On-line automatic ingot stripper for glue gloves

A technology of demoulding machine and demoulding mechanism, which is applied in the field of online automatic demoulding machine for rubber gloves, which can solve the problems of high production cost, high labor intensity of workers, and harsh working conditions, so as to reduce the probability of manual contact with gloves , simple and practical structure, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

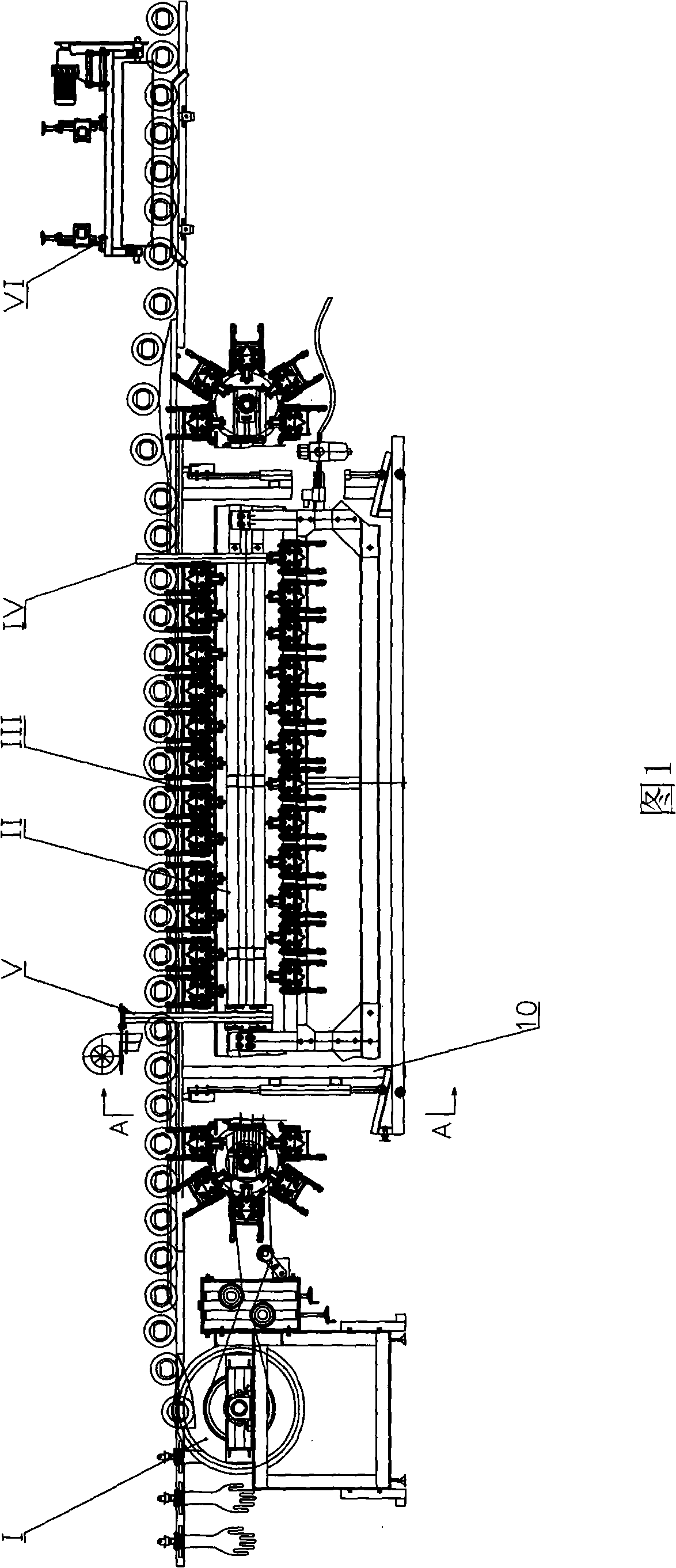

