Acoustic surface wave device

A surface acoustic wave and end face technology, which is applied in piezoelectric devices/electrostrictive devices, semiconductor/solid-state device parts, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problem that electromagnetic shielding structures cannot be installed It can prevent the inflow of resin, improve the sealing performance, and improve the yield of qualified products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

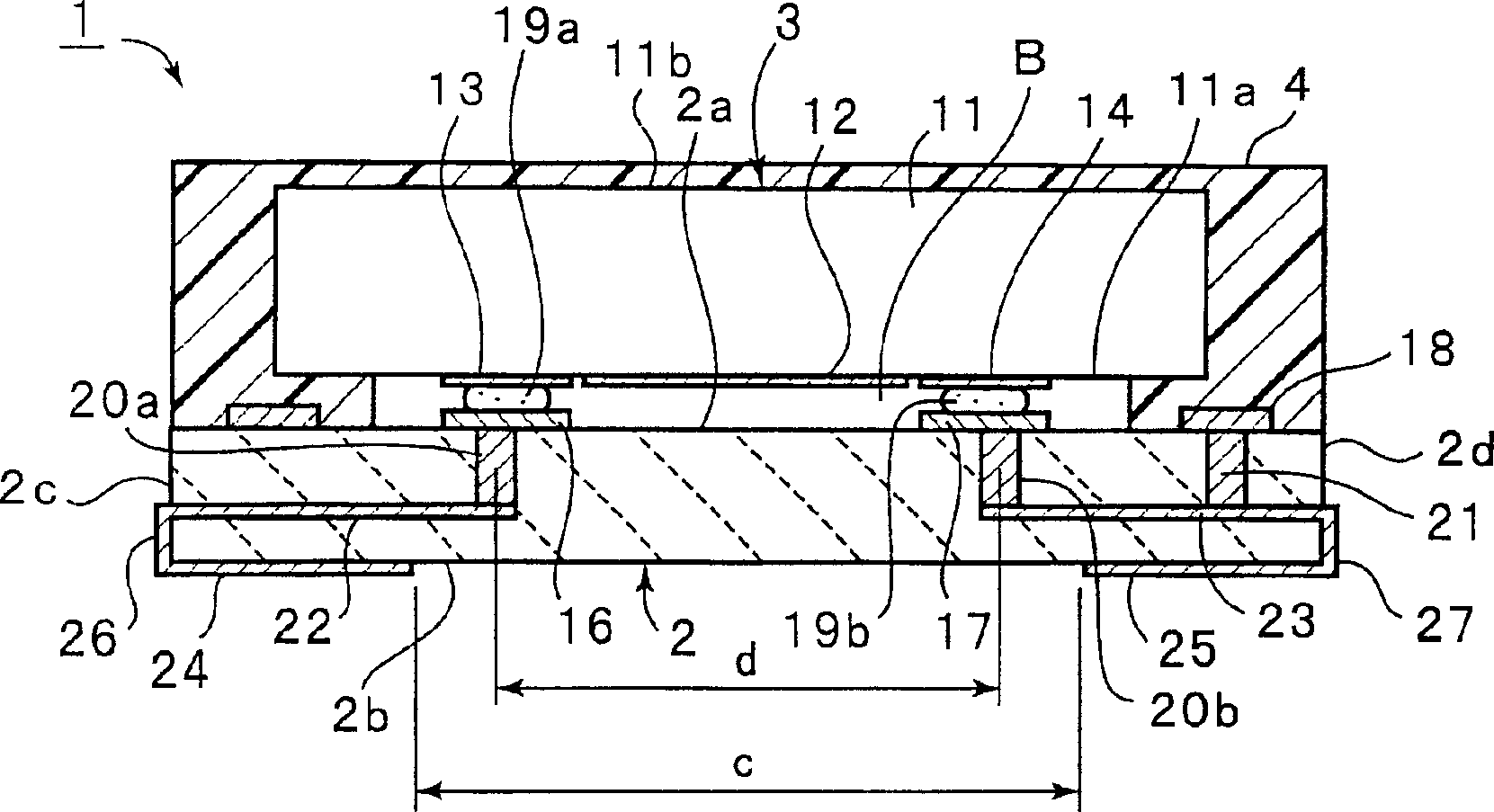

[0083] In the following, specific embodiments of the present invention will be described with reference to the drawings, so that the present invention can be understood.

