Stirring device applicable to liquid medicine and chemical feed liquid

A stirring device and chemical technology, which is applied to mixers with rotating stirring devices, mixer accessories, chemical instruments and methods, etc., can solve the problems of cumbersome process and increase the burden on operators, and achieve simple operation and improved service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

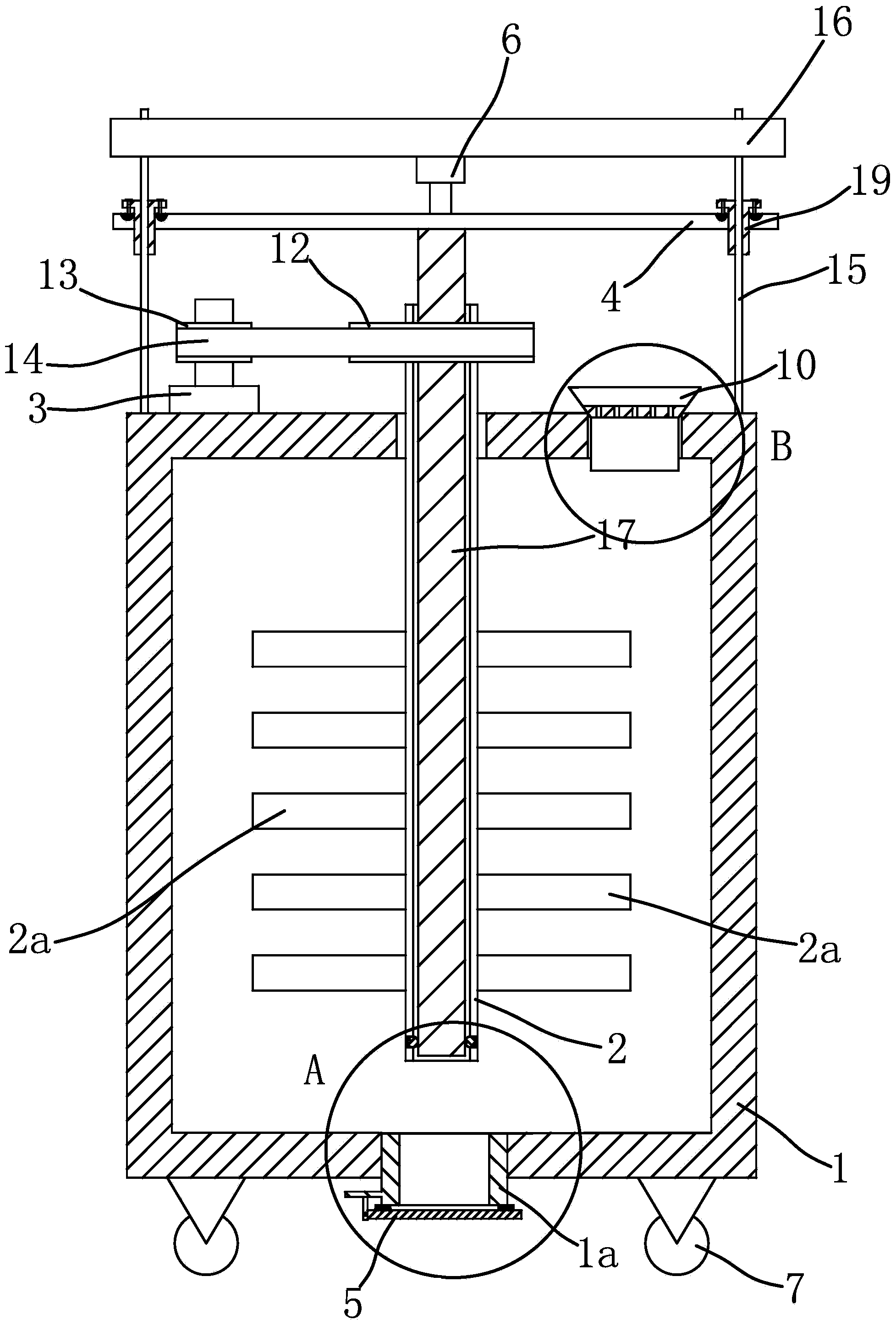

[0041] The stirring device suitable for liquid medicine and chemical material liquid is mainly used for stirring the material liquid. Such as figure 1 As shown, the stirring device suitable for liquid medicine and chemical feed liquid includes: a tank body 1, a stirring shaft 2, a motor 3, a guide plate 4, a cover plate 5, and an air cylinder 6.

