Assembly tool for elastic ring installation and its push rod and guide sleeve

A technology for assembling tooling and elastic rings, used in manufacturing tools, hand-held tools, etc., can solve the problems of not being too large, axial fold deformation, deflection, etc., and achieve the effect of easy production and reduced production difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

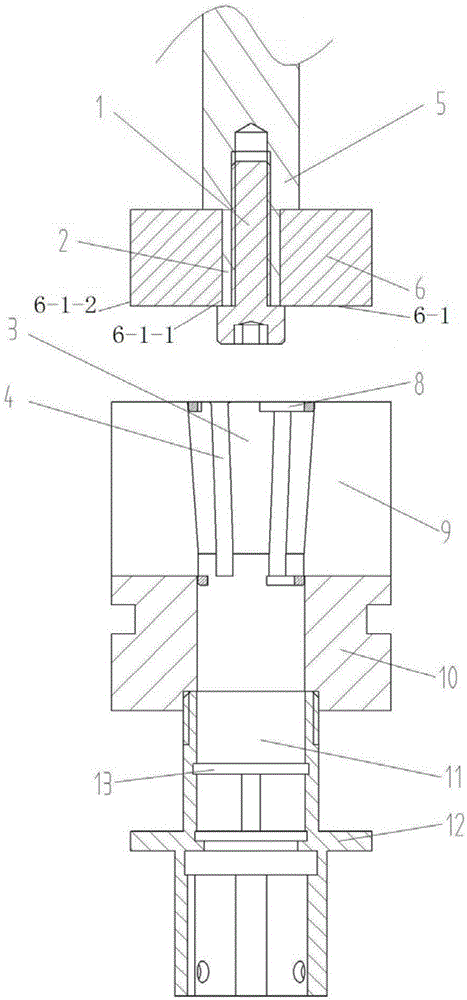

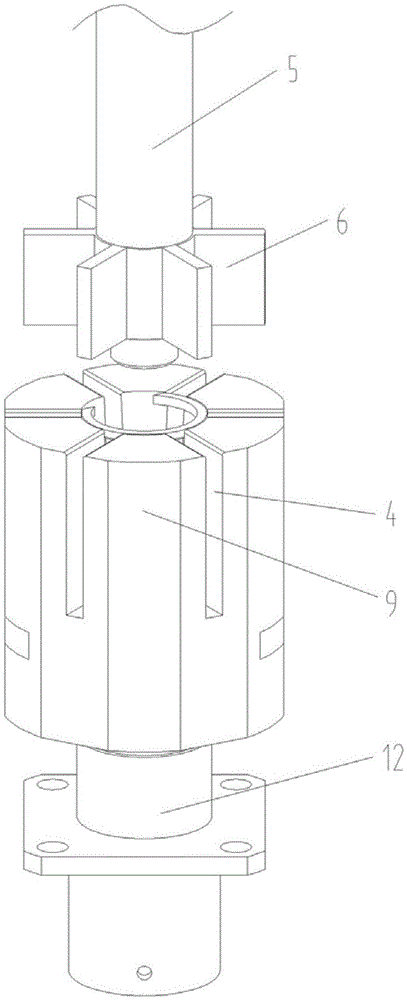

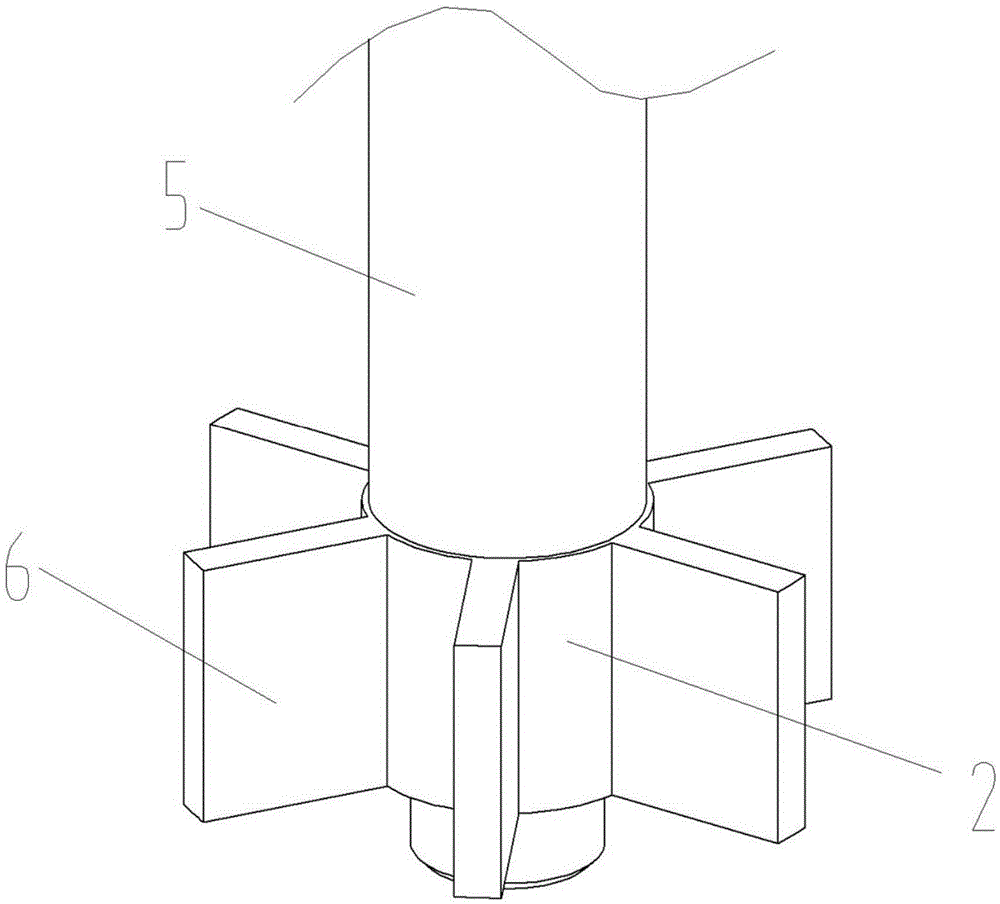

[0022] Examples of assembly tooling for elastic ring installation Figure 1~4 As shown: it includes a guide sleeve 9, a connecting sleeve 10, and a rod body 5 whose lower end is a push end. The push end of the rod body is covered with an installation sleeve 2 whose axis extends in the up and down direction, and a plurality of first sleeves are arranged at intervals around the circumference of the installation sleeve. The push block 6 with its end facing the inside of the rod body and the end extending toward the outside of the rod body. The extension direction of the head and end of the push block is the radial direction of the rod body, and the locking screw 1 whose axis extends in the vertical direction is screwed on the lower end of the rod body, and the mounting sleeve is fixedly clamped between the rod body and the locking screw. The lower end of each push block is provided with a push end face 6- which is used to straddle the upper end face of the elastic ring along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com