Patents

Literature

64results about How to "Realize the drilling operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

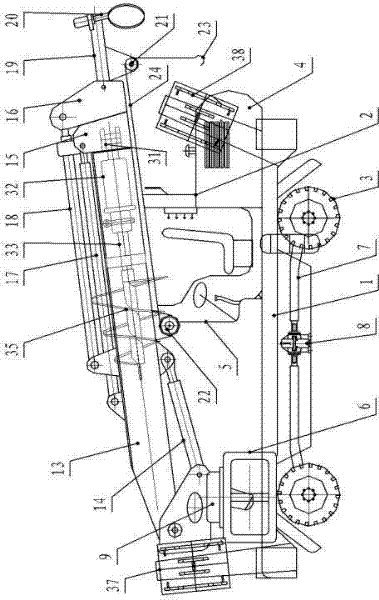

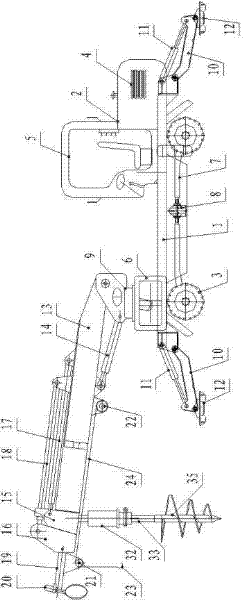

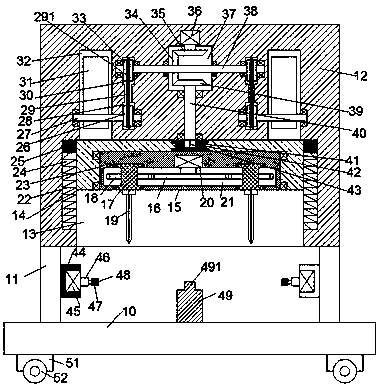

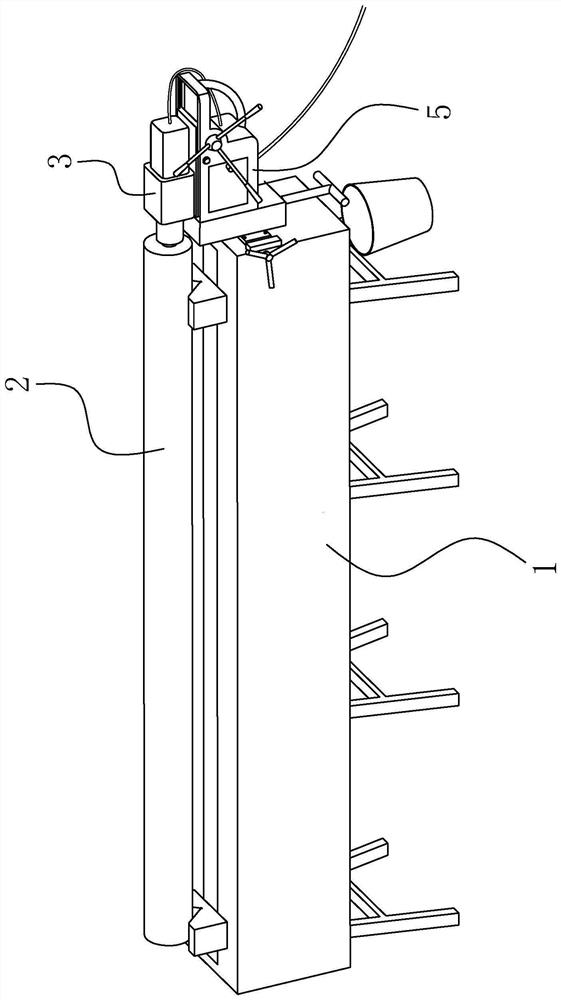

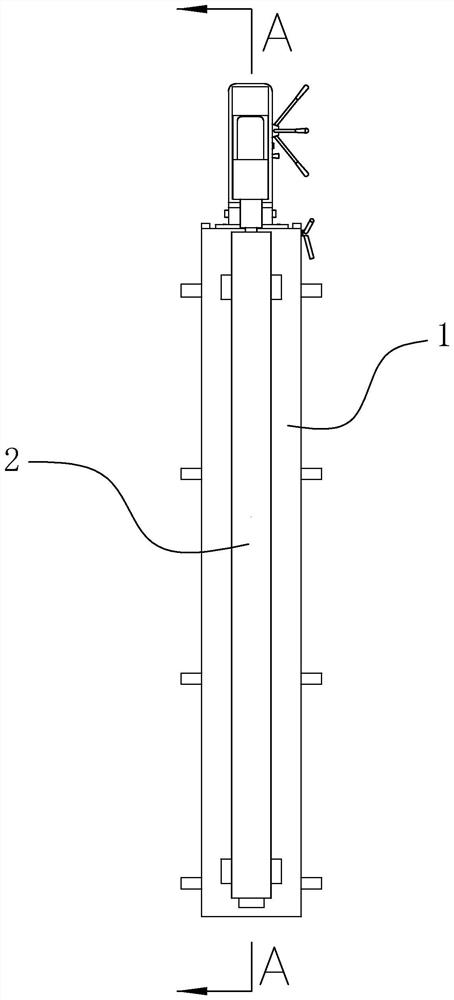

Multi-function line pole machine

ActiveCN102296876AReduce labor intensityImprove construction efficiencyTowersTransfer caseNatural disaster

The invention discloses a multifunctional stringing pole-erecting machine which comprises a power operation vehicle with a walking chassis, wherein the lower part of the walking chassis is provided with walking wheels, the rear part of the walking chassis is provided with a power mechanism and a driving control chamber, the front part of the walking chassis is provided with a rotary support, the power mechanism is in transmission connection with the walking wheels through a transmission shaft under the walking chassis and a transfer case, the power mechanism is in hydraulic transmission connection with the rotary support, a rotary base is arranged on the rotary support, a pole lifting device is rotatably connected to the rotary base, the lower part of the pole lifting device is provided with a drilling mechanism, and the front end and the rear end of the walking chassis are respectively provided with a foldable front support leg and a foldable rear support leg. The multifunction stringing pole-erecting machine is a power grid stringing construction mechanical device integrating drilling and pole erecting, is integrally of an electrohydraulic control mode, is especially suitable for emergence rush repair when a power grid suffers from natural disasters, and is more suitable for environment with larger pole-erecting operation density in rugged and narrow places and places into which construction vehicles can not enter.

Owner:HENAN POWER TRANSMISSION & TRANSFORMATION CONSTR CO LTD +2

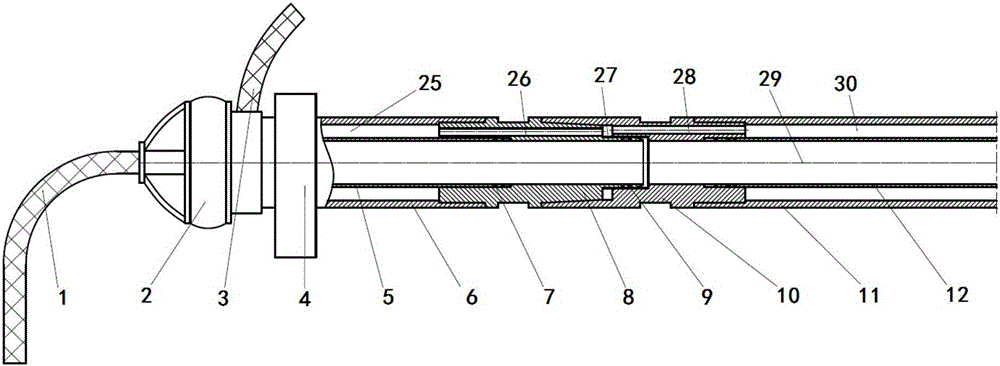

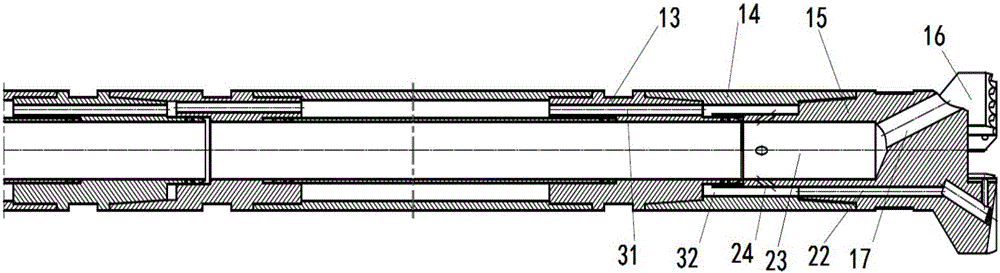

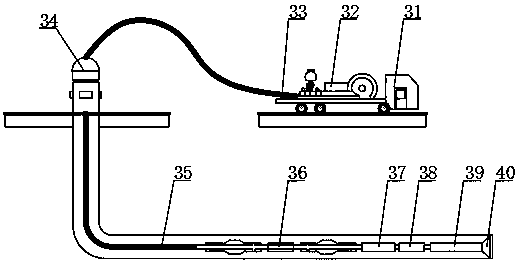

Injection type suction drilling tool for cutting removal of drilling center of weak formation and using method of drilling tool

InactiveCN105781419AImprove slag feeding efficiencyImprove drilling efficiencyDrilling rodsConstructionsEngineeringDrill cuttings

The invention discloses an injection type suction drilling tool for residual removal of a drilling center of a weak formation. The drilling tool comprises an air inlet pipe, a cutting removal pipe, a power head and a drill rod, wherein a cutting removal passage and an air inlet passage are formed in the drill rod; an injection type suction drill bit is arranged at the front end of the drill rod; cutting heads are arranged on the end part of the injection type suction drill bit; cutting inlets are formed in the top sidewall of the injection type suction drill bit; injection holes are formed in the inner sidewalls of the cutting heads; high-pressure injection passages are formed in the injection type suction drill bit. According to the drilling tool, a negative pressure area is formed in the cutting removal passage by jetting of the high-pressure injection passages in the cutting removal passage of the center, a suction effect on drilling cuttings is achieved by the cutting inlets, a stirring effect on the bottom of a borehole is achieved by air jets injected by the injection holes, and the drilling cuttings at the bottom of the borehole are driven to be transferred into the cutting holes, and are promoted to enter the cutting removal passage of the center through the cutting inlets, so that the problems of jamming of the drilling tool, burying of the drilling tool, difficulty in removal of the cuttings in the borehole and the like in an existing coal bed gas exhaust drilling process are solved, the drilling efficiency is greatly improved, and the drilling depth is greatly increased.

