High-efficiency drilling equipment for carbon fiber compound products

A technology for composite products and drilling equipment, applied in metal processing and other directions, can solve the problems of cumbersome operation, time-consuming and labor-intensive, labor-intensive, etc., and achieve the effects of low price, improved accuracy, and prevention of item loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

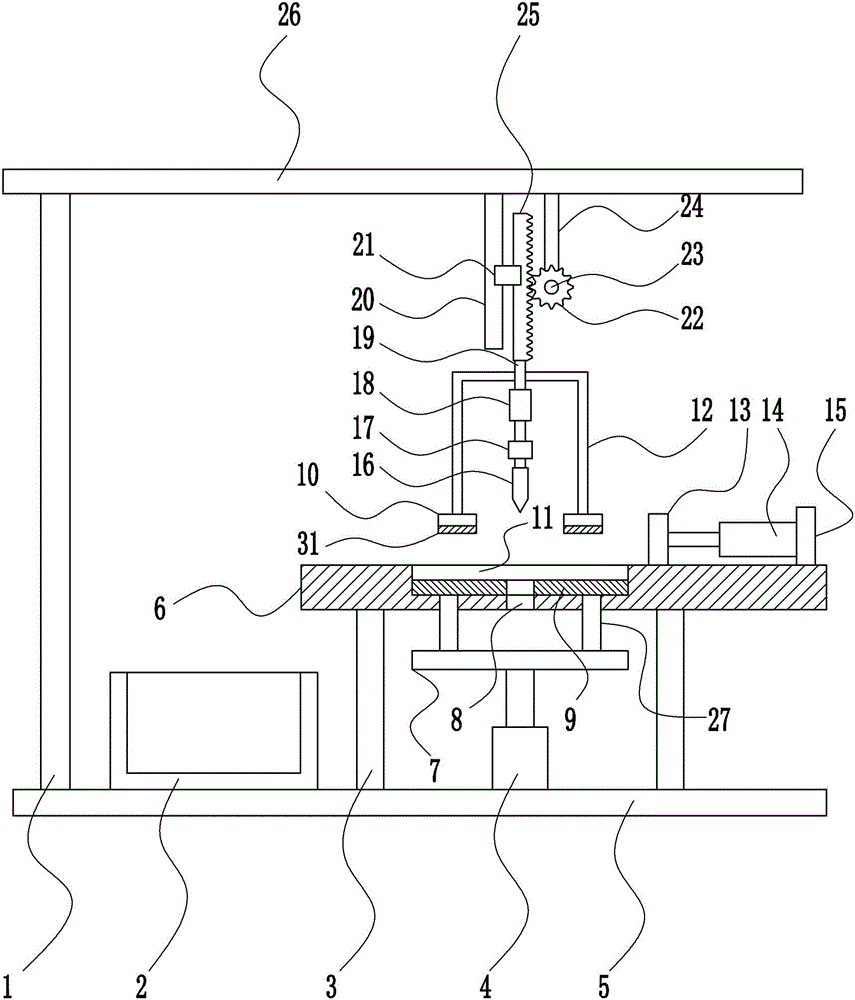

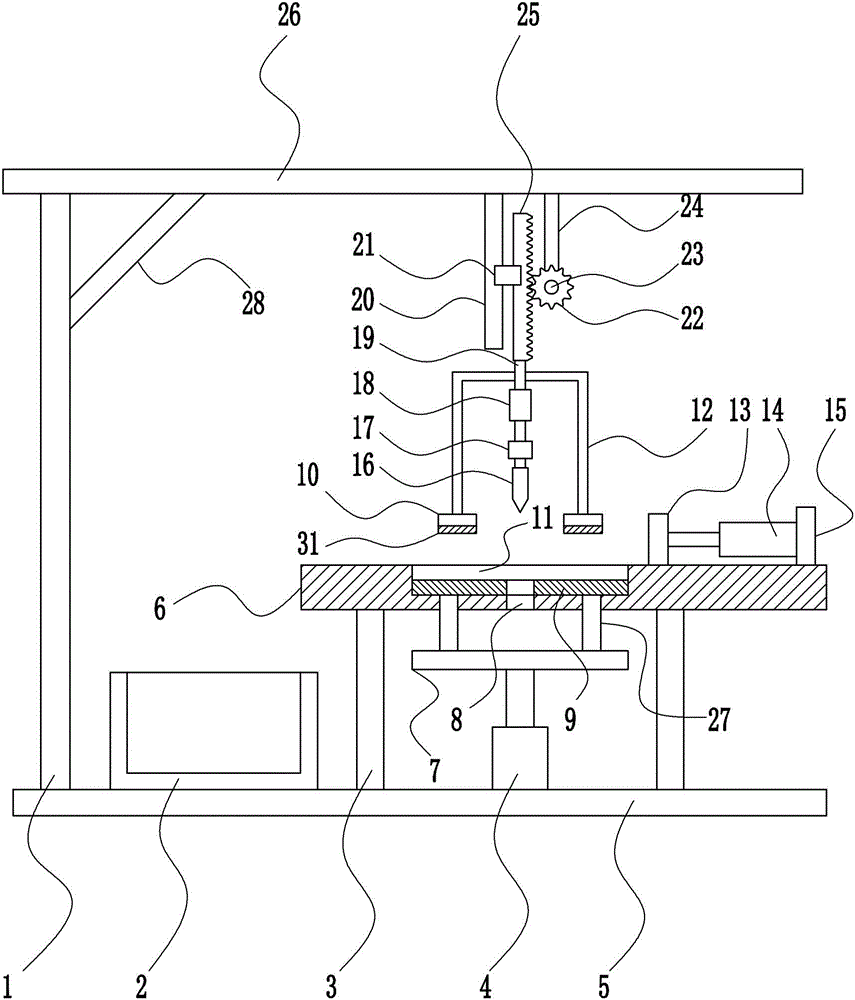

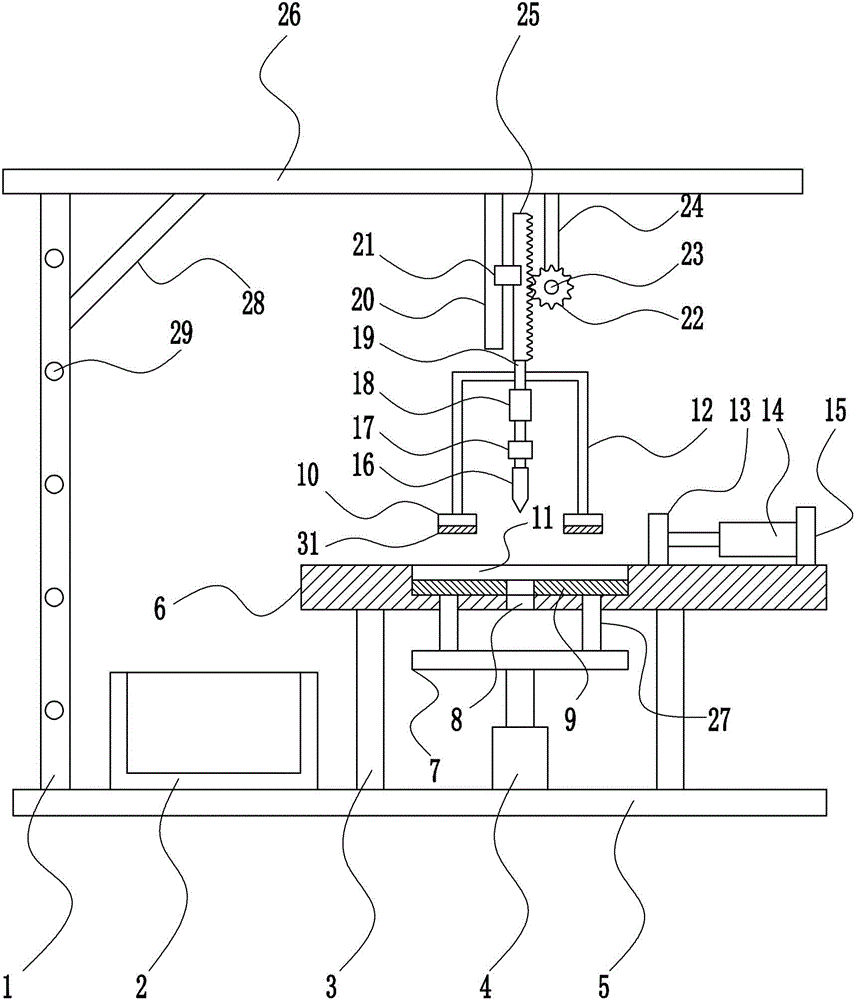

[0036] A high-efficiency drilling equipment for carbon fiber composite products, such as Figure 1-4 As shown, it includes a left frame 1, a collection box 2, a support rod 3, a first electric push rod 4, a bottom plate 5, an operating table 6, a first fixed plate 7, a push plate 9, a pressing block 10, an L-shaped bracket 12, Jack block 13, second electric push rod 14, baffle plate 15, drill bit 16, first motor 17, third electric push rod 18, pole 19, slide rail 20, slider 21, gear 22, second motor 23, The second fixed plate 24, the rack 25, the top plate 26 and the push rod 27, the left frame 1 is welded on the left side of the top of the base plate 5, the left and right sides of the top of the bottom plate 5 are welded symmetrically with the support rod 3, between the left frame 1 and the support rod 3 A collection box 2 is placed on the top of the bottom plate 5, and a first electric push rod 4 is connected on the top of the bottom plate 5 between the two support rods 3 th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com