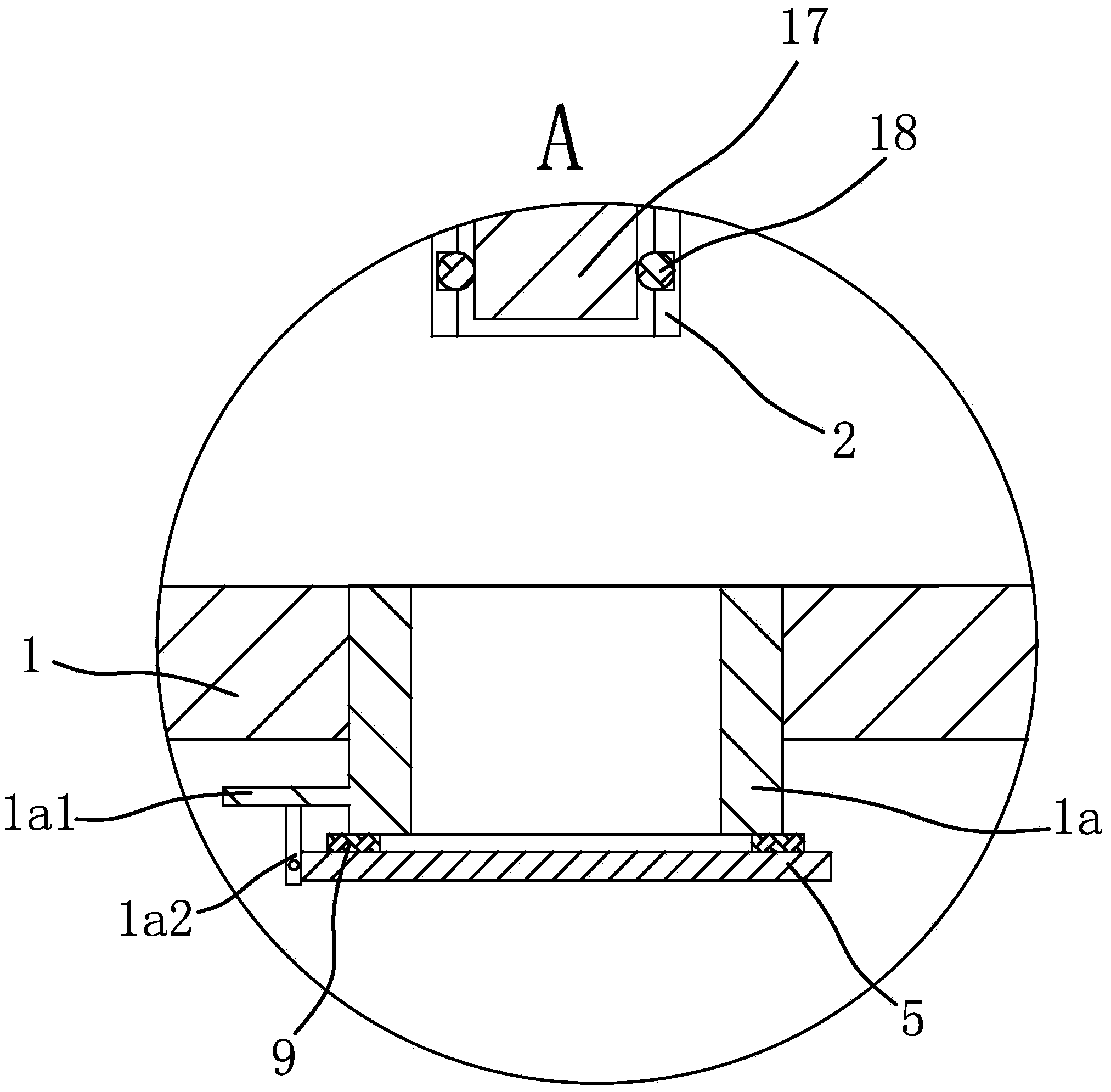

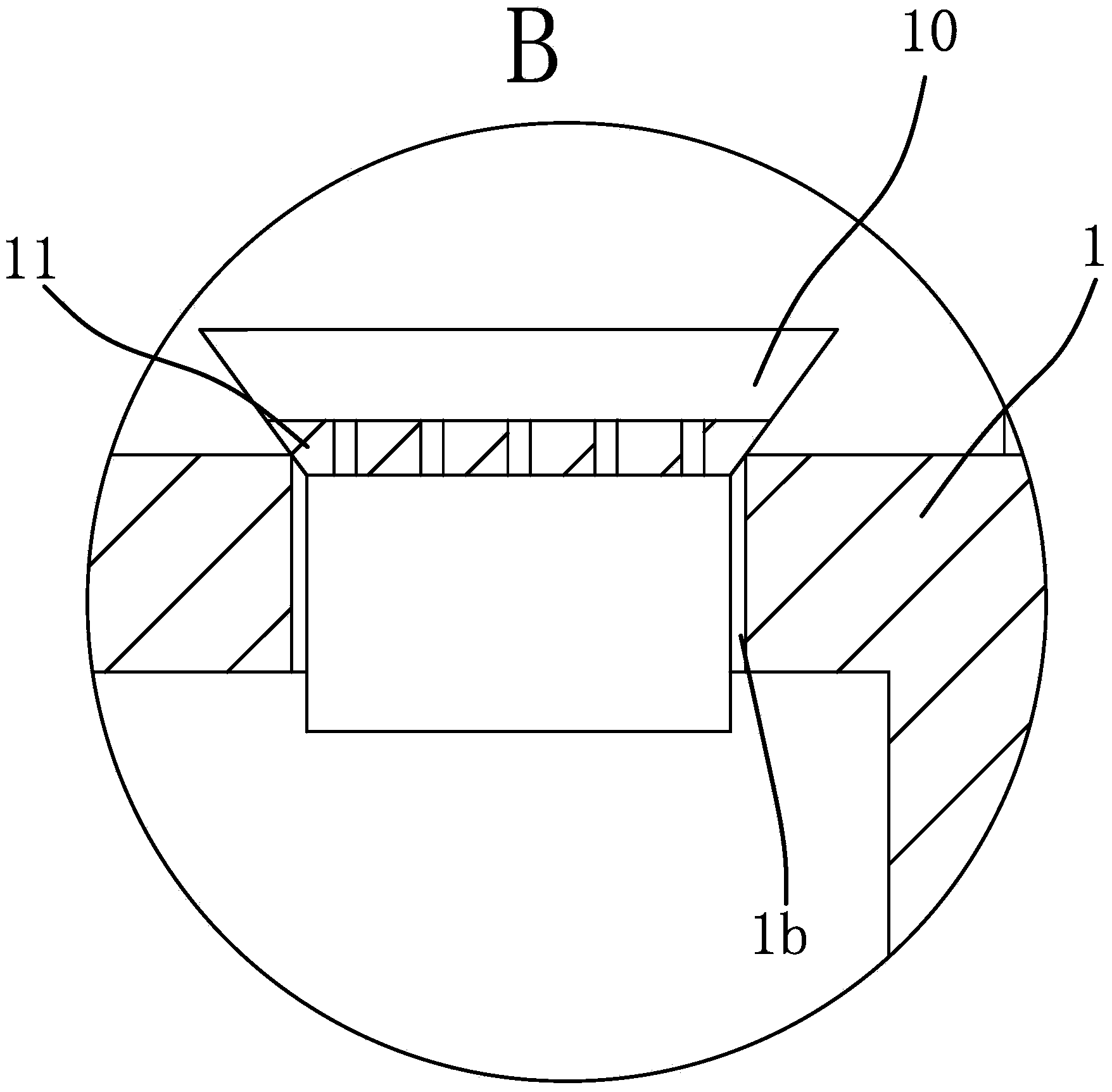

[0042] Wherein, the tank body 1 is a cuboid and has an inner cavity, and four rollers 7 are arranged at the bottom of the tank body 1 to facilitate the movement of the tank body 1 . The four rollers 7 are arranged symmetrically along the centerline of the tank body 1 , and the bottom of the tank body 1 has a liquid outlet pipe 1a communicating with the inner cavity thereof, and the liquid outlet pipe 1a is located at the center of the bottom of the tank body 1 . Further optimization, the liquid outlet pipe 1a and the tank body 1 are molded from the same material at one time, thereby improving the sealing performance of the connectio...

Embodiment 2

[0055] The structure and principle of this second embodiment are basically the same as that of the first embodiment. The difference is that the guide member is a guide rail and there are two guide rails. Both sides of the guide plate 4 have protruding sliders respectively, and the two sliders are respectively embedded in the corresponding rails. When the guide plate 4 reciprocates and translates under the action of the cylinder 6, the slider also translates up and down in the guide rail with the guide plate 4 and plays a better guiding effect, so that the ejector rod 17 can move down stably and make the cover plate 5 smoothly Rotate around the hinge point to open the liquid outlet pipe 1a, thereby further shortening the time it takes for the liquid outlet pipe 1a to turn from the sealed state to the open state.

Embodiment 3

[0057] The structure and principle of this third embodiment are basically the same as those of the first embodiment, except that the transmission mechanism includes a large gear and a small gear that mesh with each other, the large gear is connected with the output shaft of the motor 3, and the small gear is connected with the upper end of the stirring shaft 2 . The motor 3 drives the stirring shaft 2 to rotate through gear transmission, and has the advantage of stable transmission, so that the material liquid can be fully stirred.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com