Method for preparing finger spindle compact spinning knitted flannel

A technology of compact spinning and knitting velvet, which is applied in the field of textile fabrics. It can solve the problems of irregular twisting triangle area, excessive yarn hairiness, no control, etc., achieve smooth yarn, reduce yarn breakage rate, and eliminate yarn The effect of the balloon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

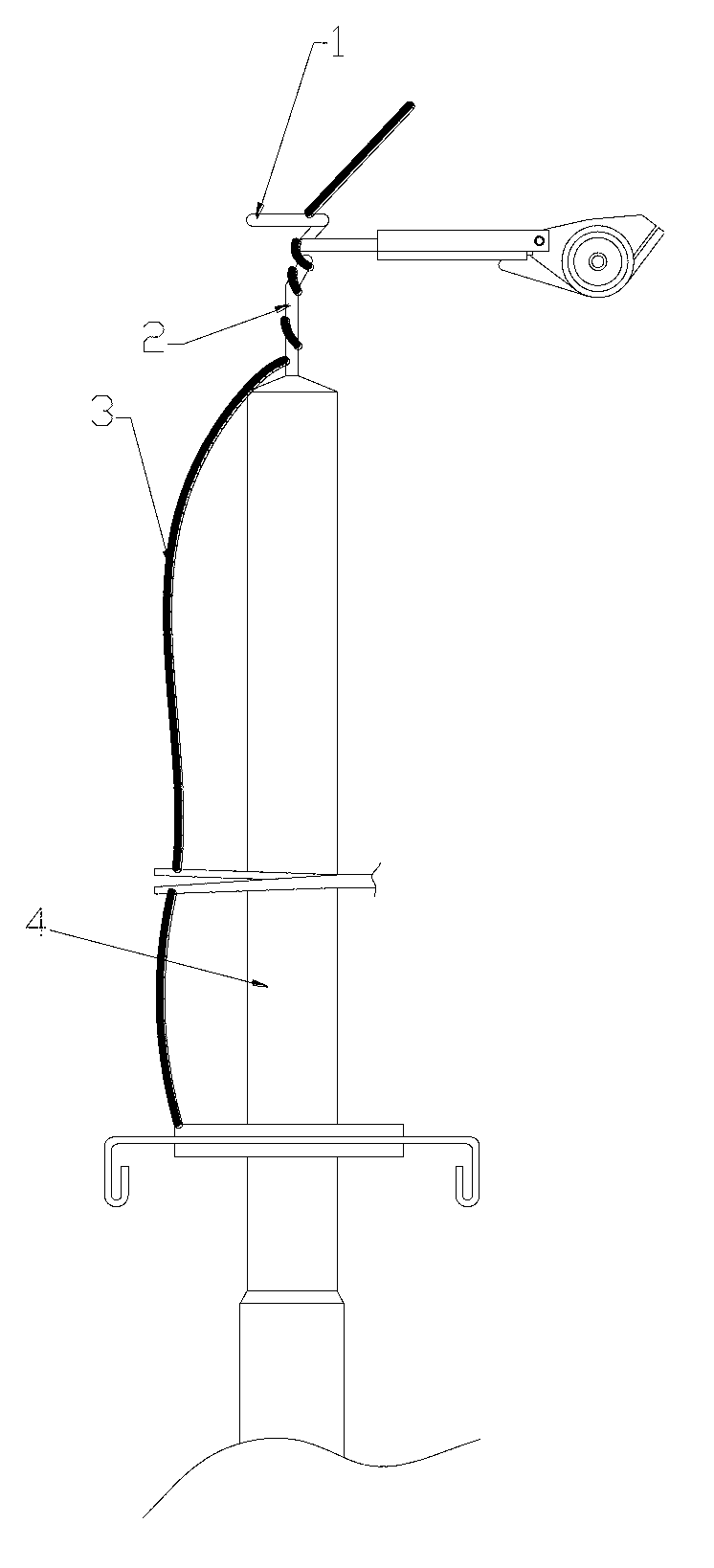

Image

Examples

Embodiment

[0016] A method for preparing knitted fleece by finger-spindle compact spinning, the steps of which are: dyed fiber → mixing and wool opening → carding machine → second needle and carding pass → combing machine → second needle and carding pass → drawing (one to three passes) → roving ( Twisted)→Compact spinning with finger spindles→Two-fold twisting (untwisted)→Finished knitted fleece.

[0017] Select high-count and high-grade fibers such as cashmere, high-count wool, ultra-fine merino wool and other fiber raw materials for dyeing. After mixing and opening, the carding machine has repeatedly combed and synthesized roving, and then enters into spinning. In the middle process of spinning production Among them, the ordinary spinning frame is transformed and innovated into a finger-spindle compact spinning frame. During the production process:

[0018] 1) Add a negative pressure device at the front roller outlet to make the fibers move according to the prescribed trajectory, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com