Owner:CHONGQING UNIV

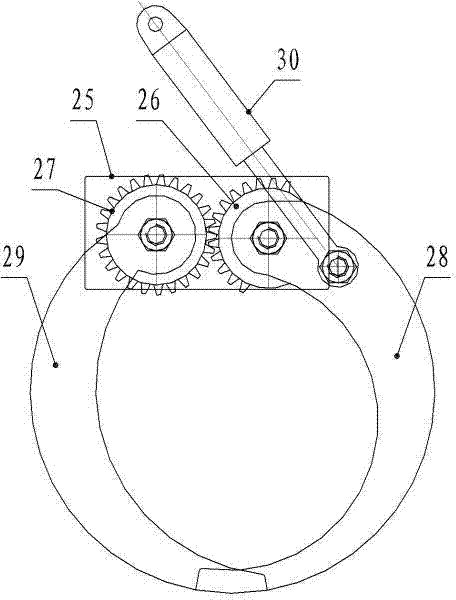

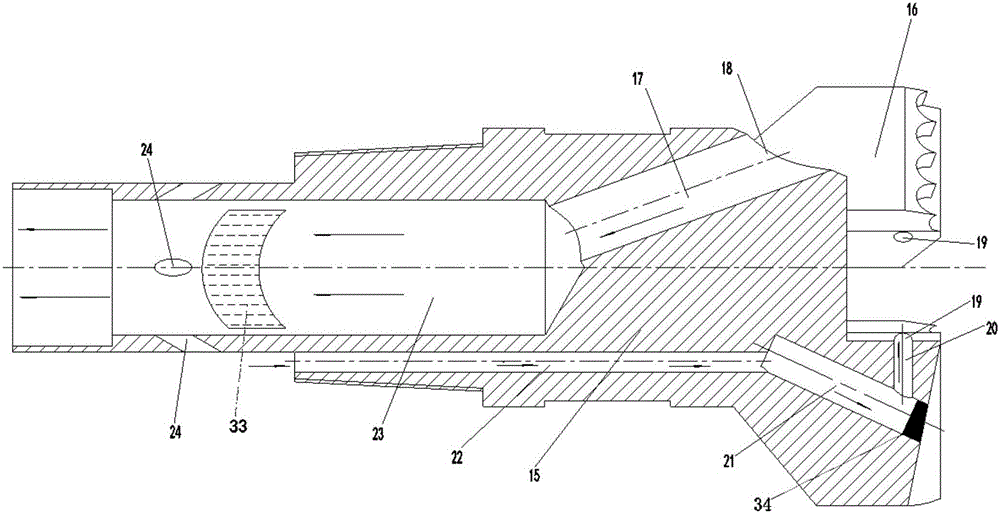

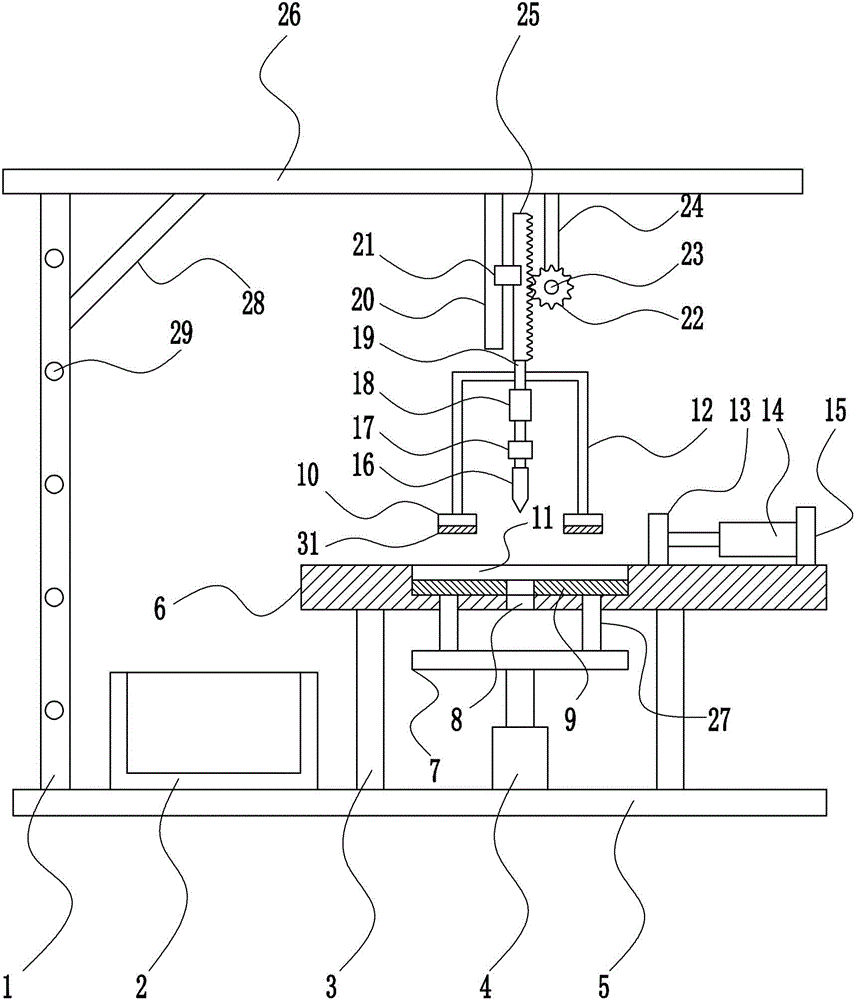

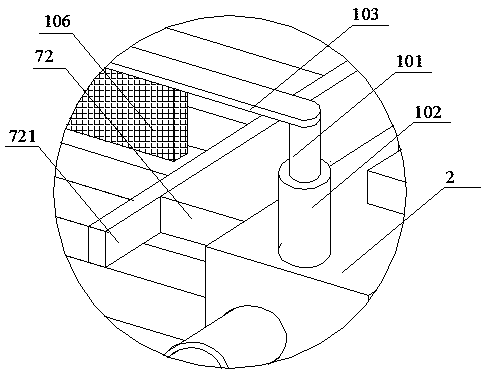

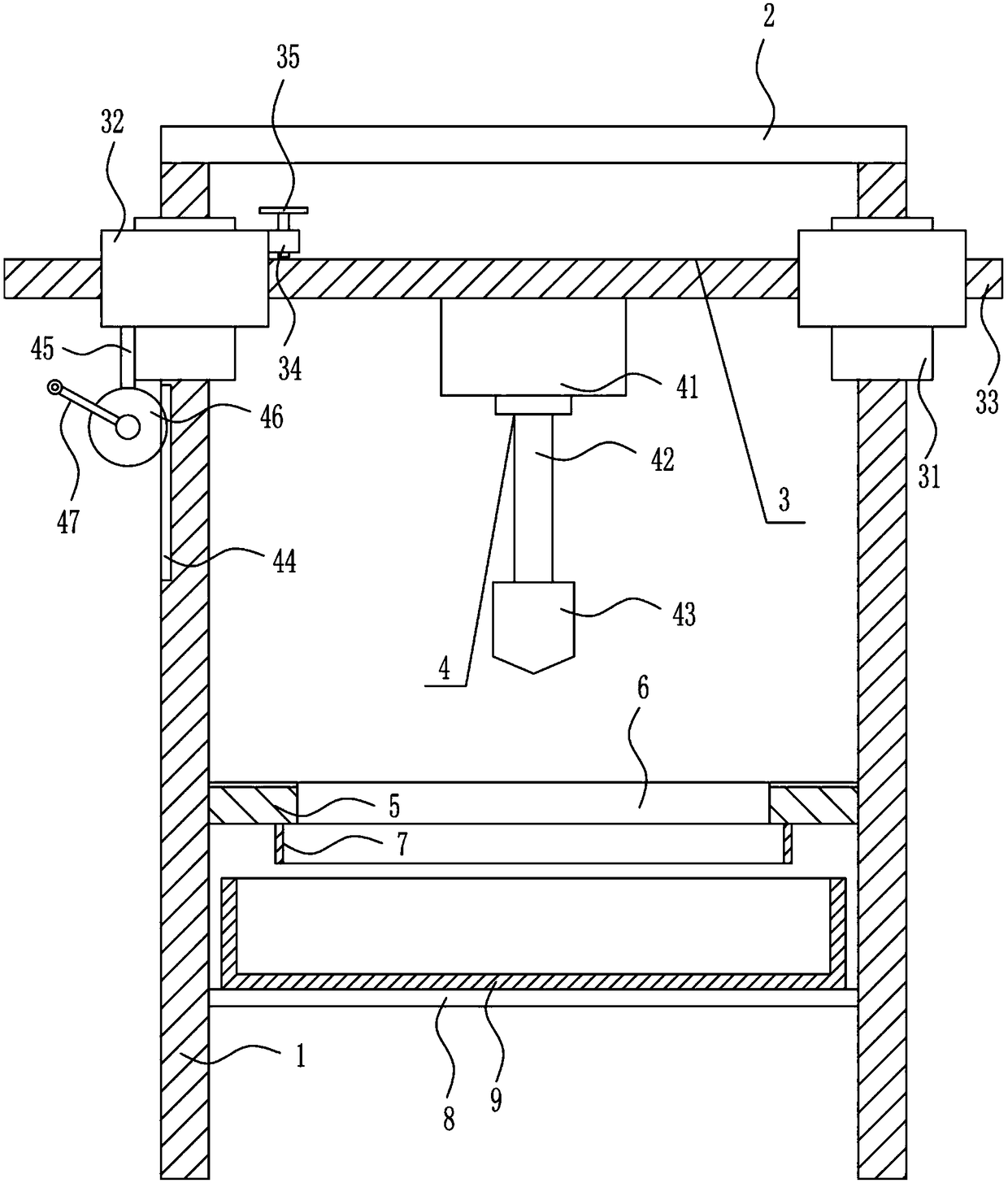

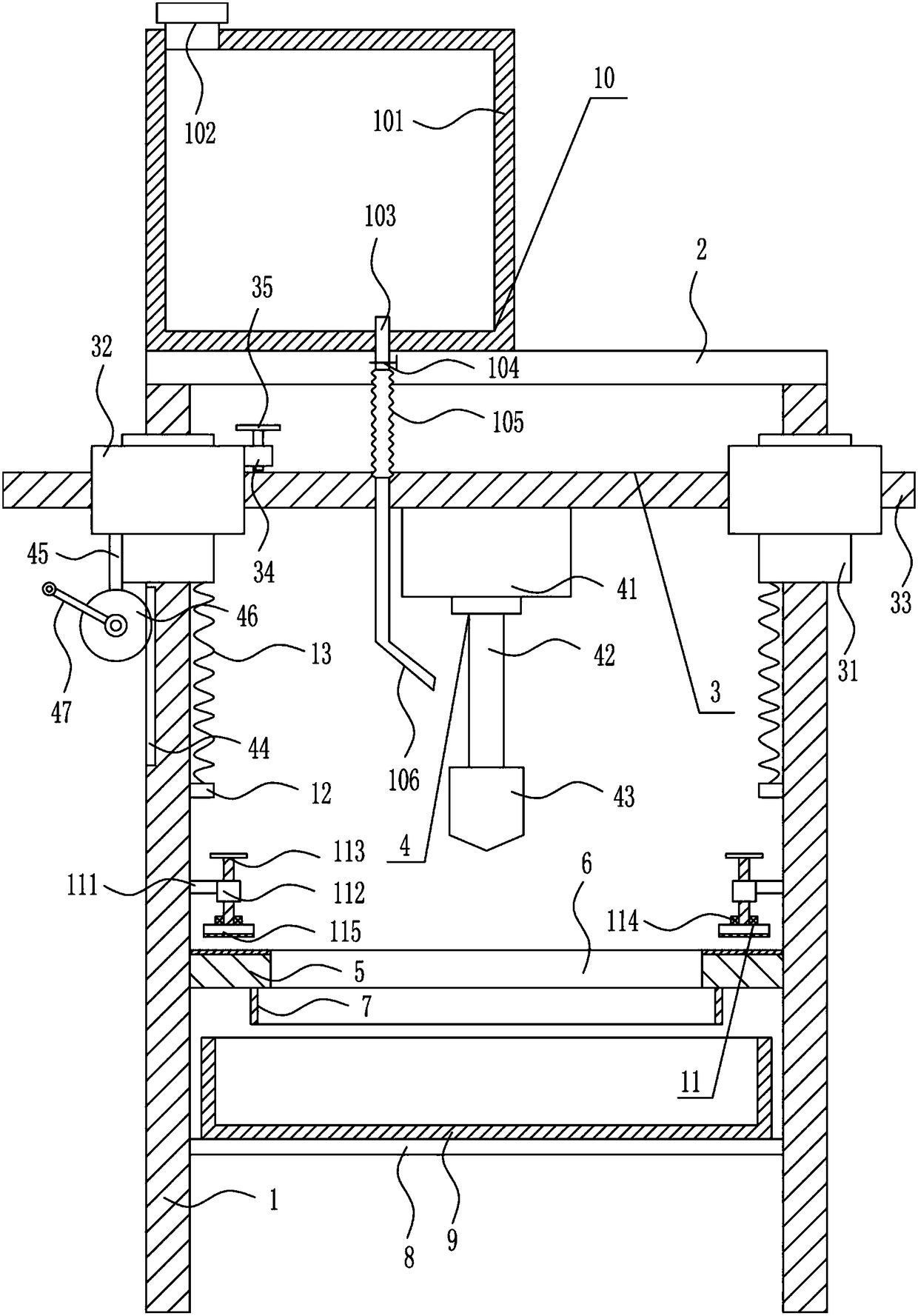

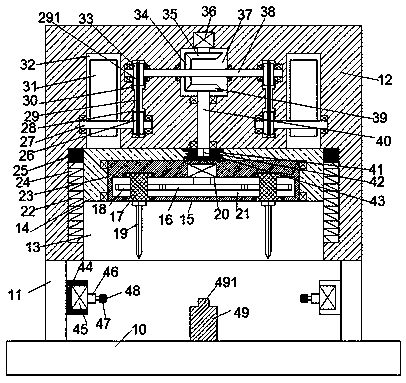

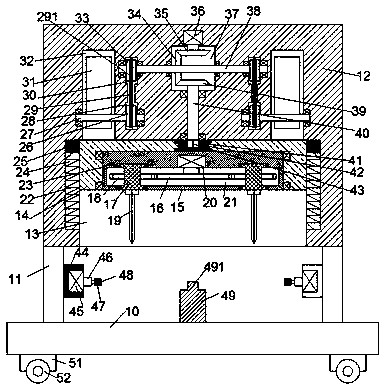

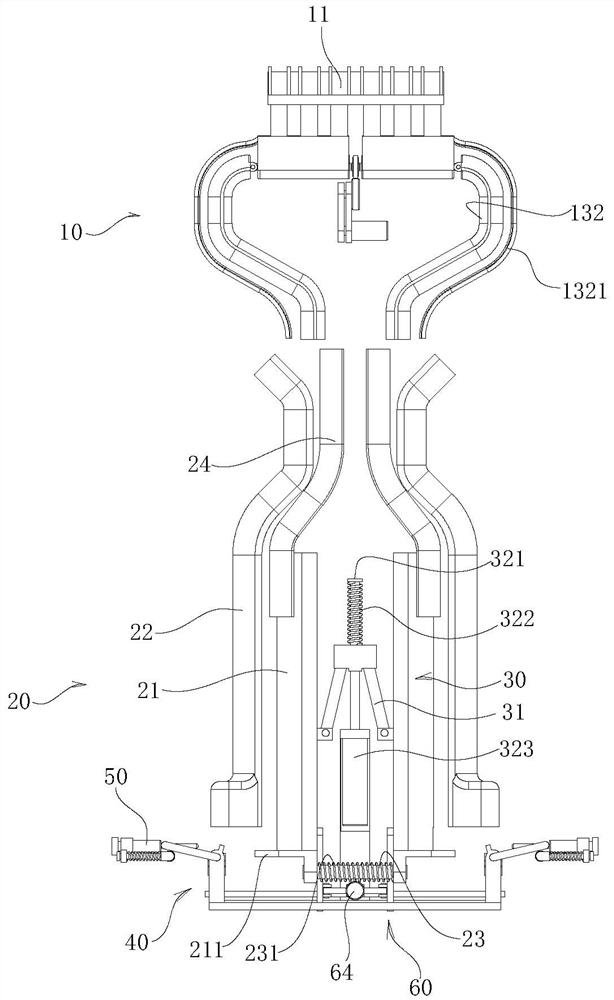

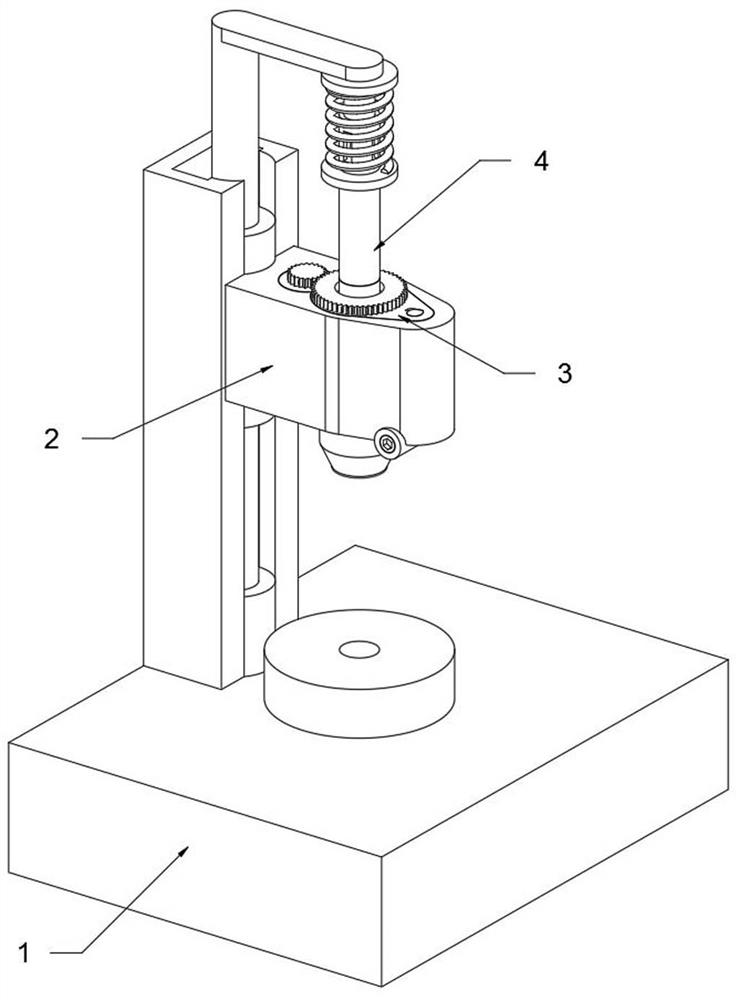

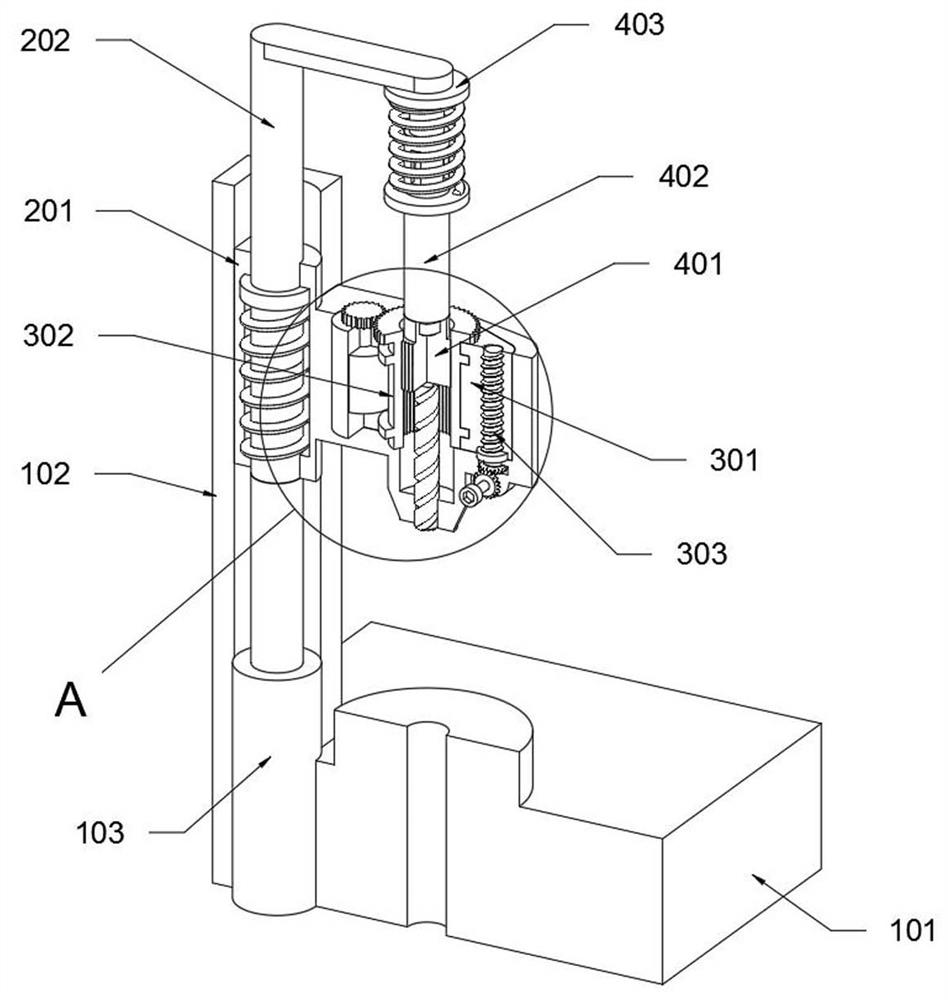

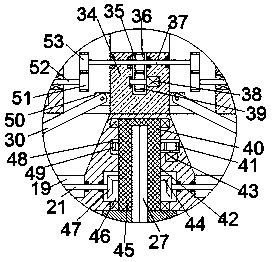

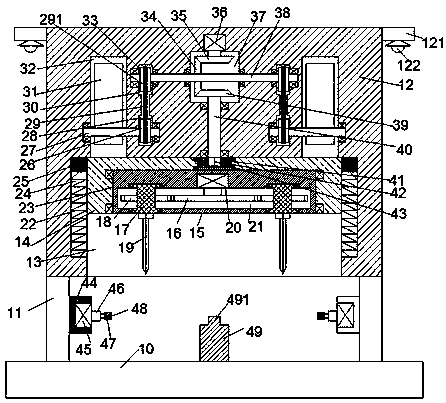

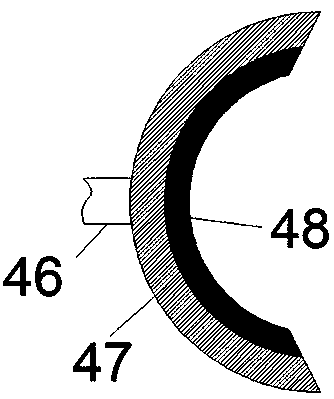

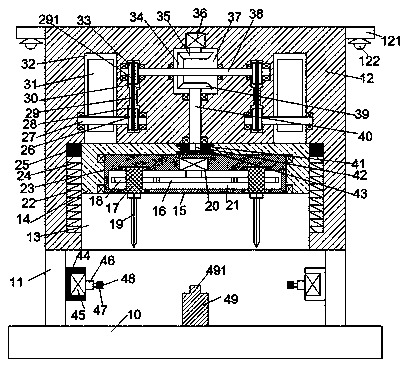

Rotatable workpiece drilling device

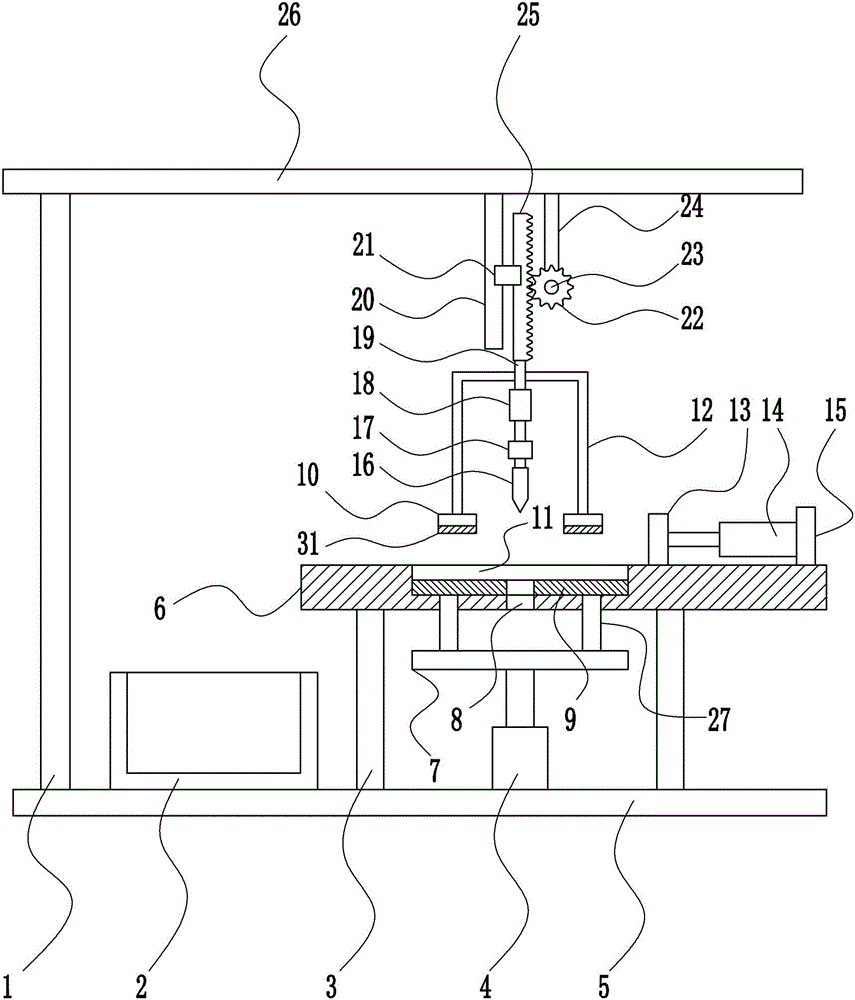

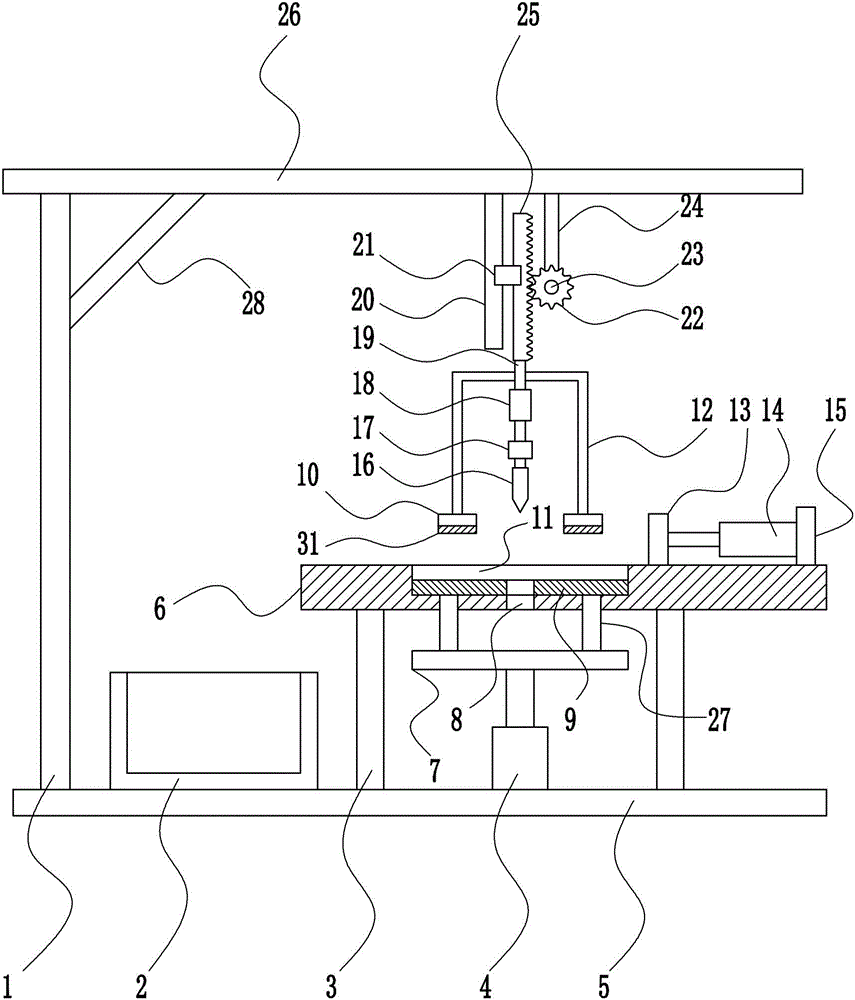

InactiveCN107486732ARealize the drilling operationPrecise positioningAutomatic control devicesFeeding apparatusDrill bitEngineering

The invention discloses a rotatable workpiece drilling device, which comprises a base, on which a support rod and a beam are arranged, the beam is arranged on the support rod, and a motor is installed on the beam. seat, a drilling motor is installed on the motor mounting seat, a drill bit is arranged on the drilling motor, the drilling motor is connected to the motor mounting seat through a guide rail, and on the motor mounting seat A drilling motor adjustment handle is also provided; a rotating motor seat is also provided on the base, a rotating motor is arranged on the rotating motor seat, and the output shaft of the rotating motor is connected with a workpiece holding seat through a connecting rod, Two adjustable clamping blocks are arranged on the workpiece clamping seat. The rotatable workpiece drilling device provided by the present invention can realize multi-directional drilling operation by driving the workpiece clamping seat through the rotating motor, and can realize precise positioning through the stepping motor, and has high processing precision.

