Nitride semiconductor wafer, nitride semiconductor chip, method of manufacture thereof, and semiconductor device

A technology of nitride semiconductor and manufacturing method, applied in semiconductor/solid-state device manufacturing, semiconductor device, semiconductor laser, etc., can solve the problem of high luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

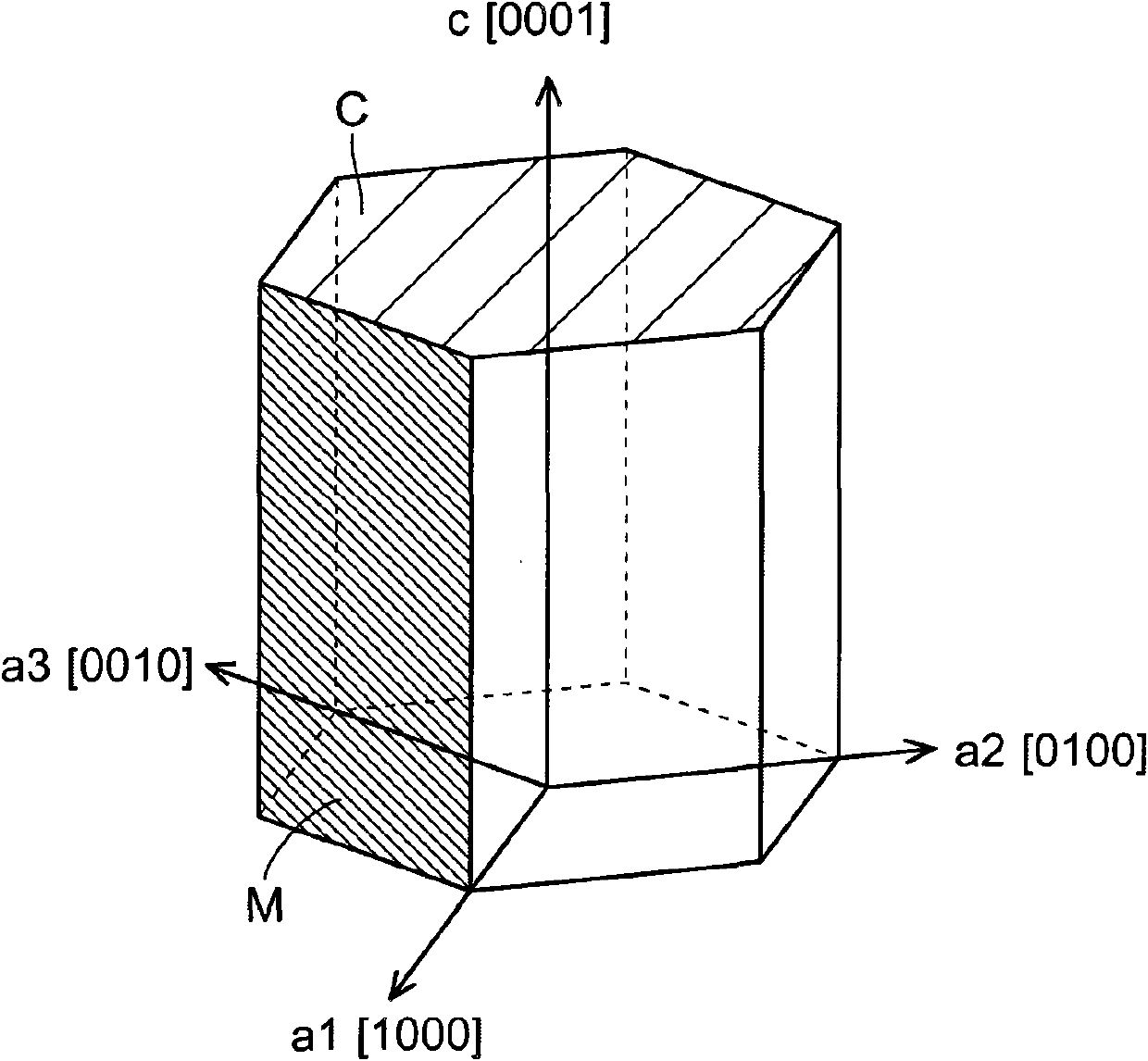

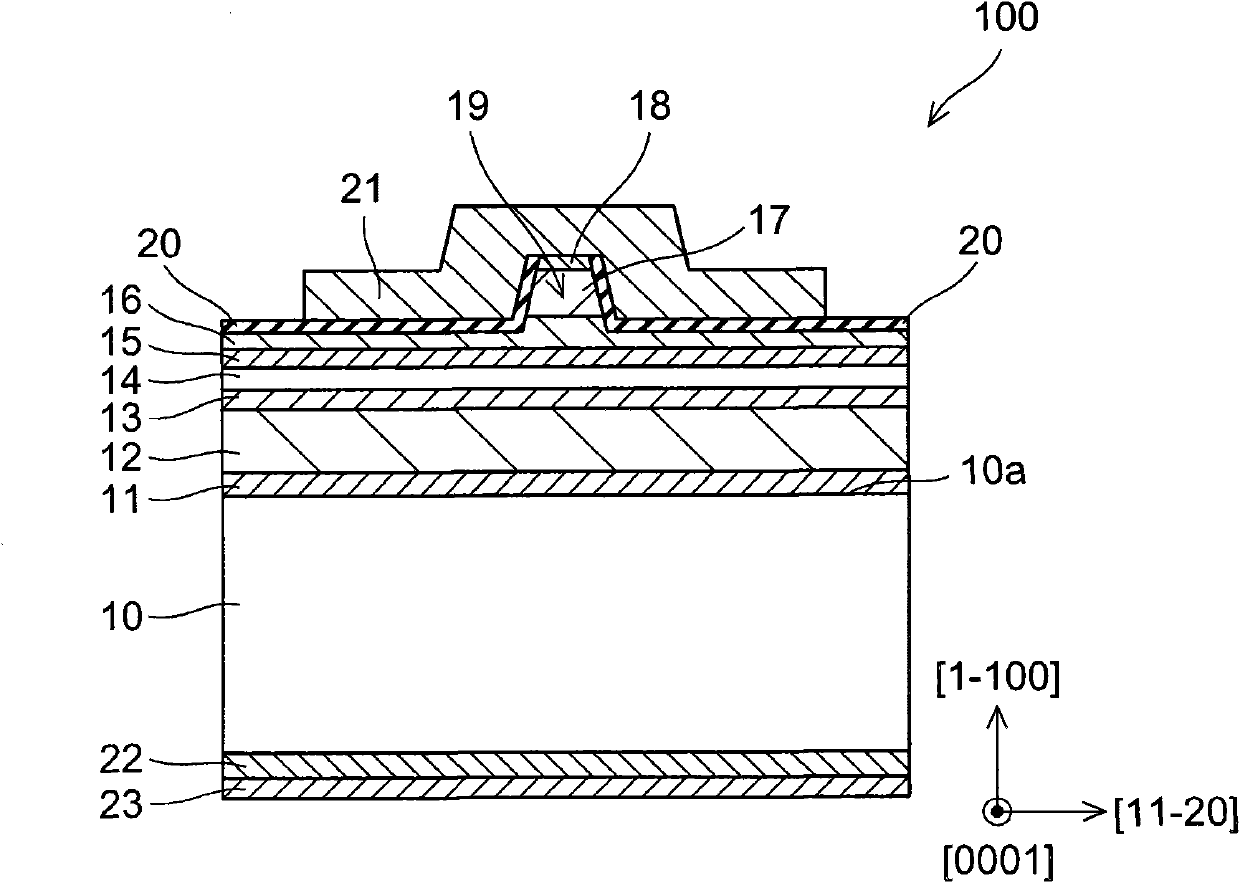

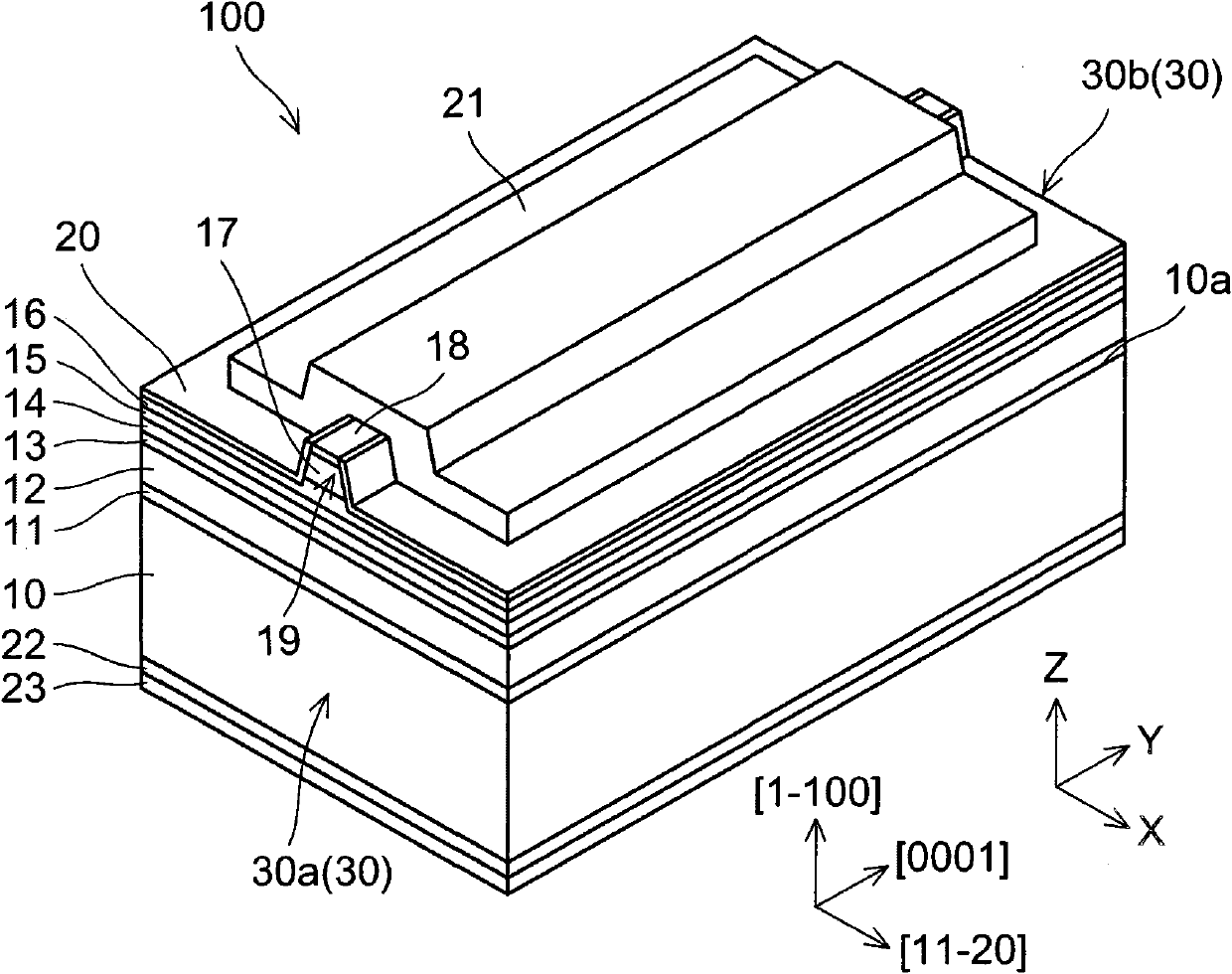

[0218] figure 1 It is a schematic diagram for explaining the crystal structure of a nitride semiconductor. figure 2 It is a cross-sectional view showing the structure of the nitride semiconductor laser device according to the first embodiment of the present invention. image 3 It is an overall perspective view of the nitride semiconductor laser device according to the first embodiment of the present invention. Figure 4 ~ Figure 6 It is a diagram for explaining the structure of the nitride semiconductor laser device according to the first embodiment of the present invention. First, refer to Figure 1 to Figure 6 The structure of the nitride semiconductor laser device 100 according to the first embodiment of the present invention will be described.

