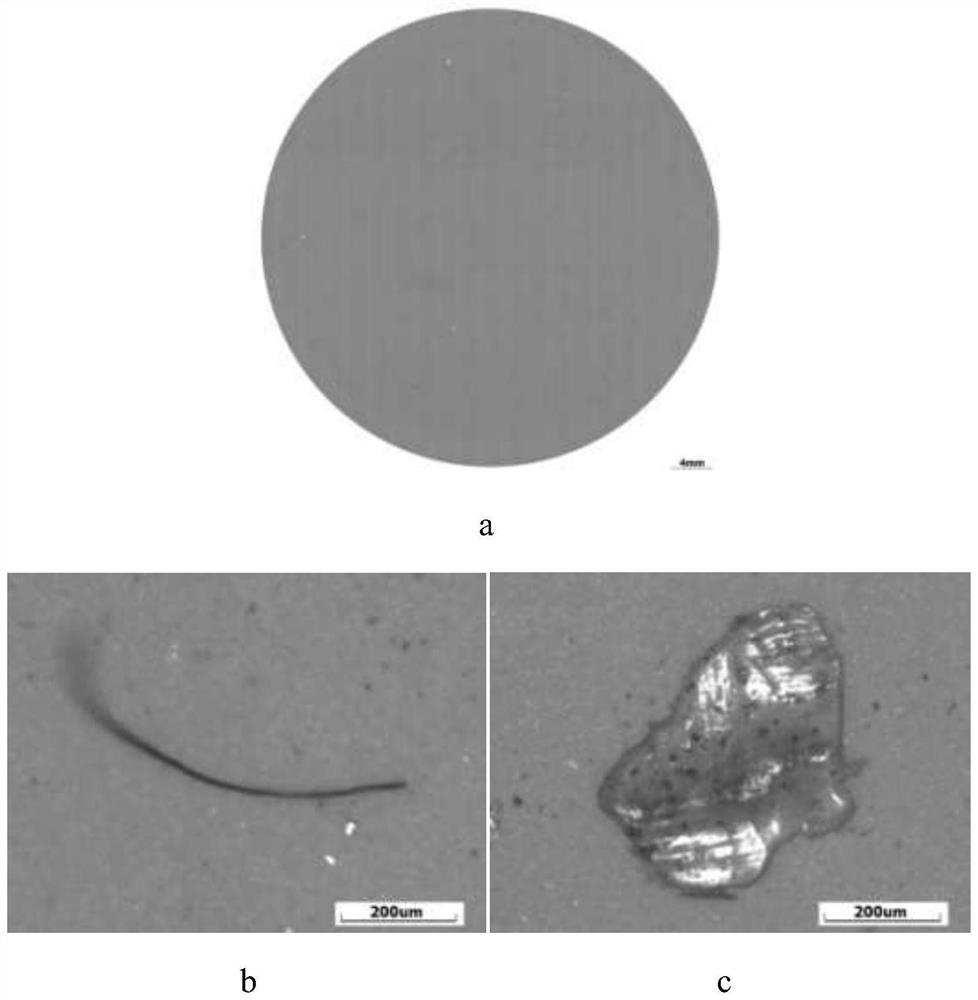

[0047] S2. After the stirring is completed, take out the polytetrafluoroethylene round rod equipped with a m...

Embodiment 2

[0057] A method for detecting metallic magnetic impurities in positive electrode materials, comprising the steps of:

[0058] S1. Weigh 0.5Kg of the negative electrode material sample and disperse it in 5Kg of acetone, stir magnetically at a speed of 1500rpm for 3h, and then sonicate for 0.5h to obtain the sample solution;

[0059] Put the sample solution in the container, insert a polytetrafluoroethylene round rod equipped with a magnetic rod into the sample solution and fix it, and use a stirrer on both sides of the polytetrafluoroethylene round rod to continuously reverse at a speed of 2000rpm Stir for 6 hours for dynamic adsorption, wherein the magnetic force of the magnetic bar is 13000 Gauss, the rotation directions of the two stirrers are changed every 30 minutes at the same time, and the distance between each stirrer and the plastic round bar is the same;

[0060] S2. After the stirring is completed, take out the polytetrafluoroethylene round rod equipped with a magnet...

Embodiment 3

[0064] A method for detecting metallic magnetic impurities in positive electrode materials, comprising the steps of:

[0065] S1. Weigh 10Kg of the positive electrode material sample and disperse it in 20Kg of acetone, stir magnetically at a speed of 300rpm for 0.5h, and then sonicate for 0.5h to obtain the sample solution;

[0066] Put the sample solution in the container, insert a polytetrafluoroethylene round rod equipped with a magnetic rod into the sample solution and fix it, and use a stirrer on both sides of the polytetrafluoroethylene round rod to continuously reverse at a speed of 500rpm Stir for 2 hours to carry out dynamic adsorption, wherein the magnetic force of the magnetic rod is 5000 Gauss, the rotation direction of the two stirrers is changed every 2 minutes at the same time, and the distance between each stirrer and the plastic round rod is the same;

[0067] S2. After the stirring is completed, take out the polytetrafluoroethylene round rod equipped with a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic force | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| magnetic force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com