Drilling depth positioning device for machining

A technology of drilling depth and positioning device, which is applied in boring/drilling, metal processing equipment, drilling/drilling equipment and other directions, can solve the problems of leakage of the drill bit, lack of drilling depth positioning device, trouble, etc. Achieve the effect of improving work efficiency, improving flexibility, and using stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

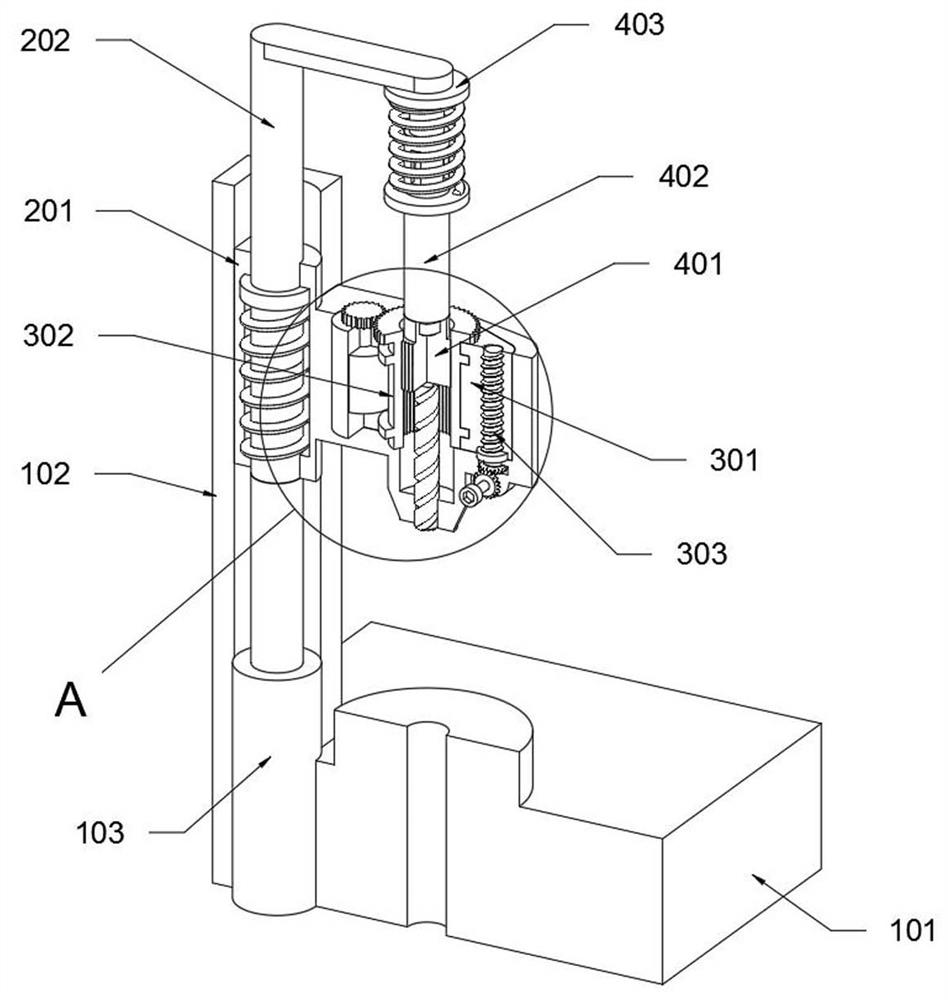

[0038] Example: please refer to Figures 1 to 8 :

