Method for inhibiting generation of pores of plate grid of valve-controlled accumulator, and plate grid mould

A battery and suppression valve technology, applied in the field of suppressing the formation of valve-controlled battery grids and battery grids, can solve the problems of high technical requirements in grid production, difficult implementation by battery manufacturers, and high production costs, so as to reduce product loss. efficiency and waste of resources, increase the rate of qualified products, and save capital costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

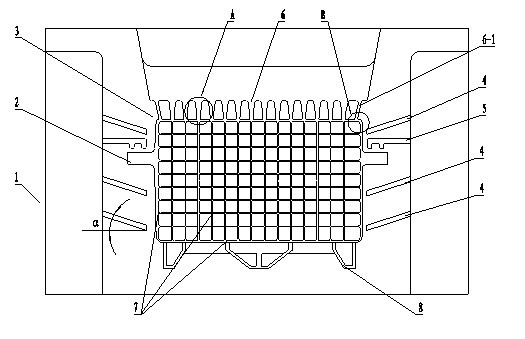

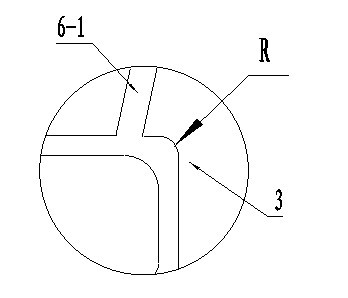

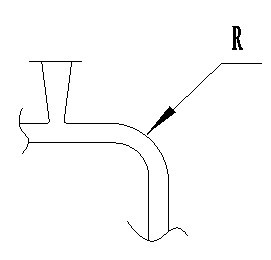

Image

Examples

Embodiment 1

[0029] Example 1: Melt the grid raw material lead-calcium-tin-aluminum alloy (1# lead alloy) at a melting temperature of 480°C; heat the grid mold to 180°C; take 30 g of cork powder and 10% of sodium silicate in parts by mass. g, 5 g of bentonite, 1000 g of water to prepare a release agent, wherein the density of sodium silicate is 1.250g / cm3, the cork powder is passed through a 200 mesh sieve, and the bentonite is passed through a 160 mesh sieve; the prepared release agent is evenly sprayed in the mold cavity; the liquid lead-calcium-tin-aluminum alloy is cast in the grid mold, and the mold is released after the alloy is solidified and cooled.

Embodiment 2

[0030] Example 2: Melt the grid raw material lead-calcium-tin-aluminum alloy (1# lead alloy) at a melting temperature of 500°C; heat the grid mold to 230°C; take 35 g of cork powder and sodium silicate 15 g, 5 g of bentonite, 1000 g of water to prepare a release agent, wherein the density of sodium silicate is 1.250 g / cm3, the cork powder is passed through a 200 mesh sieve, and the bentonite is passed through a 160 mesh sieve; the prepared release agent is evenly sprayed on the mold Inner cavity: Cast the liquid lead-calcium-tin-aluminum alloy in the grid mold, and release the mold after the alloy is solidified and cooled.

Embodiment 3

[0031] Example 3: Melt the grid raw material lead-calcium-tin-aluminum alloy (1# lead alloy) at a melting temperature of 510°C; heat the grid mold to 210°C; take 33 g of cork powder and sodium silicate in parts by mass 18 g, 5 g of bentonite, 1000 g of water to prepare a release agent, wherein the density of sodium silicate is 1.250 g / cm3, the cork powder is passed through a 200 mesh sieve, and the bentonite is passed through a 160 mesh sieve; the prepared release agent is evenly sprayed on the mold Inner cavity: Cast the liquid lead-calcium-tin-aluminum alloy in the grid mold, and release the mold after the alloy is solidified and cooled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com