Owner:南京淳飞怿建筑科技有限公司

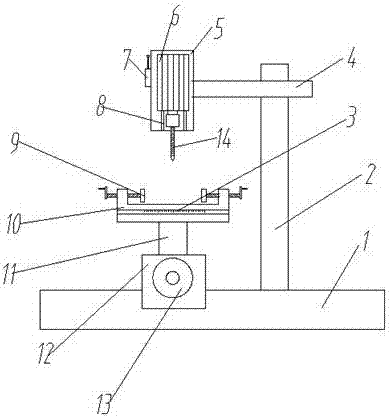

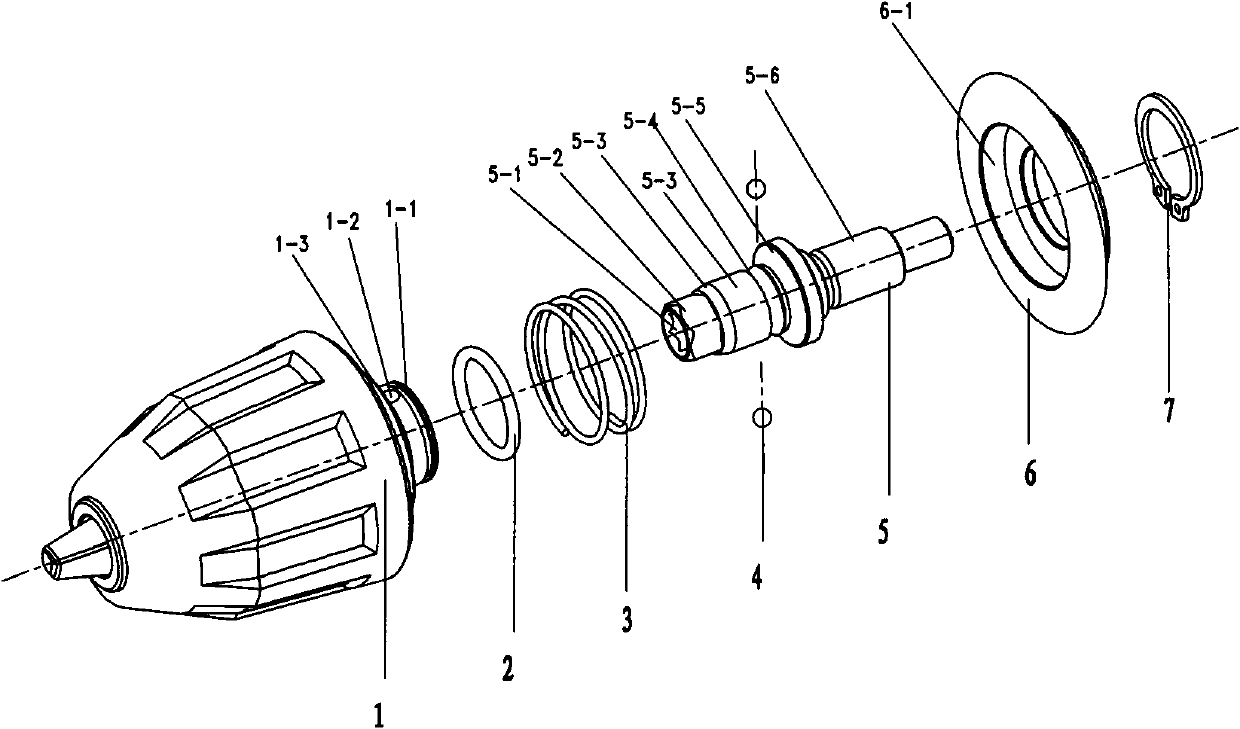

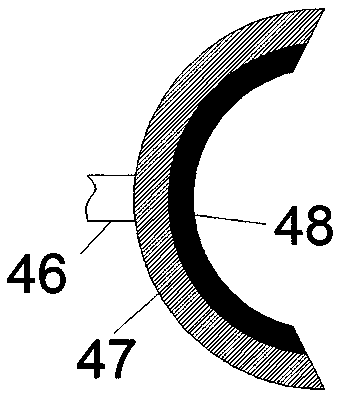

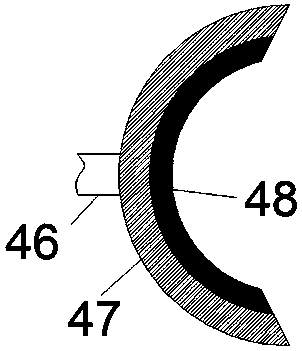

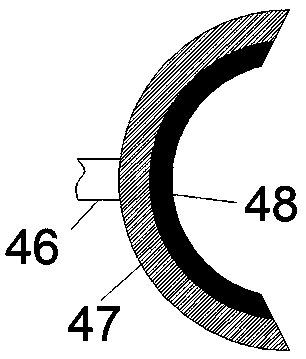

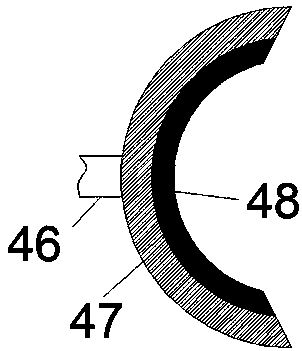

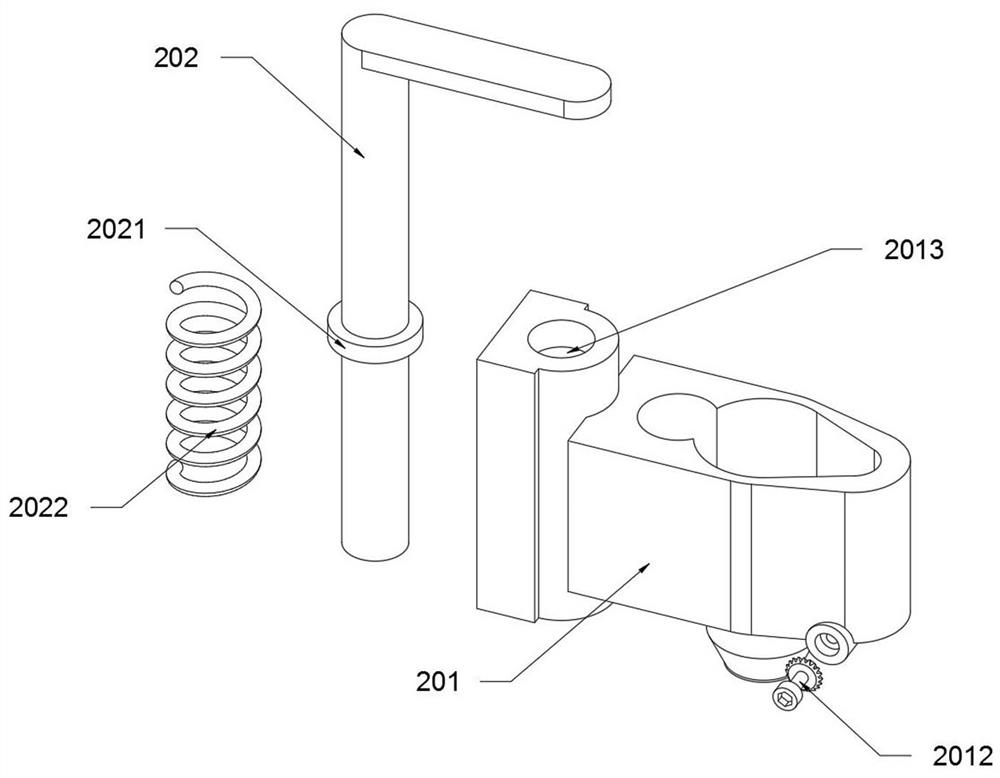

Quick-change drill chuck

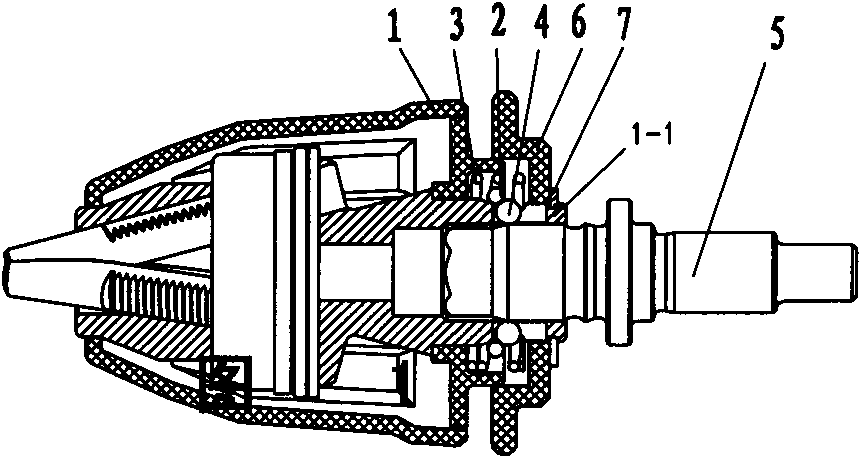

ActiveCN102166663AEasy to unplugRealize the drilling operationChucksAxial displacementElastic component

The invention relates to a quick-change drill chuck which belongs to the technical field of tools. The drill chuck mainly comprises a chuck body, a compression spring, an unlocking ring and an electric-drill output shaft; when the unlocking ring is shoved out by the compression spring, so that the unlocking ring is arranged away from the rear end face of the chuck body, and the tapered transitionsection of the unlocking ring is pressed against a meshing component, so that a radial elastic component is in a diameter expanding state, the radial elastic component is in the state that through carrying out diameter shrinkage and extrusion on the meshing component, the radial elastic component is close to the end of a slot hole away from the chuck body, and the radial elastic component is dropped into a groove and performed perforation by the unlocking ring so as to carry out radial constraint on the unlocking ring; when the unlocking ring overcoming the compression spring is arranged at the position close to the rear end face of the chuck body, the radial elastic component is subjected to axial displacement and diameter expanding with the unlocking ring along the tapered section of a sleeve so as to respectively break away the extrusion and radial constraint on the meshing component. After the quick change drill chuck provided by the invention is adopted, because the unlocking ring is not required to be controlled in the whole process of inserting the unlocking ring into the chuck body, and the forced direction acted on the unlocking ring and the pullout direction of the unlocking ring are consistent when the unlocking ring is pulled out from the chuck body, the operation of inserting the unlocking ring into the chuck body or pulling the unlocking ring out from the chuck body is handy and very convenient.

Owner:NANJING JIUCHI ELECTROMECHANICAL IND

High-efficiency drilling equipment for carbon fiber compound products

ActiveCN106426387AConvenience to workPrevent items from being lostMetal working apparatusFiberMaterials science

The invention relates to drilling equipment, in particular to high-efficiency drilling equipment for carbon fiber compound products. The technical problem to be solved is to provide the high-efficiency drilling equipment for the carbon fiber compound products with capability of reducing the labor intensity of workers, time and labor saving and simple operation. In order to solve the technical problem, the invention provides the high-efficiency drilling equipment for the carbon fiber compound products. The high-efficiency drilling equipment comprises a left frame, a collecting box, support rods, a first electric push rod, a baseplate, a console, a first fixed plate, a push plate, a pressing block, an L-shaped bracket, a top block, a second electric push rod and the like; the left frame is welded on the left side of the top of the baseplate; and the support rods are symmetrically welded on the right side of the top of the baseplate left and right. The high-efficiency drilling equipment achieves the effects of capability of reducing the labor intensity of the workers, time and labor saving and simple operation.

Owner:溧阳材生复合材料技术有限公司

Coiled tubing well-drilling robot control system capable of controlling drilling speed and bit pressure

InactiveCN109519164ARealize the drilling operationStepless adjustment of drill pressureAutomatic control for drillingDifferential pressureStreamflow

The invention relates to the field of oil and gas field development, in particular to a coiled tubing well-drilling robot control system capable of controlling drilling speed and bit pressure. The coiled tubing well-drilling robot control system is characterized in that a telescopic cylinder control module of a well-drilling robot includes a differential pressure sensor, a flow sensor, an electricproportional flow valve, an electric proportional relief valve and a three-position four-way electromagnetic reversing valve, wherein the bit pressure of a drilling column is regulated by the electric proportional relief valve, and the drilling speed of the drill column is adjusted by the electric proportional flow valve. Compared with the prior art, the coiled tubing well-drilling robot controlsystem has the following advantages that the combined control of the electric proportional relief valve and the electric proportional flow valve enables the well-drilling robot to push the drill string to advance forward with the optimal drilling speed and the bit pressure, and the coiled tubing well-drilling robot control system can adapt to different formations and well depths.

Owner:SOUTHWEST PETROLEUM UNIV

Mechanical part drilling device

ActiveCN111673112AImprove drilling efficiencyReduce labor costsBoring/drilling componentsBoring/drilling machinesPhysicsElectric machinery

The invention discloses a mechanical part drilling device and relates to the technical field of machining. The mechanical part drilling device comprises a base. The lower surface of the base is fixedly connected with supporting legs. The upper surface of the base is fixedly connected with a transverse feeding mechanism. The upper surface of the transverse feeding mechanism is fixedly connected with a longitudinal feeding mechanism. The upper surface of the longitudinal feeding mechanism is fixedly connected with a clamping and fixing seat. The upper surface of the base is fixedly connected with left vertical plates. The upper portions of the left vertical plates are fixedly connected with a left transverse plate. The upper portion of the left transverse plate is fixedly connected with a left mounting base. The upper surface of the left mounting base is fixedly connected with a tool changing mechanism. The tool changing mechanism is fixedly connected with a cutter head. The upper portion of the cutter head is fixedly connected with a locking mechanism. The upper surface of the base is fixedly connected with right vertical plates. The upper portions of the right vertical plates are fixedly connected with a right transverse plate. The right transverse plate is fixedly connected with a right mounting bas. The lower portion of the right mounting base is fixedly connected with a first electric push rod. The first electric push rod is fixedly connected with a motor. According to the mechanical part drilling device, a drill bit can be replaced conveniently through the tool changingmechanism, cutting tools can be used rapidly through the cutter head, the drilling efficiency is improved, and the labor cost is lowered.

