Patents

Literature

154results about "Boring/drilling apparatus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

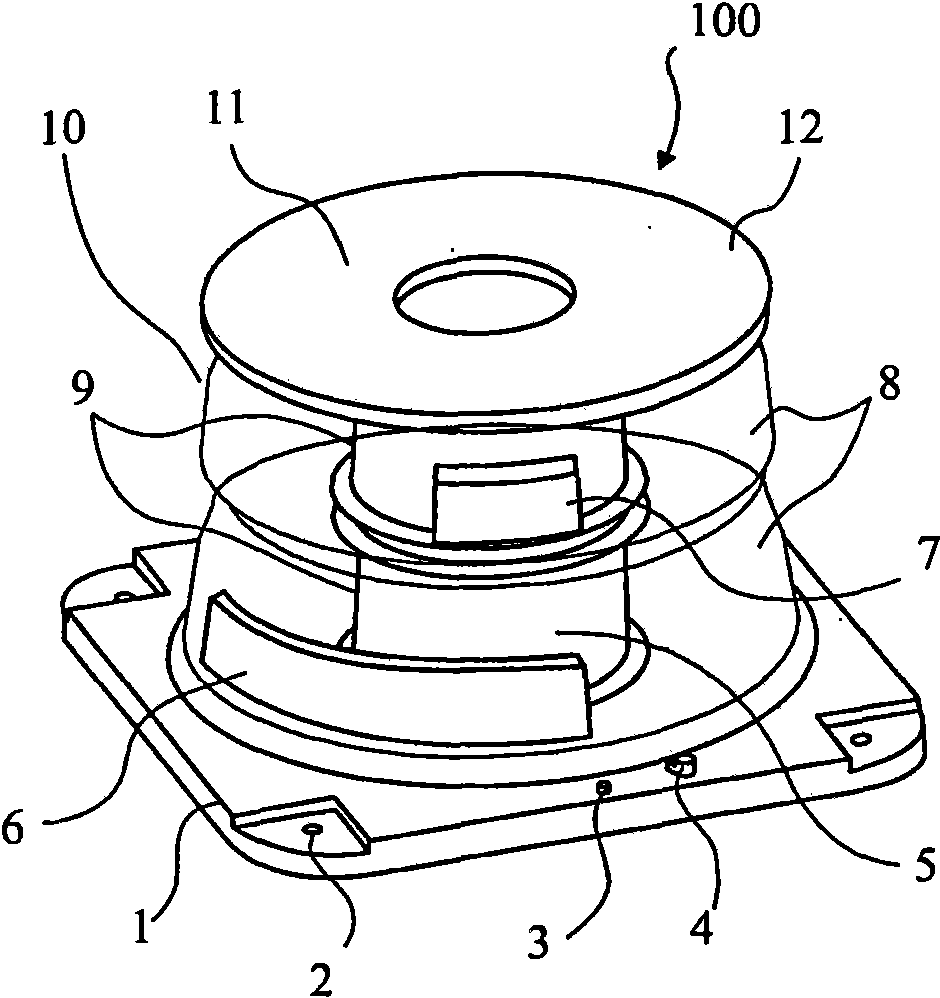

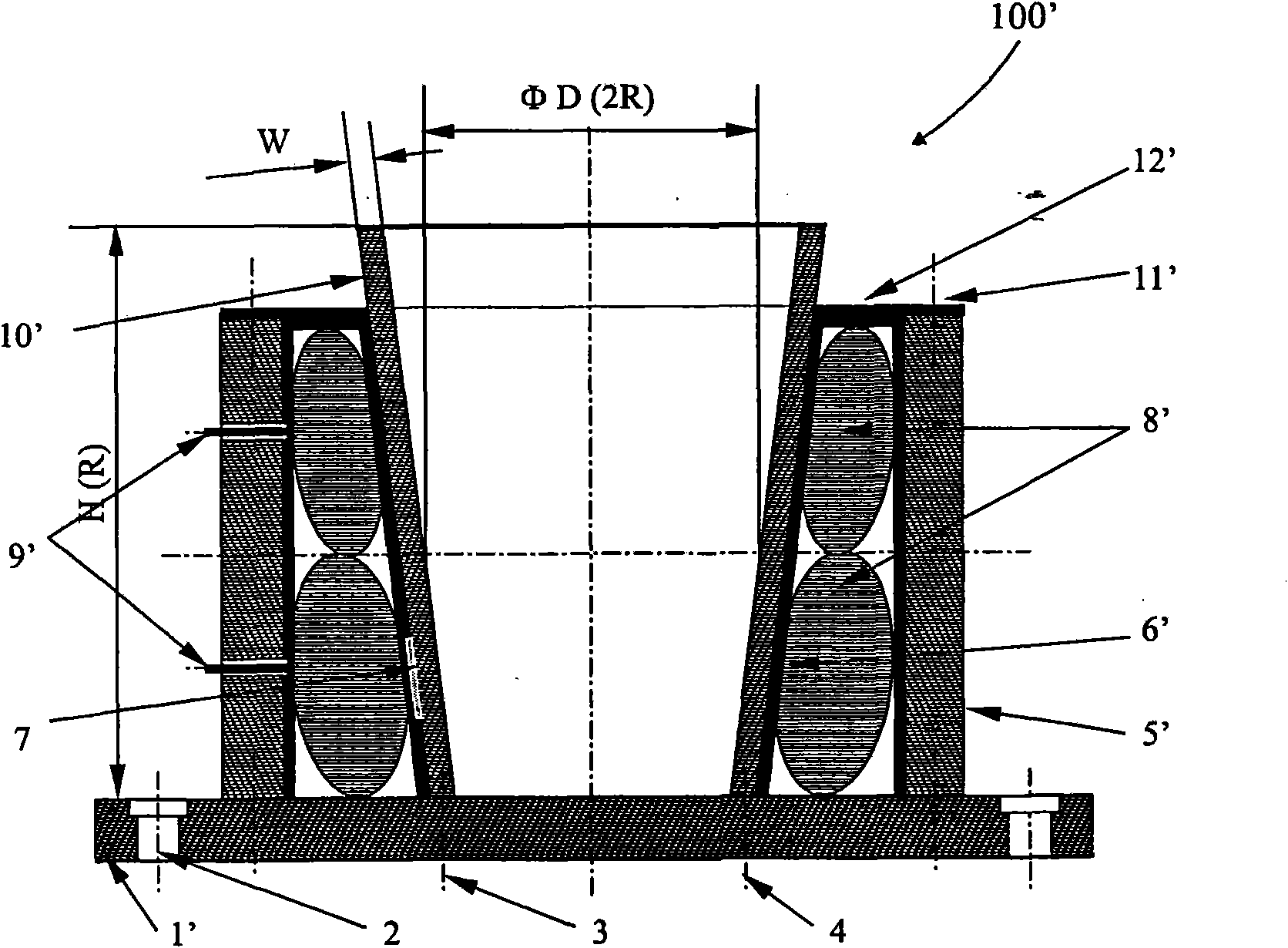

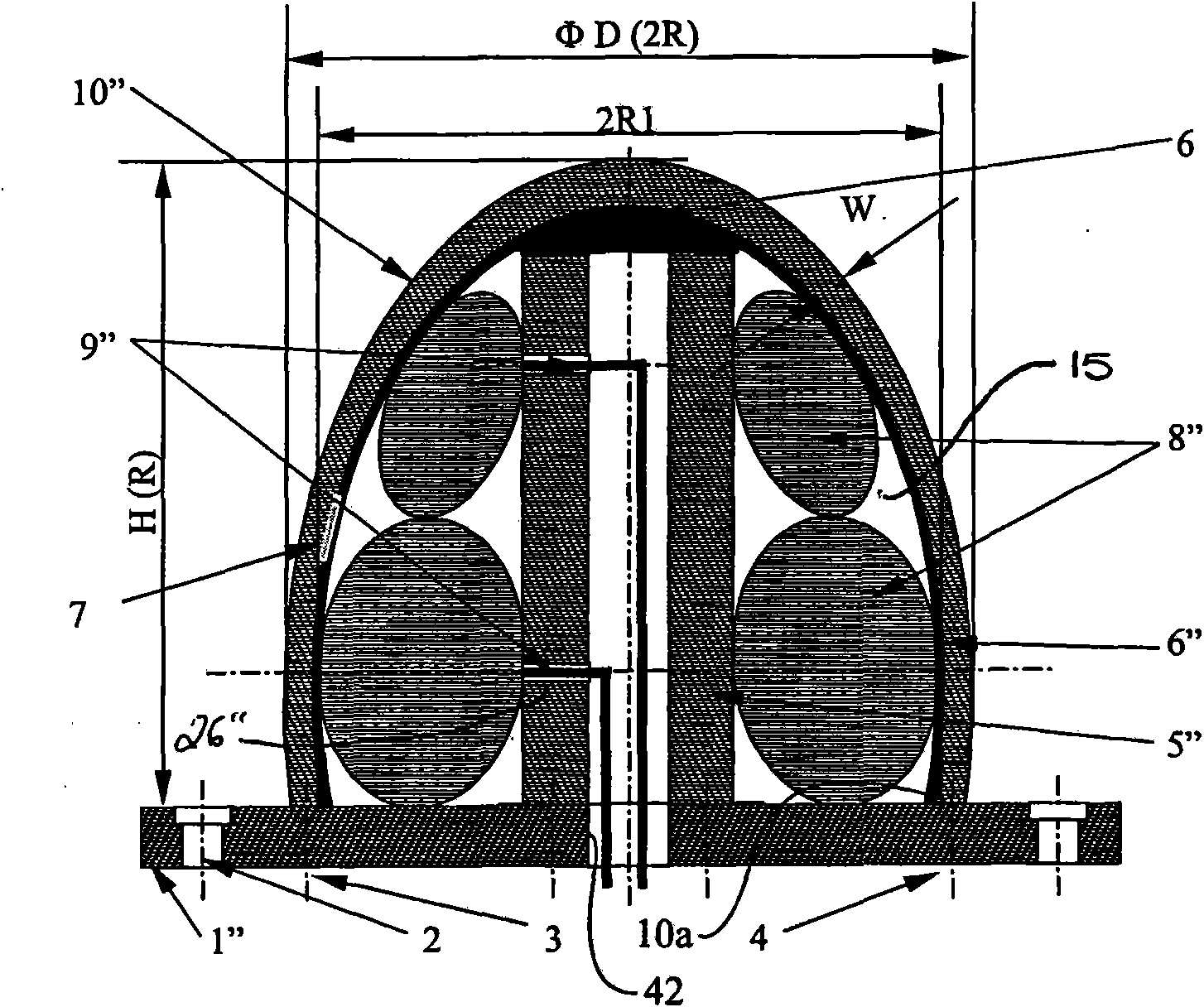

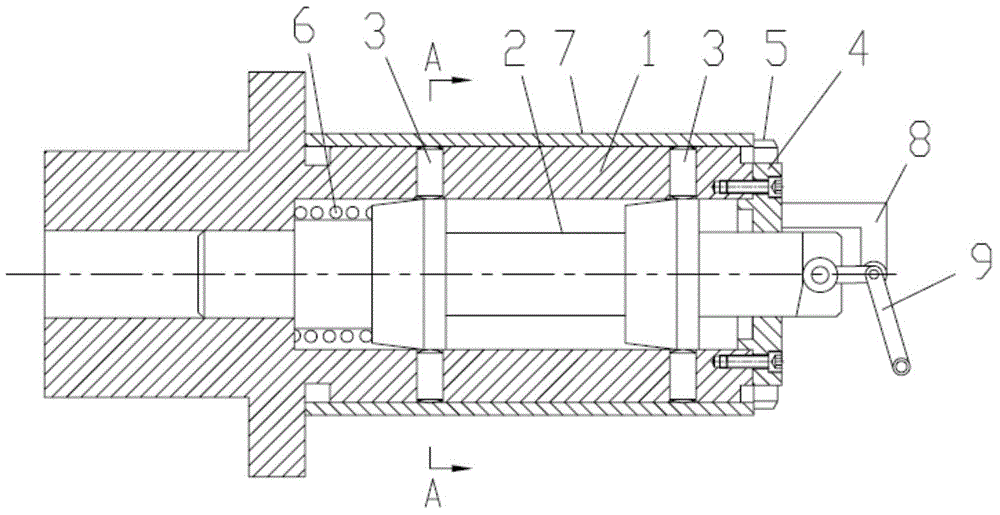

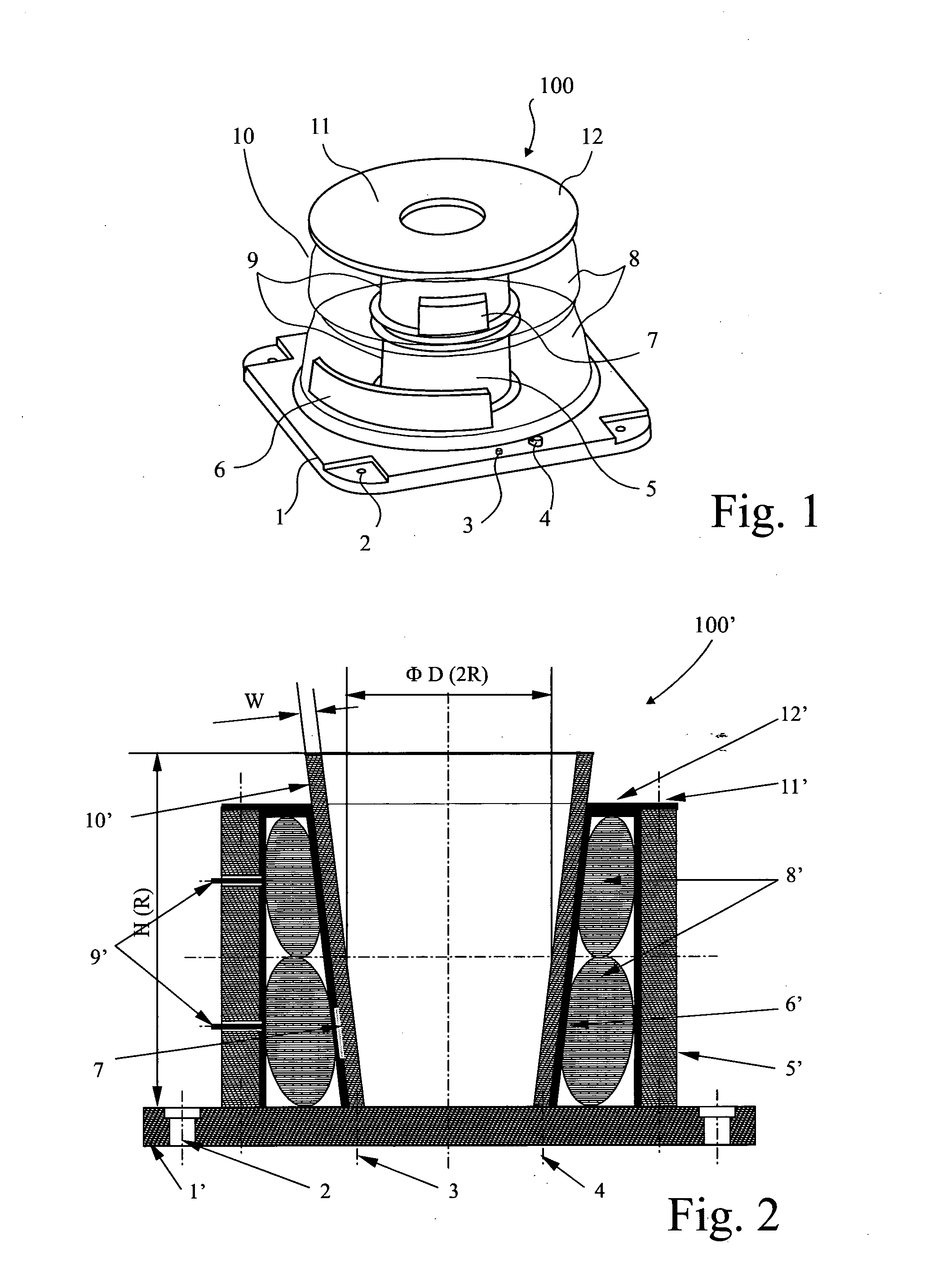

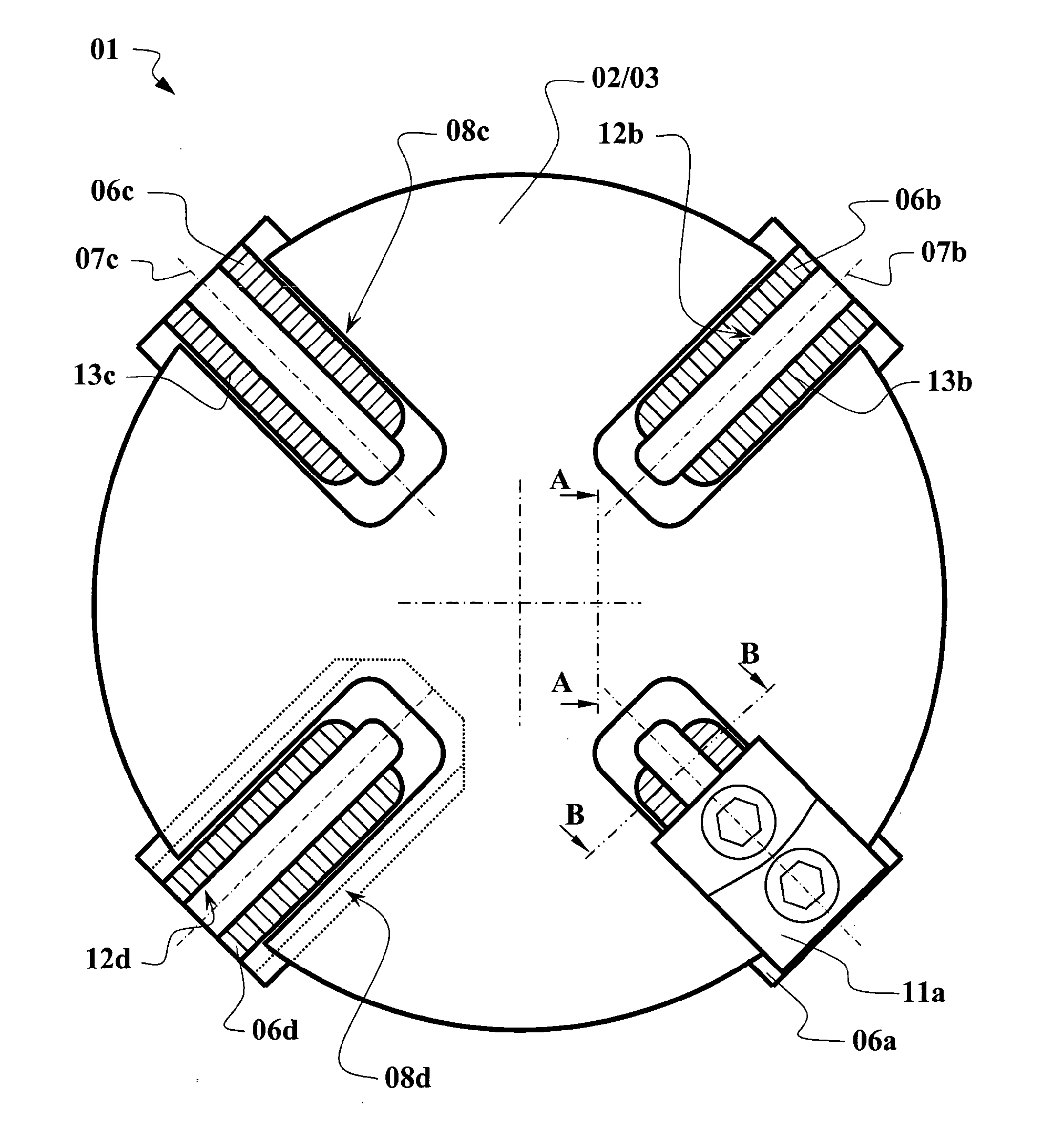

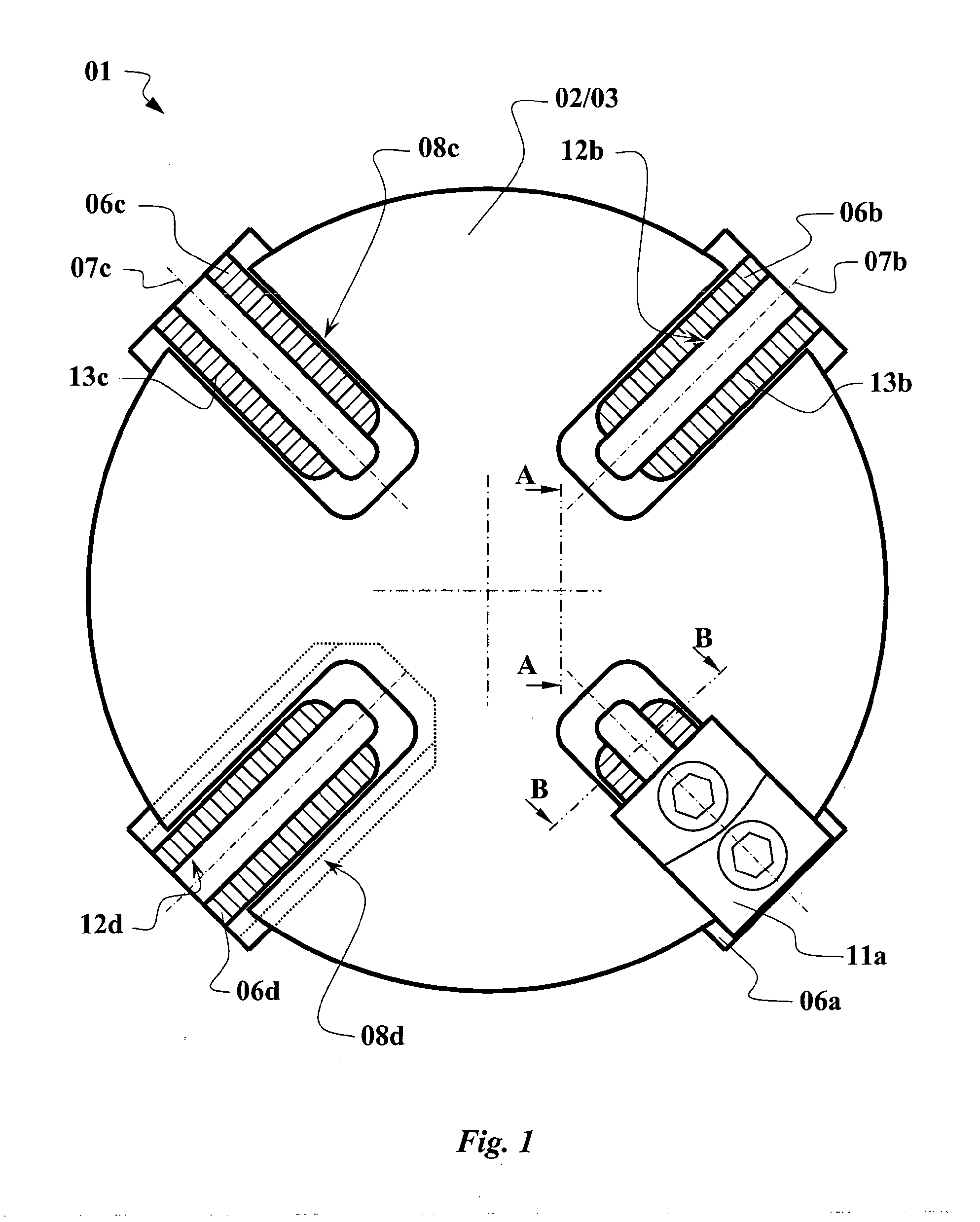

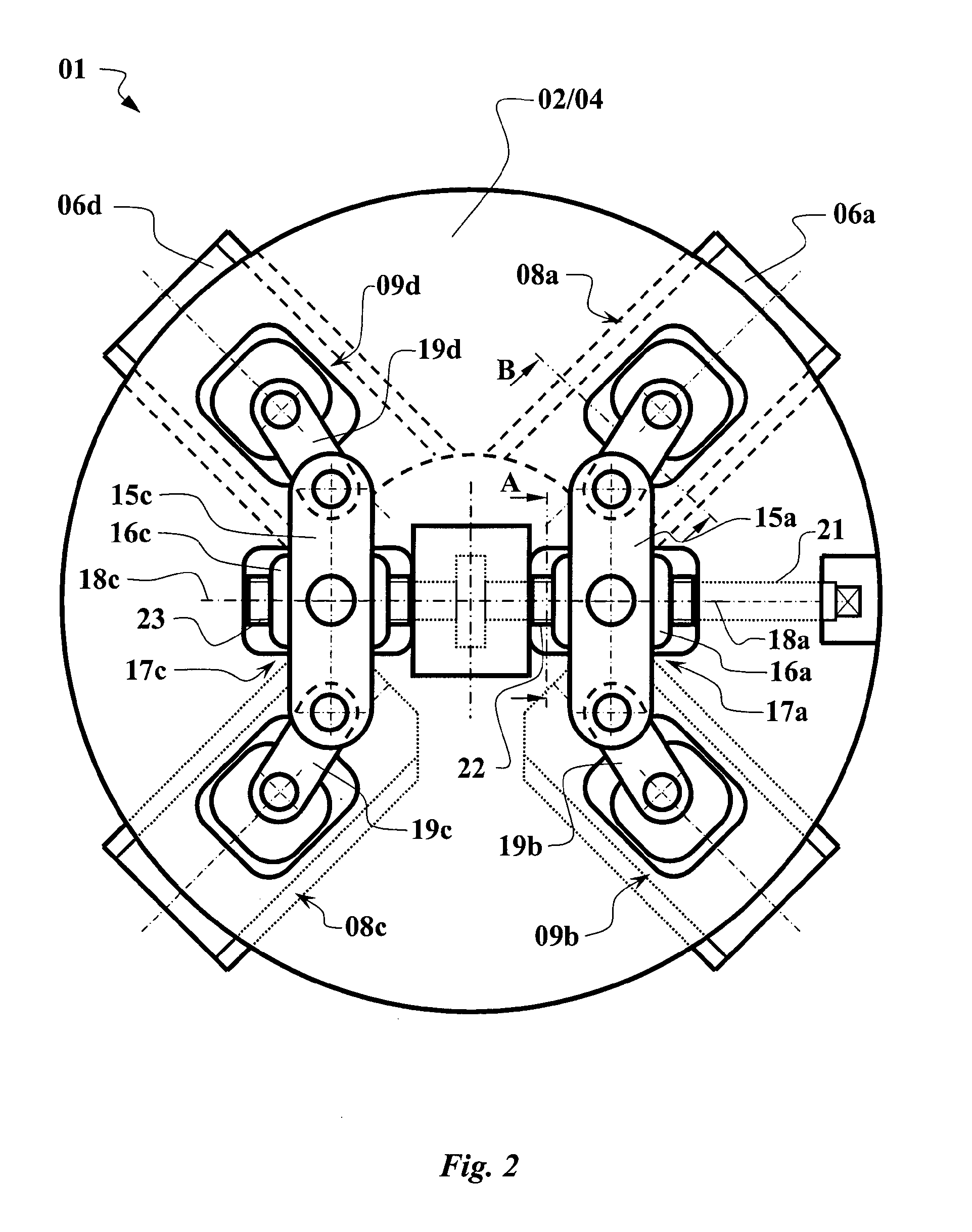

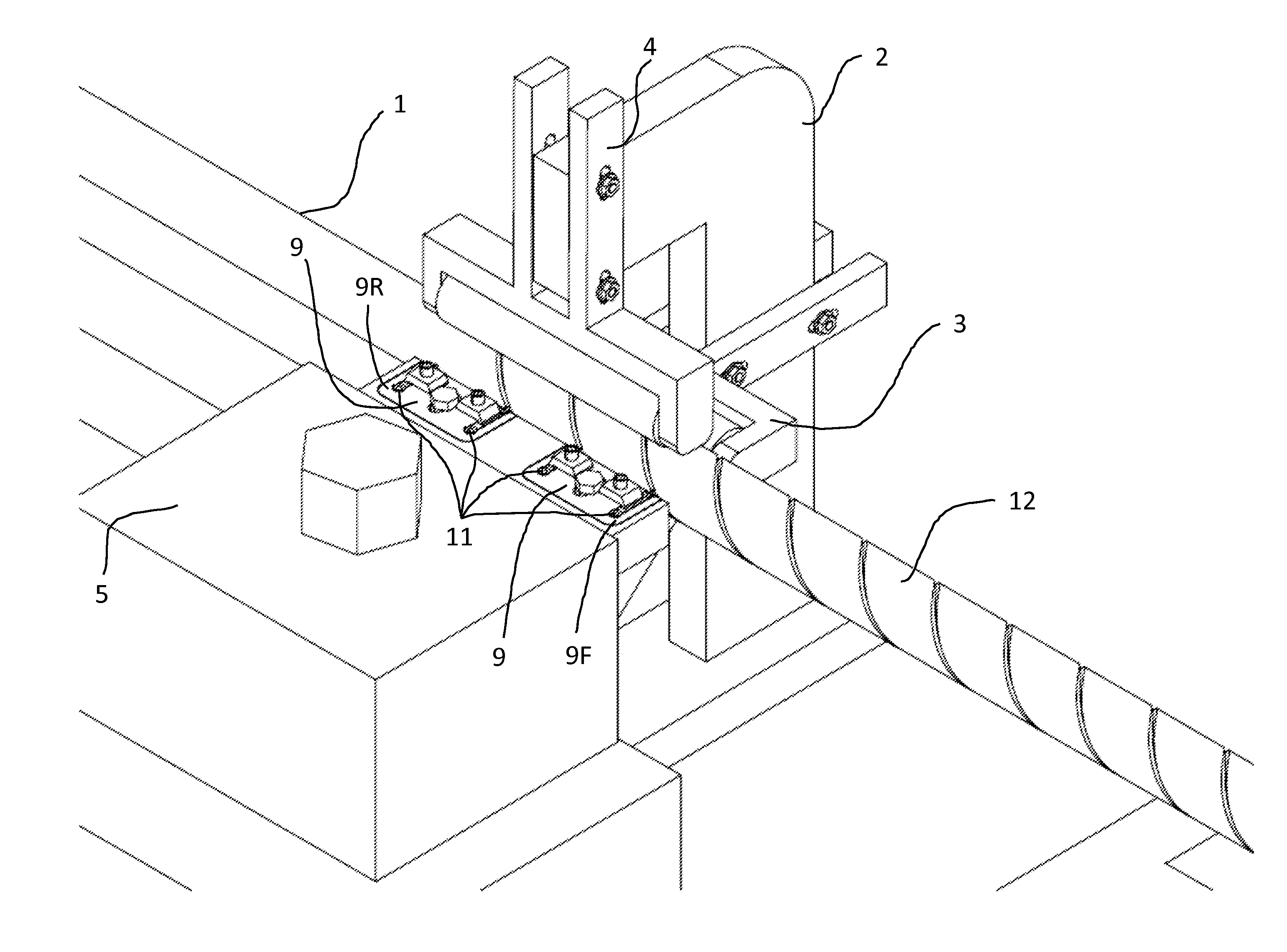

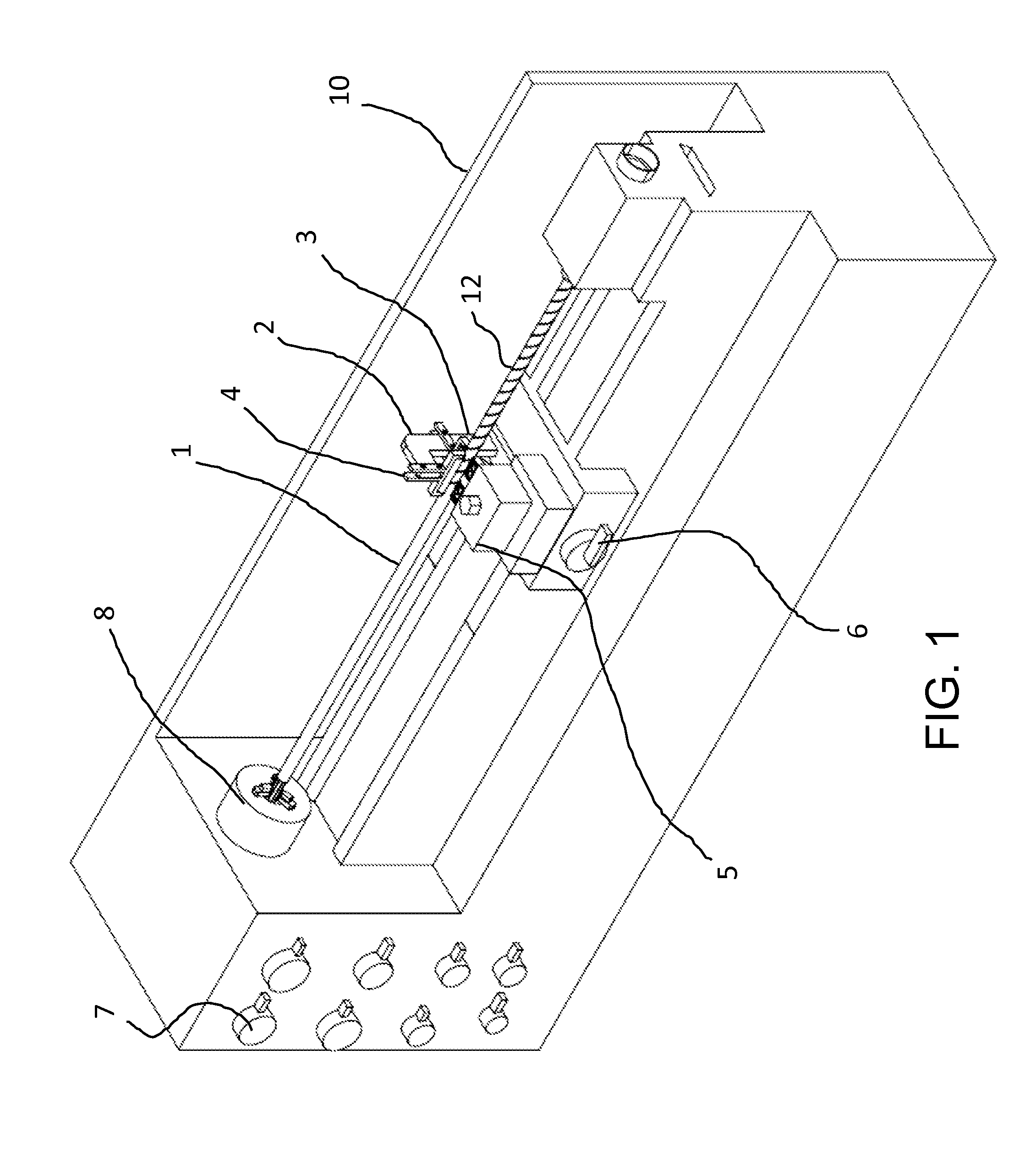

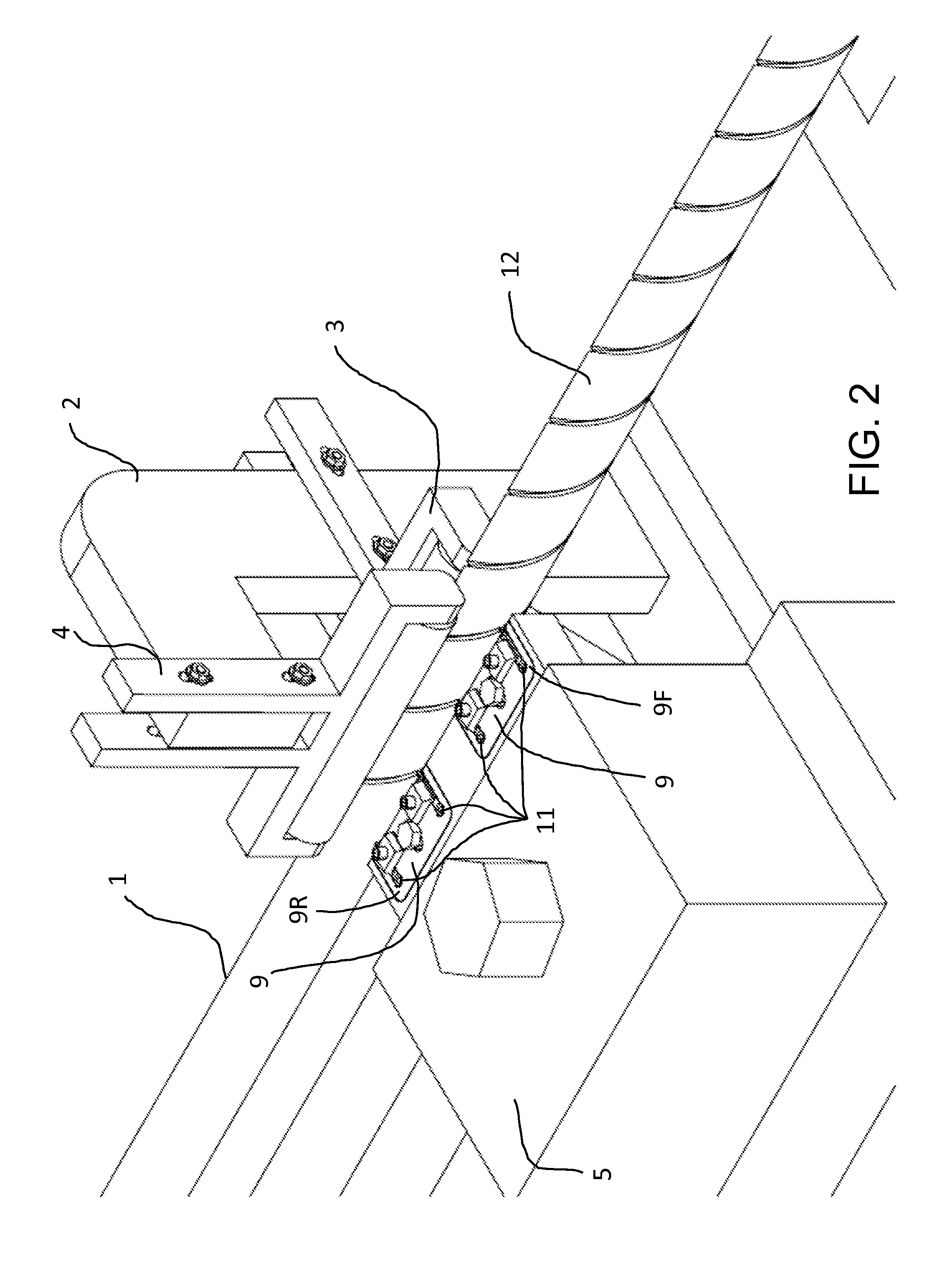

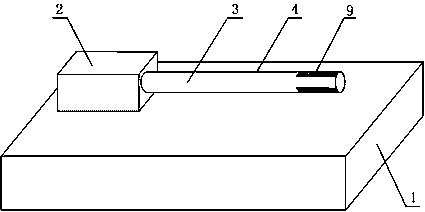

Adaptive design of fixture for thin-walled shell/cylindrical components

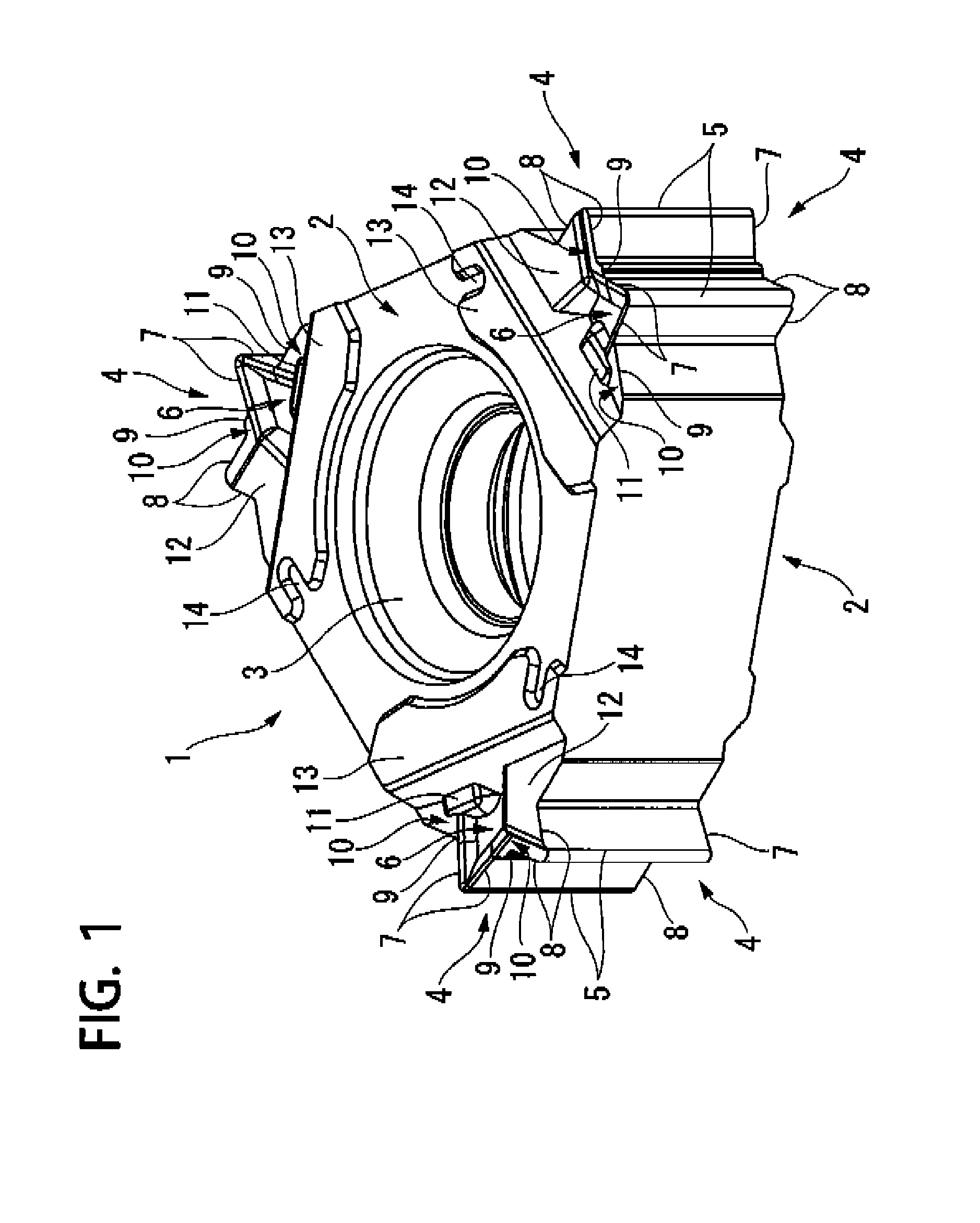

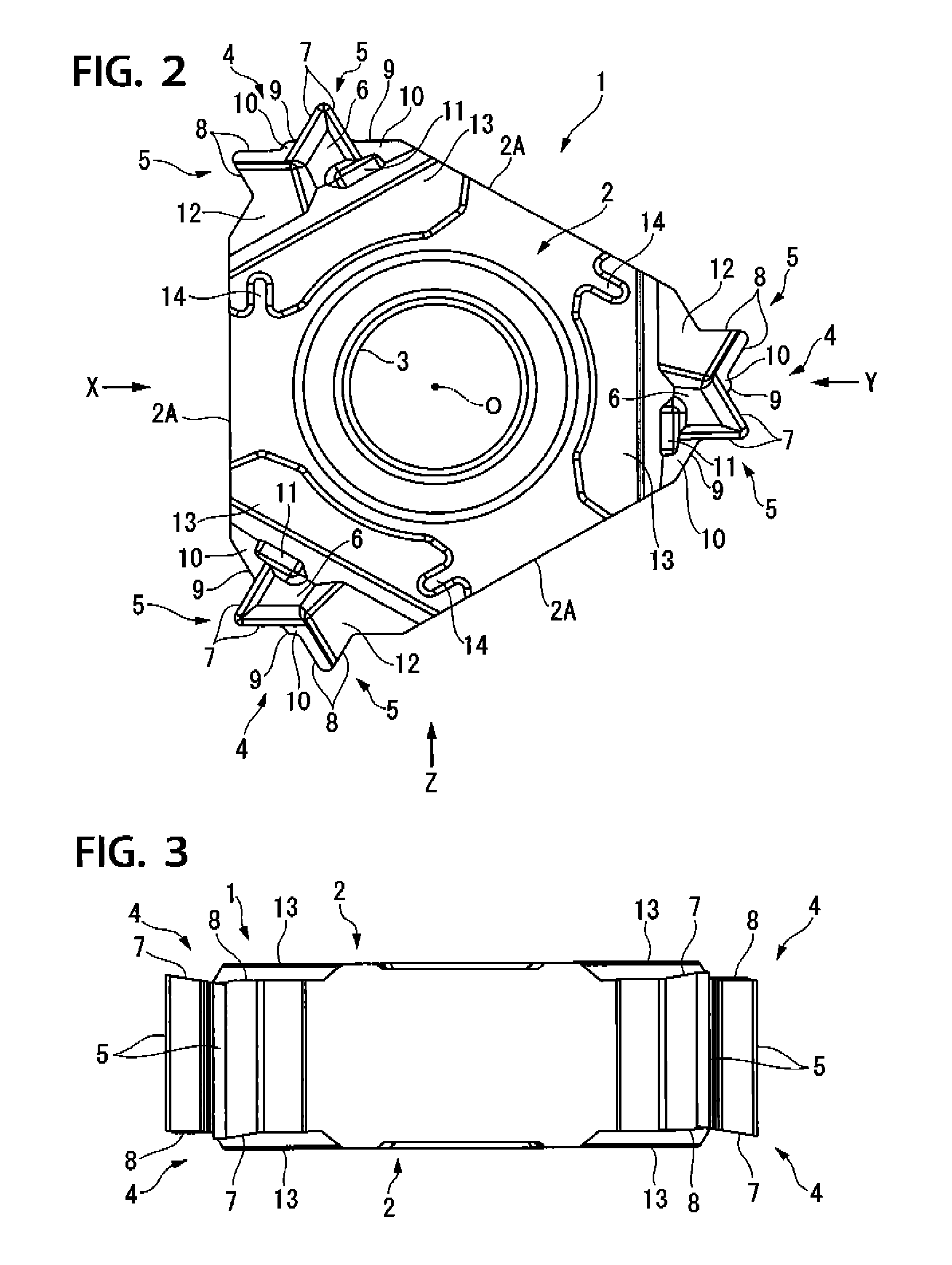

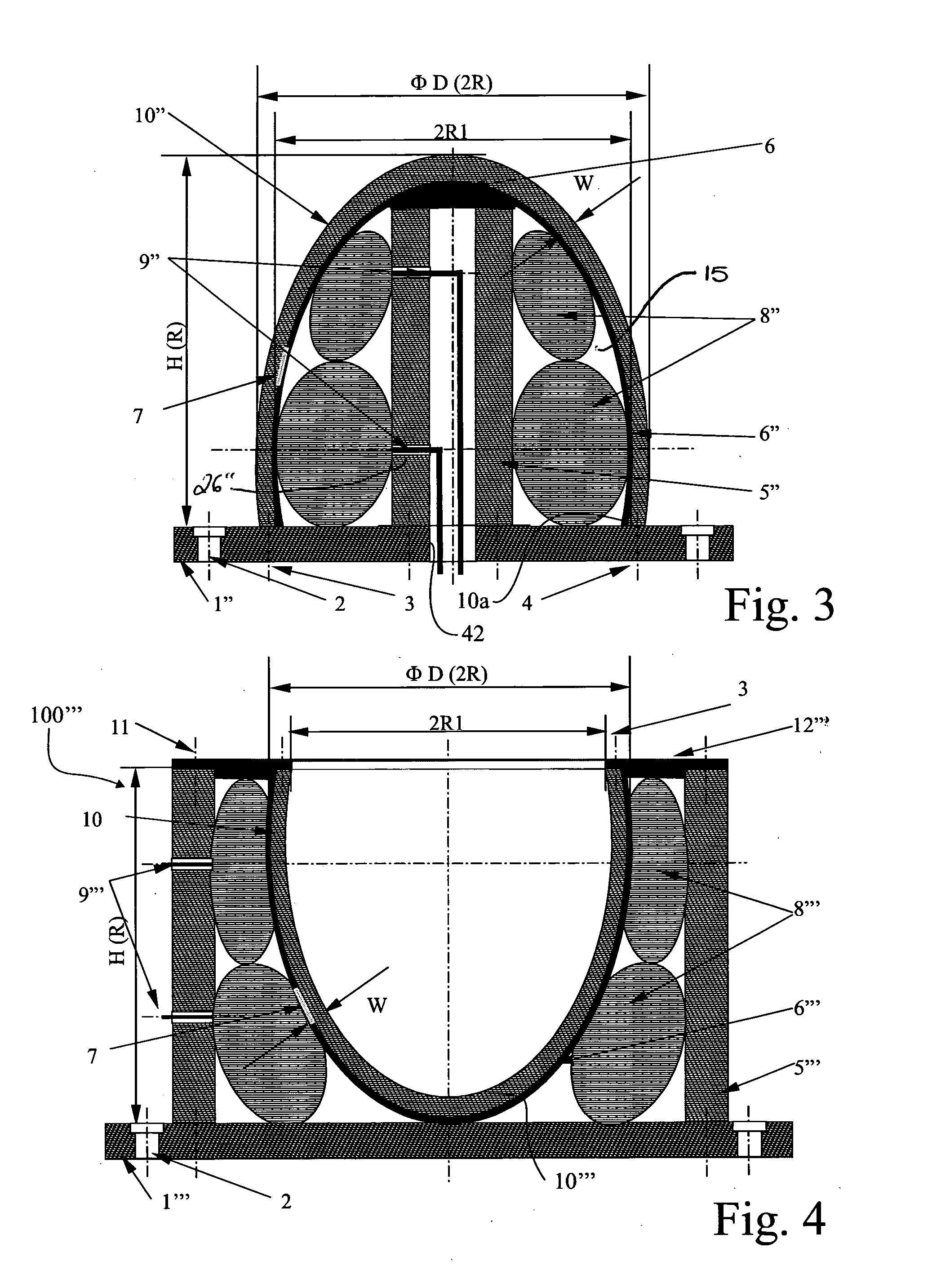

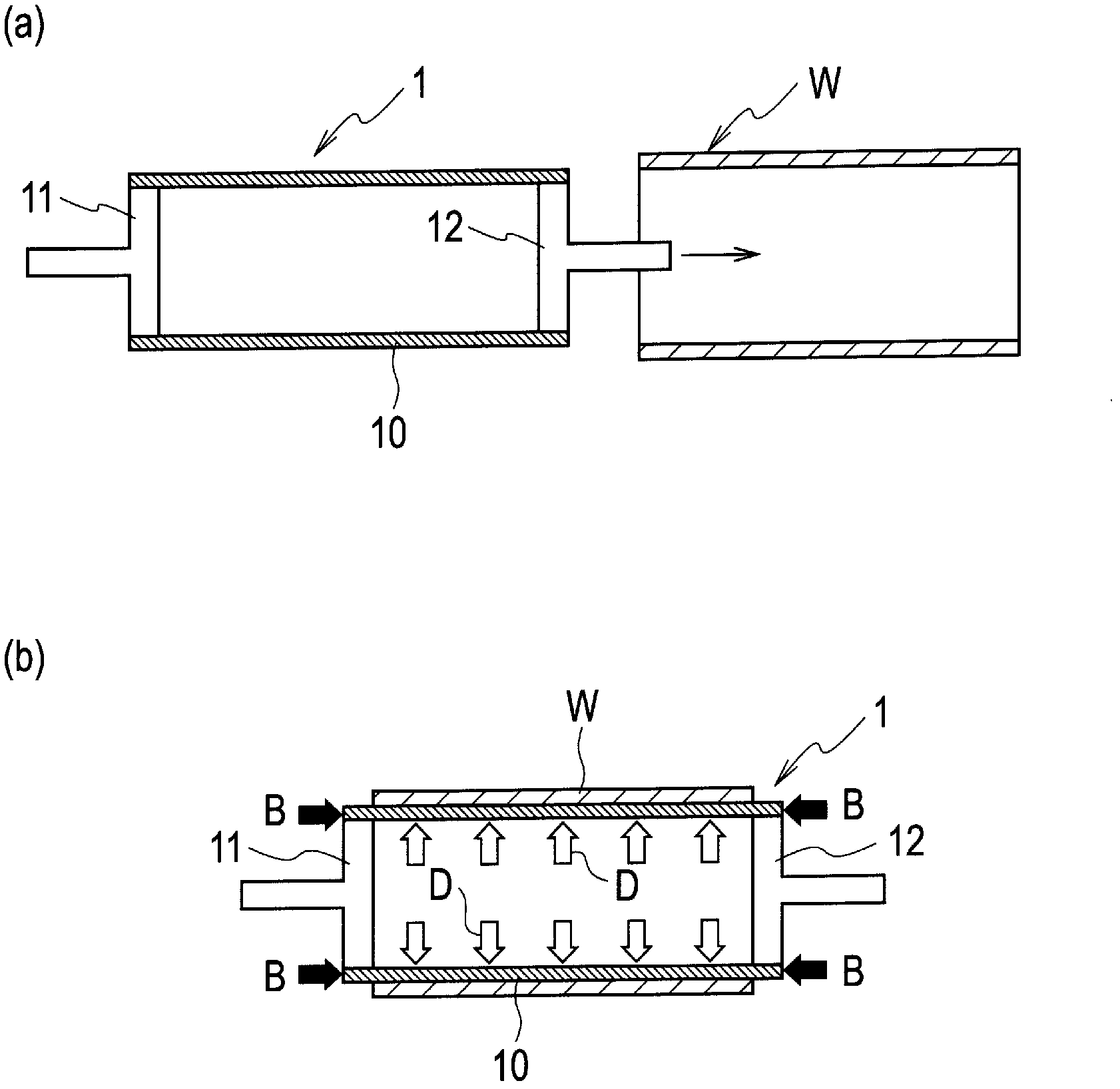

