Thin wall processing technology and its special-purpose knife tool

A processing technology and cutting tool technology, which is applied in the field of thin-wall processing technology and its special cutting tools, can solve the problems of wall thickness limitation, high rejection rate, low processing efficiency, etc., and achieve stability, high qualified product rate, and high processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

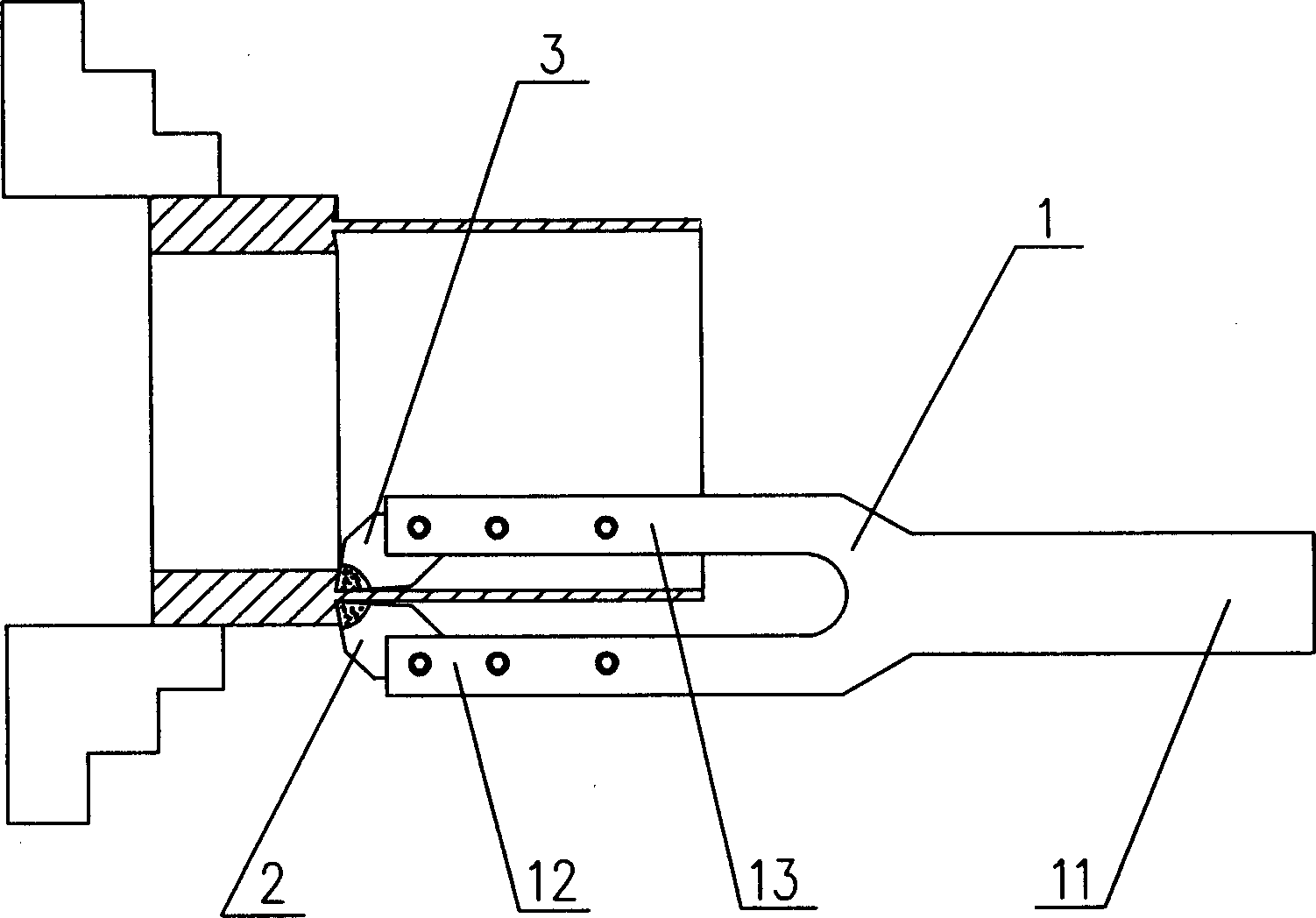

[0012] Such as figure 1 It is a schematic diagram of the processing process of the present invention. This thin-wall processing has the following processes: 1) clamp the workpiece blank on the chuck fixture; 2) fix the special tool 1 capable of processing the required thin-wall thickness on the feeder, And make the line of two cutting points on the outer diameter processing cutter head 2 and the inner diameter processing cutter head 3 on the special tool 1 perpendicular to the feeding direction of the cutter 1; 3) feed cutting; 4) cutting and blanking. Such as figure 1 The cutting tool 1 on the handle comprises a knife handle 11, a left front fork 12 and a right front fork 13, and the left front fork 12 and the right front fork 13 protrude forward in a U-shape at the front end of the knife handle 11, and are respectively fixed on the left front fork 12 and the right front fork 13 The outer diameter processing cutter head 2 and the inner diameter processing cutter head 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com