Owner:鲁仲斐

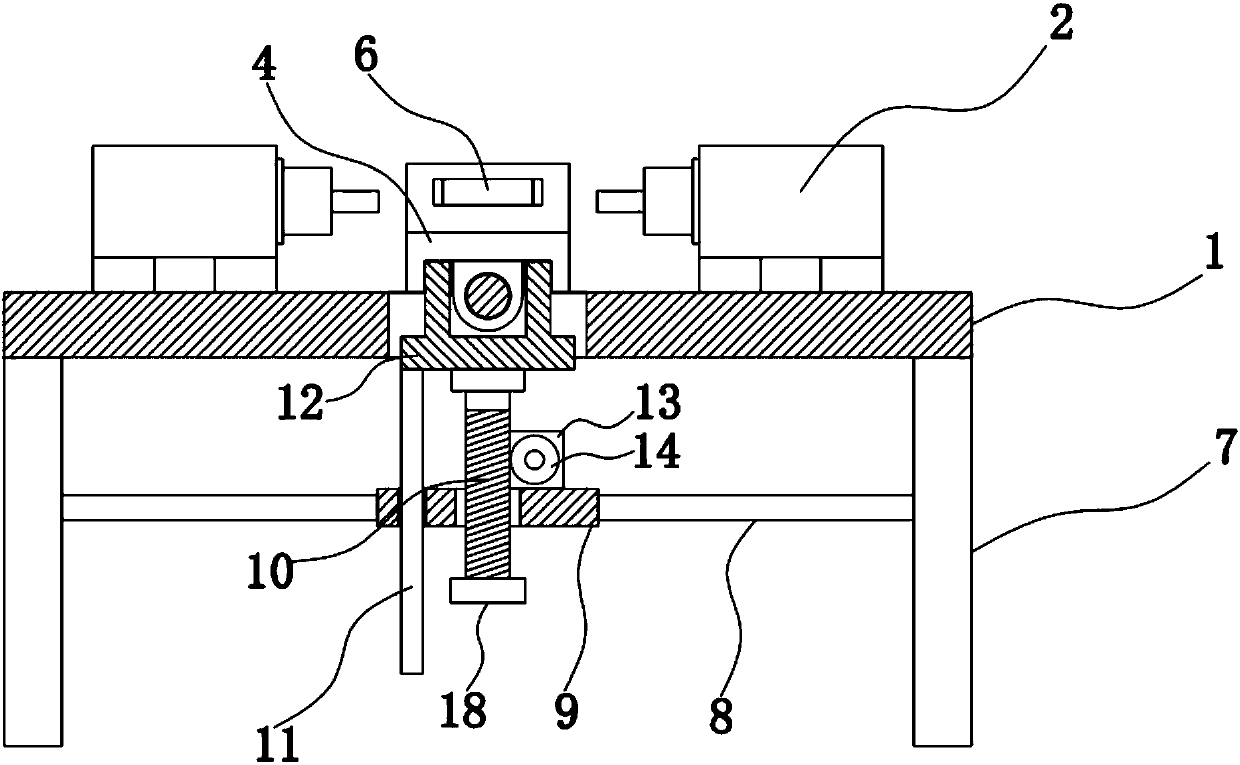

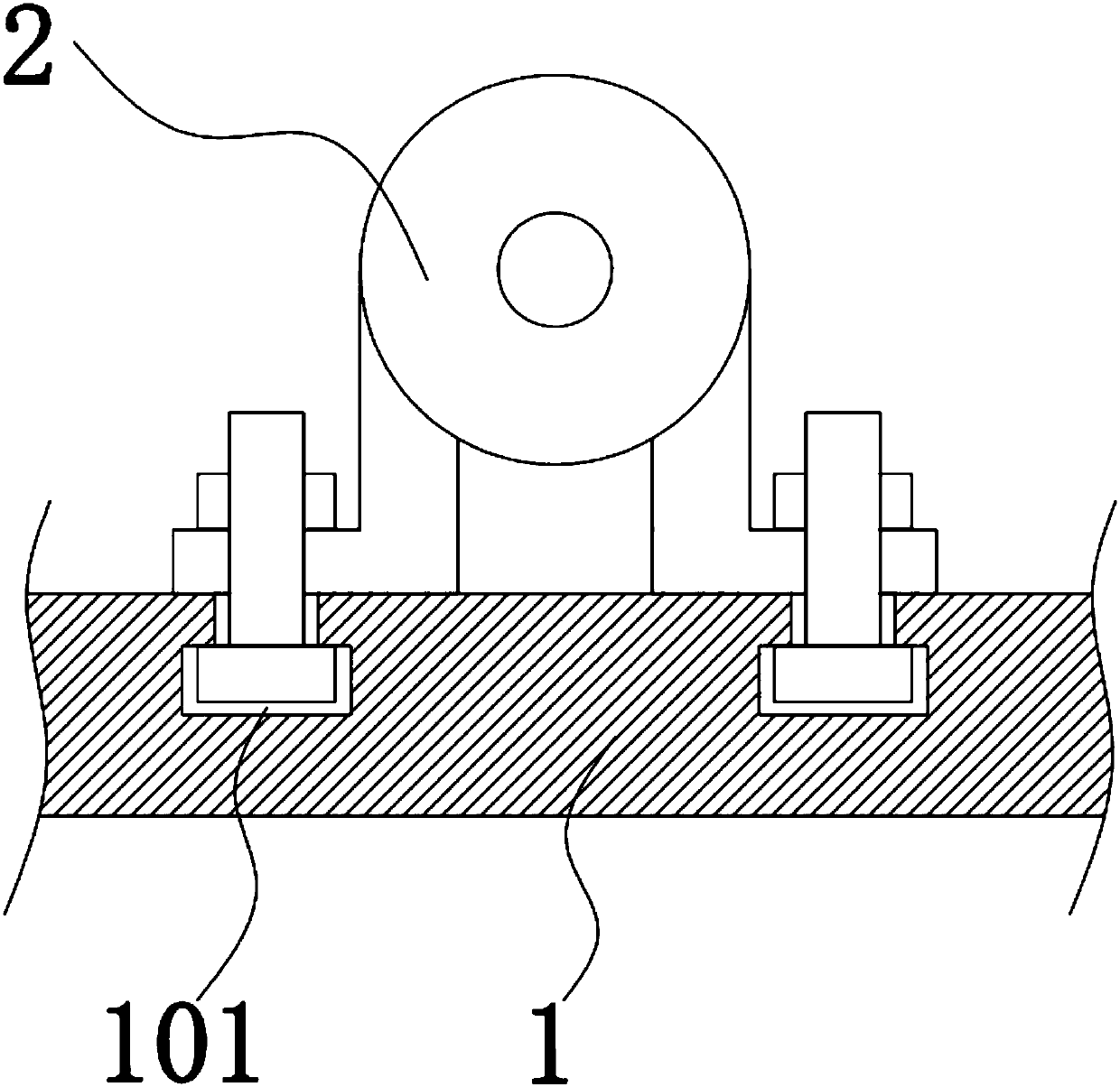

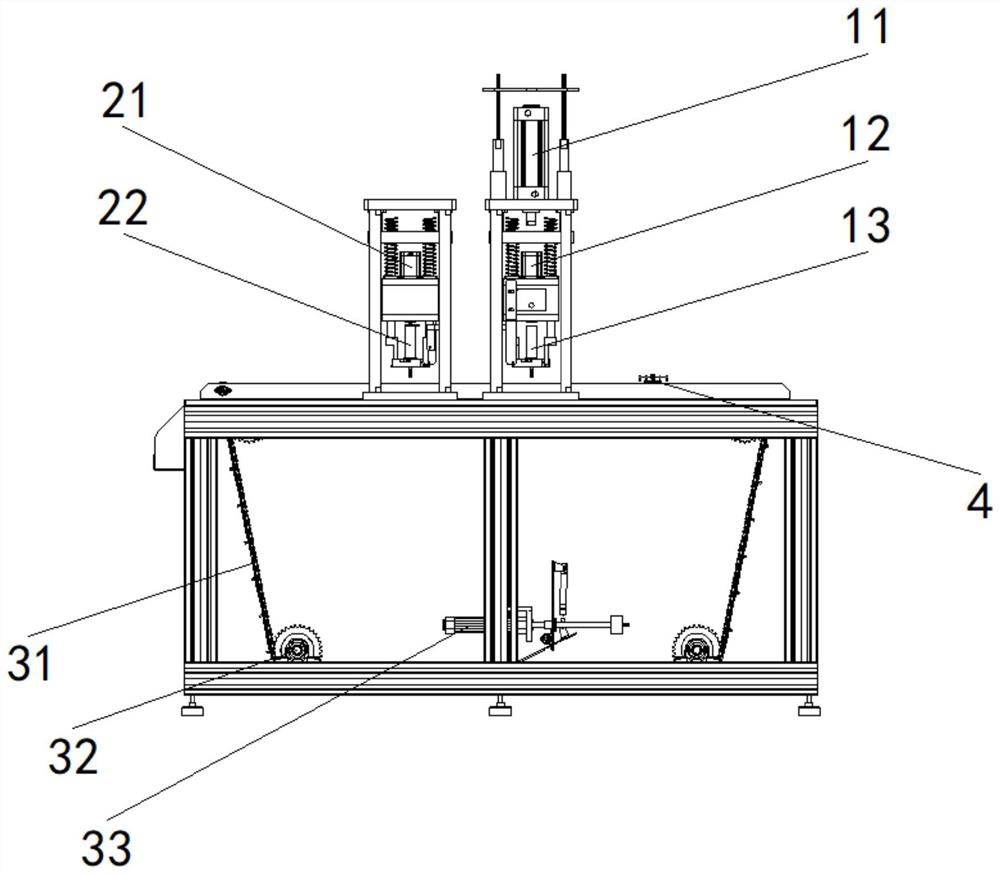

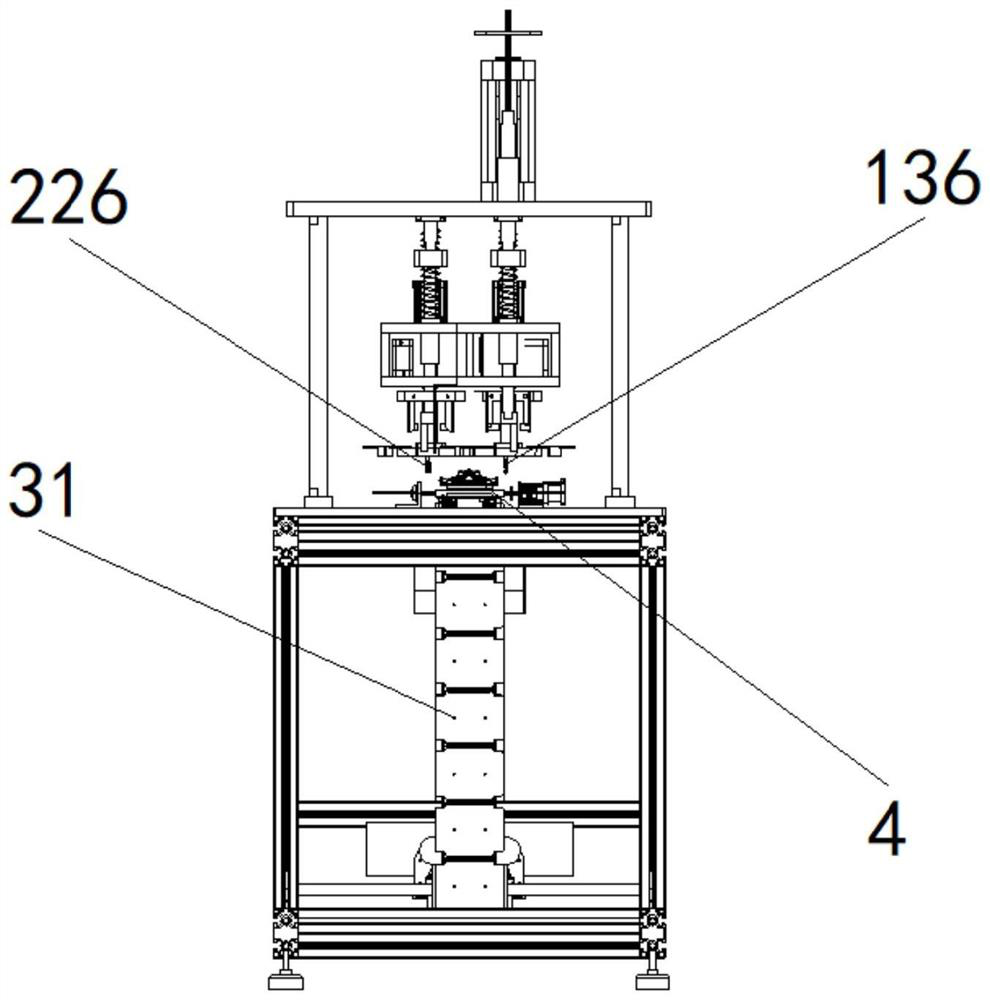

Double-drilling-machine machining platform for drilling press

InactiveCN108015310AEasy to fixRealize the drilling operationFeeding apparatusPositioning apparatusTurbineMachining

The invention discloses a double-drilling-machine machining platform for a drilling press. The double-drilling-machine machining platform comprises a working platform and a supporting seat. The working platform is fixed to a rack. A groove is formed in the middle portion of the working platform. Drilling machines are symmetrically mounted on the surface of the working platform and located on the two sides of the groove. A lead screw is arranged on the supporting seat. A sliding sleeve is in threaded connection with the lead screw. The sliding sleeve is fixed to the bottom of a workpiece fixingplatform. The two ends of the workpiece fixing platform are provided with fixed plates. An air cylinder is mounted on the outer side of each fixed plate. Clamping jaws are fixed to the telescopic ends of the air cylinders. The bottom of the supporting seat is rotatably connected to the top end of a threaded rod. The threaded rod is engaged with a turbine. The turbine is fixed to the output end ofa first stepping motor. Through the double-drilling-machine machining platform, a workpiece is fixed firmly; in the drilling process, the workpiece can be adjusted up and down, and left and right sothat the double-drilling-machine machining platform can conduct drilling operation on different positions of the workpiece; under the action of the two drilling machines, the double-drilling-machine machining platform can conduct drilling on the two sides of the workpiece simultaneously, and the drilling machining efficiency is improved.