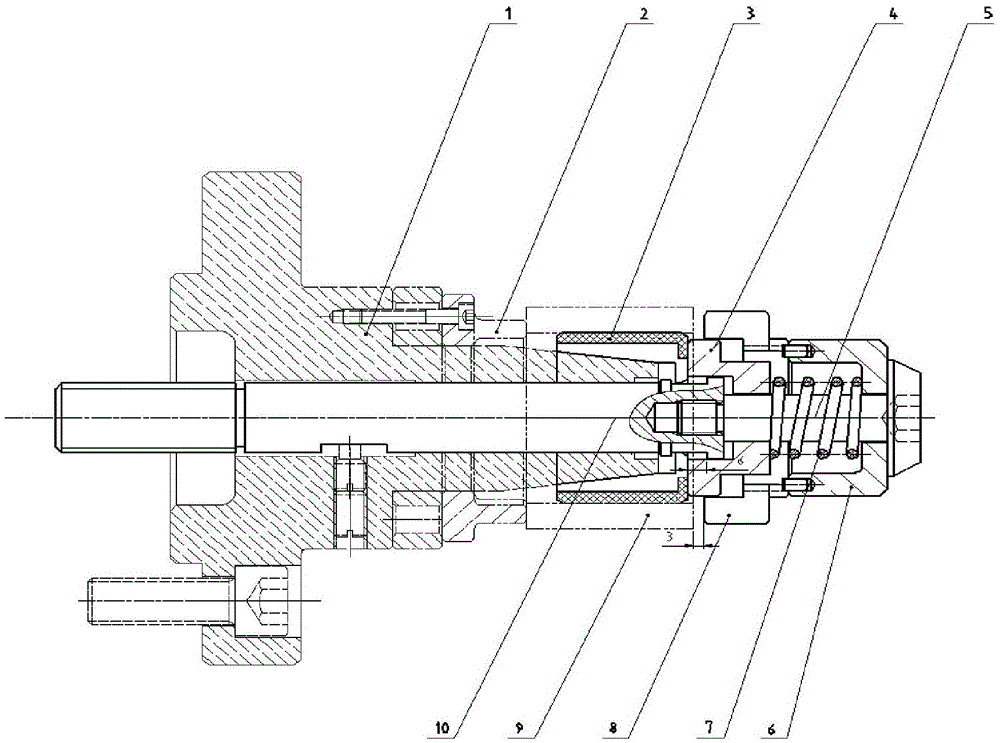

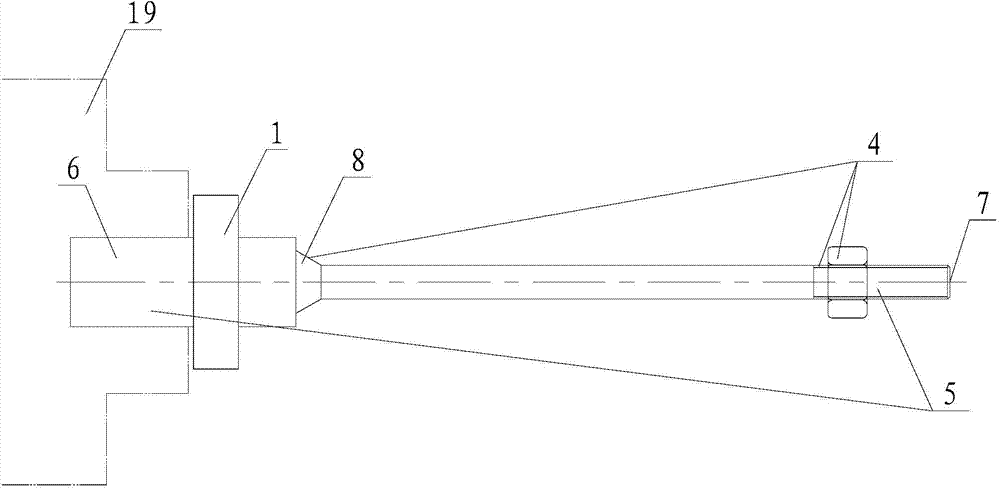

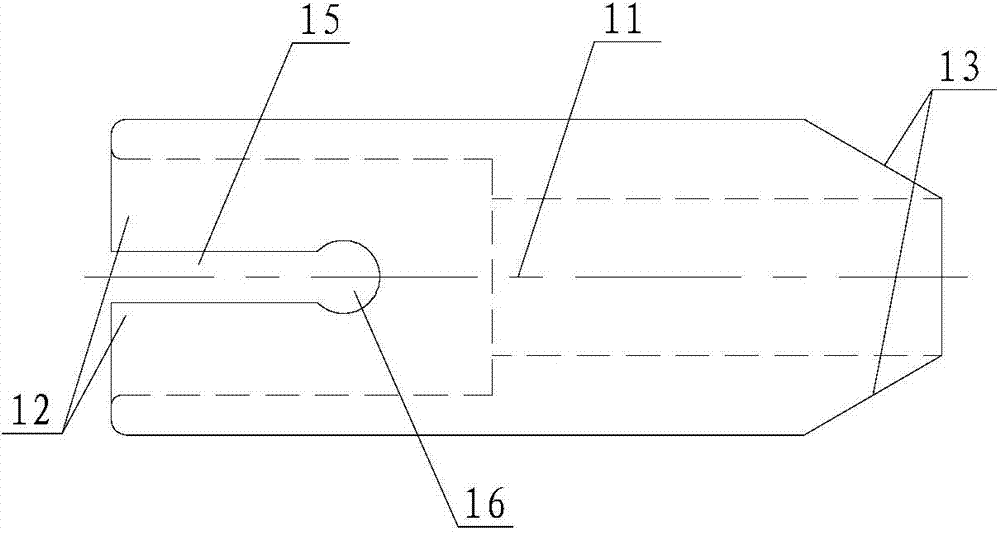

A group of fixtures for thin-walled shell / cylindrical components (10) while they are being machined internally and externally, has a mounting base (1 ) having mounting holes, positioning pins and clamps to locate one end of the thin-walled component. A supporting arbour or cylinder (5) is fixed in the base. A circular lid (12) is fixed to the supporting arbour or cylinder and has a wedged step to locate the other end of the cylindrical component for internal and external machining, or the major open end of shell component for internal machining. A pair of modified vehicle wheel inner tubes (8) are disposed around the supporting arbour or cylinder. A multi-layered sacrificial liner (7) surrounds the pressure element and is adapted to fit between it and the thin-walled components. When properly inflated according to the design and validation procedure, the fixture adaptively holds the thin-walled components for machining, with sufficient supporting rigidity and dynamic stability.

Owner:UNIV OF SHEFFIELD

Thread cutting insert

InactiveUS7909546B2Increase the number ofEasy to useThread cutting toolsCutting insertsEngineeringMechanical engineering

In this thread cutting insert, on a common edge section of front and back faces of an insert main body, there is formed a pair of cutting edge sections that project from the edge section when seen from a direction facing the front and back faces, and on at least two of four projecting faces that respectively face the front and back face sides of the pair of these cutting edge sections, there is formed a thread cutting edge with the projecting face serving as a rake face.