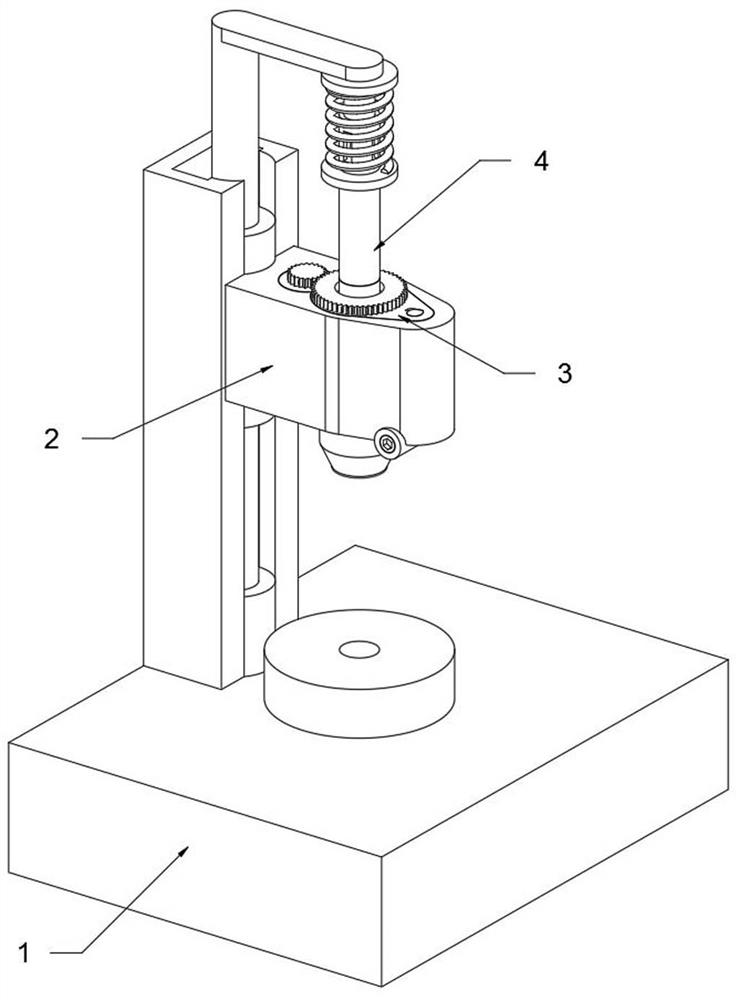

[0039] The invention provides a drilling depth positioning device for machining, which comprises a platform assembly 1;

[0040] The platform assembly 1 includes a drilling platform 101, a supporting vertical rod 102 and a driving rod 103. The supporting vertical rod 102 is fixedly installed on one side of the top of the drilling platform 101, and the driving rod 103 is fixedly installed inside the drilling platform 101;

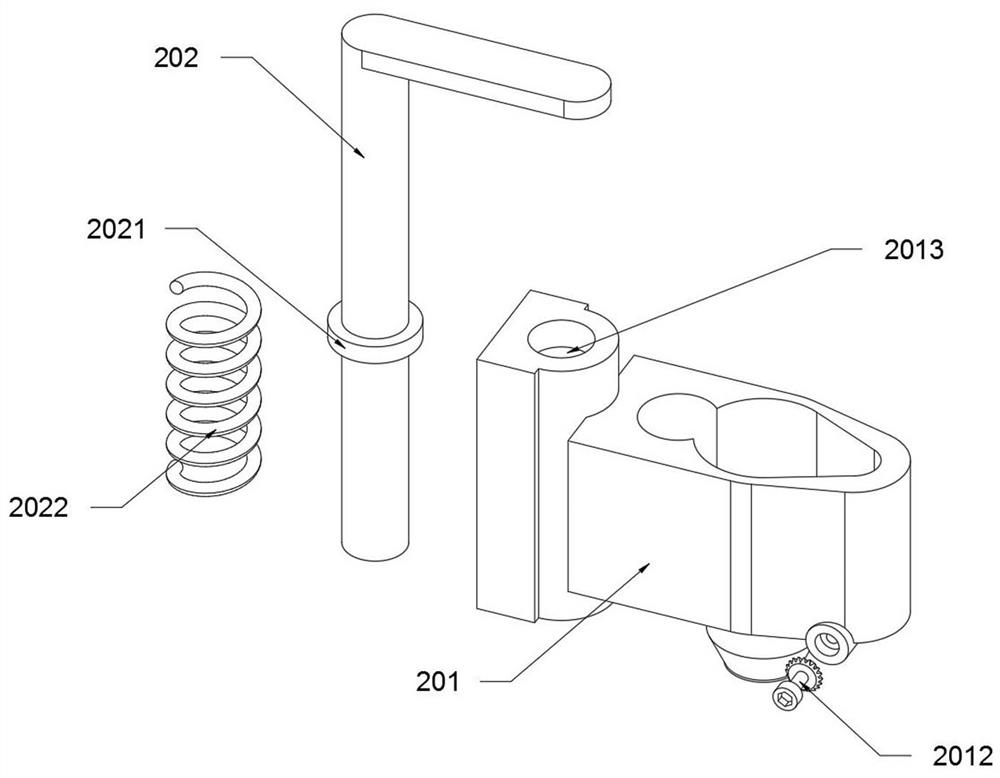

[0041] The support assembly 2 includes a support housing 201 and a follow-up pressure rod 202. The support housing 201 is inserted into the support vertical rod 102, the follow-up pressure rod 202 is inserted into the support housing 201, and the bottom end of the follow-up pressure rod 202 vertical rod is fixedly installed on the top of the drive rod 103;

[0042] The drilling positioning assembly 3 includes a positioning housing 301, a synchronous sleeve 302 and a positioning adjusting rod 303. The positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com