Owner:莒南县彭川车桥有限公司

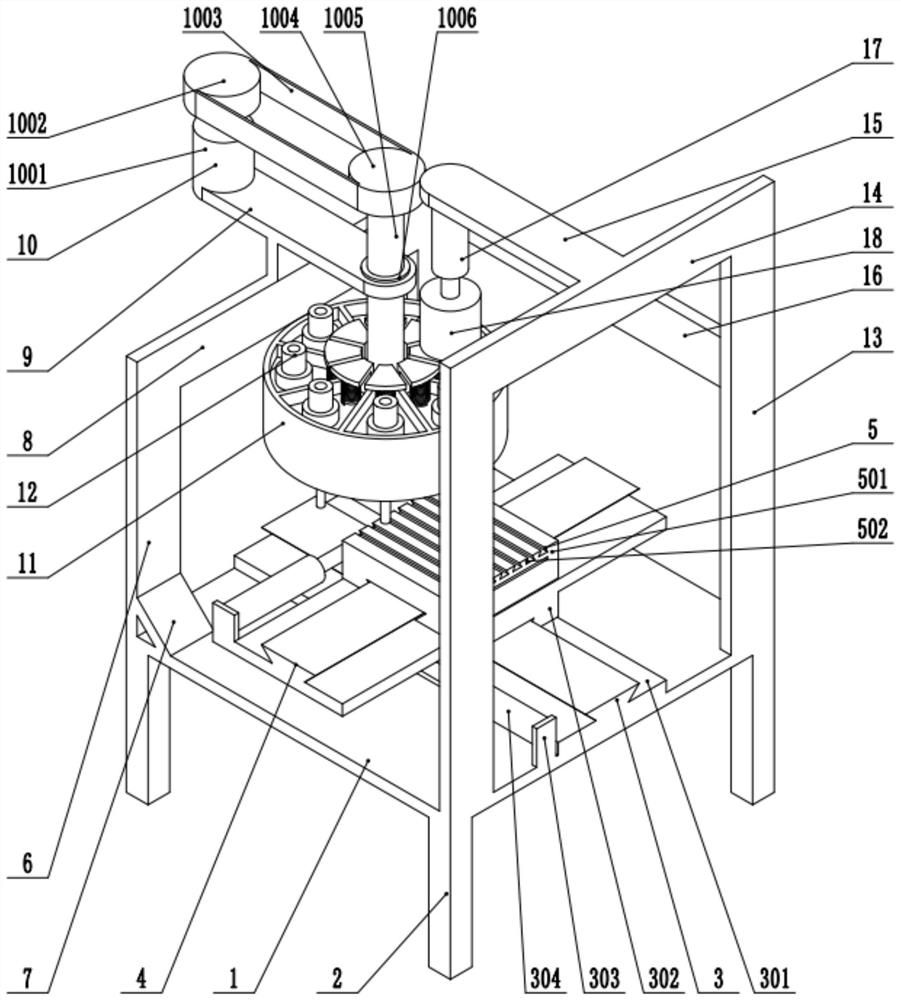

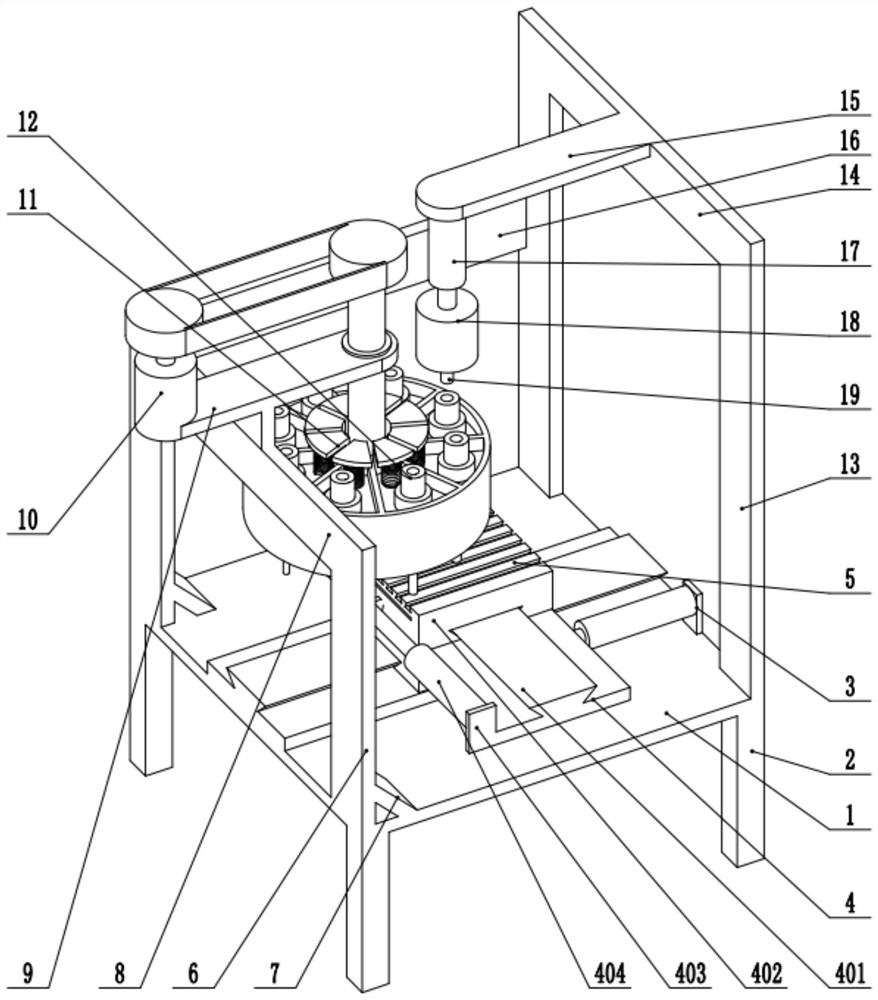

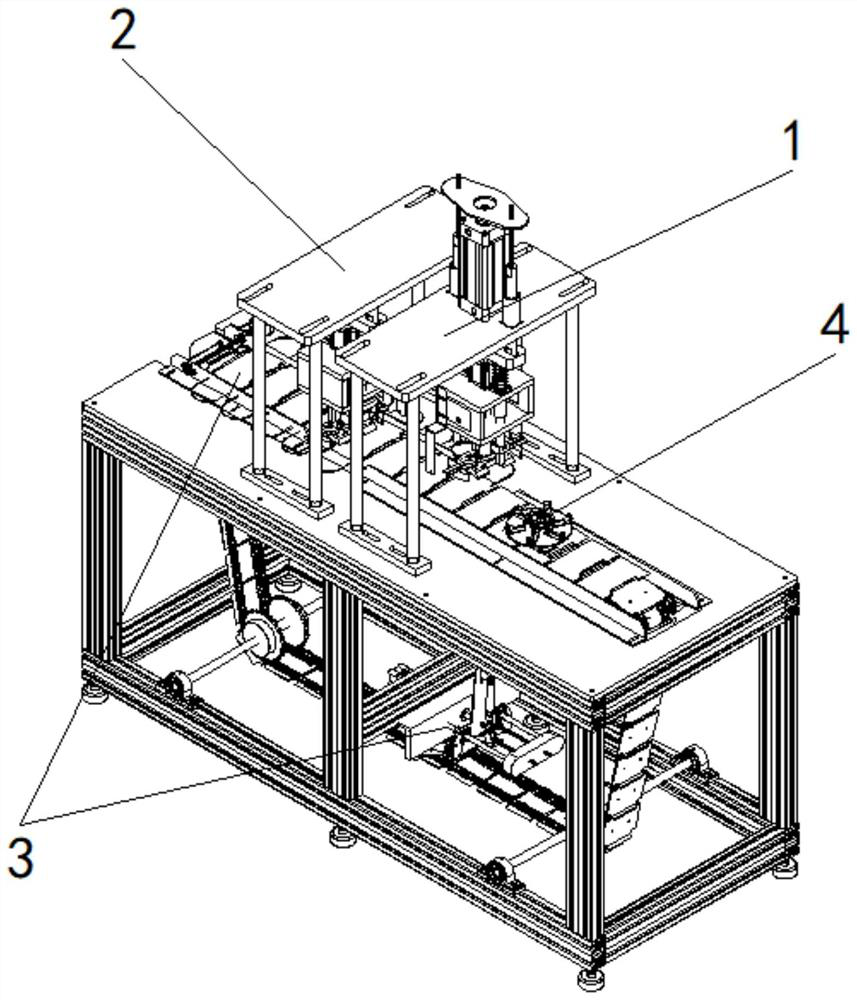

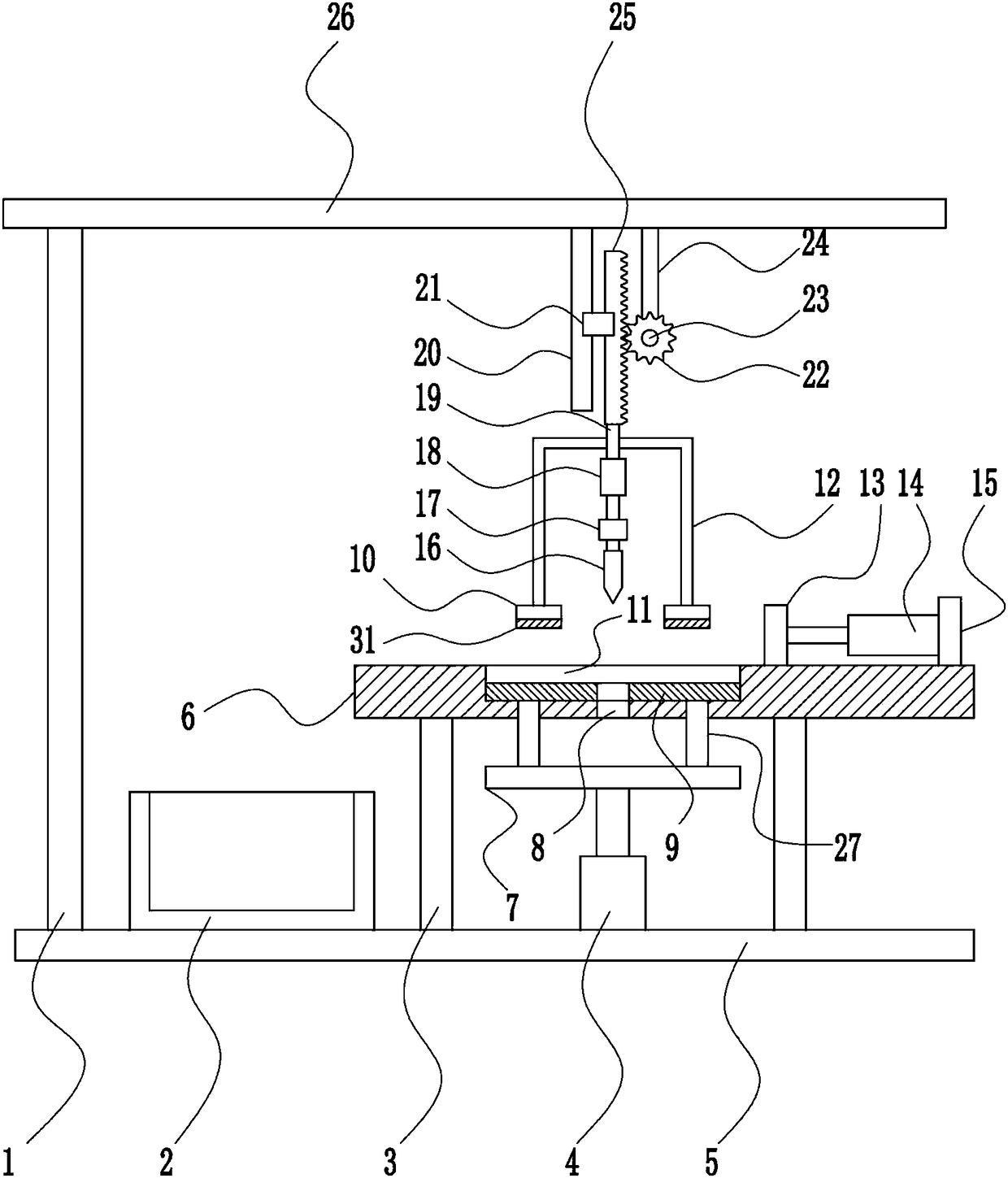

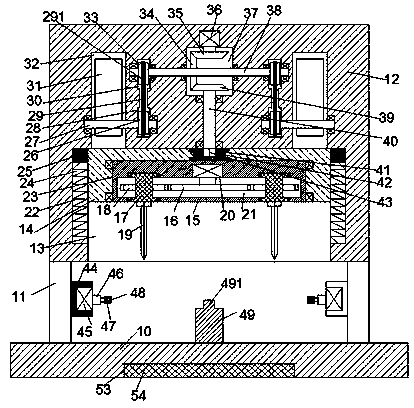

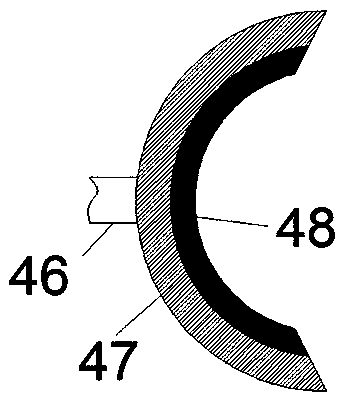

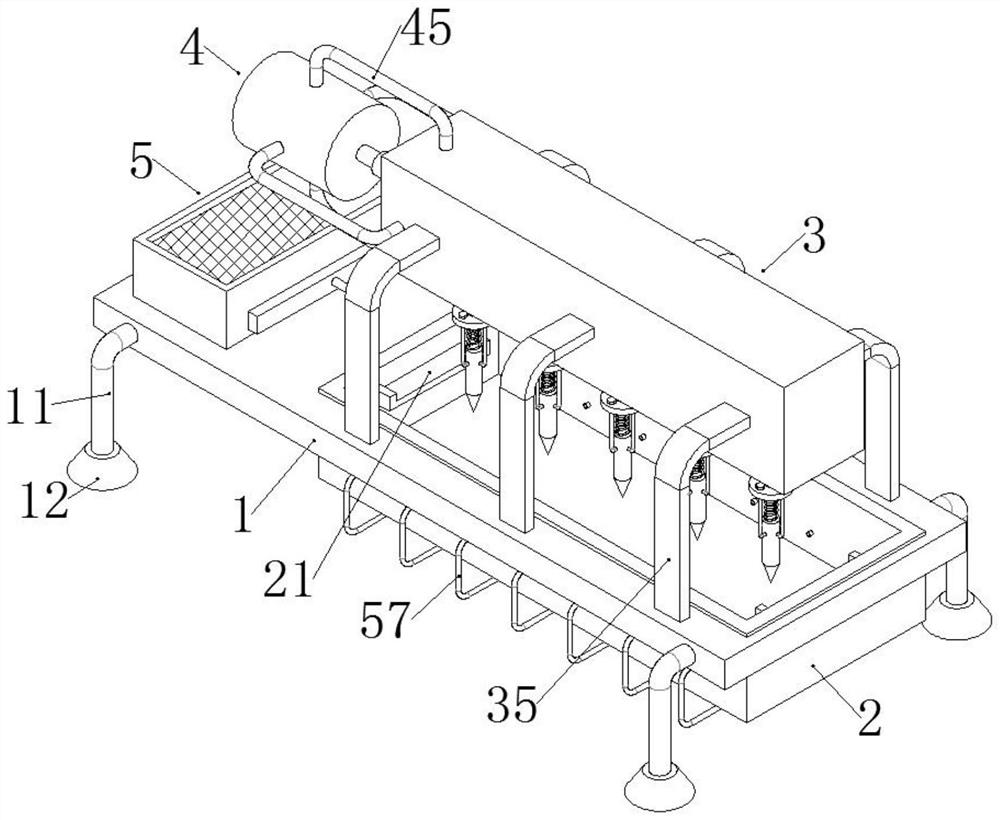

Multifunctional high-efficiency intensive furniture board machining device

InactiveCN109551572AWith recycling functionHigh processing stabilityStationary drilling machinesReciprocating motionEngineering

The invention discloses a multifunctional high-efficiency intensive furniture board machining device. The multifunctional high-efficiency intensive furniture board machining device comprises a first working table and a second working table, and further comprises a plate conveying mechanism, a drilling mechanism, an arc-shaped guide mechanism, a sliding mechanism, a plate limiting mechanism and anexternal packing treatment mechanism, wherein the plate conveying mechanism is arranged between the first working table and the second working table, and a plate is conveyed along the length directions of the first working table and the second working table; the drilling mechanism is suspended above the plate conveying mechanism, and the drilling angle of a drill bit of the drilling mechanism canbe adjusted; the arc-shaped guide mechanism is arranged on the end surface of the first working table; the arc-shaped guide mechanism can do horizontal reciprocating motion in the width direction of the first working table through the sliding mechanism; the plate limiting mechanism comprises a horizontal transverse limiting mechanism and a horizontal longitudinal limiting mechanism; the external packing treatment mechanism comprises a sucker assembly which is horizontally arranged and a rotating rod which is arranged at the bottom of the sucker assembly. The multifunctional high-efficiency intensive furniture board machining device has the functions of multi-angle drilling, external packaging treatment and waste recovery, and meanwhile, the board machining stability is high, and the machining quality is good.

Owner:HEFEI HUIZHI NEW MACHINERY TECH CO LTD

High-strength anti-fracture plastic steel pile

InactiveCN109083126ARealize the drilling operationSimple structureBulkheads/pilesEngineeringHigh intensity

The invention discloses a high-strength anti-fracture plastic steel pile. The high-strength anti-fracture plastic steel pile includes a base, pillars arranged on the end face of the top of the base inleft-right symmetry and a placement frame arranged on the upper portions of the pillars, the end face of the bottom of the placement frame is internally provided with a sliding cavity with a downwardgroove opening, the sliding cavity is internally and slidably provided with a sliding frame, the end face of the bottom of a rotating table is internally provided with a first rotating groove, the rotating table is rotatably installed on the first rotating groove through a bearing, the rotating table is internally provided with a second rotating groove extending left and right, the inner top wallof the second rotating groove is fixedly provided with a first motor, the bottom of the first motor is in power connection with a first tooth-shaped wheel located in the second rotating groove, the upper and lower end walls of the second rotating groove are internally and rotatably provided with shell sleeves in left-right symmetry through a bearing, and the shell sleeves are fixedly provided with second tooth-shaped wheels which are connected with the first tooth-shaped wheel in a fit mode.

Owner:广州普隆智能设备有限公司

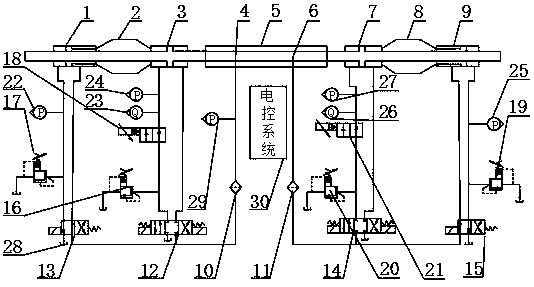

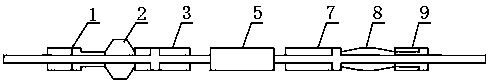

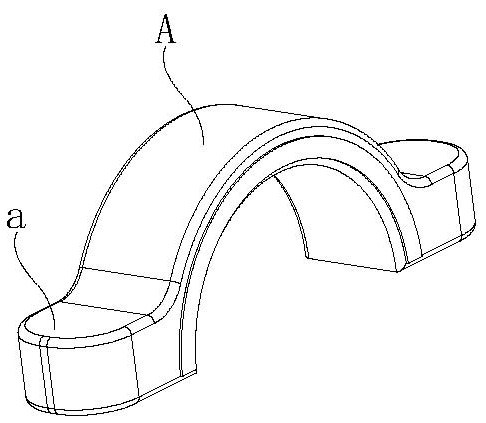

Drilling and tapping equipment

InactiveCN114589495ALow efficiencyEasy to installWork clamping meansAutomatic workpiece supply/removalProcess engineeringDrill hole

The invention provides drilling and tapping equipment. The drilling and tapping equipment comprises a rack, a drilling device and a tapping device. The rack is provided with a conveying device for conveying profiles; the drilling device comprises a drilling assembly and a first driving assembly erected on the rack; the drilling assembly is provided with a drilling tool located above the conveying device, and the first driving assembly is used for controlling lifting motion and rotation of the drilling tool; the tapping device is located on the lower station of the drilling device and comprises a tapping assembly and a second driving assembly erected on the rack. The tapping assembly is provided with a tapping tool located above the conveying device, and the second driving assembly is used for controlling lifting motion and rotation of the tapping tool. The automatic drilling and tapping equipment solves the problems that traditional drilling and tapping equipment is large in error and low in efficiency, and has the advantages of replacing manual labor and being high in automation degree.