Owner:MITSUBISHI MATERIALS CORP

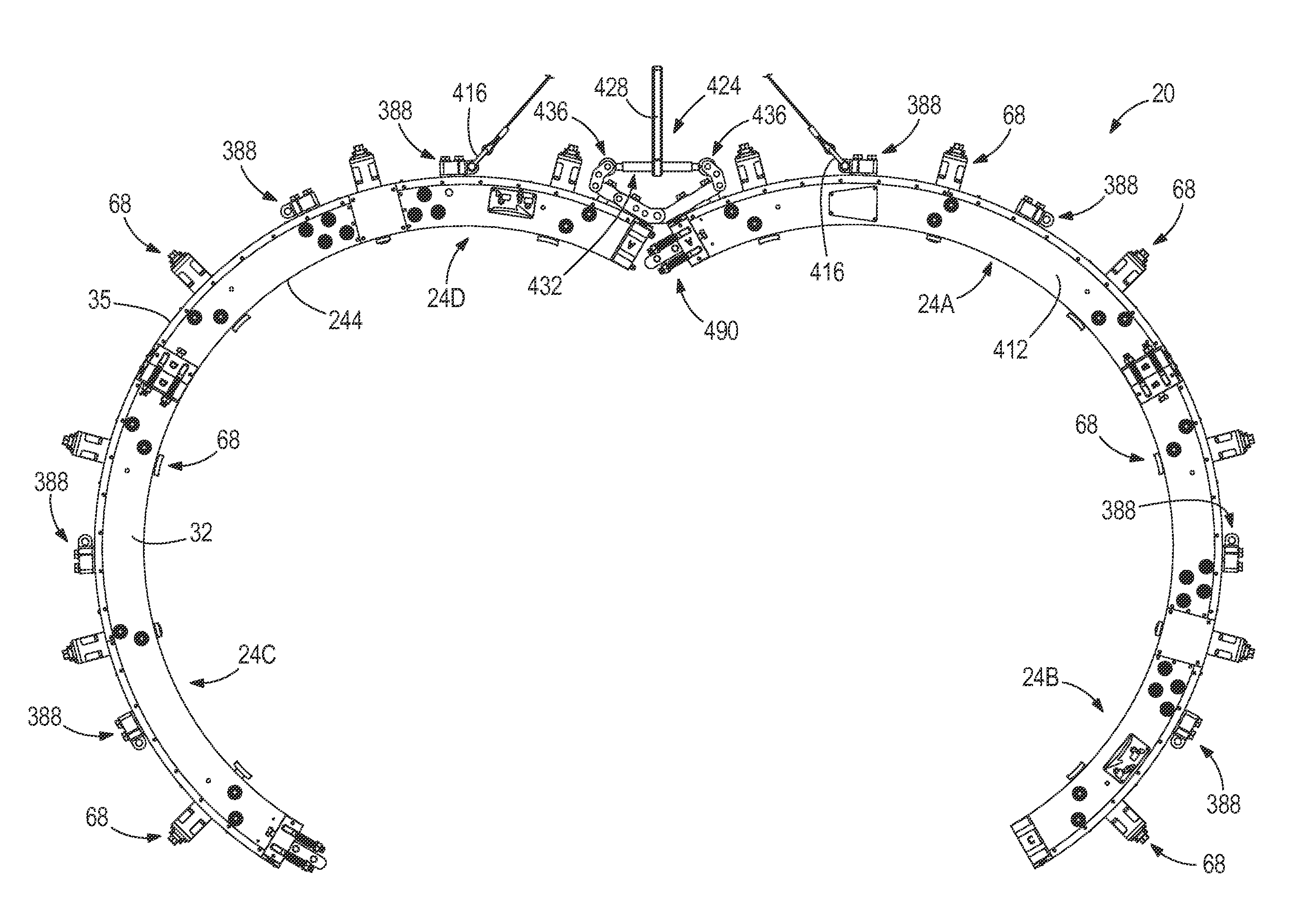

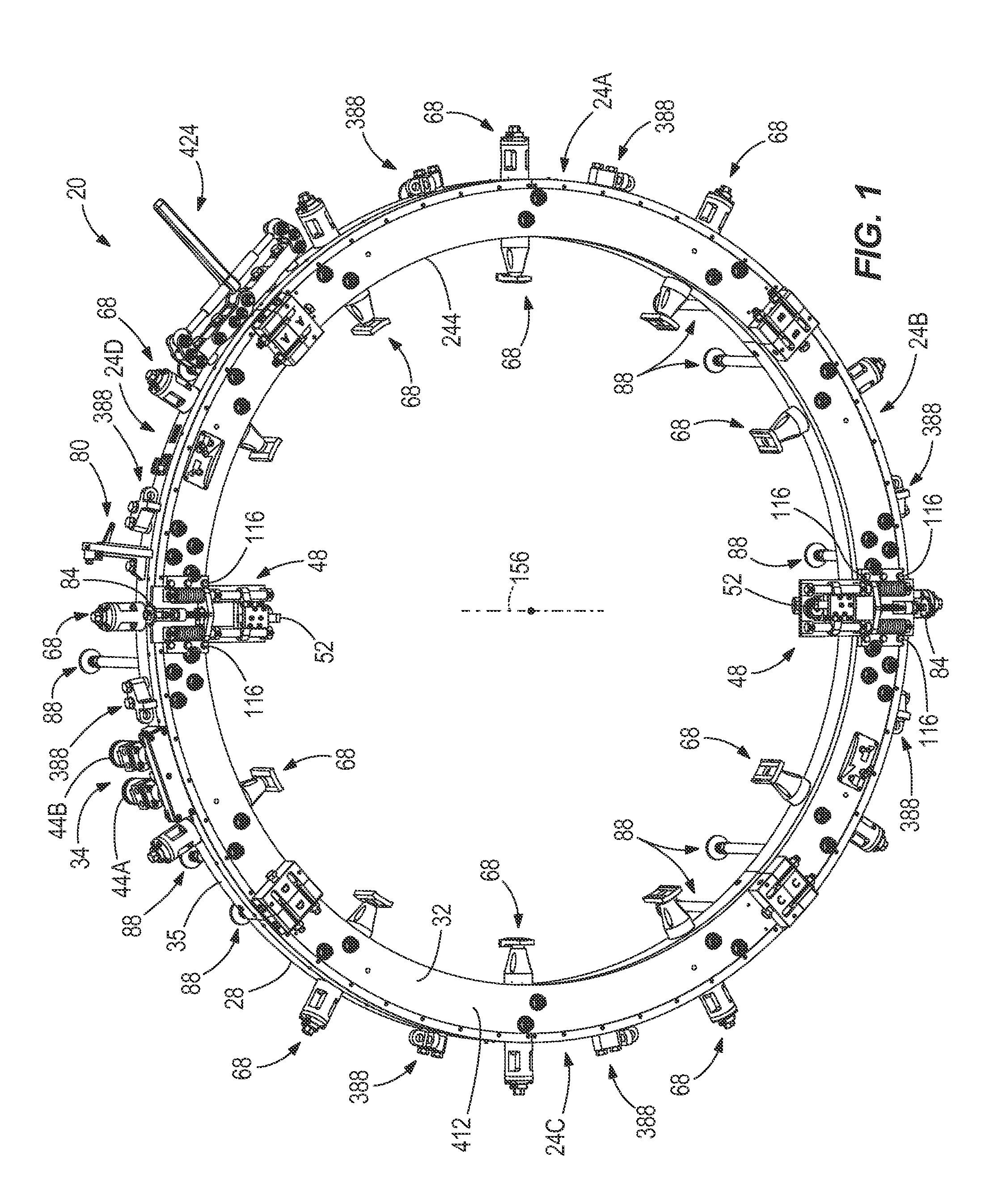

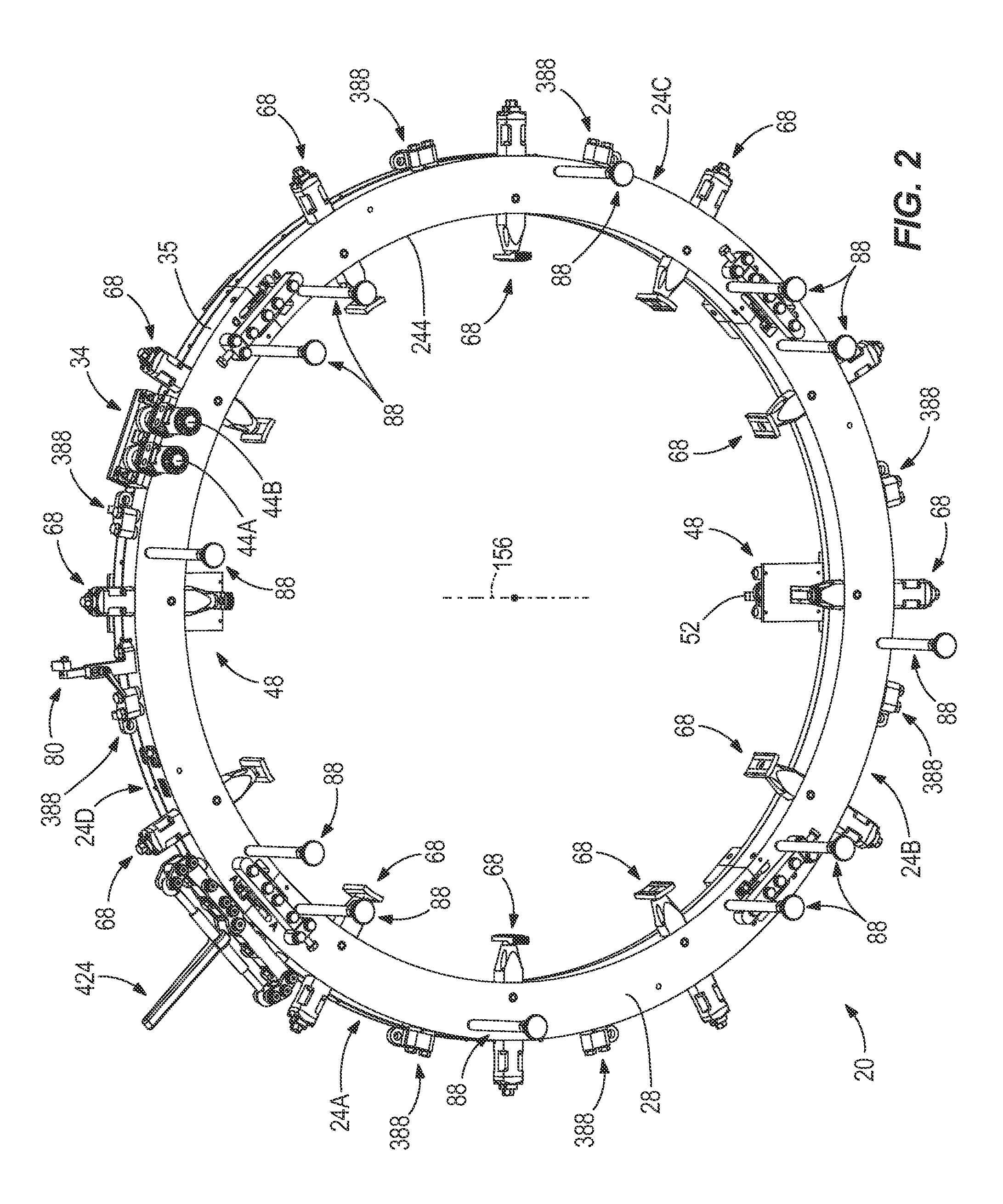

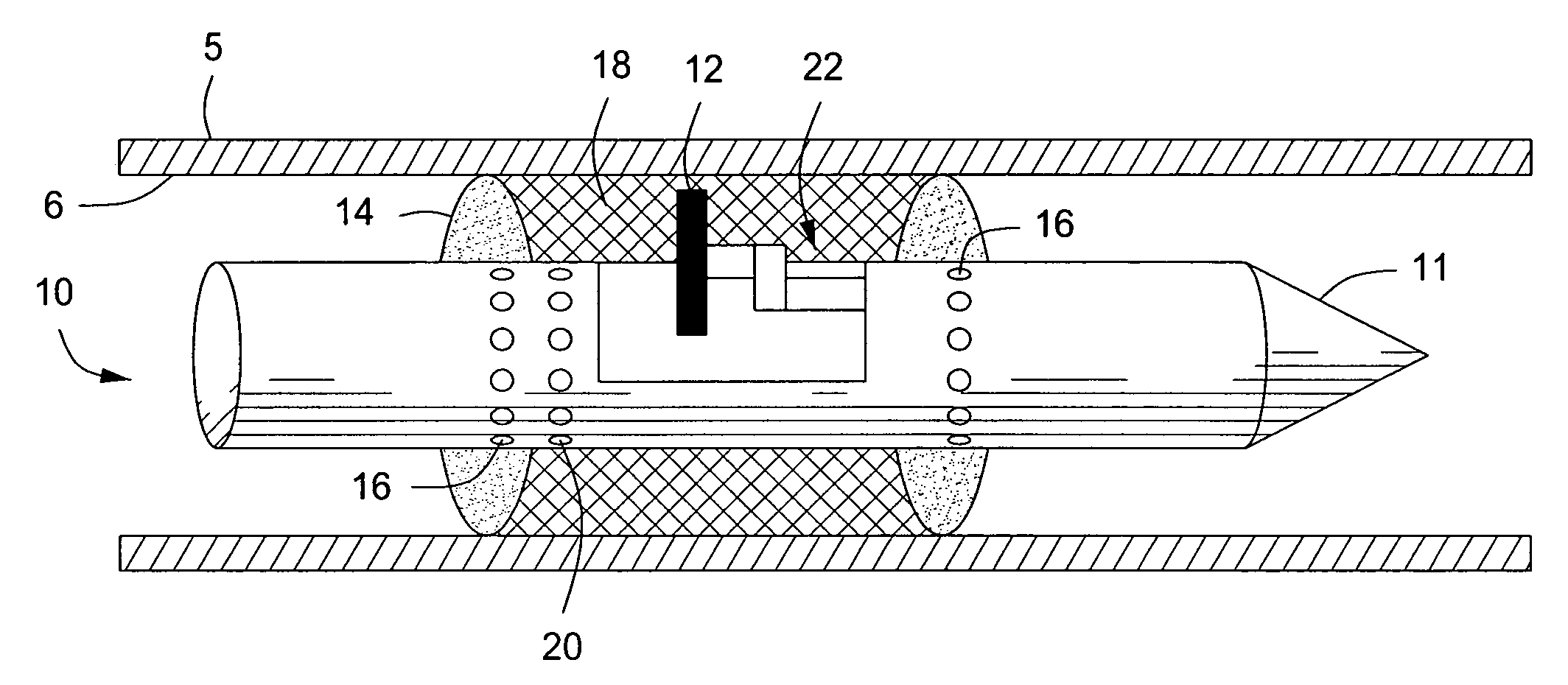

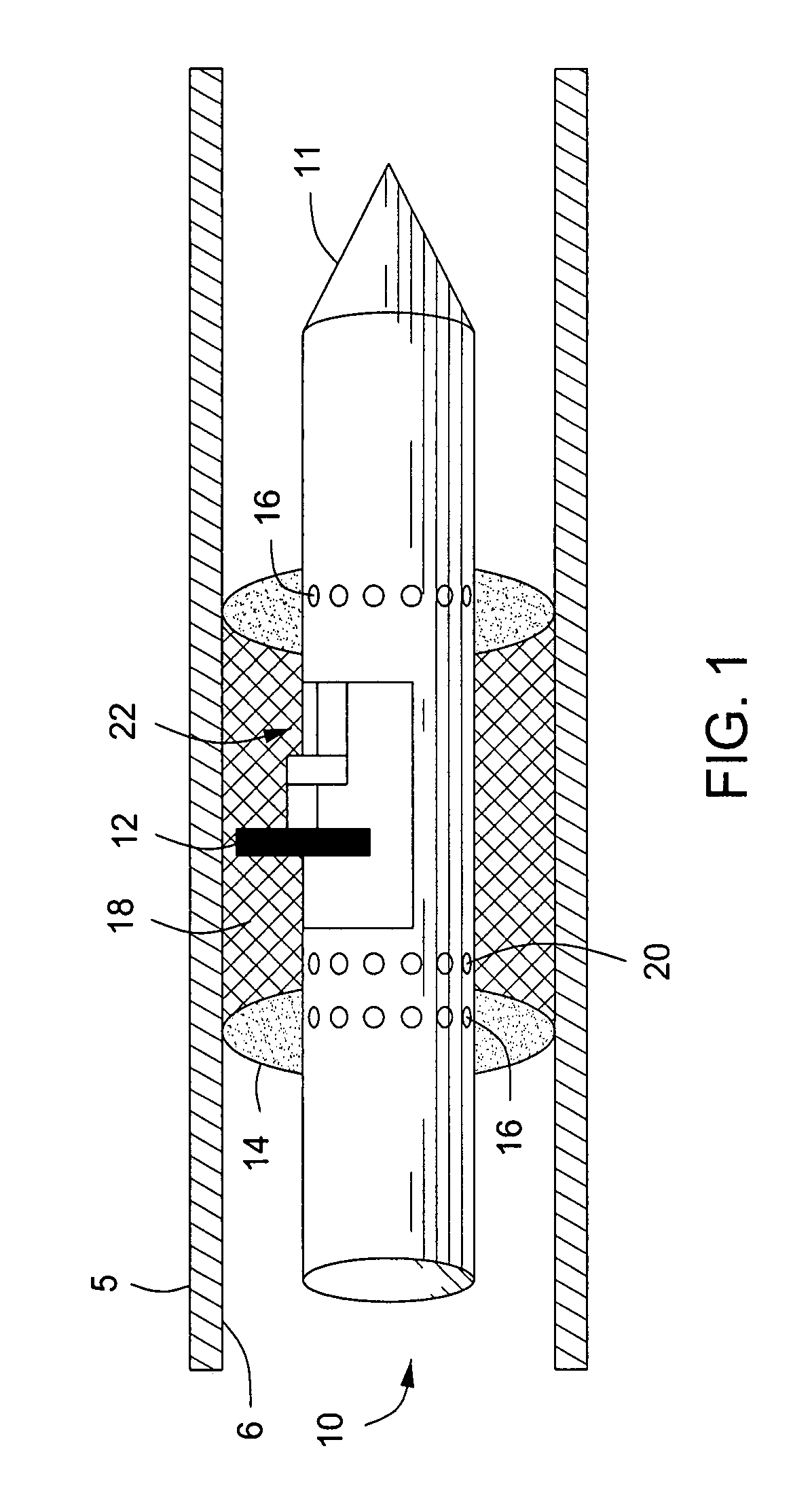

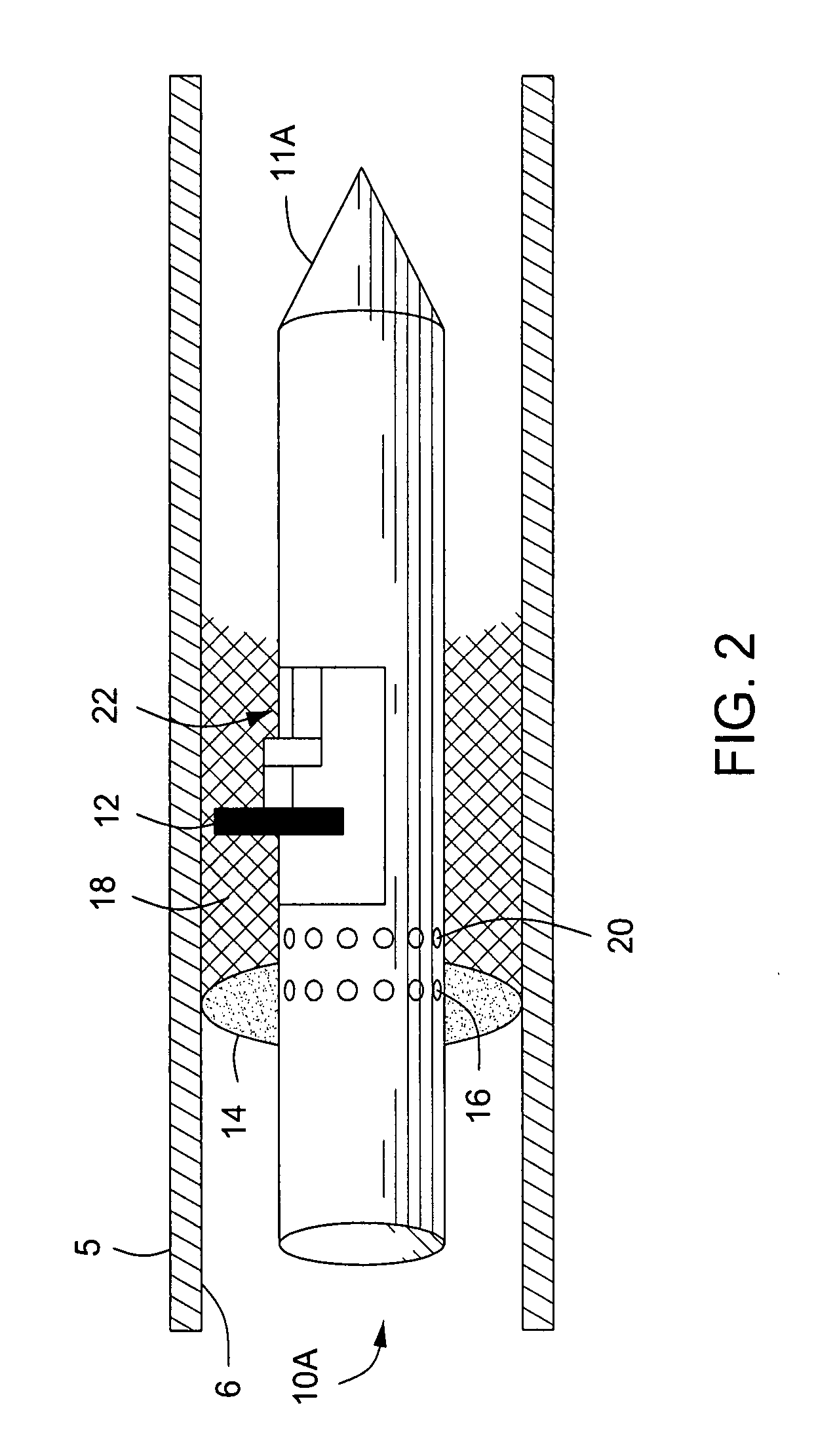

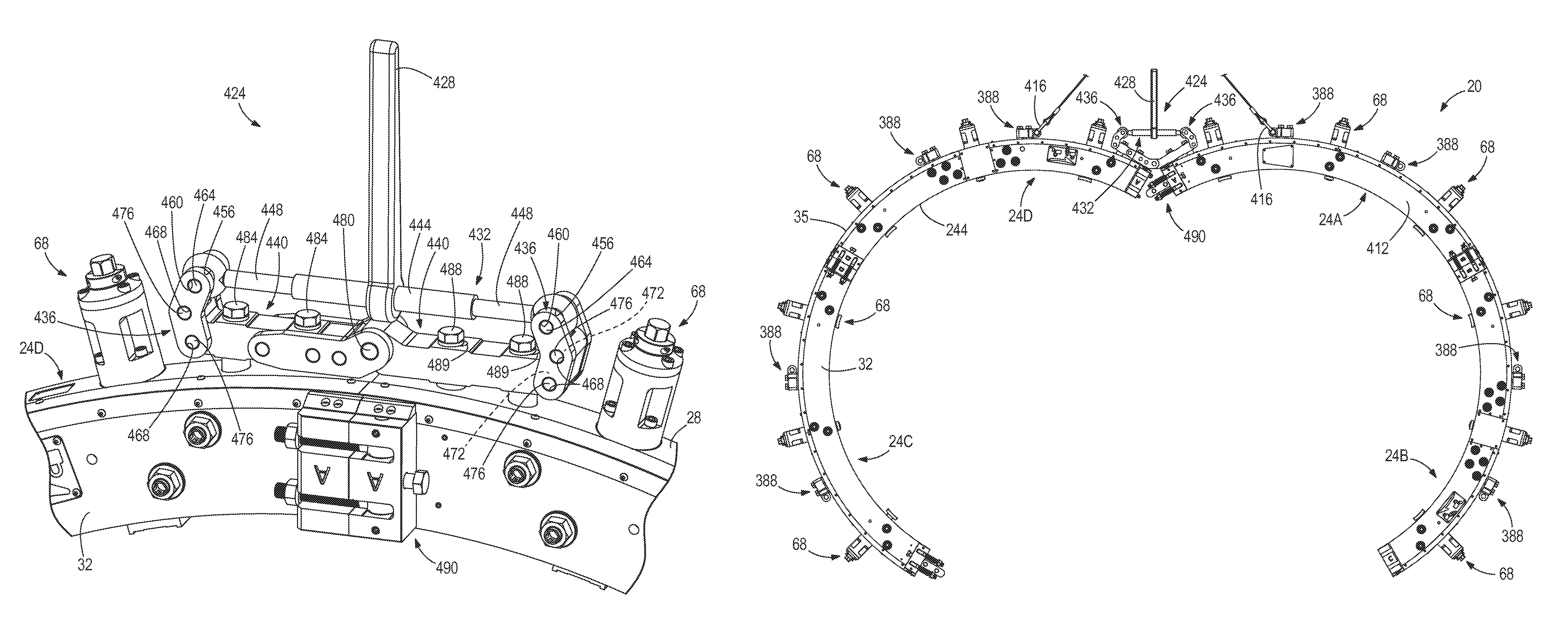

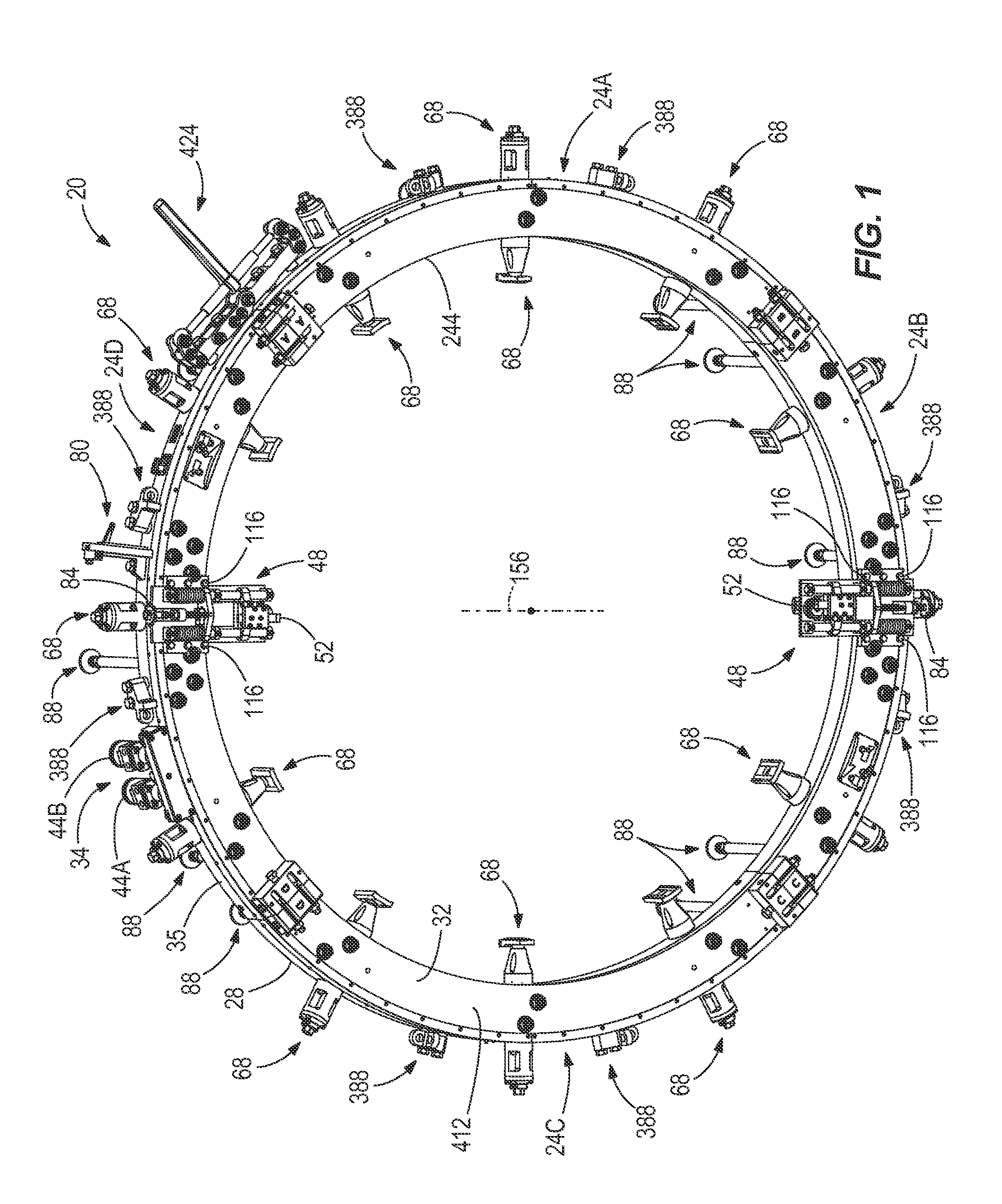

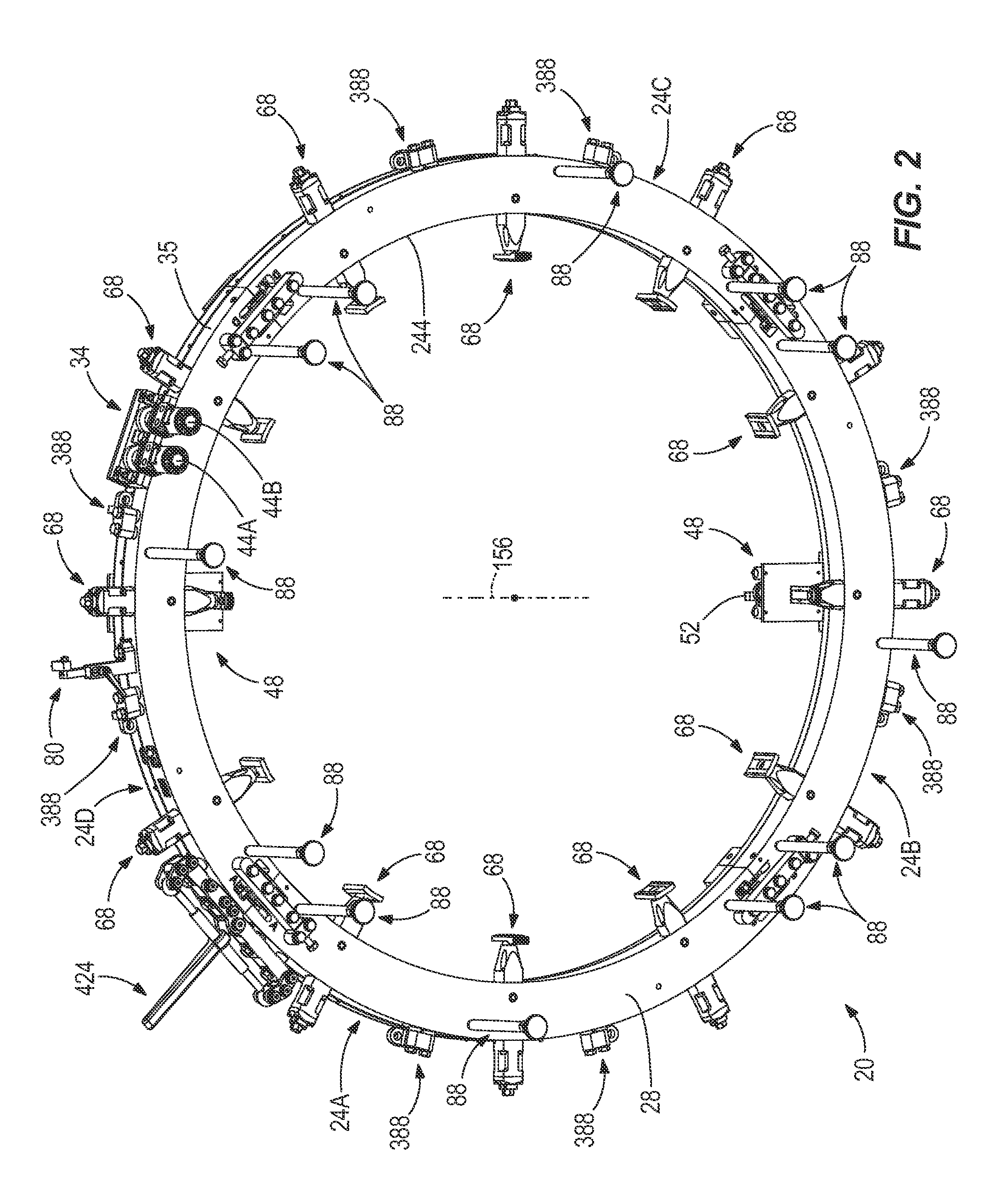

