Crimping connector and manufacturing method thereof

A technology of connectors and connecting parts, which is applied in the direction of contact manufacturing, connection, fixed connection, etc., can solve the problems of unbalanced pressure, difficult manufacturing, high stress, etc., and achieve simple bending steps, good structural strength, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

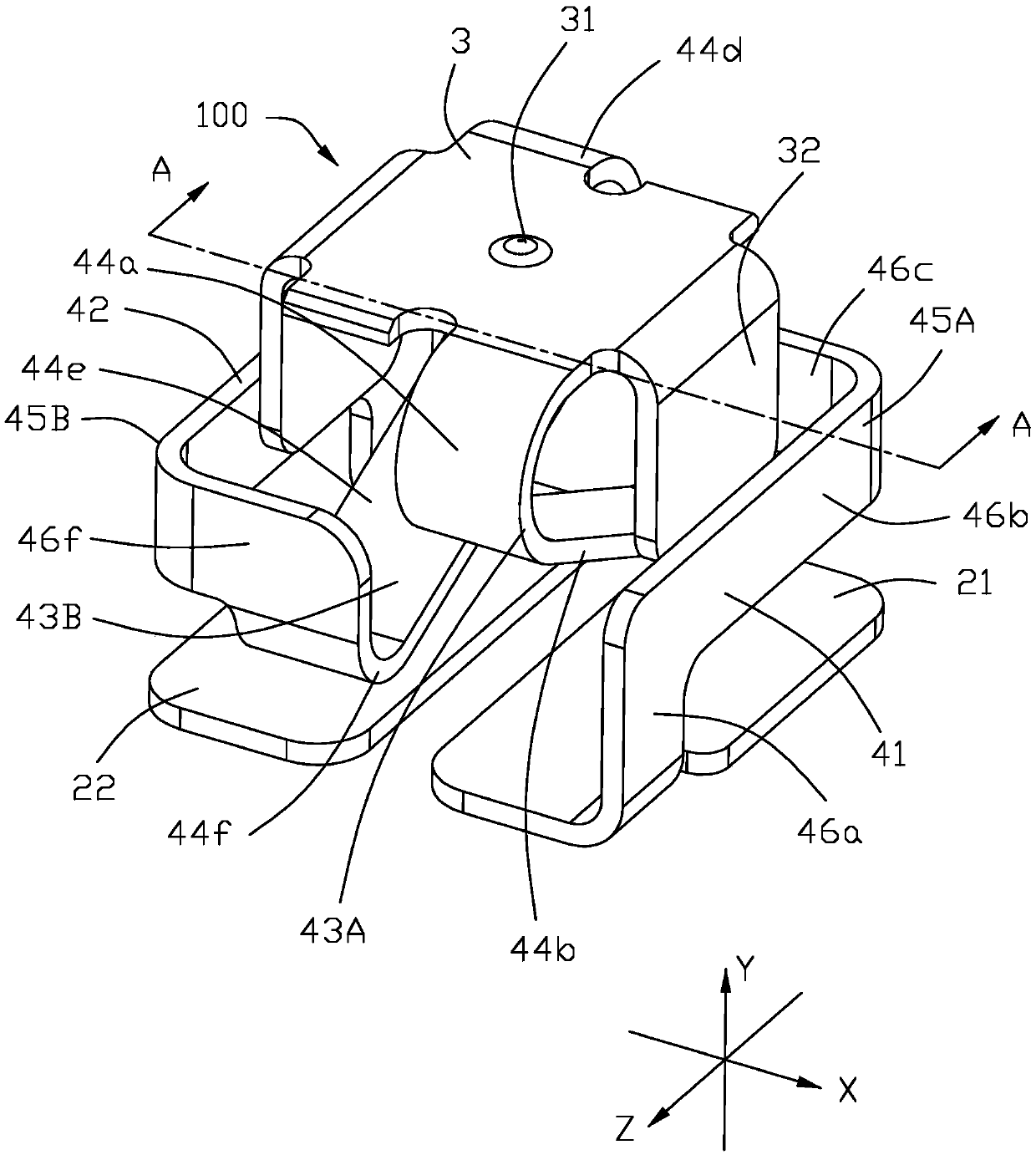

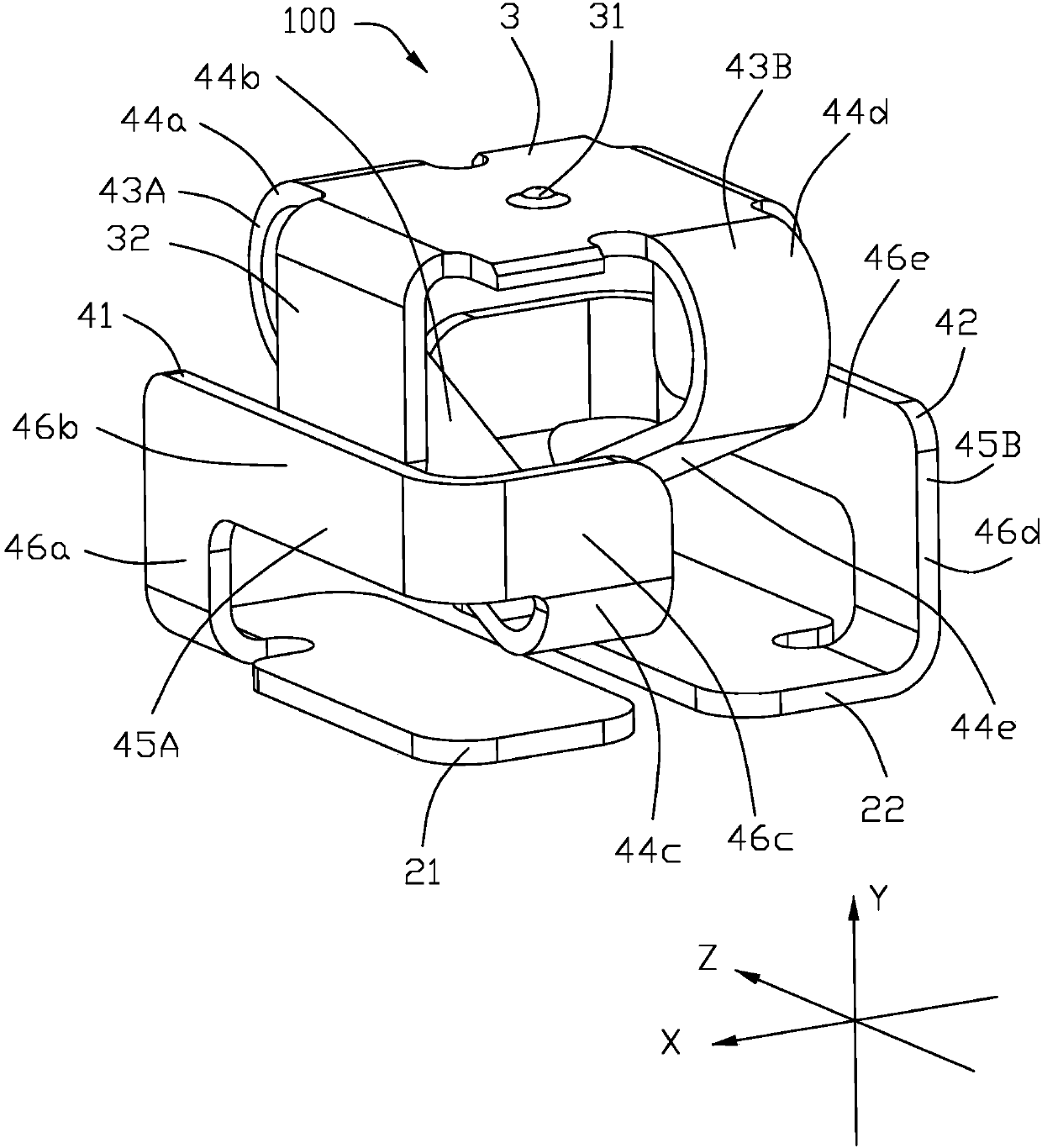

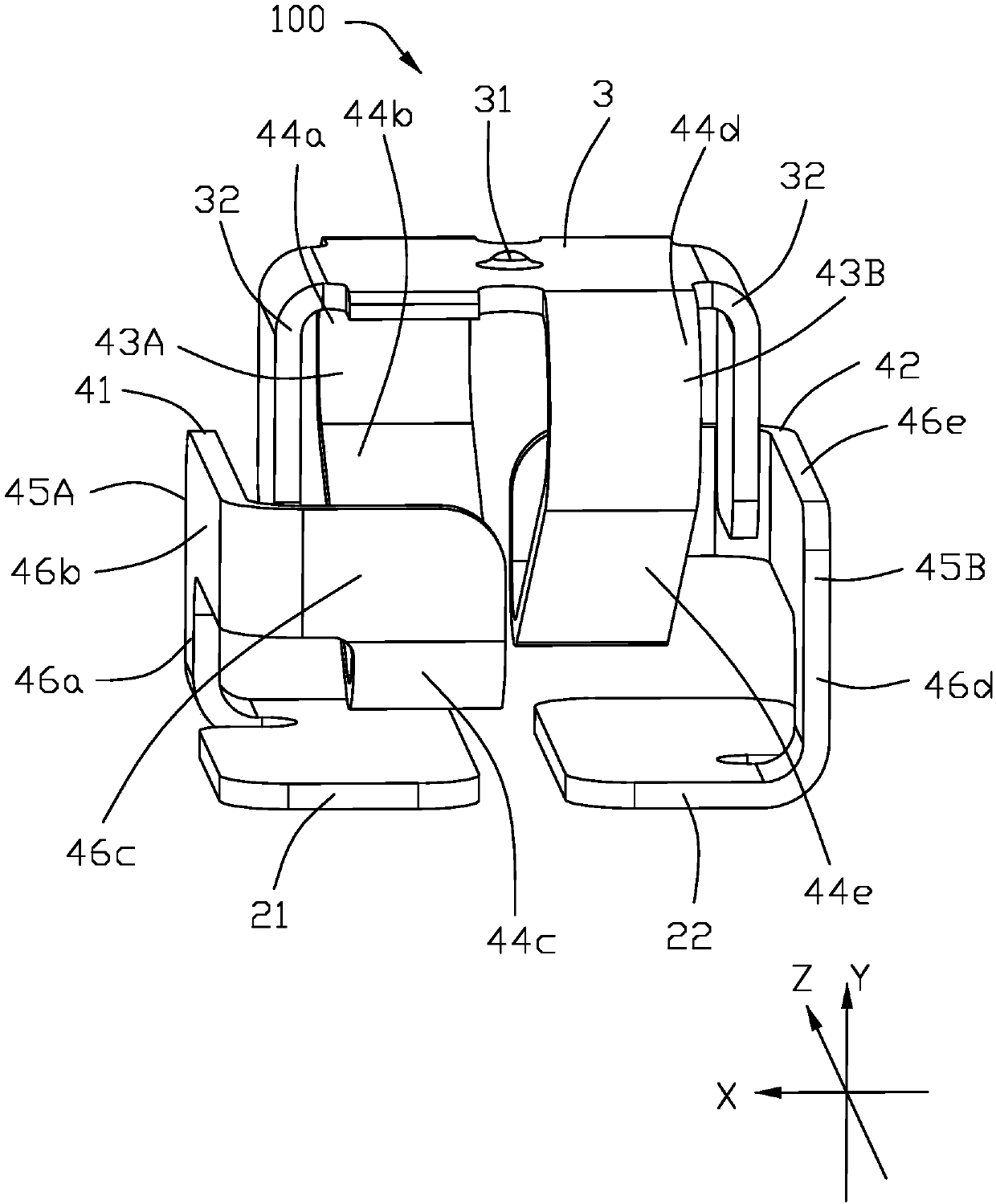

[0042] Below, will combine Figure 1 to Figure 13 The specific implementation manner of the crimp connector 100 of the present invention is introduced. The direction definitions involved in the description of the present invention are all based on figure 1 As a reference, define the pressure plate 3 of the crimping connector 100 for crimping with the butt connector (not shown) as the upper end, that is, the crimping direction is the up-down direction; the horizontal direction perpendicular to the up-down direction, that is, the left-right direction direction; and a front-rear direction perpendicular to the up-down direction and the lateral direction. exist Figure 1 to Figure 13 Among them, the X-axis represents the left-right direction, and the direction pointed by the arrow of the X-axis is left; the Y-axis represents the up-down direction, and the direction pointed by the arrow of the Y-axis is upward; the Z-axis represents the front-back direction, and the direction poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com