Owner:佛山市信新瀚家居科技有限公司

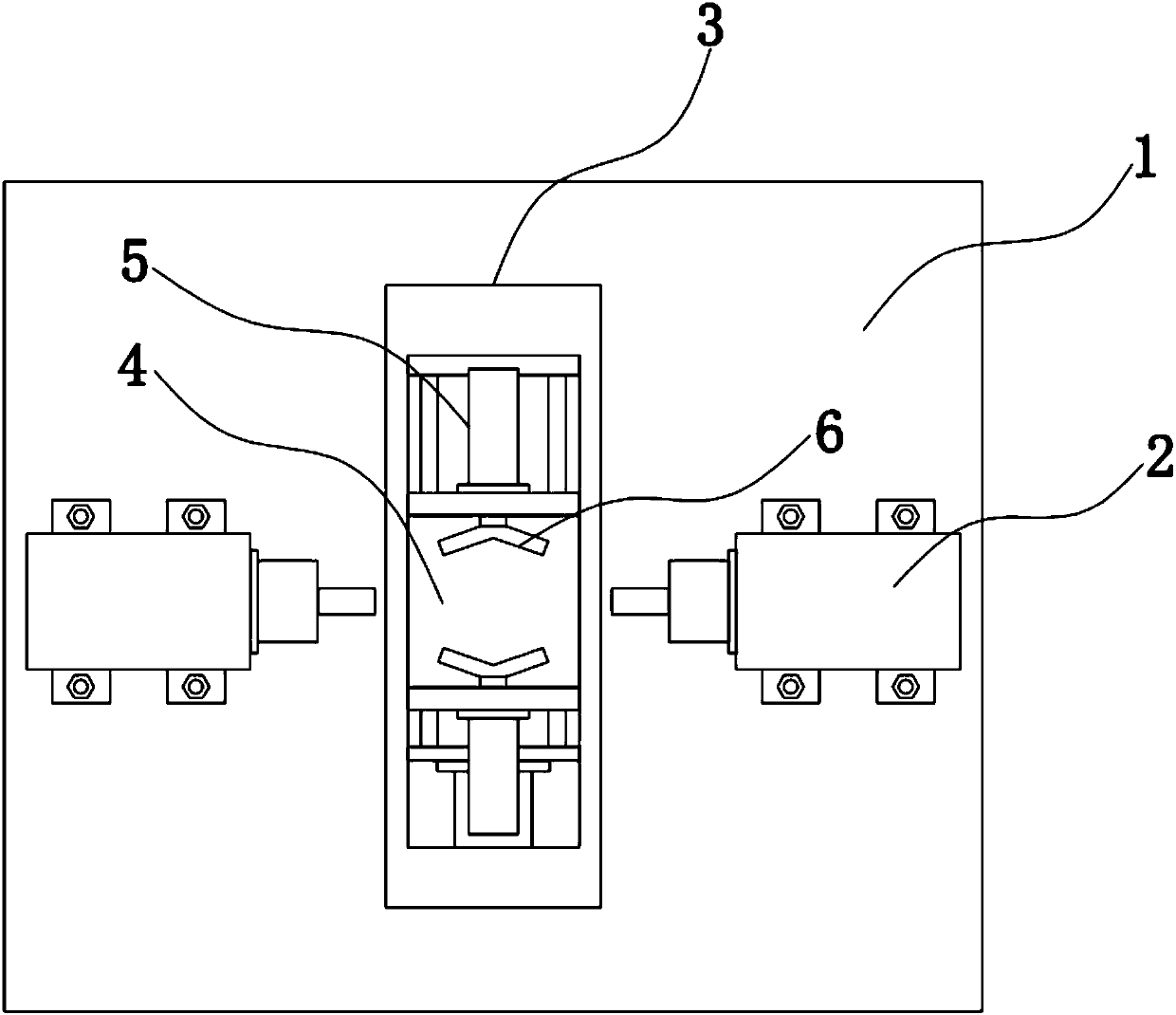

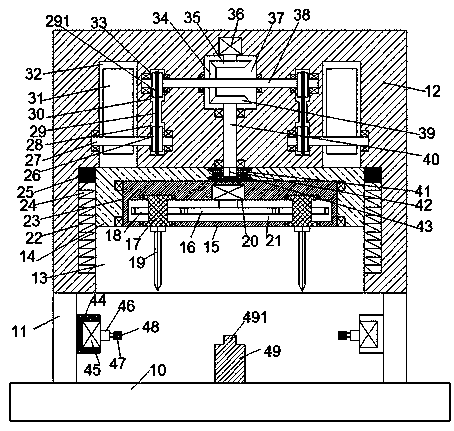

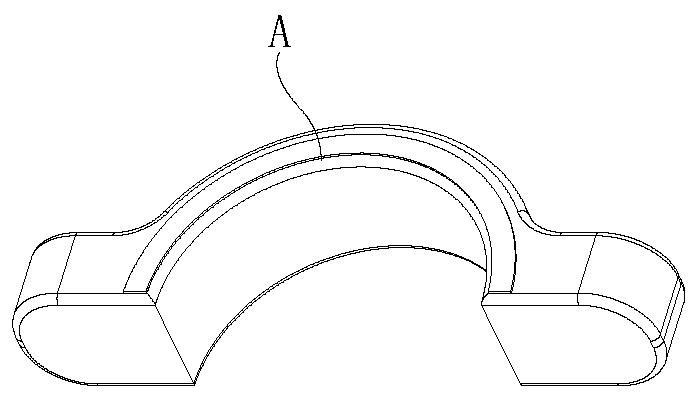

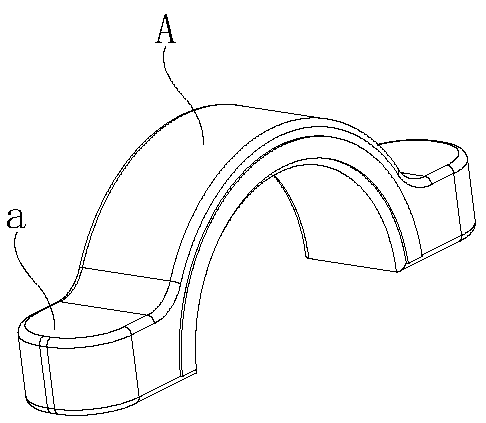

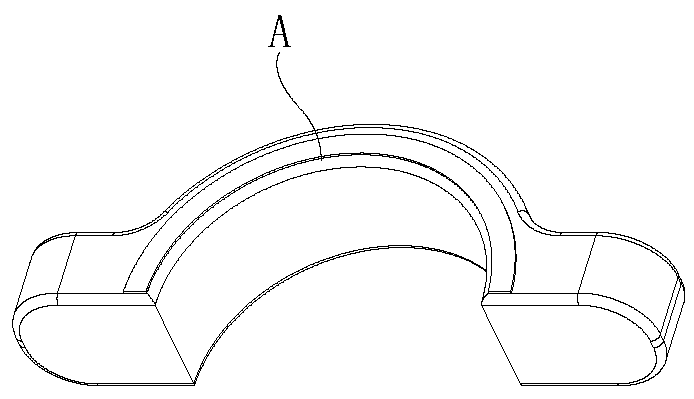

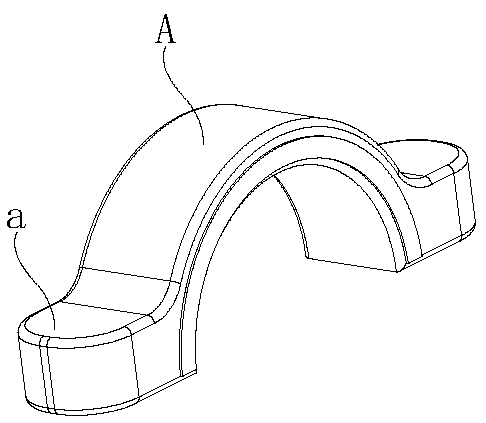

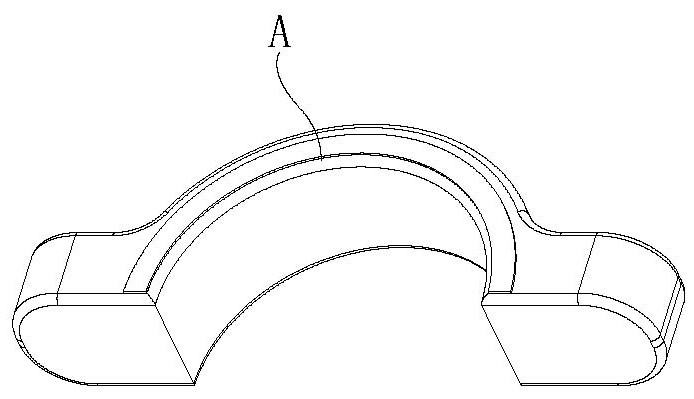

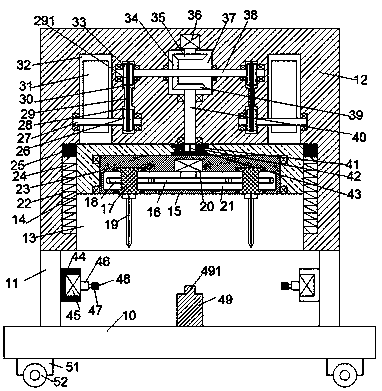

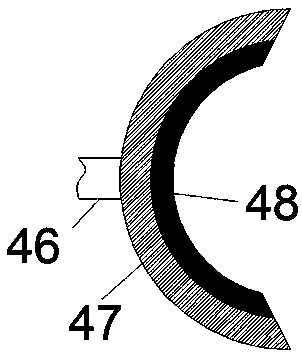

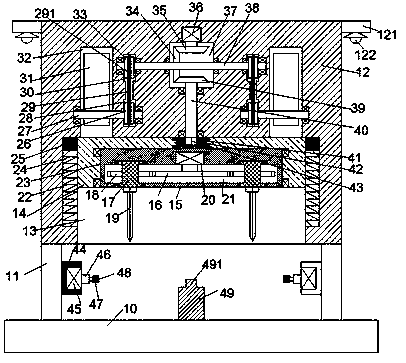

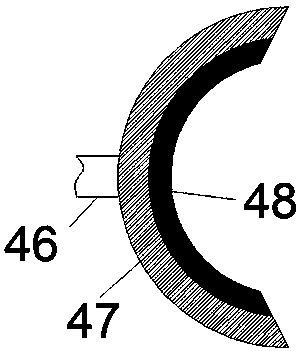

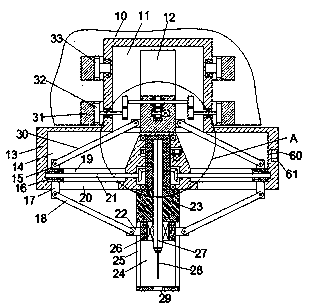

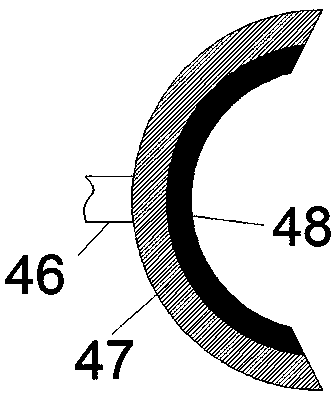

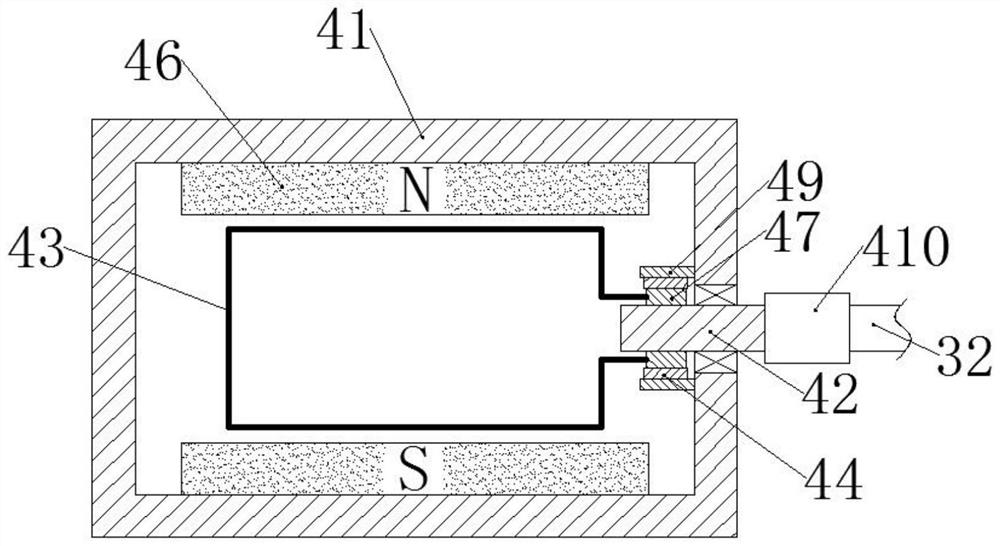

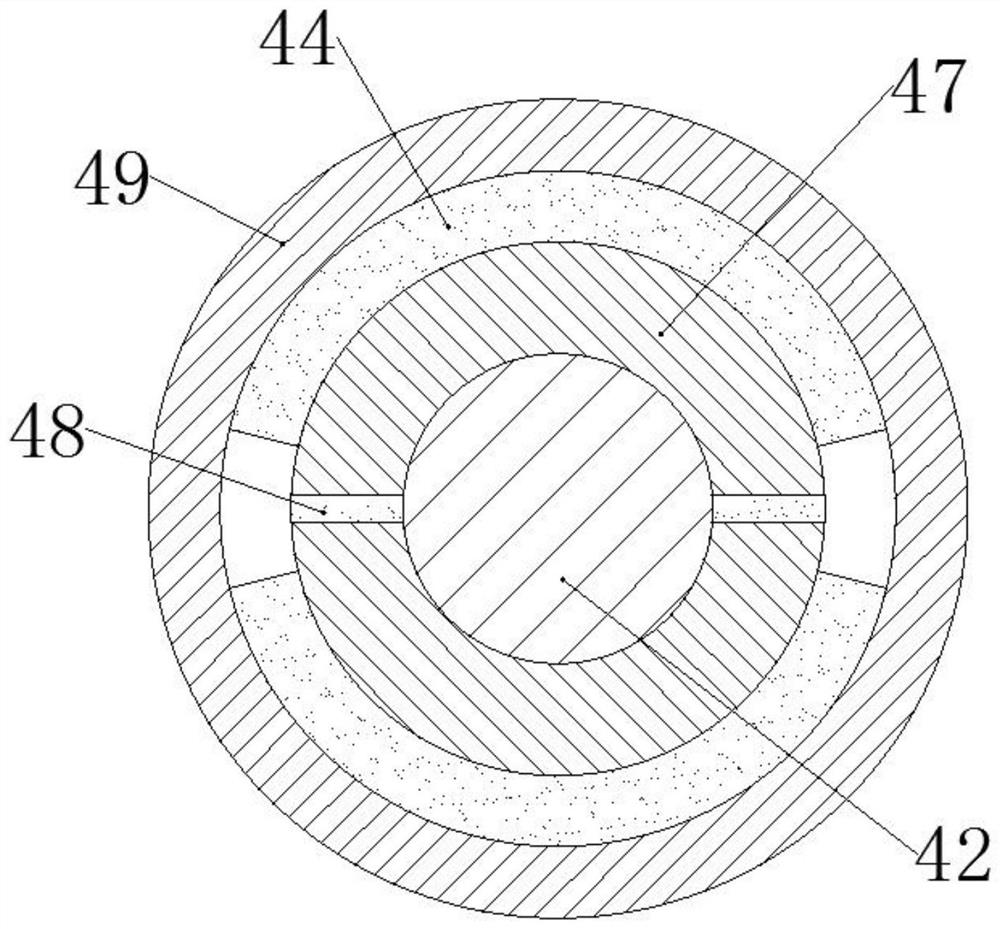

Perforating device for mounting surfaces of bearing blanks

ActiveCN111299654ARealize the drilling operationIncrease productivityStacking articlesMetal working apparatusClassical mechanicsEngineering

The invention relates to a perforating device for mounting surfaces of bearing blanks. The perforating device comprises a blank stacking mechanism used for stacking the blanks in order. A core positioning mechanism is arranged at an outlet of the blank stacking mechanism and used for core positioning of the blanks stacked in order. A clamping mechanism is arranged beside the outlet of the blank stacking mechanism and used for clamping the mounting surfaces of the two ends of the blanks. Drill bits are arranged on the lateral sides of the clamping mechanism and vertically move along the mounting surfaces of the two ends of the blanks to conduct drilling. A discharging mechanism is arranged beside the blank stacking mechanism and used for discharging perforated bearings. By the adoption of the perforating device, the blanks can be automatically fed to realize automatic drilling of bearing seats, and the production efficiency and quality of the bearing seats are improved.