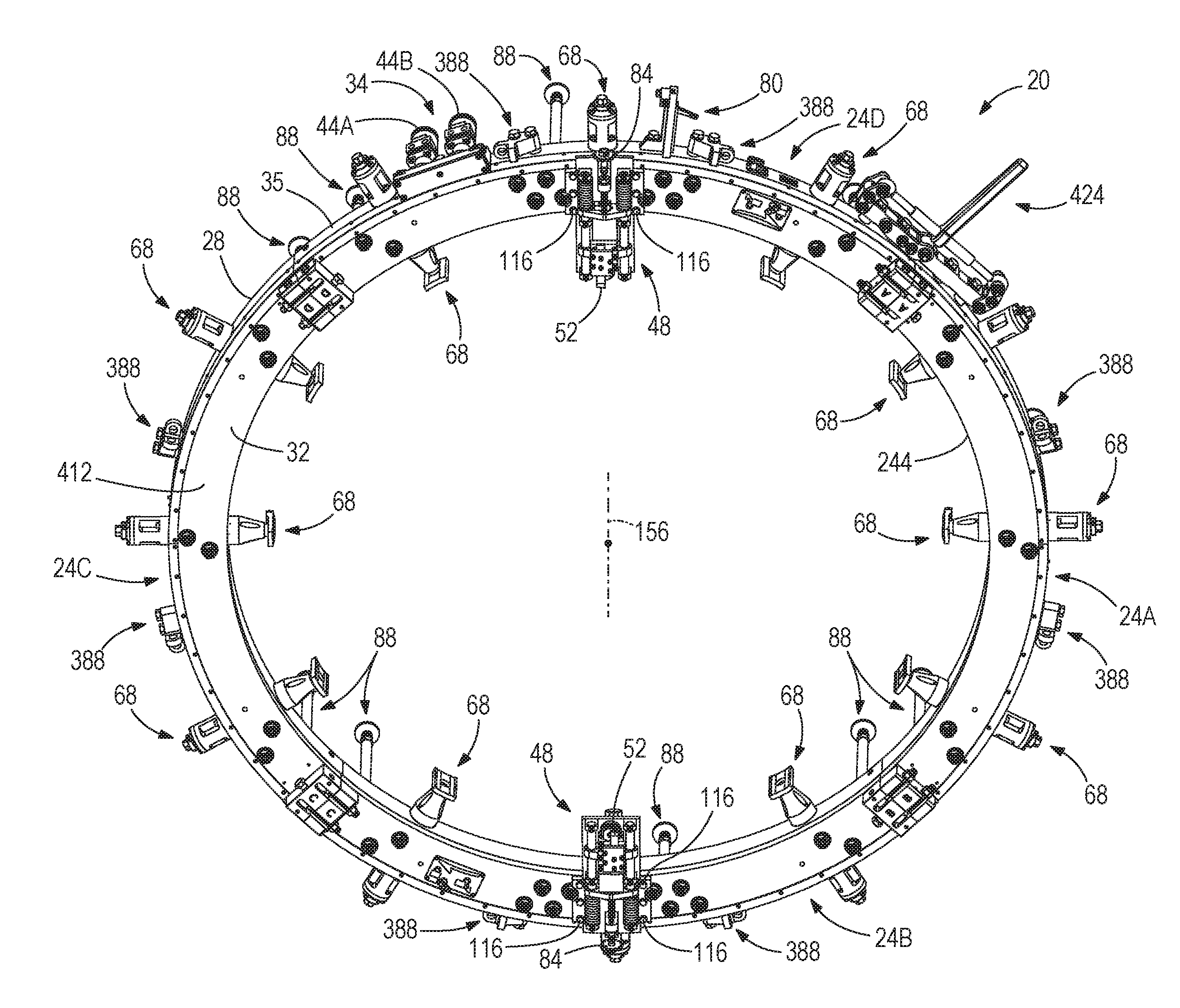

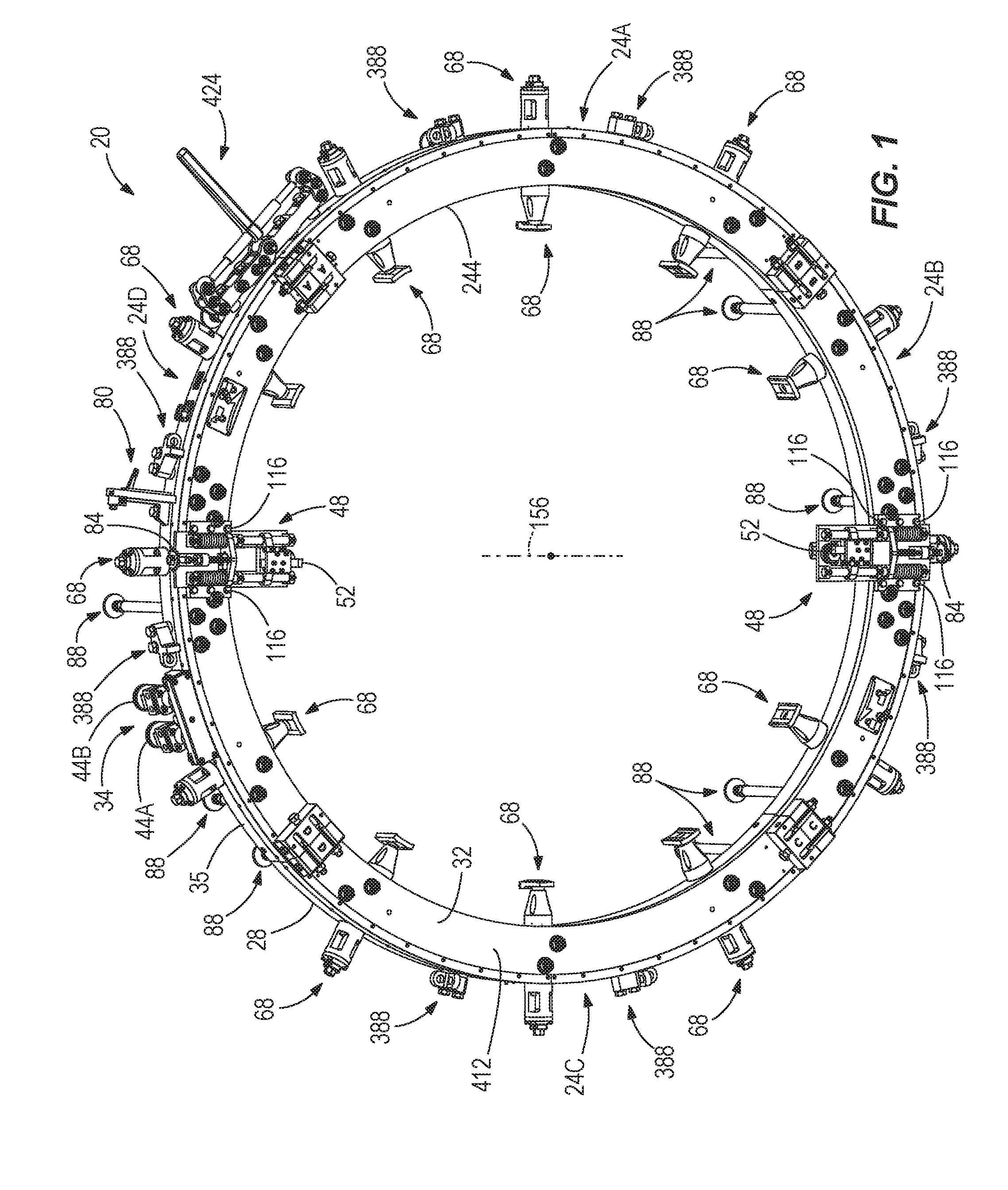

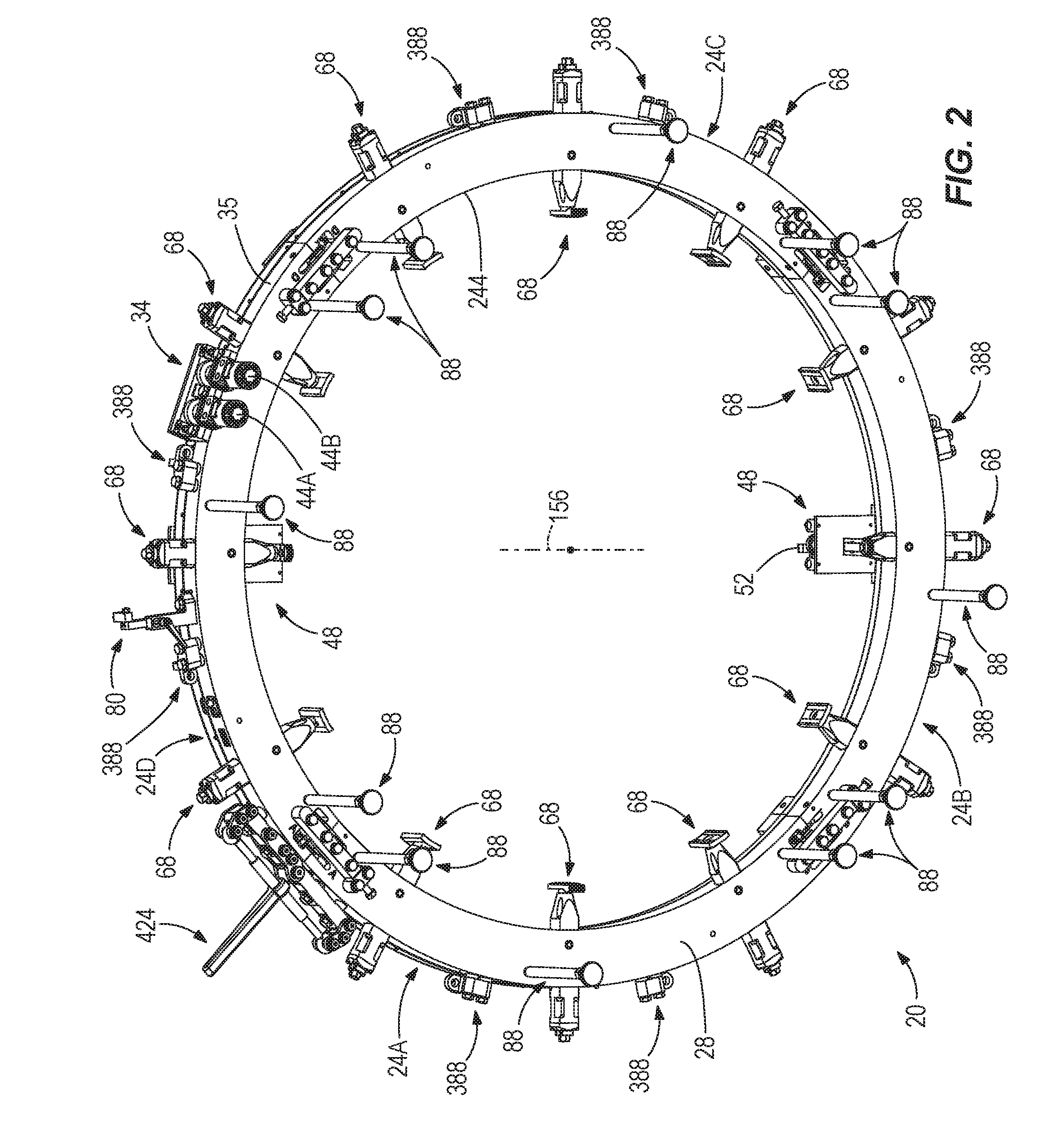

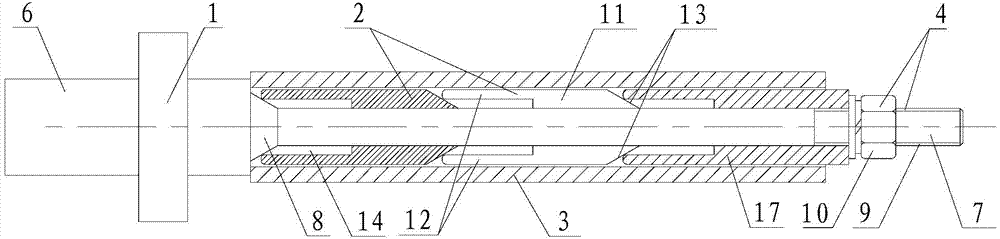

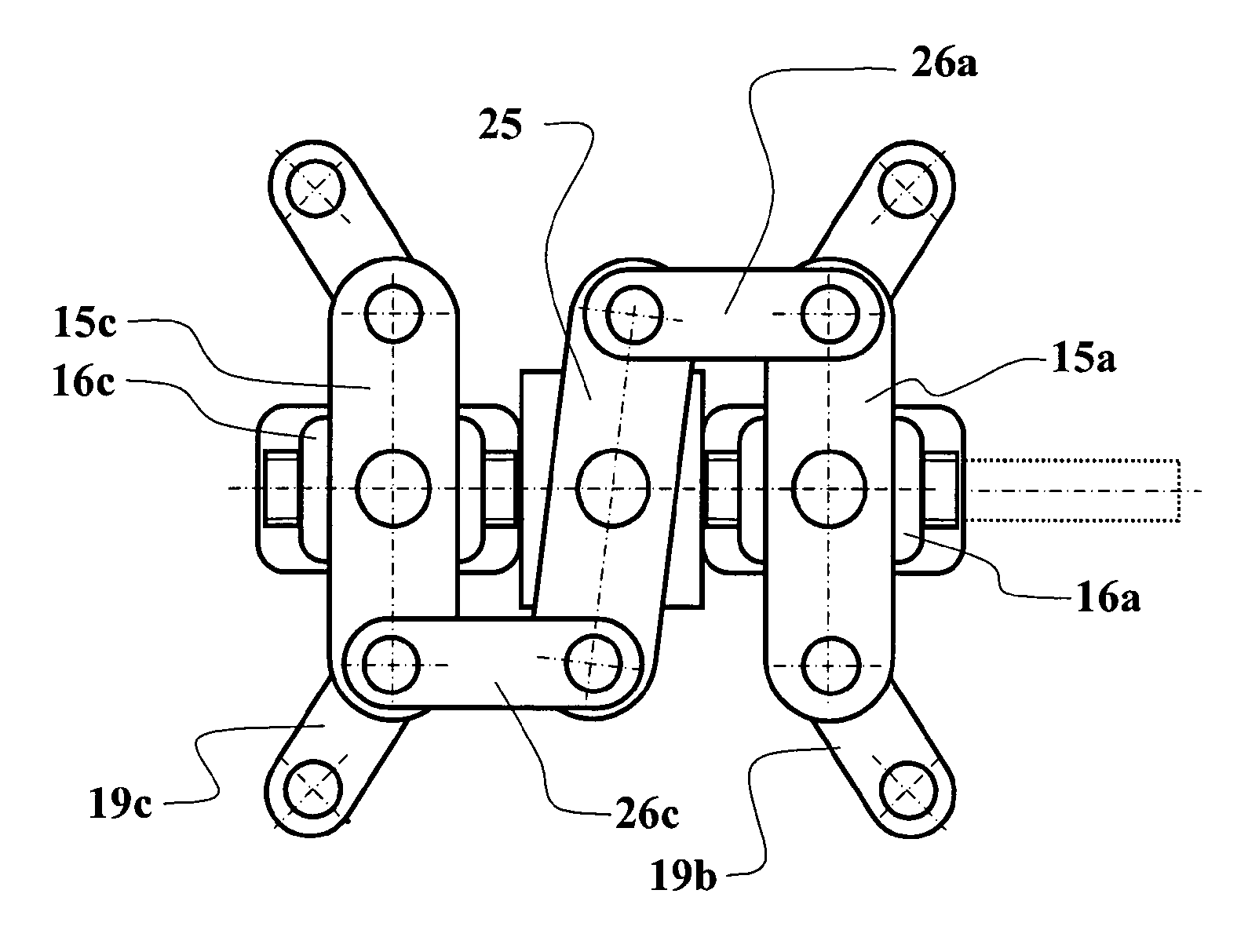

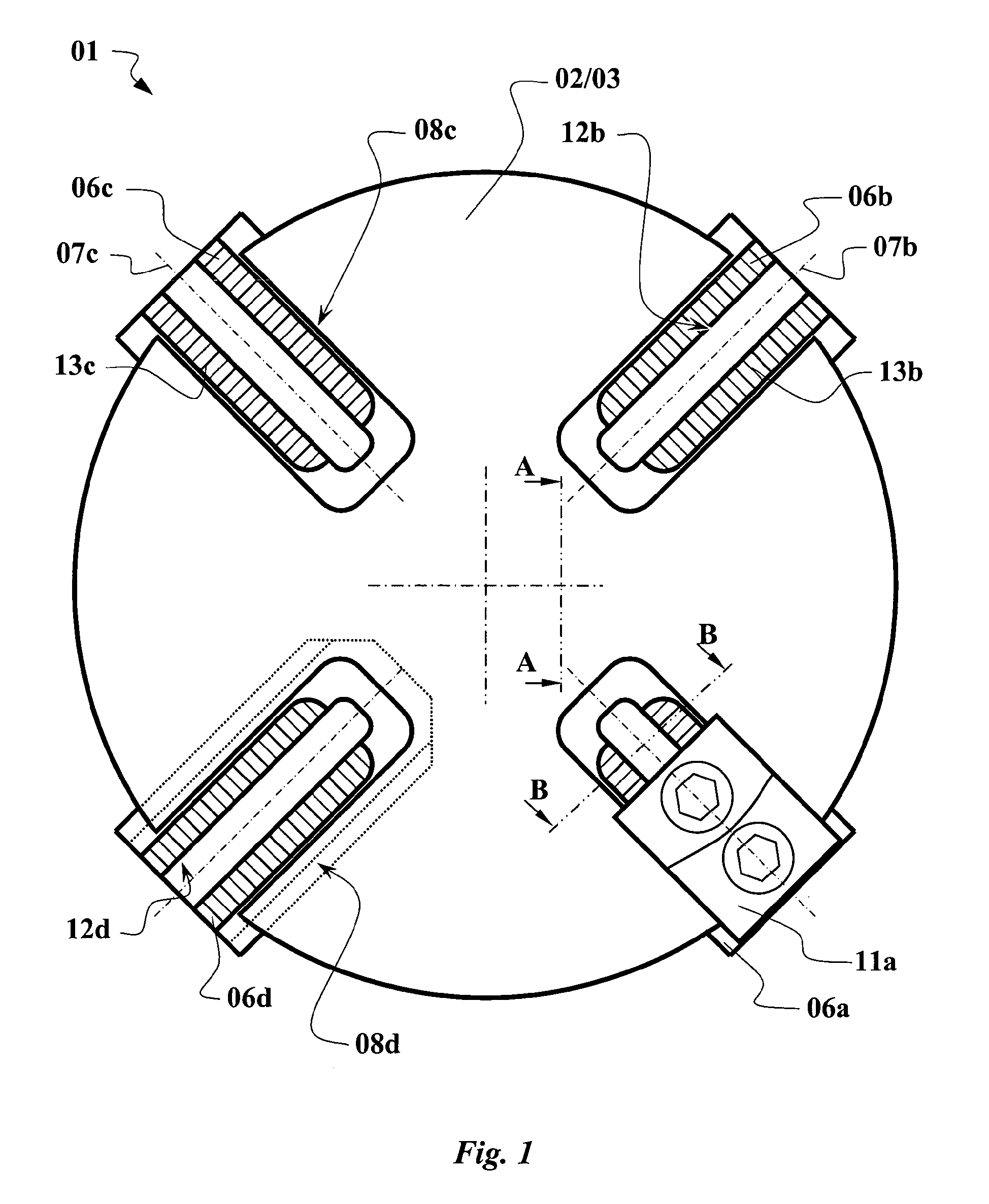

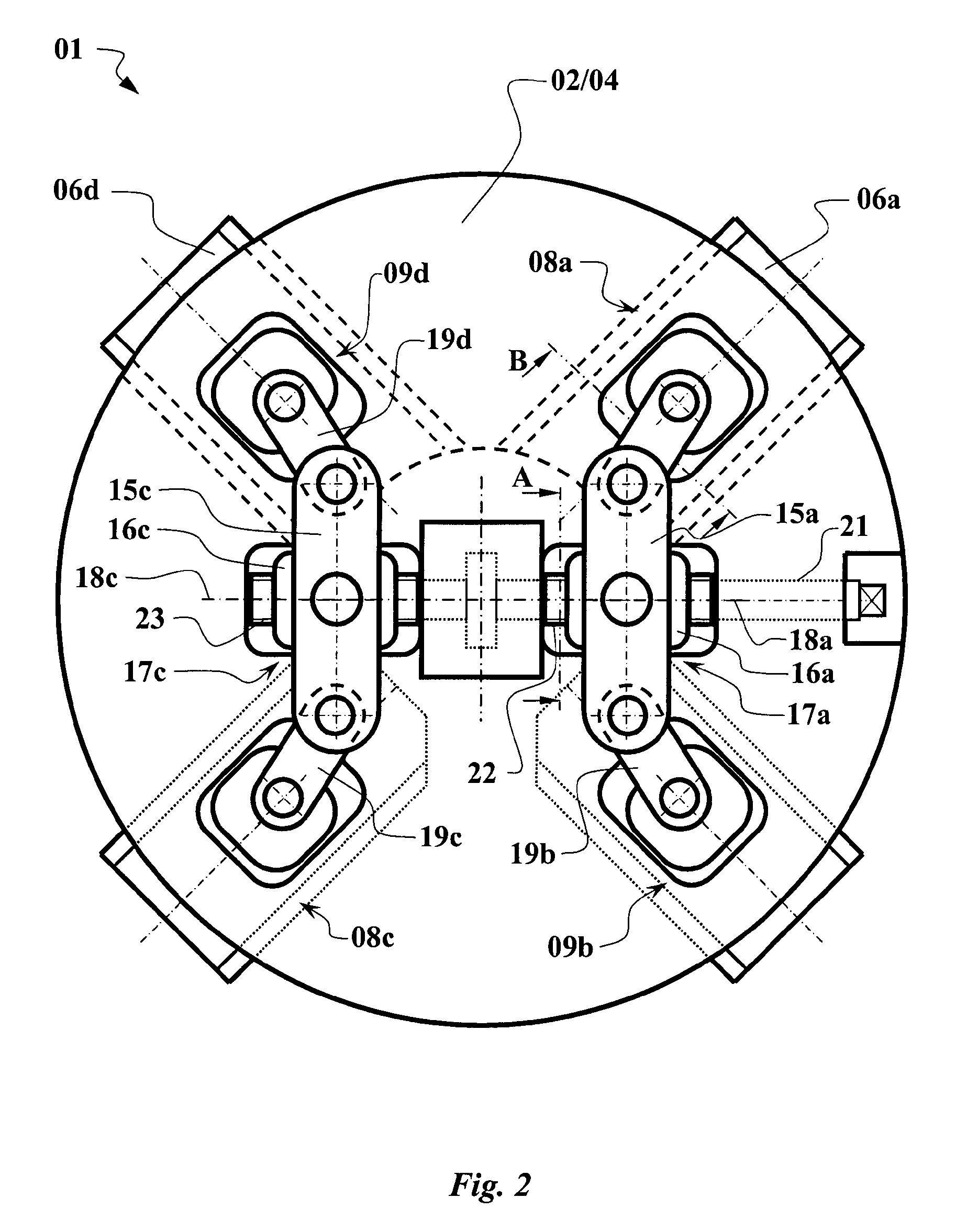

Pipe machining apparatuses and methods of operating the same

Pipe machining apparatuses are provided. In some aspects, a pipe machining apparatus may include a hinge to allow two sections of the pipe machining apparatus to move relative to one another. In another aspect, a support member may be provided to support a pipe machining apparatus on a surface. In a further aspect, a support member may be provided that allows lifting of a pipe machining apparatus in either a horizontal position or a vertical position.

