Alcohol solvus hollow cup armature coil production line system and production method thereof

A technology of armature coils and coreless cups, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of manpower input, artificial tin immersion, single application of devices, etc., to achieve stable load current and load speed, and consistent external dimensions Good sex, improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

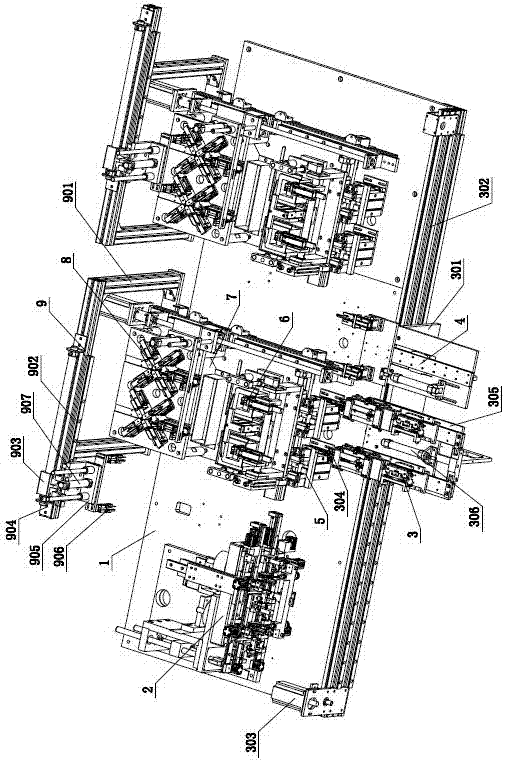

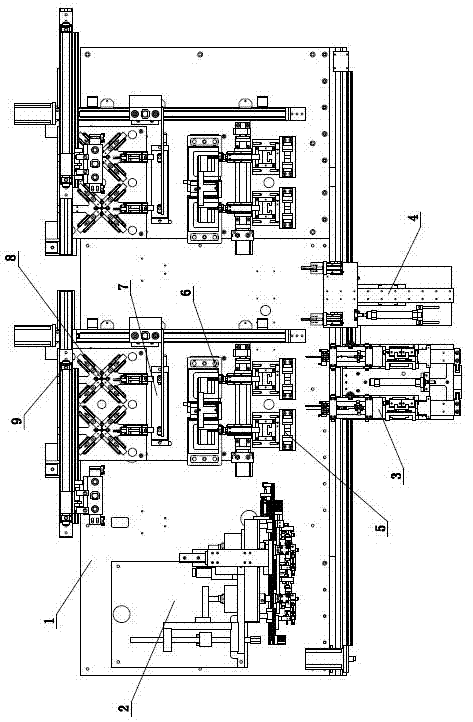

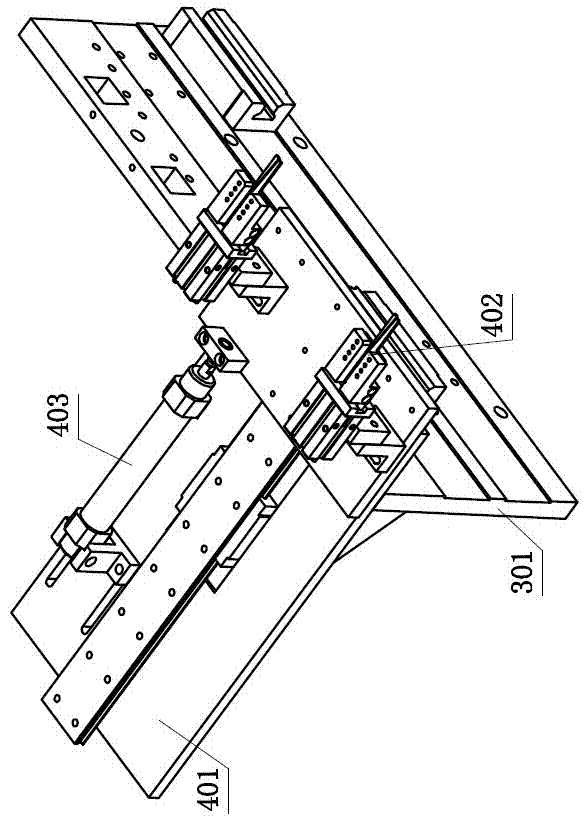

[0055] See attached Figures 1 to 5 , the alcohol-soluble line hollow cup armature coil production line system in the accompanying drawings includes a workbench 1, a winding machine 2 and an electrical control cabinet with a PLC controller, wherein: the winding machine 2 is fixed on the top of the workbench 1 At the starting station. At least one production line mechanism is provided on the station after the winding machine 2, and the production line mechanism includes a thermocompression forming device 5, a tin immersion device 6, an alcohol immersion device 7, and a rounding device that are sequentially arranged on the workbench 1. 8 and the manipulator above the rounding device 8 picks up the conveying device 9. Between the winding machine and the hot-press forming device 5 of the production line mechanism, there is a conveying twisting device 3 that rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com