Owner:岳西县顺达机械有限公司

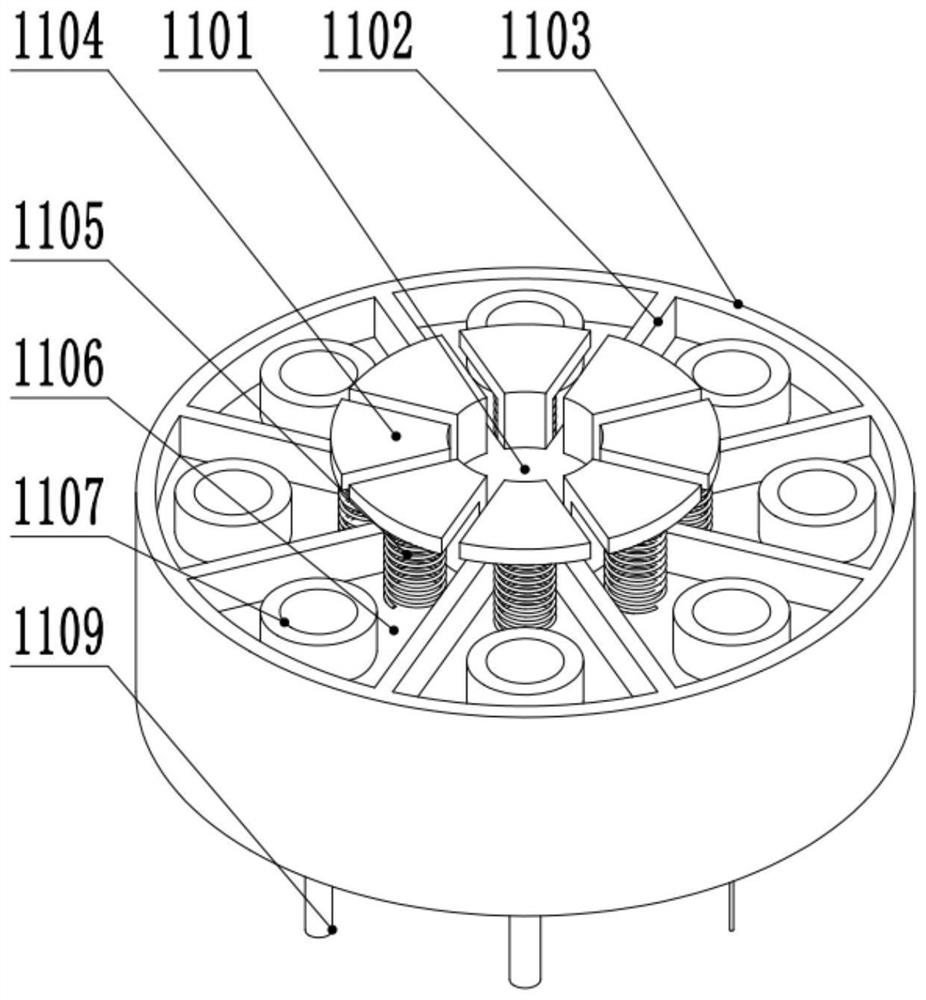

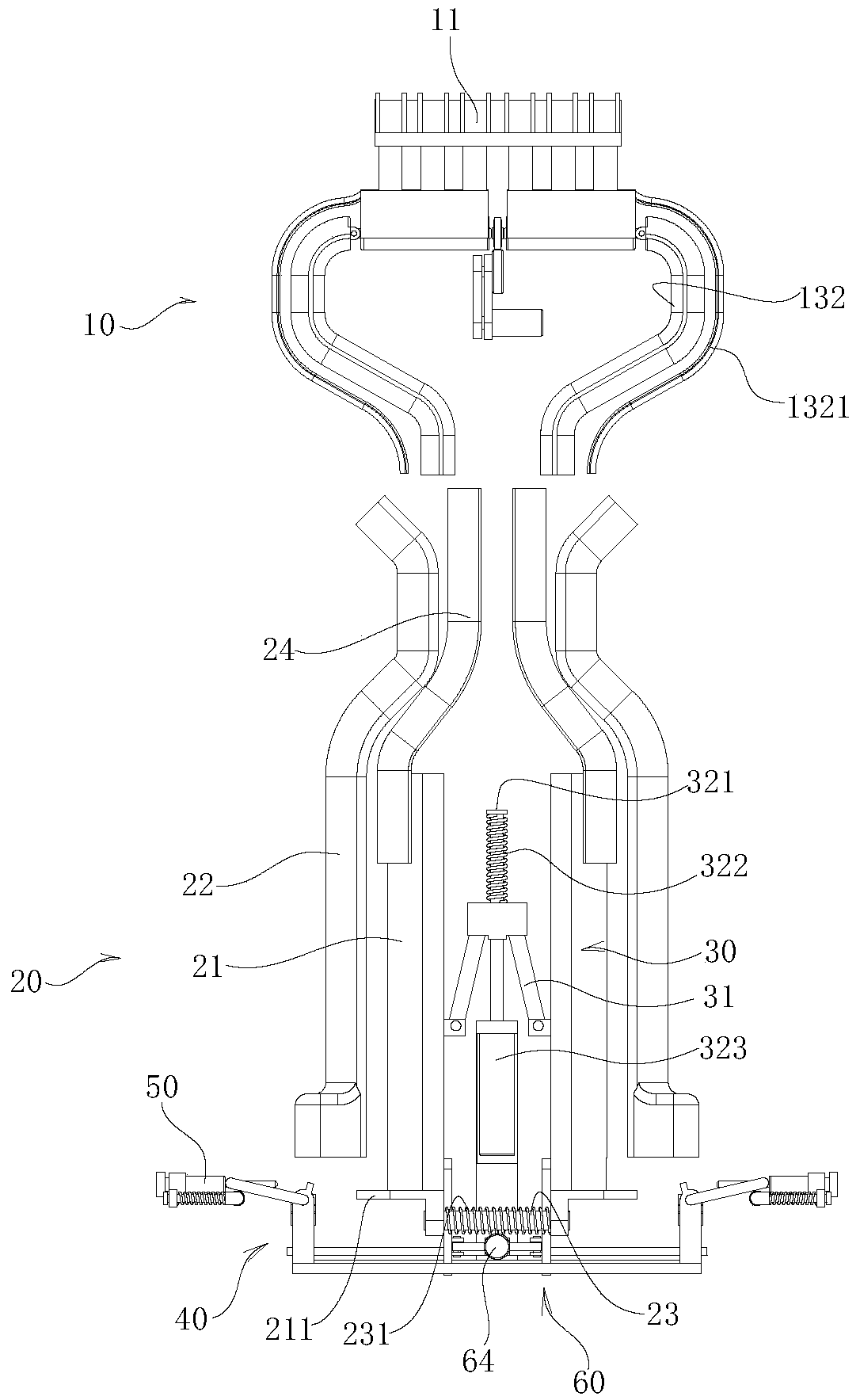

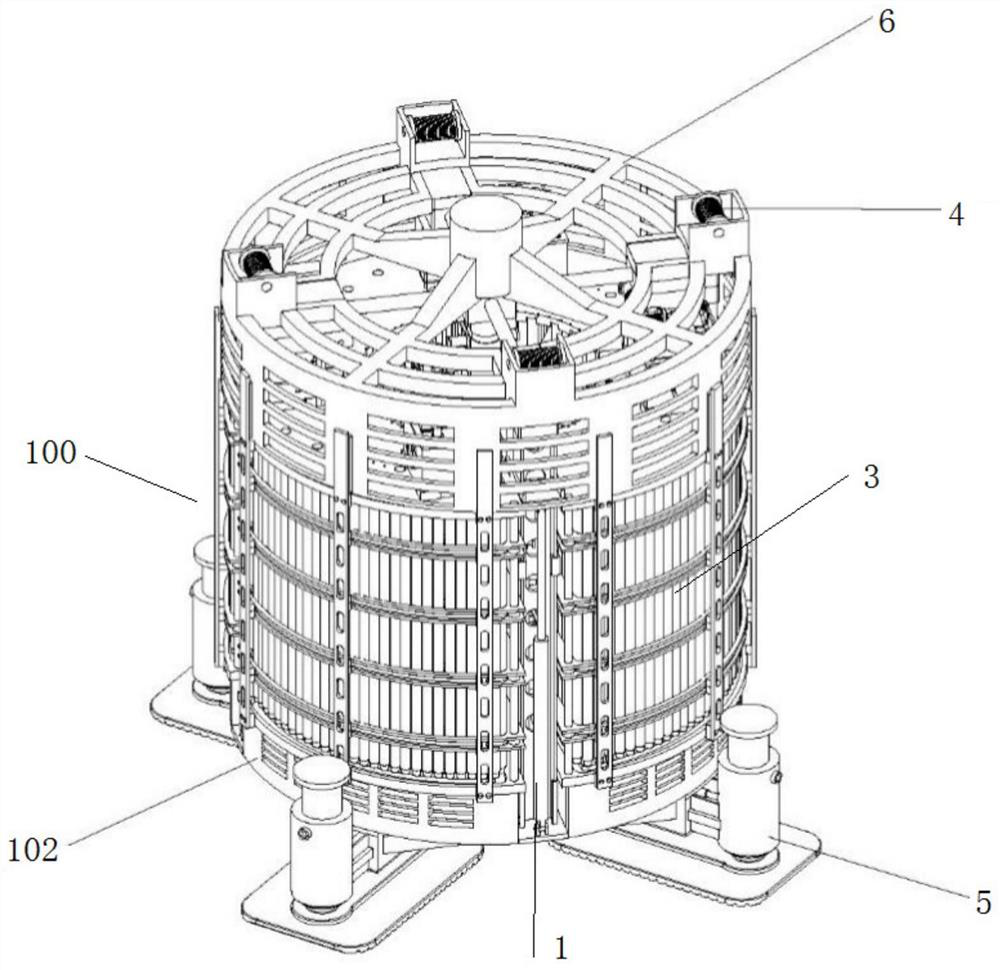

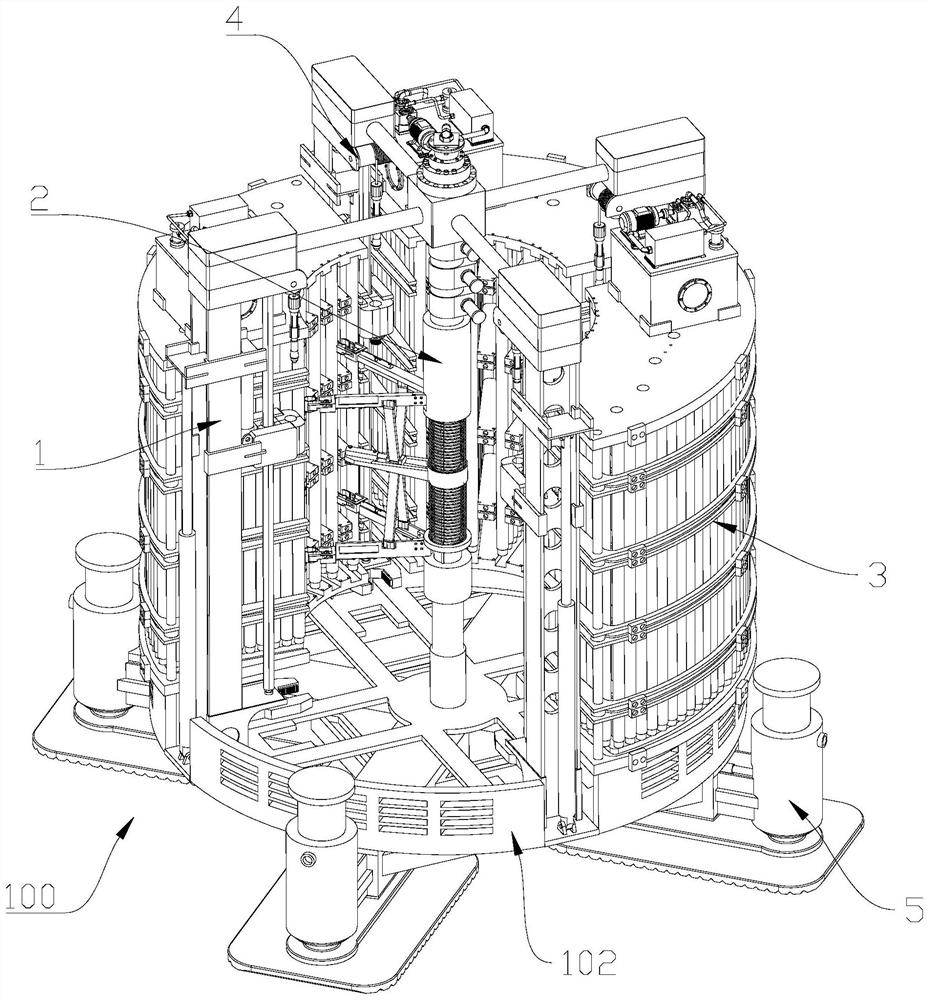

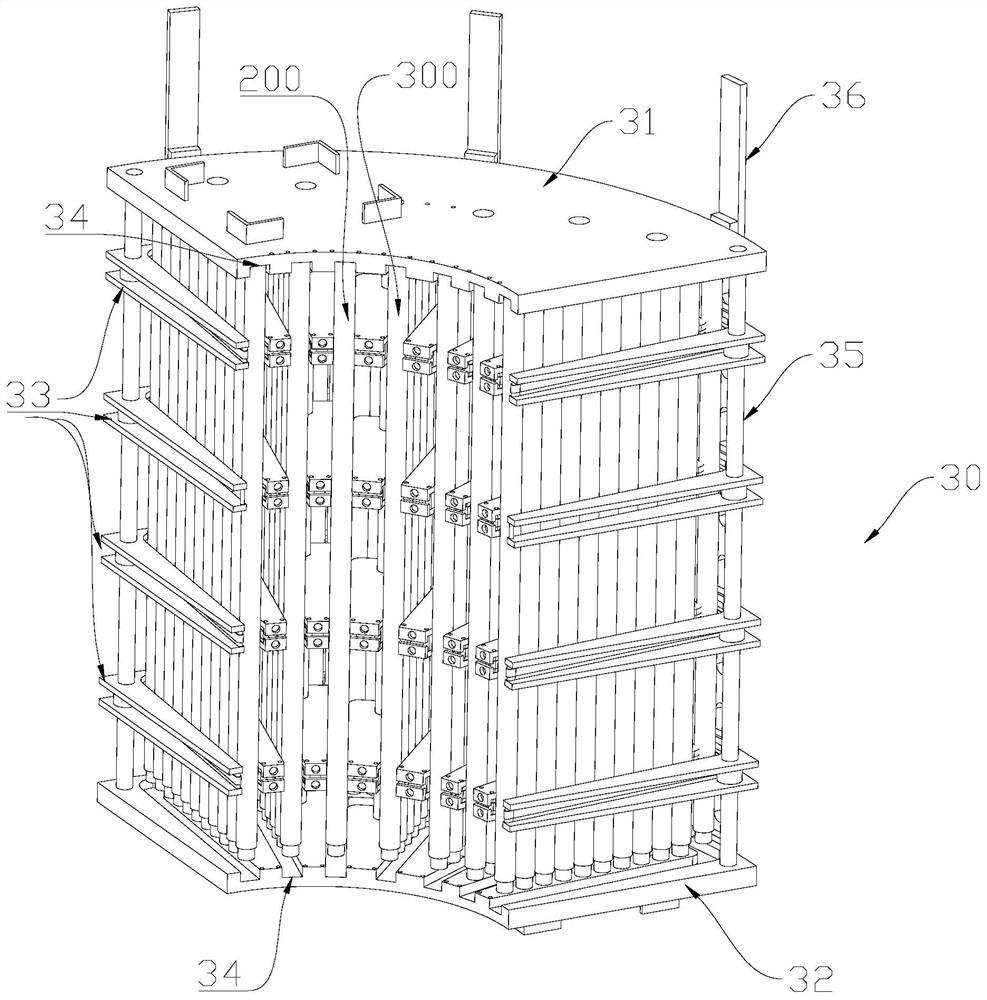

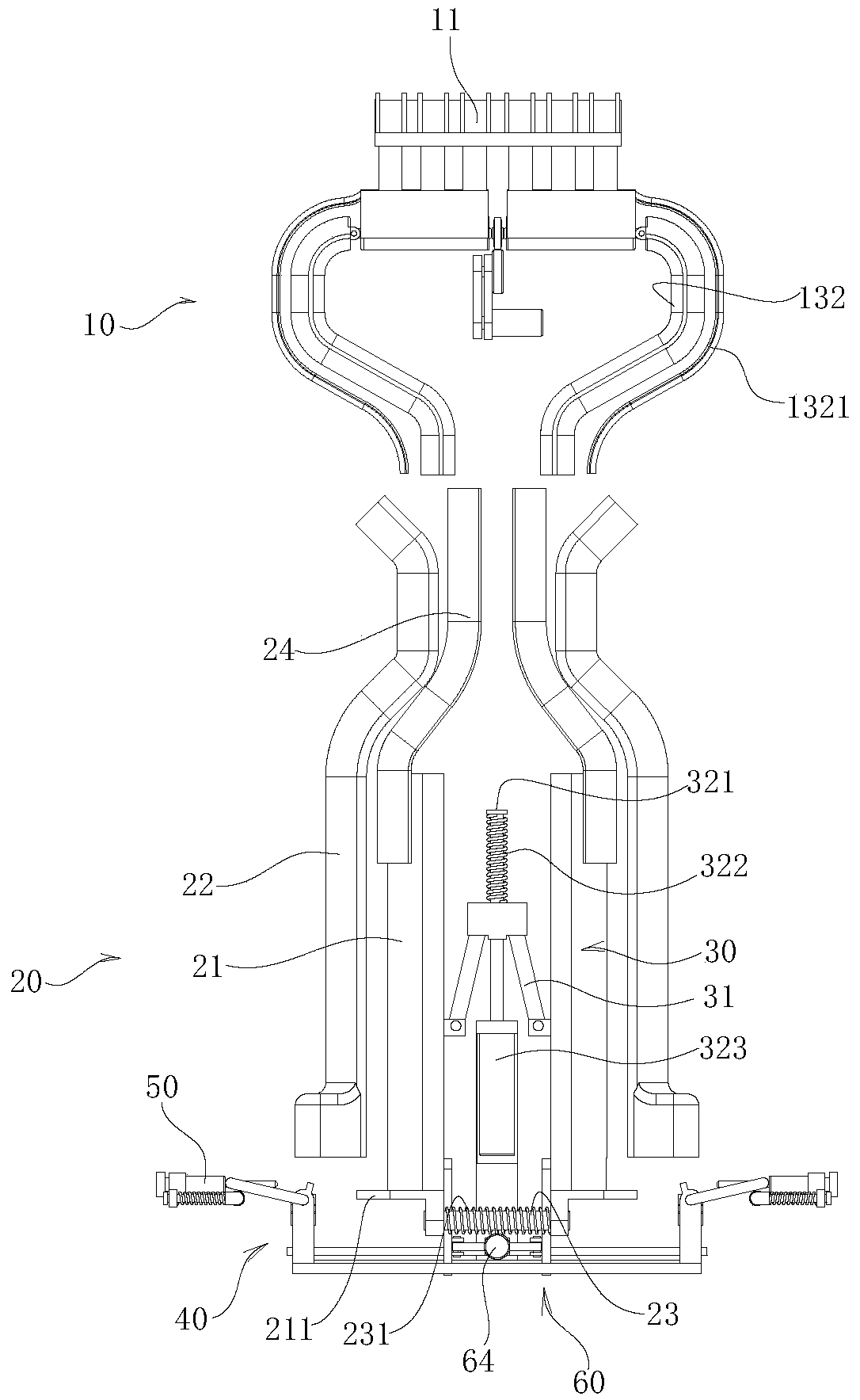

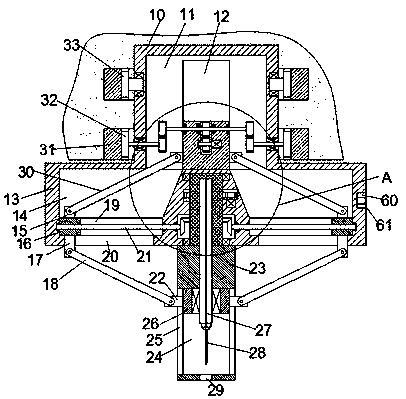

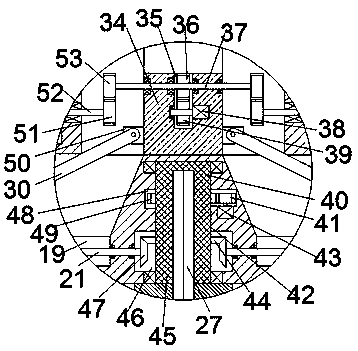

Central control type seabed multi-head continuous sampling drilling machine

ActiveCN114000829AOptimize layoutIncrease the number ofDrilling rodsConstructionsMechanical engineeringDrilling machines

The invention provides a central control type seabed multi-head continuous sampling drilling machine which solves the problem that the sampling efficiency is low when a drilling machine works. The drilling machine comprises a drilling machine body, the drilling machine body is provided with a drilling tool transporting mechanism, two or more power drilling mechanisms used for driving drilling rods to drill downwards and drilling tool storage mechanisms used for storing the drilling rods and core barrels, the drilling tool storage mechanisms are arranged around the central axis of the drilling machine body, and one power drilling mechanism is arranged between every two adjacent drilling tool storage mechanisms; and the drilling tool transporting mechanism is located in the center of the drilling machine body and can rotate by 360 degrees with the central axis of the drilling machine body as a rotating shaft, and the drilling tool transporting mechanism can grab all the drilling rods and the core barrels at different positions in the drilling tool storage mechanism in the rotating process and transports the drilling rods and the core barrels between the corresponding power drilling mechanism and the corresponding storage mechanism. The internal space of the drilling machine is fully utilized, the number of the power drilling mechanisms is two or more, more drilling tools can be carried for sea operation, and the single-time sampling operation efficiency is improved.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

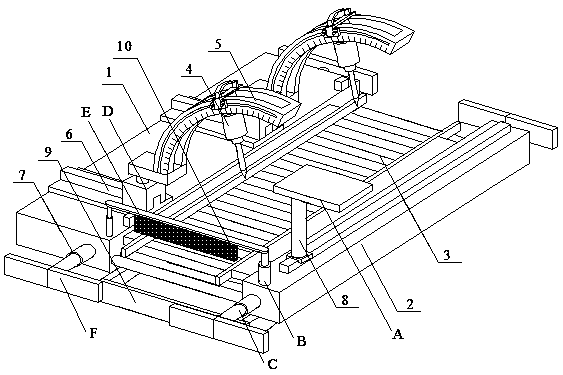

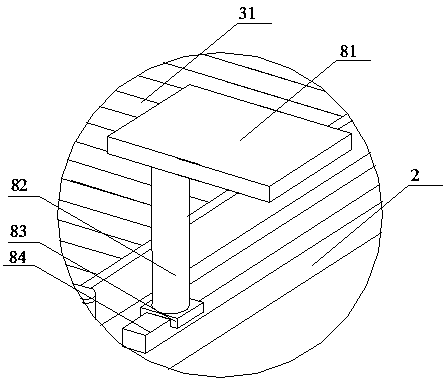

A high-efficiency drilling equipment for carbon fiber composite products

ActiveCN106426387BReduce labor intensityRealize the drilling operationMetal working apparatusFiberHigh effectiveness

The invention relates to drilling equipment, in particular to high-efficiency drilling equipment for carbon fiber compound products. The technical problem to be solved is to provide the high-efficiency drilling equipment for the carbon fiber compound products with capability of reducing the labor intensity of workers, time and labor saving and simple operation. In order to solve the technical problem, the invention provides the high-efficiency drilling equipment for the carbon fiber compound products. The high-efficiency drilling equipment comprises a left frame, a collecting box, support rods, a first electric push rod, a baseplate, a console, a first fixed plate, a push plate, a pressing block, an L-shaped bracket, a top block, a second electric push rod and the like; the left frame is welded on the left side of the top of the baseplate; and the support rods are symmetrically welded on the right side of the top of the baseplate left and right. The high-efficiency drilling equipment achieves the effects of capability of reducing the labor intensity of the workers, time and labor saving and simple operation.

Owner:溧阳材生复合材料技术有限公司

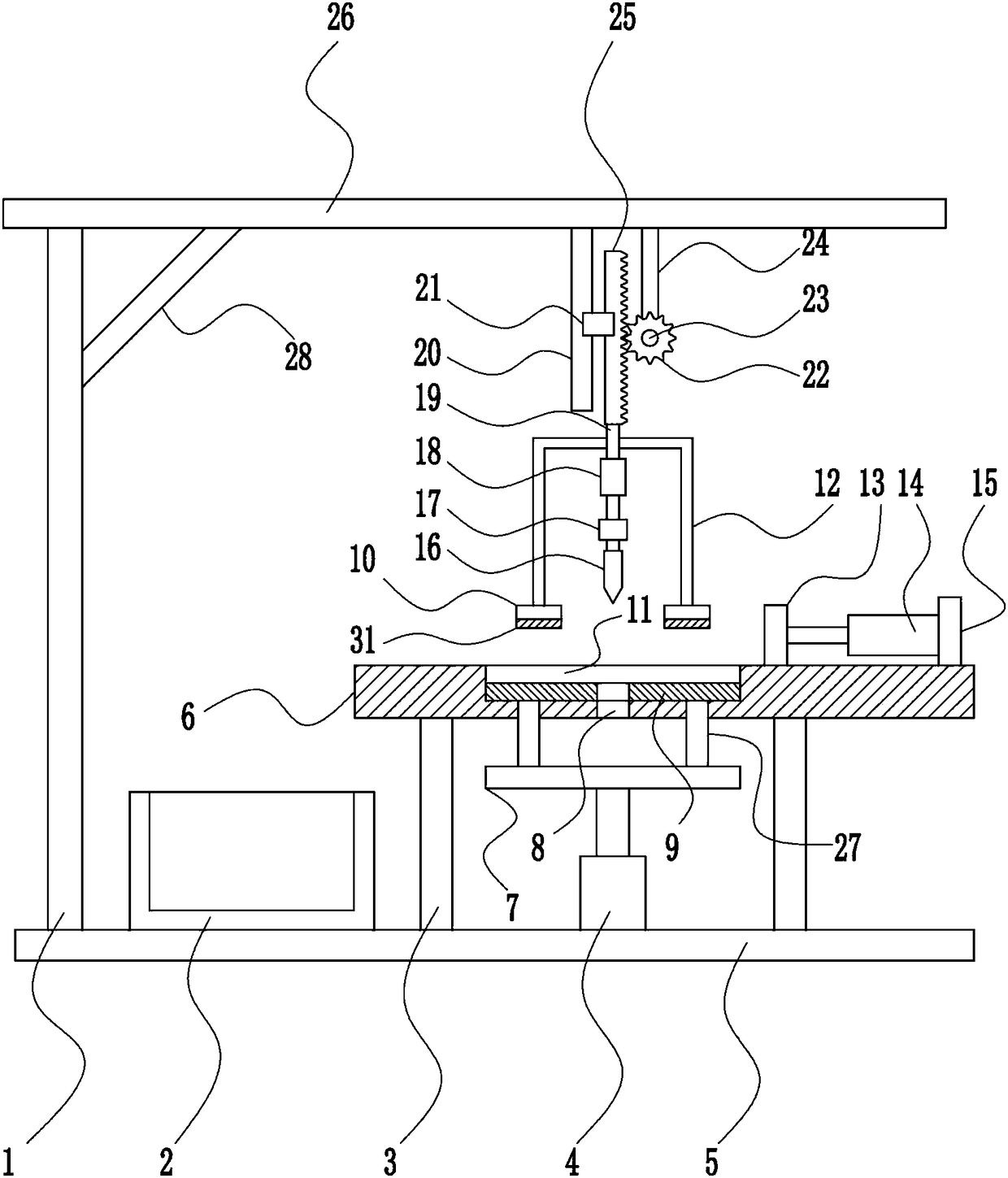

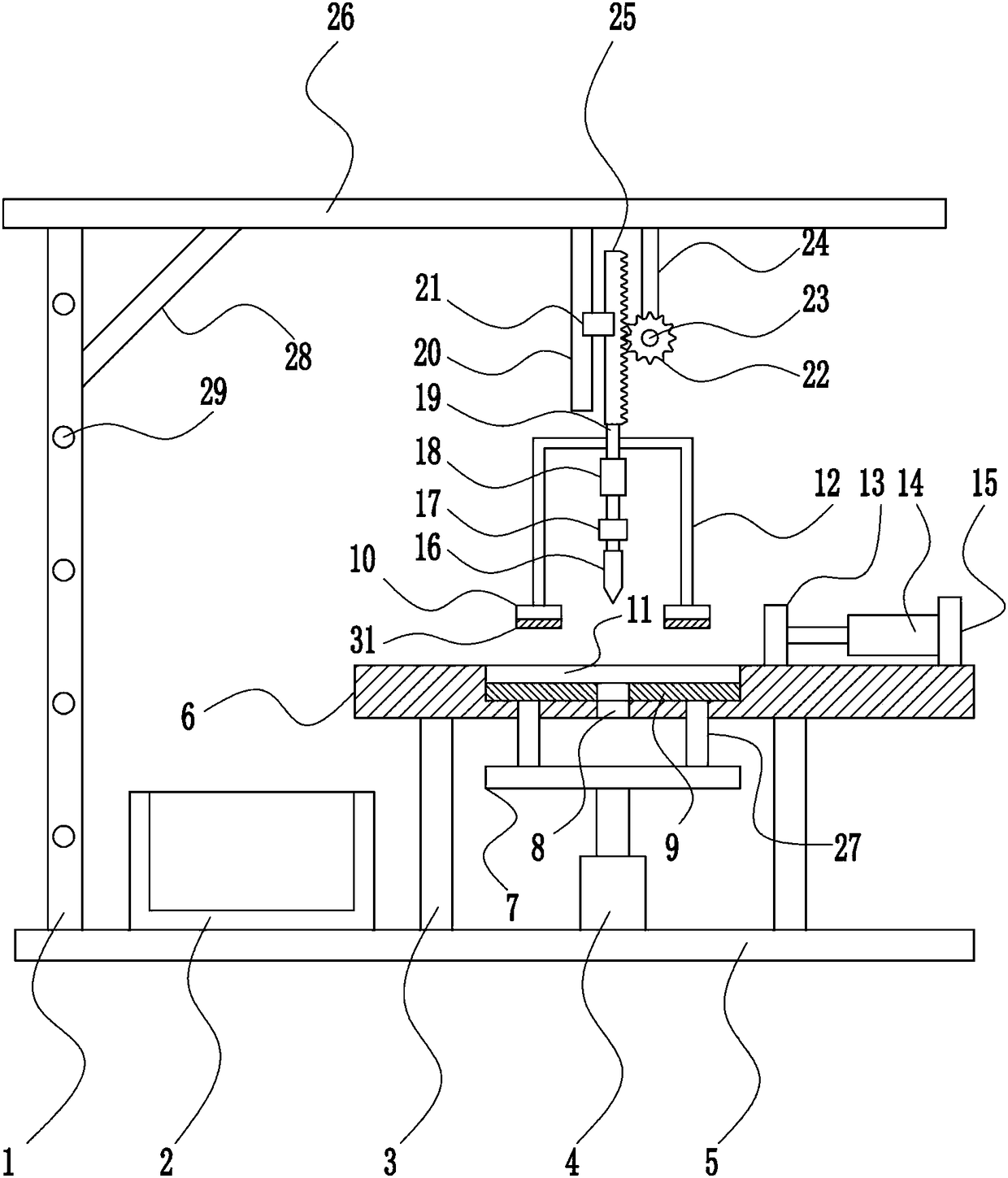

Fixed type ceramic tile floor drilling equipment for construction engineering

InactiveCN108582509ARealize the drilling operationEasy to useWorking accessoriesStone-like material working toolsMoving partsCeramic tiles