[0219] Such as figure 1 As shown, the nitride semiconductor constituting the nitride semiconductor laser device 100 of the first embodiment has a hexagonal crystal structure. In this crystal structure, the c-axis [0001] of th...

Embodiment 1

[0316] As the nitride semiconductor laser element of Example 1, a GaN substrate having an inclination angle of 1.7 degrees in the a-axis direction and +0.1 degrees in the c-axis direction with respect to the m-plane {1-100} was used, and the same as the above-mentioned first The nitride semiconductor laser device of the embodiment is the same as the nitride semiconductor laser device. The In composition ratio of the well layer was set to 0.25, and the Al composition ratio of the barrier layer was set to 2%. Other configurations of this first embodiment are the same as those of the above-mentioned first embodiment. In addition, a nitride semiconductor laser element produced in the same manner as the nitride semiconductor laser element of the first embodiment was used as a comparative example 1 using a GaN substrate (front m-plane substrate) having no off-angle. Other structures of the nitride semiconductor laser device of Comparative Example 1 are the same as those of Example ...

Embodiment 2

[0319] As the nitride semiconductor laser device of Example 2, a GaN substrate with an inclination angle of 4 degrees in the a-axis direction and +1 degree in the c-axis direction with respect to the m-plane {1-100} was used to form a barrier layer. by Al s In t Ga u A nitride semiconductor laser device composed of N (s+t+u=1). In this embodiment 2, the barrier layer is made of Al s In t Ga u N (s=0.02, t=0.01, u=0.97) configuration. That is, in Example 2, the barrier layer is made of AlInGaN. The structure of Example 2 other than the barrier layer is the same as that of the above-mentioned first embodiment (Example 1). In Example 2, the same effects as those in Example 1 above can be obtained.

[0320] And in the structure of the above-mentioned embodiment 2, even if the Al s In t Ga u When the Al composition ratio s of the barrier layer composed of N (s+t+u=1) is set in the range of 0

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com