Owner:ILLINOIS TOOL WORKS INC

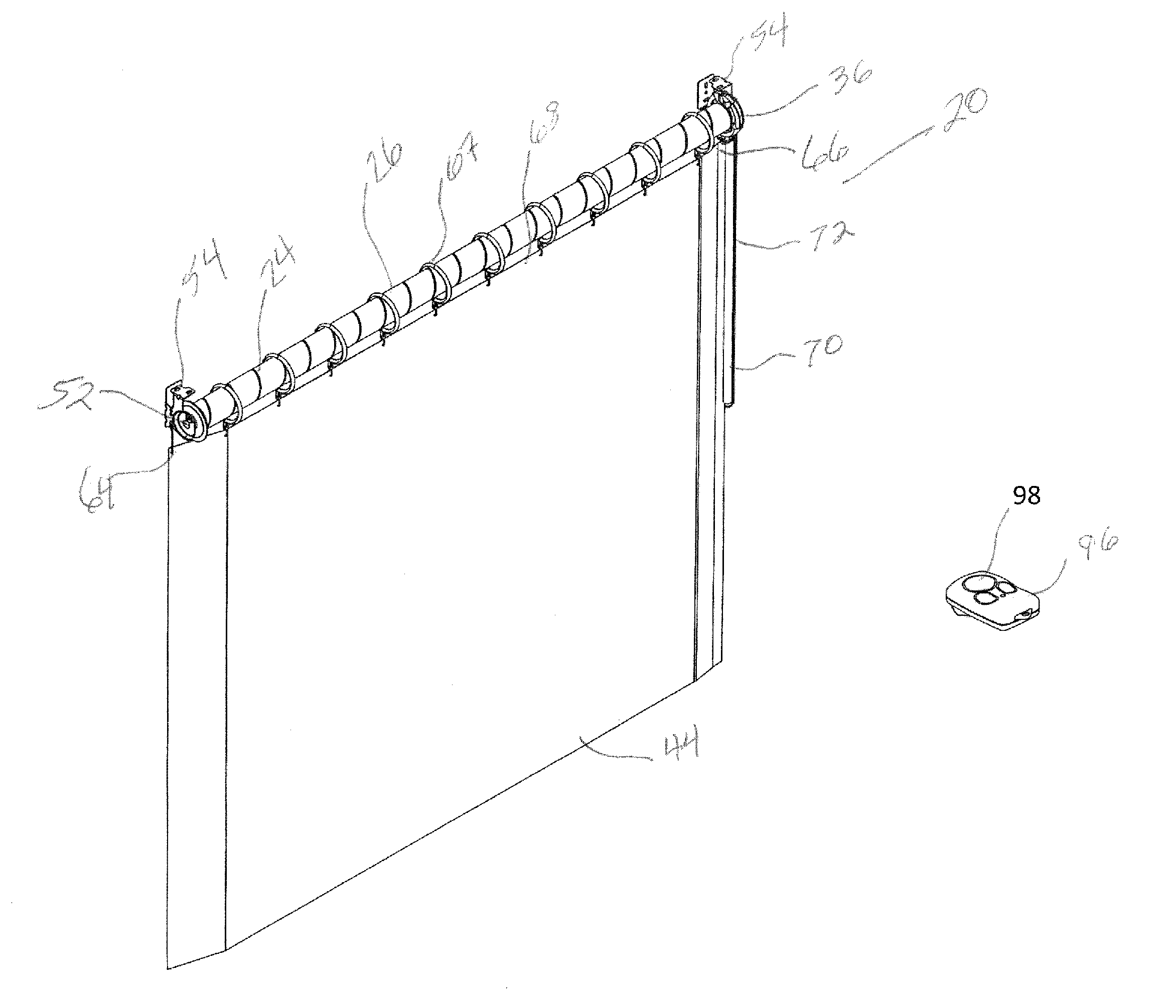

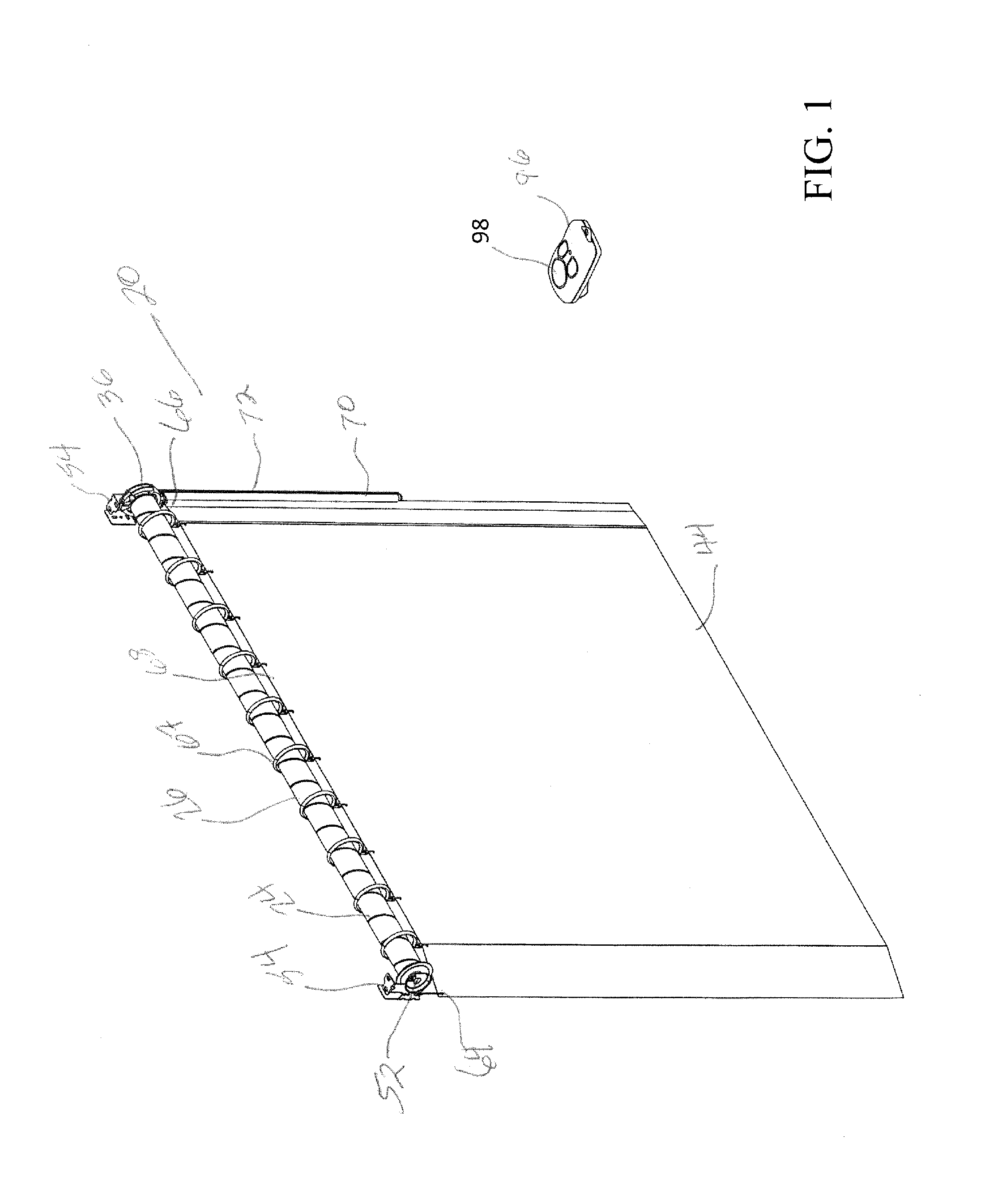

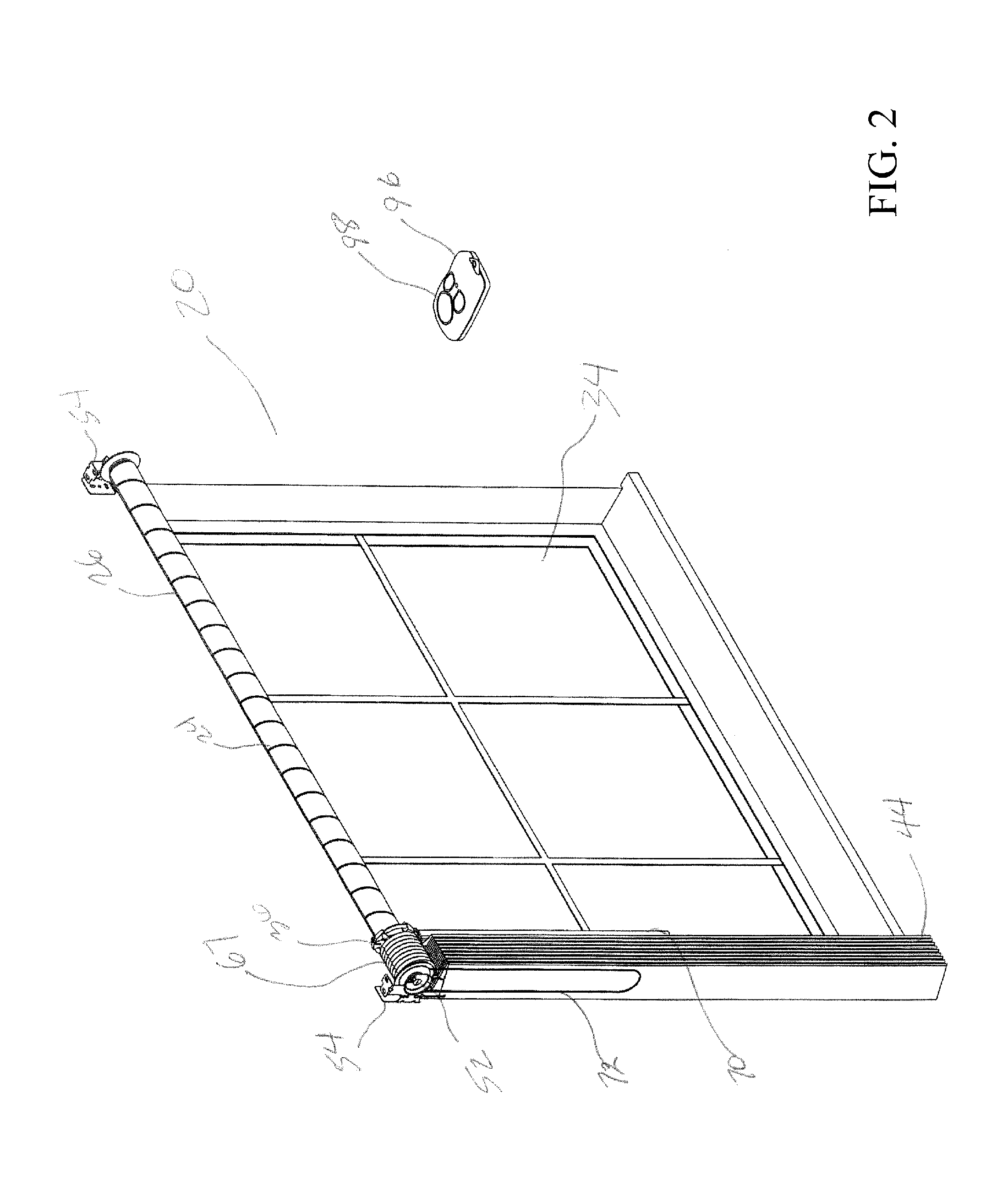

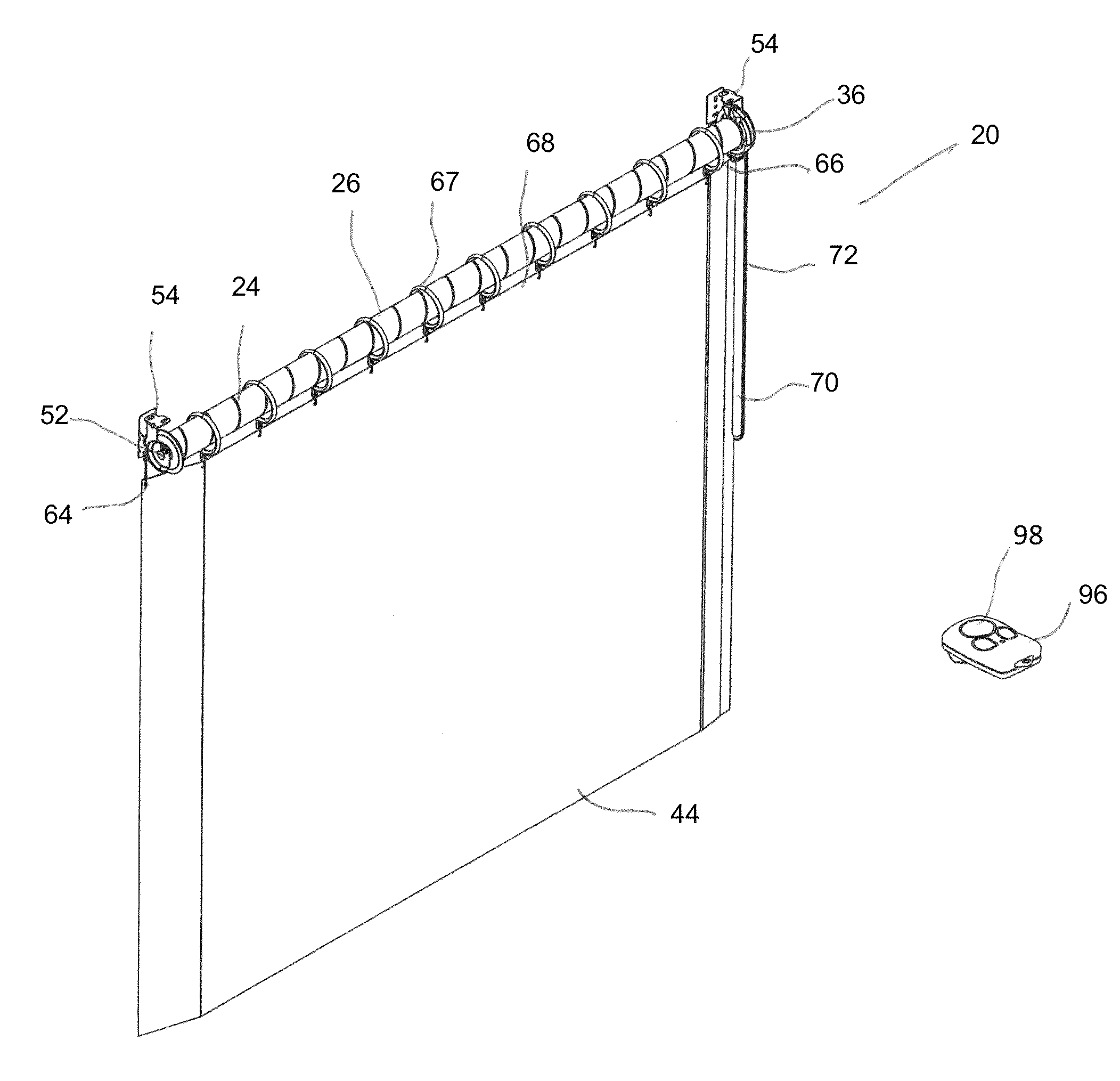

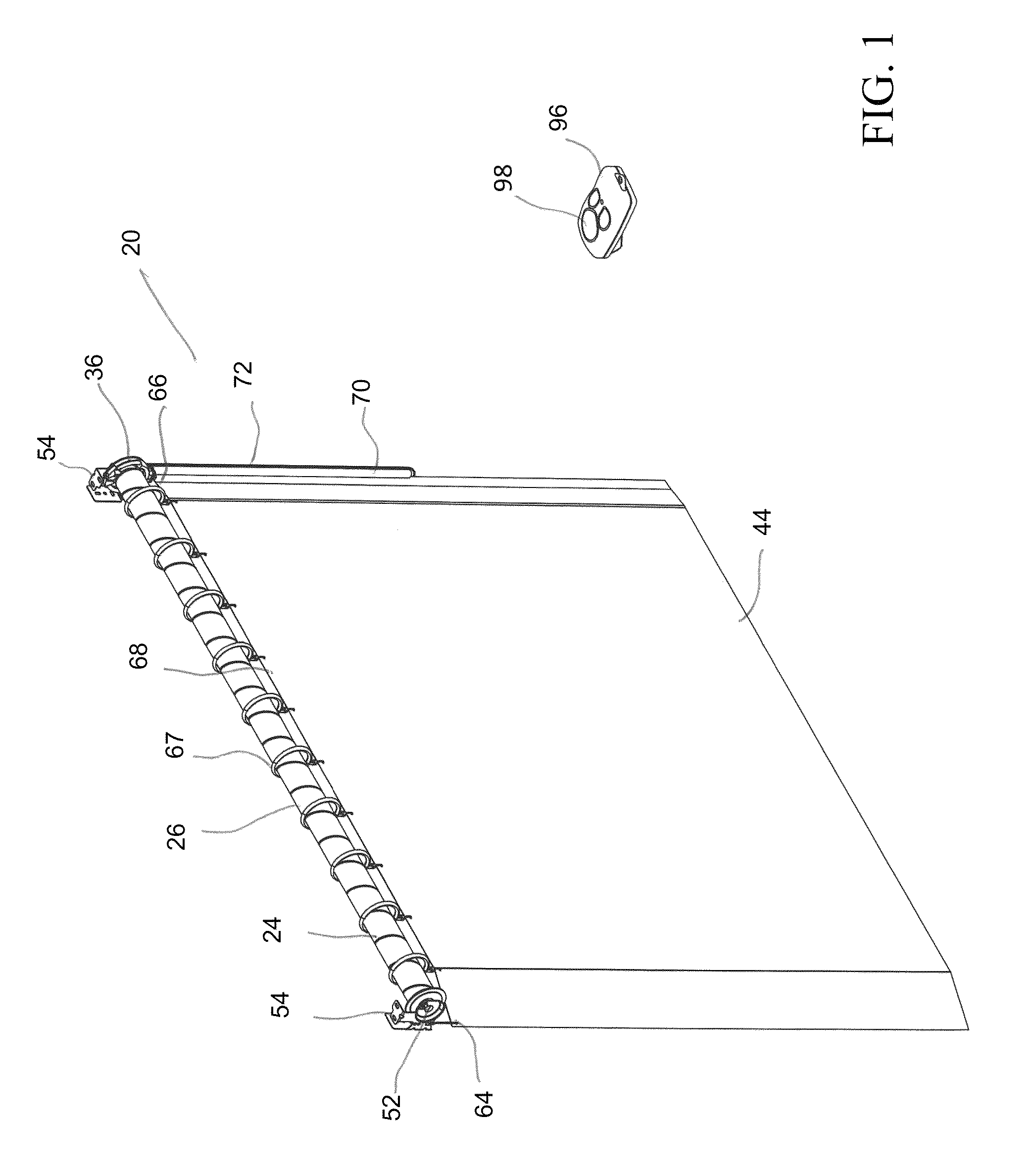

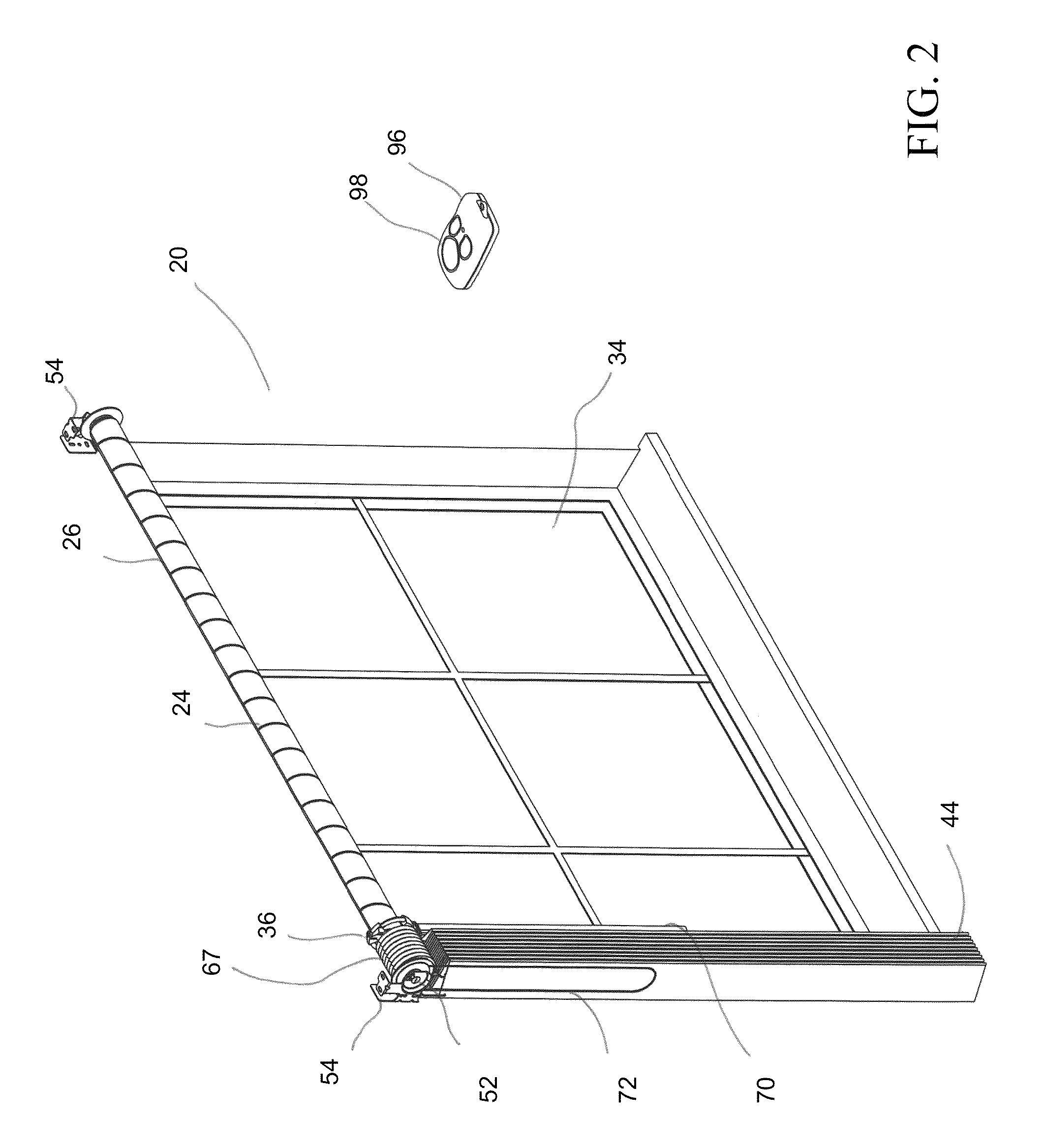

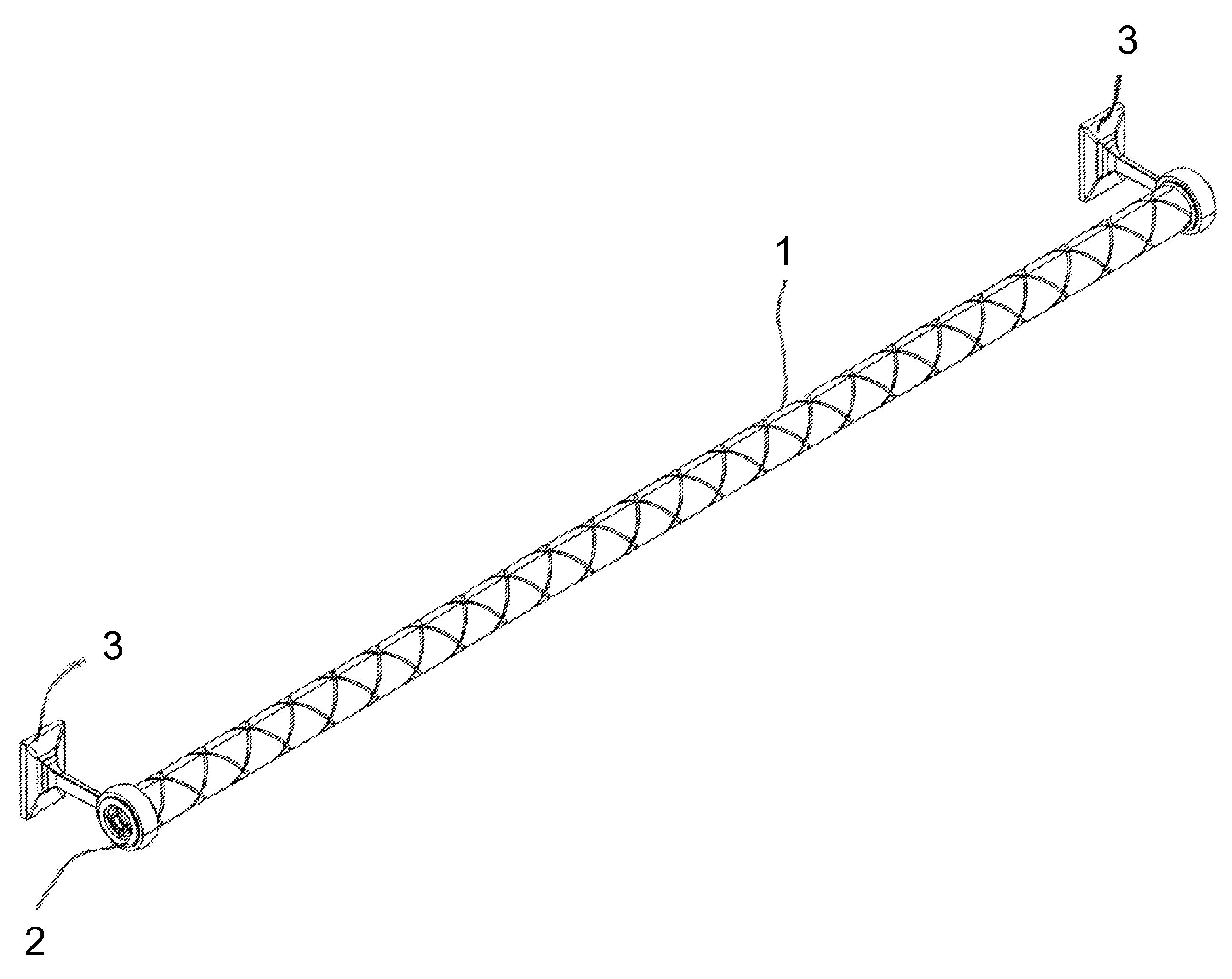

Method and apparatus for linked horizontal drapery panels having varying characteristics to be moved independently by a common drive system

A curtain assembly comprises a rotatable drive element wherein at least one helical guide structure is formed on, or into, the outer surface of the drive element. A drive attachment element having a structure that communicates with the helical guide