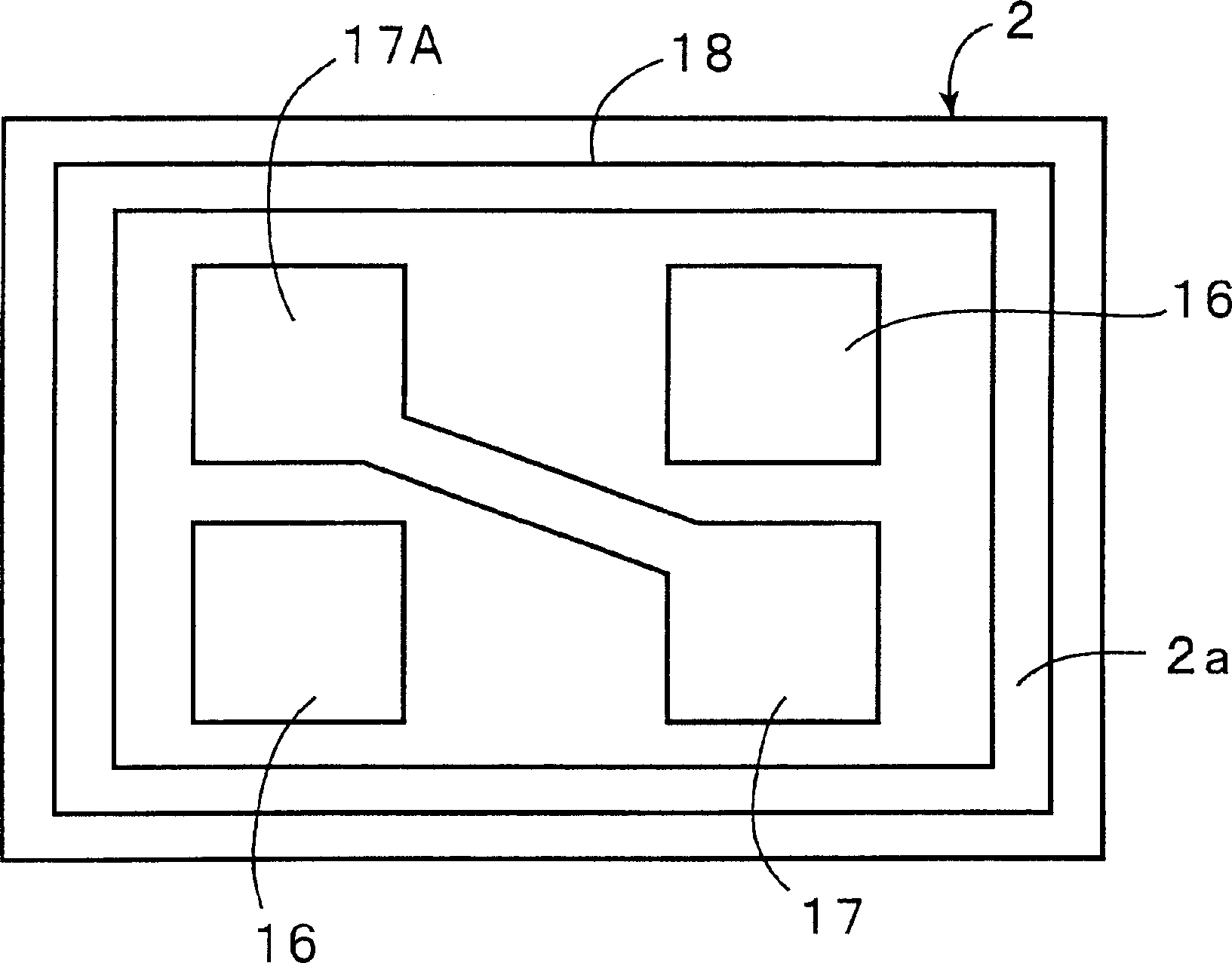

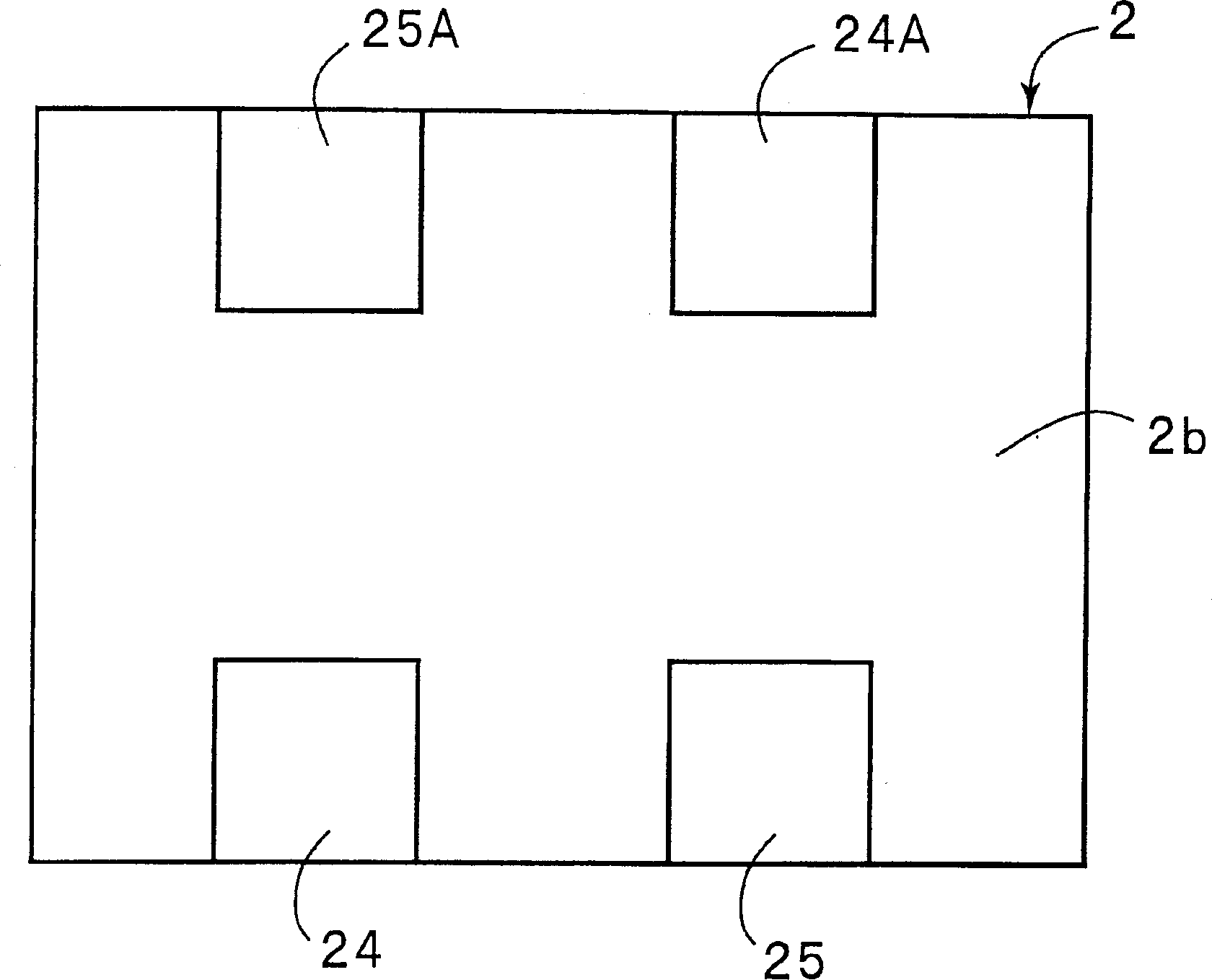

[0084] figure 1 is a cross-sectional view of the surface acoustic wave device according to the first embodiment of the present invention. The surface acoustic wave device 1 has a multilayer substrate 2 and a surface acoustic wave element 3 bonded to the multilayer substrate 2 by bumps. The periphery of the surface acoustic wave element 3 is covered with a resin sealing layer 4 .

[0085] The surface acoustic wave element 3 has a surface wave substrate 11 . The surface wave substrate 11 is constituted by a voltage substrate, a structure in which a piezoelectric thin film is laminated on an insulating substrate, or a structure in which a piezoelectric thin film is further laminated on a piezoelectric substrate.

[0086] The surface wave substrate 11 has first and second main surfaces 11a and 11b. Electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com