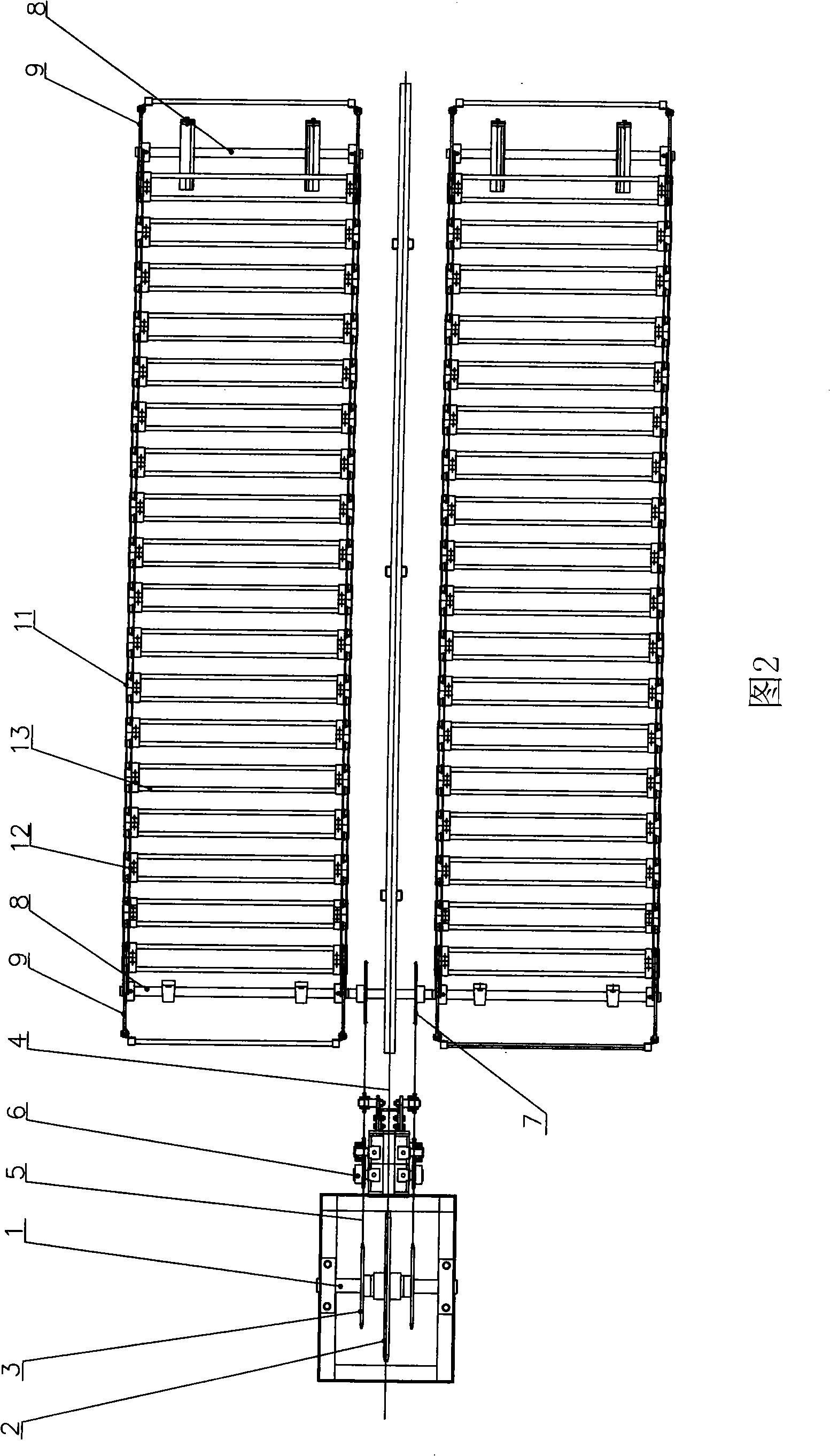

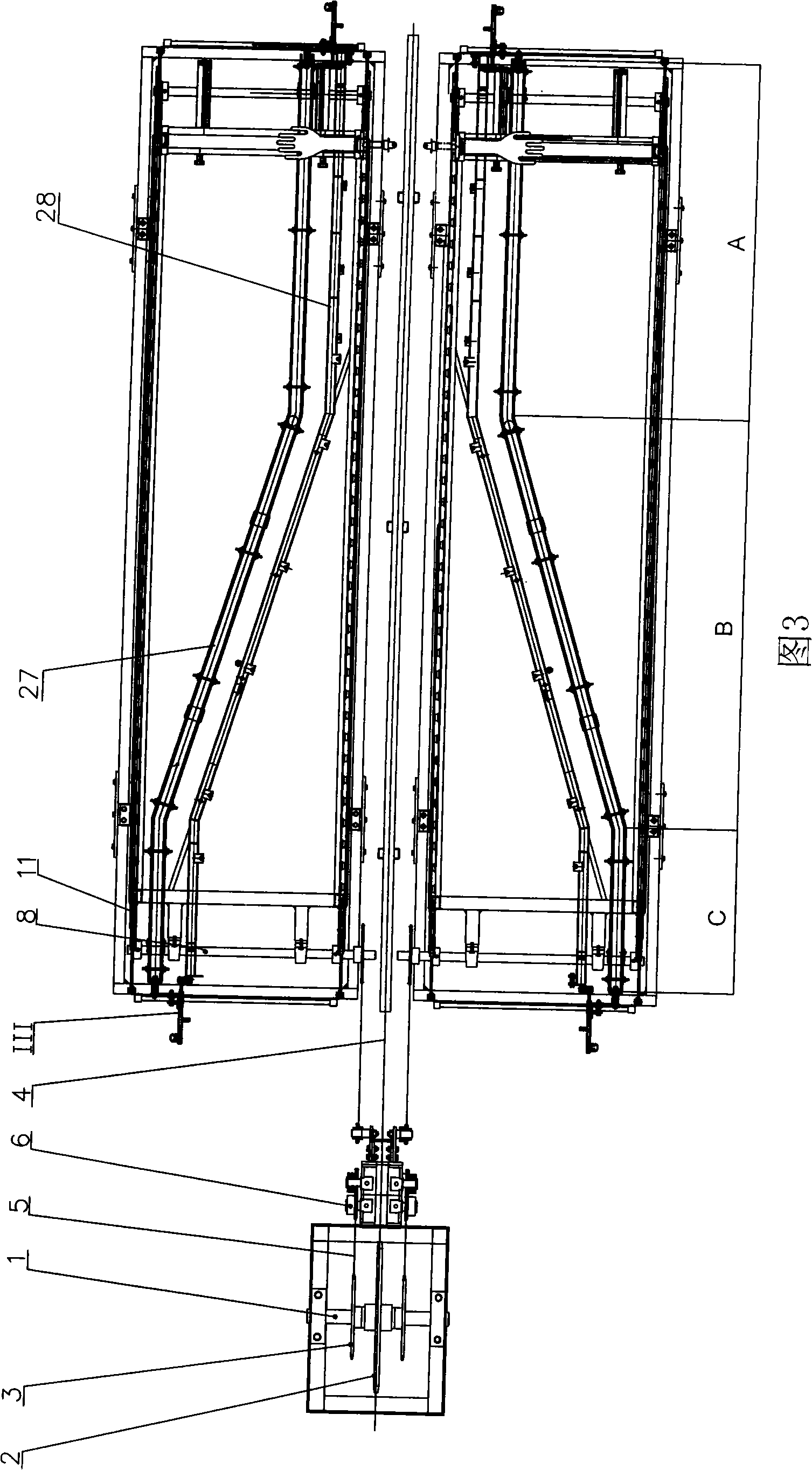

[0035] The rubber glove online automatic demoulding machine shown in the figure is mainly composed of a synchronous power take-off mechanism I, a guide rail control mechanism II, a glove stripping mechanism III, a glove blowing mechanism IV, a glove blowing mechanism V and a glove crimping mechanism VI composition. in:

[0036] The synchronous power take-off mechanism 1 has a drive sprocket 2 and a secondary sprocket 3 coaxially arranged on the main shaft 1. The driving sprocket 2 meshes with the main transmission chain 4 for continuous transmission of the hand mold 42 on the horizontal glove production line, and rotates with the operation of the main transmission chain 4. The secondary sprocket 3 is adjusted by the secondary transmission chain 5 and the tension The device 6 is connected with the power output sprocket 7, thereby driving the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com