Automatic pipe cutting machine

A pipe cutting machine, automatic technology, applied in the direction of pipe shearing device, shearing device, accessories of shearing machine, etc., can solve the problems of specification adjustment, inability to process square pipes of different specifications, etc., and achieve the effect of smooth movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

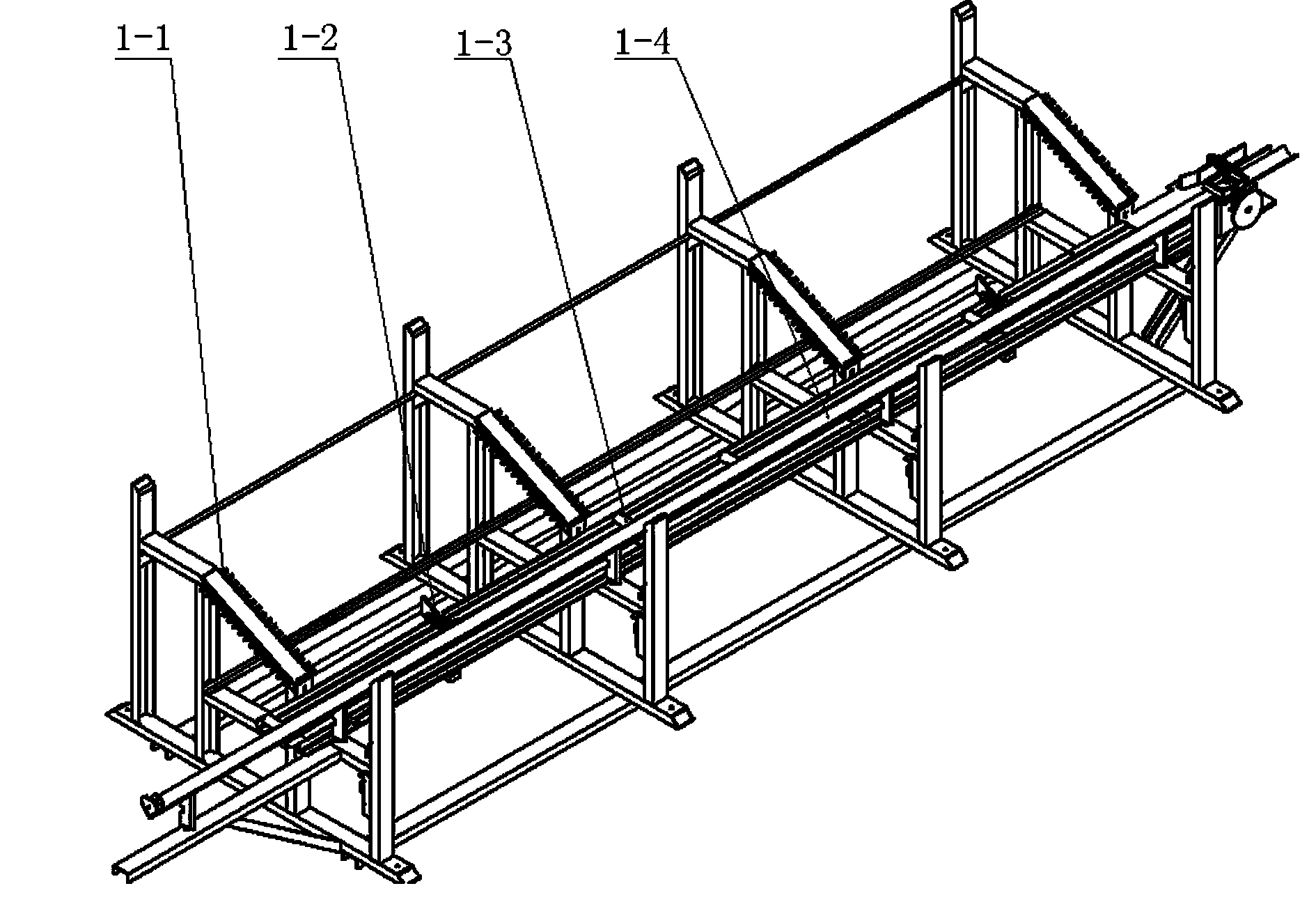

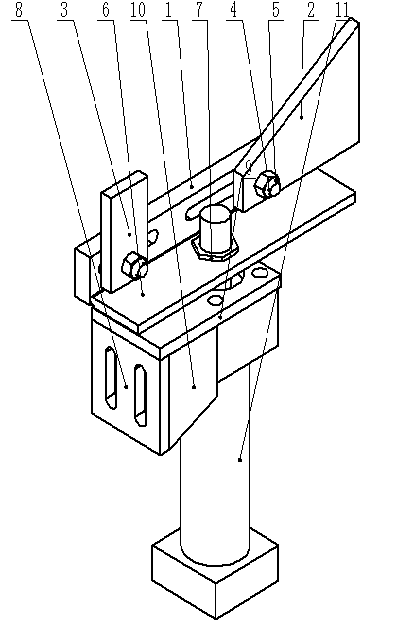

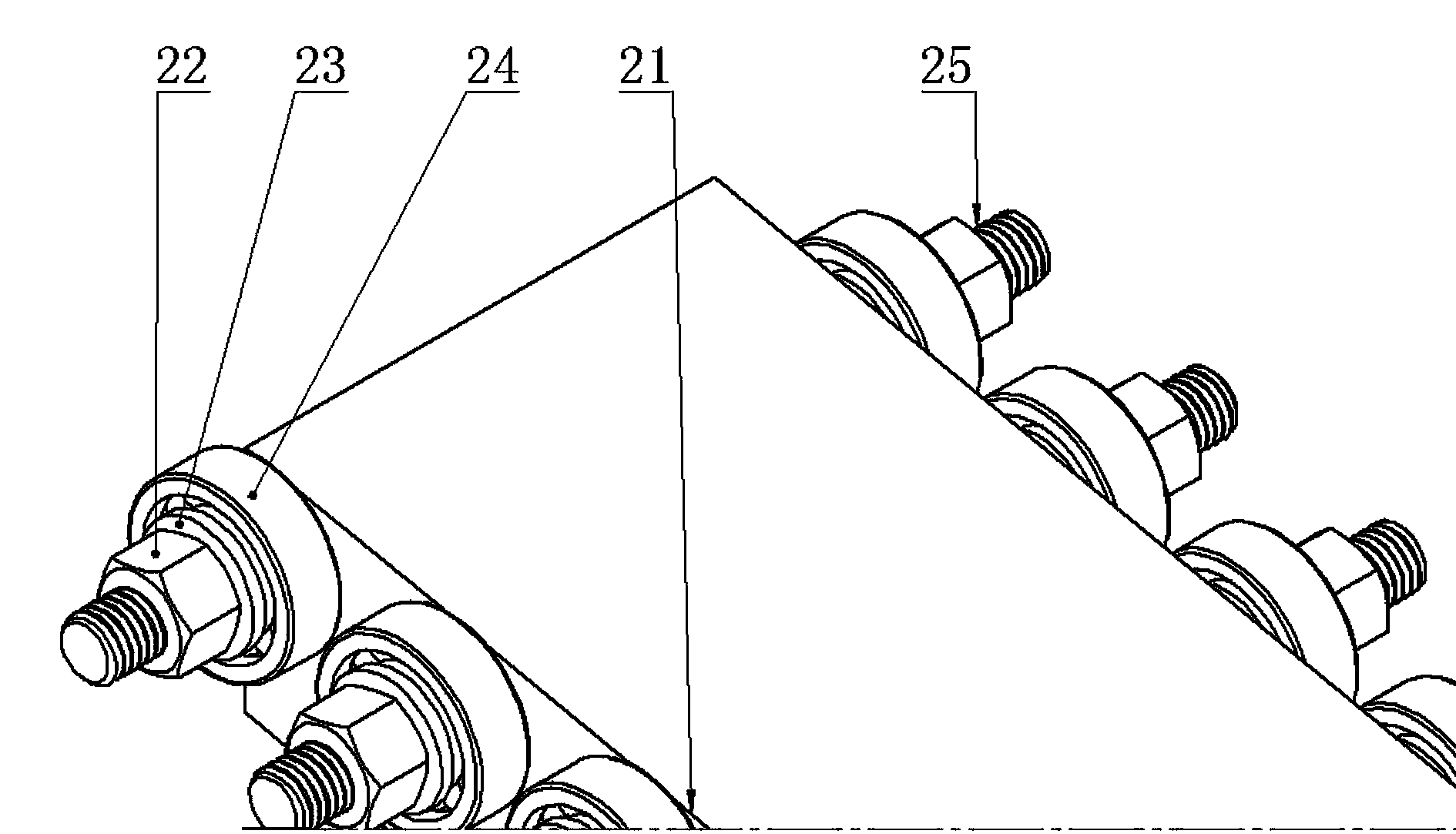

[0015] Such as Figure 1 to Figure 3 shown. An automatic pipe cutting machine of the present invention consists of a material storage and distribution rack, a material retrieving mechanism, a feeding track 1-3, a material pushing system 1-4, a cutting system including an automatic clamping mechanism and an automatic cutting mechanism, and a material that has been cut and blanked. System Components. The storage and distribution rack is provided with an inclined track 1-1 and a positioning block for retrieving materials. The positioning block for retrieving materials is a folded plate. The vertical part is connected to the column on the inclined track close to the feeding track through a screw, and the upper part is folded at an angle. Make it perpendicular to the inclined track, and adjust the height of the part above the inclined track surface according to the specificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com