The invention relates to drilling equipment, in particular to fixed type ceramic tile floor drilling equipment for construction engineering. According to the technical purposes of the fixed type ceramic tile floor drilling equipment for the construction engineering, the drilling process can be defined, the consumed time is short, and operation is easy and convenient. The fixed type ceramic tile floor drilling equipment for the construction engineering comprises supporting legs, a connecting plate, adjusting mechanisms, drilling mechanisms, an operating table, a guiding frame and the like; theconnecting plate is arranged on the tops of the left and right side supporting legs; the adjusting mechanisms are installed on the supporting legs; the drilling mechanisms are installed on moving parts of the adjusting mechanisms; the position, close to the middle lower portion, between the left and right side supporting legs is connected with the operating table; and the middle portion of the operating table is provided with a through hole. According to the fixed type ceramic tile floor drilling equipment for the construction engineering, due to mutual cooperation between the adjusting mechanisms and the drilling mechanisms, drilling is performed on ceramic tile floors placed on the operating table; and meanwhile due to optimization of a spraying mechanism and a fixed mechanism, the effects that the drilling process can be defined, the consumed time is short, and operation is easy and convenient are achieved.

Owner:李子轩

Bearing pedestal machining system

ActiveCN111299653ARealize the drilling operationIncrease productivityStacking articlesPositioning apparatusStructural engineeringMachining system

The invention relates to a bearing pedestal machining system. The system comprises a bearing blank mechanism, an outlet of a blank feeding mechanism is connected with a feeding port of a blank stacking mechanism, the blank stacking mechanism is used for neatly stacking blanks, a core setting mechanism is arranged at the outlet of the blank stacking mechanism, and the core setting mechanism is usedfor core-setting the neatly stacked blanks; a clamping mechanism is arranged beside the outlet of the blank stacking mechanism and used for clamping installation faces at the two ends of a blank; a drill bit is arranged beside the clamping mechanism, and the drill bit moves in the vertical direction of the installation faces at the two ends of the blank and conducts drilling operation. The systemcan automatically realize the introduction of the blanks, thereby realizing automatic drilling operation on the bearing pedestal, and improving the production efficiency and quality of the bearing pedestal.

Owner:岳西县顺达机械有限公司

Porous ceramic wet curtain fixing framework

InactiveCN109016177ARealize the drilling operationSimple structureWorking accessoriesStone-like material working toolsBogieEngineering

The invention discloses a porous ceramic wet curtain fixing framework which comprises a base body, supporting rods and a mounting frame, wherein the supporting rods are arranged on the top end surfaceof the base body in a left-right symmetric manner; the mounting frame is arranged on the supporting rods; a sliding cavity of which the opening end faces down is arranged in the bottom end surface ofthe mounting frame; a sliding frame is smoothly mounted in the sliding cavity; a first rotating cavity is arranged in the bottom end surface of a rotating frame; the rotating frame is rotatably mounted in the first rotating cavity through a bearing I; a second rotating cavity which extends left and right is arranged in the rotating frame; a first motor is fixedly arranged on the inner top wall ofthe second rotating cavity; a toothed wheel which is positioned in the second rotating cavity is dynamically connected with the bottom of the first motor; left-right symmetric rotating sleeves are rotatably mounted in the upper and lower end walls of the second rotating cavity through bearings II; and second toothed wheels which are connected with the first toothed wheel in a matching manner arefixedly arranged on the rotating sleeves.

Owner:广州冠松电力科技有限公司

Novel anti-breaking plastic steel plate pile

InactiveCN109176707ARealize the drilling operationSimple structureMetal working apparatusMoving frameSteel plates

The invention discloses a novel anti-breaking plastic steel plate pile, which comprises a base, supporting columns arranged on the end face of the top of the base in a bilateral symmetry mode, and a placement rack arranged above the supporting columns. A sliding moving cavity with a downward through opening is formed in the end face of the bottom of the placement rack. The sliding moving cavity isinternally slidably provided with a sliding moving frame. A first rotary groove is arranged in the end face of the bottom of a rotary disc. The first rotary groove is rotatably provided with a rotarydisc through bearings. A second rotary groove extending left and right is arranged in the rotary disc. A first motor is fixedly arranged on the inner top wall of the second rotary groove. The bottomof the first motor is connected with a first toothed wheel located in the second rotary groove in a power mode. Shell sleeves in bilateral symmetry are rotatably arranged in the upper end wall and thelower end wall of the second rotary groove through bearings. Second toothed wheels connected with the first toothed wheel in a fit mode are arranged on the shell sleeves.

Owner:广州普隆智能设备有限公司

High-end porous ceramic wet curtain fixing frame

InactiveCN109080000ARealize the drilling operationSimple structureWorking accessoriesStone-like material working toolsBogiePower mode

The invention discloses a high-end porous ceramic wet curtain fixing frame. The high-end porous ceramic wet curtain fixing frame comprises a base, supporting rods and a mounting frame, wherein the supporting rods are arranged on the end surface of the top of the base in a left and right symmetrical mode, and the mounting frame is arranged above the supporting rods. A sliding cavity with a downwardopening is formed in the end surface of the bottom of the mounting frame. A sliding frame is smoothly installed in the sliding cavity, a first steering cavity is formed in the end surface of the bottom of a steering frame, and the steering frame is rotatably installed on the first steering cavity through bearings. A second steering cavity is formed in the steering frame in a left and right extending mode. A first motor is fixedly arranged on the inner top wall of the second steering cavity, and a first tooth wheel which is located in the second steering cavity is connected to the bottom of the first motor in a power mode. Left and right symmetrical steering sleeves are rotatably arranged in the up and down end walls of the second steering cavity through bearings, and a second tooth wheelconnected with the first tooth wheel in a matching mode are fixedly arranged on the steering sleeves.

Owner:广州冠松电力科技有限公司

Aluminum material production equipment

InactiveCN109014977ASimple structureHigh degree of automationLarge fixed membersBoring/drilling machinesEngineeringMechanical engineering

The invention discloses aluminum material production equipment. The aluminum material production equipment comprises a sliding base, an arranging frame and a guide arm, wherein the sliding base is arranged in a wall in a front-back moving manner through a drive device, the arranging frame and the sliding base are integrally arranged, and the guide arm is fixedly arranged at the bottom of the arranging frame. An up-down-extending first sliding groove is formed in the guide arm and internally provided with a first sliding block in a sliding manner. An up-down-extending spline shaft is arranged in the first sliding block in a rotation fit manner. A first communication groove communicating with the outside is symmetrically formed in the left side wall and the right side wall of the first sliding groove. The end faces of the left side and the right side of the first sliding block are symmetrically provided with first connection blocks stretching out of the first communication groove. The part, located above the guide arm, in the arranging frame is provided with a first rotation groove, a casing pipe is rotationally arranged in the first rotation groove through a bearing, a spline groovewith a downward notch is formed in the casing pipe, and a second communication groove is formed between the spline groove and the first sliding groove.

Owner:广州腾耐计算机科技有限公司

Bearing processing system

ActiveCN111299653BRealize the drilling operationIncrease productivityStacking articlesMetal working apparatusStructural engineeringMachining system

The invention relates to a bearing pedestal machining system. The system comprises a bearing blank mechanism, an outlet of a blank feeding mechanism is connected with a feeding port of a blank stacking mechanism, the blank stacking mechanism is used for neatly stacking blanks, a core setting mechanism is arranged at the outlet of the blank stacking mechanism, and the core setting mechanism is usedfor core-setting the neatly stacked blanks; a clamping mechanism is arranged beside the outlet of the blank stacking mechanism and used for clamping installation faces at the two ends of a blank; a drill bit is arranged beside the clamping mechanism, and the drill bit moves in the vertical direction of the installation faces at the two ends of the blank and conducts drilling operation. The systemcan automatically realize the introduction of the blanks, thereby realizing automatic drilling operation on the bearing pedestal, and improving the production efficiency and quality of the bearing pedestal.

Owner:岳西县顺达机械有限公司

Drilling device for center point of end face of screw

PendingCN113664242AImprove drilling efficiencyHigh precisionBoring/drilling machinesDrill holeDrill bit

The invention relates to a drilling device for a center point of an end face of a screw. The drilling device comprises a support and a drill. A first moving frame is arranged on the side wall of one end of the support. A second moving frame is arranged on the first moving frame. A third moving frame is arranged on the second moving frame. The drill is arranged on the third moving frame. A drill bit of the drill adjusted through the first moving frame, the second moving frame and the third moving frame is aligned to and positioned at the center position of the end face of the screw on the support. The drilling device has the advantages that the drill bit is aligned to the center position of the end of the screw by adjusting the position of the drill, time and labor are saved, and the drilling efficiency is high; and the left-right position, the up-down position and the front-back position of the drill bit are adjusted through the first moving frame, the second moving frame and the third moving frame correspondingly, and therefore the drill bit is aligned to the center position of the end of the screw, the left-right position and the up-down position do not need to be adjusted again after one-time alignment, the drilling operation of the end of the screw can be achieved only by controlling the drill to move front and back along an installing base, precision is improved, and the drilling quality is better.

Owner:浙江华鼎机械有限公司

High-end slurry casting porous mould

InactiveCN108972843ARealize the drilling operationSimple structureCeramic shaping apparatusWorking accessoriesSlurryEngineering

The invention discloses a high-end slurry casting porous mould which comprises a base, supporting columns and a mounting frame. The supporting columns are arranged on the top end face of the base in abilaterally symmetric manner, the mounting frame is arranged on the supporting columns, a sliding cavity with a downward opening is formed in the bottom end face of the mounting frame, a rotating frame is slidably mounted in the sliding cavity, a first rotating cavity is formed in the bottom end face of the rotating frame, the rotating frame is rotatably mounted in the first rotating cavity through a rotating bearing, a second rotating cavity extending left and right is formed in the rotating frame, a first motor is fixedly arranged on the inner top wall of the second rotating cavity, the bottom of the first motor is in power connection with a first rotating gear positioned in the second rotating cavity, bilaterally symmetric rotating sleeves are rotatably mounted in the upper end wall and the lower end wall of the second rotating cavity through rotating bearings, and second rotating gears engaged with the first rotating gear are fixedly arranged on the rotating sleeves.

Owner:广州市灵汐科技有限公司

Advanced grouting forming porous mold

InactiveCN108994340ARealize the drilling operationSimple structureFeeding apparatusPositioning apparatusGear wheelEngineering

Owner:广州市灵汐科技有限公司

Drilling depth positioning device for machining

ActiveCN114406316AAvoid breakingPrecise positioningMetal working apparatusBoring/drilling machinesEngineeringMachining

The invention provides a drilling depth positioning device for machining, and relates to the technical field of drilling depth positioning devices.The drilling depth positioning device comprises a drilling positioning assembly, a positioning shell is inserted into a supporting shell, when the drilling depth positioning device is used, the drilling positioning assembly can limit and adjust the maximum drilling depth of a drill bit assembly, and the maximum drilling depth of the drill bit assembly can be adjusted; according to the drilling device, positioning is more accurate during drilling, the drilling device can adapt to the operation of drilling a workpiece at different depths, and a drill bit of a drill bit assembly of the drilling device is hidden in a supporting shell in a reset state, so that the phenomenon that the drill bit is broken due to external bumping and collision when not used can be avoided; the problems that an existing drilling device is not provided with a drilling depth positioning device, multiple times of repeated measurement and drilling are needed for drilling a hole with the needed depth, the steps are tedious and quite troublesome, and a drill bit is exposed out of the device and is prone to being broken due to external collision and collision are solved.

Owner:南通林赛尔智能装备有限公司

Injection molding device

InactiveCN109108327ARealize the drilling operationSimple structureFeeding apparatusPositioning apparatusGear wheelEngineering

The invention discloses an injection molding device. The device comprises a base, supporting columns and a mounting frame arranged above the supporting columns, the supporting columns are arranged onthe end face of the top of the base in a bilateral symmetry manner, a sliding cavity with a downward opening is formed in the bottom end face of the mounting frame, a rotating frame is arranged in thesliding cavity in a sliding manner, a first rotating cavity is formed in the bottom end face of the rotating frame, the first rotating cavity is rotatably provided with a rotating frame through a rotating bearing, a second rotating cavity extending left and right is formed in the rotating frame, a first motor is fixedly arranged on the inner top wall of the second rotating cavity, the bottom of the first motor is in power connection with a first rotating gear located in the second rotating cavity, rotating sleeves in bilateral symmetry are rotatably arranged in the upper and lower end walls of the second rotating cavity through rotating bearings, and second rotating gears engaged with the first rotating gear are fixedly arranged on the rotating sleeve.

Owner:广州市灵汐科技有限公司

Transparent daylighting panel device

InactiveCN109129683ASimple structureHigh degree of automationMetal working apparatusMechanical engineeringEngineering

The invention discloses a transparent daylighting panel device comprising a sliding platform, an arrangement frame and a column body. The sliding platform can be driven by a drive device to move backand forth and is arranged in a wall body, the arrangement frame is integrated with the sliding table, and the column body is fixedly arranged at the bottom of the installation frame. A first sliding push groove extending vertically is formed in the column body. A first sliding push block is movably installed in the first sliding push groove. A spline shaft extending vertically is rotationally installed in the first sliding push block in a matched manner. The left side wall and the right side wall of the first sliding push groove are symmetrically provided with first through grooves communicating with the outside. The left end face and the right end face of the first sliding push block are symmetrically provided with first connection blocks extending out of the first through grooves. A first rotation bin located above the column body is formed in the arrangement frame. A rotating pipe is rotationally installed in the first rotation bin through bearings. A spline groove with a downward open end is arranged in the rotating pipe. A second through groove is formed between the spline groove and the first sliding push groove.

Owner:广州程科电子科技有限公司

Porous ceramic disk drilling device

InactiveCN108972904ARealize the drilling operationSimple structureWorking accessoriesStone-like material working toolsControl theoryPorous ceramics

The invention discloses a porous ceramic disk drilling device which comprises a seat, supporting rods and a mounting frame, wherein the supporting rods are bilaterally symmetrically arranged on the top end surface of the seat, and the mounting frame is arranged on the upper portions of the supporting rods. A sliding cavity with a downward open end is formed in the bottom end surface of the mounting frame, a sliding frame is smoothly mounted in the sliding cavity, a first steering cavity is formed in the bottom end surface of a steering frame and rotatably provided with the steering frame through a bearing, a second steering cavity bilaterally extends and is formed in the steering frame, a first motor is fixedly arranged on the inner top wall of the second steering cavity, a first tooth wheel is in power connection with the bottom of the first motor and positioned in the second steering cavity, bilaterally symmetric steering sleeves are rotatably mounted in the upper end wall and the lower end wall of the second steering cavity through bearings, and second tooth wheels are connected with the first tooth wheel and fixedly arranged on the steering sleeves.

Owner:广州冠松电力科技有限公司

Circuit board manufacturing equipment

InactiveCN109015874ARealize the drilling operationSimple structureMetal working apparatusMechanical engineering

The invention discloses circuit board manufacturing equipment which comprises a frame base, brackets and an assembling frame, wherein the brackets are arranged on the top end surface of the baseplatein a left-right symmetric manner; the assembling frame is arranged on the brackets; a sliding joint cavity of which the through port faces down is arranged in the bottom end surface of the assemblingframe; a sliding joint frame is mounted in the sliding joint cavity in a sliding joint manner; a first rotating joint cavity is arranged in the bottom end surface of a rotating joint frame; the rotating joint frame is rotatably mounted in the first rotating joint cavity through a bearing I; a second rotating joint cavity which extends left and right is arranged in the rotating joint frame; a firstrotating motor is fixedly arranged on the inner top wall of the second rotating joint cavity; a toothed joint wheel which is positioned in the second rotating joint cavity is dynamically connected with the bottom of the first rotating motor; left-right symmetric rotating joint sleeves are rotatably mounted in the upper and lower end walls of the second rotating joint cavity through bearings II; and second toothed joint wheels which are connected with the first toothed joint wheel in a matching manner are fixedly arranged on the rotating joint sleeves.

Owner:广州品帝智能科技有限公司

Efficient plate drilling equipment for whole vehicle manufacturing of new energy automobile

InactiveCN113319330ARealize the drilling operationAdjust the strength of drillingDriving apparatusBoring/drilling componentsNew energyStructural engineering

The invention discloses efficient plate drilling equipment for whole vehicle manufacturing of a new energy automobile. The efficient plate drilling equipment comprises a base plate, a placing frame, a drilling device, a power device and a dustproof device, wherein the placing frame is fixedly connected to the base plate, the drilling device is fixedly connected right above the placing frame, the power device is arranged on the left side of the drilling device, the power device is used for providing power for the drilling device, the dustproof device is connected to the placing frame through an exhaust fan, the drilling device comprises a shell, a shaft rod, a rotating shaft and drill rods, the power device comprises a power cylinder, an insulating shaft, a coil and a contact piece, and the dustproof device comprises a box body and a filter screen located in the box body. According to the efficient plate drilling equipment, through arrangement of rows of drilling rods, multiple hole machining can be conducted at the same time, the troublesome of callipers positioning is avoided, the machining efficiency is improved, in the machining process, the drilling force can be adjusted by adjusting the magnitude of current, dust generated in the machining process is treated through arrangement of the dustproof device, and the situation that the health of workers is harmed due to dust diffusion is avoided.

Owner:王亢

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com