structure to move the drive attachment element axially along the drive element when the drive element is rotated. Specific embodiments incorporate either a manual or motor-driven rotation assembly for rotating the drive element. Further specific embodiments involve a helical guide structure that comprises a helical groove and a structure that comprises a tooth that engages with the helical groove. Further specific embodiments relate to a system with linked horizontal drapery panels having varying characteristics that are moved independently by a common drive system.

Owner:QMOTION

Optimized machining process for cutting tubulars downhole

Owner:BAKER HUGHES INC

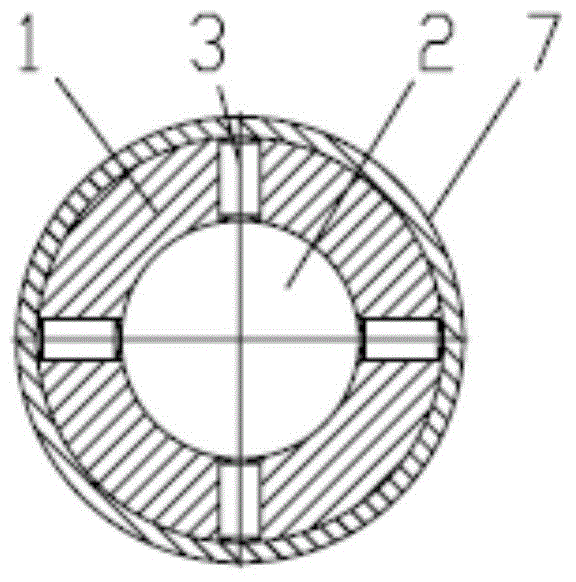

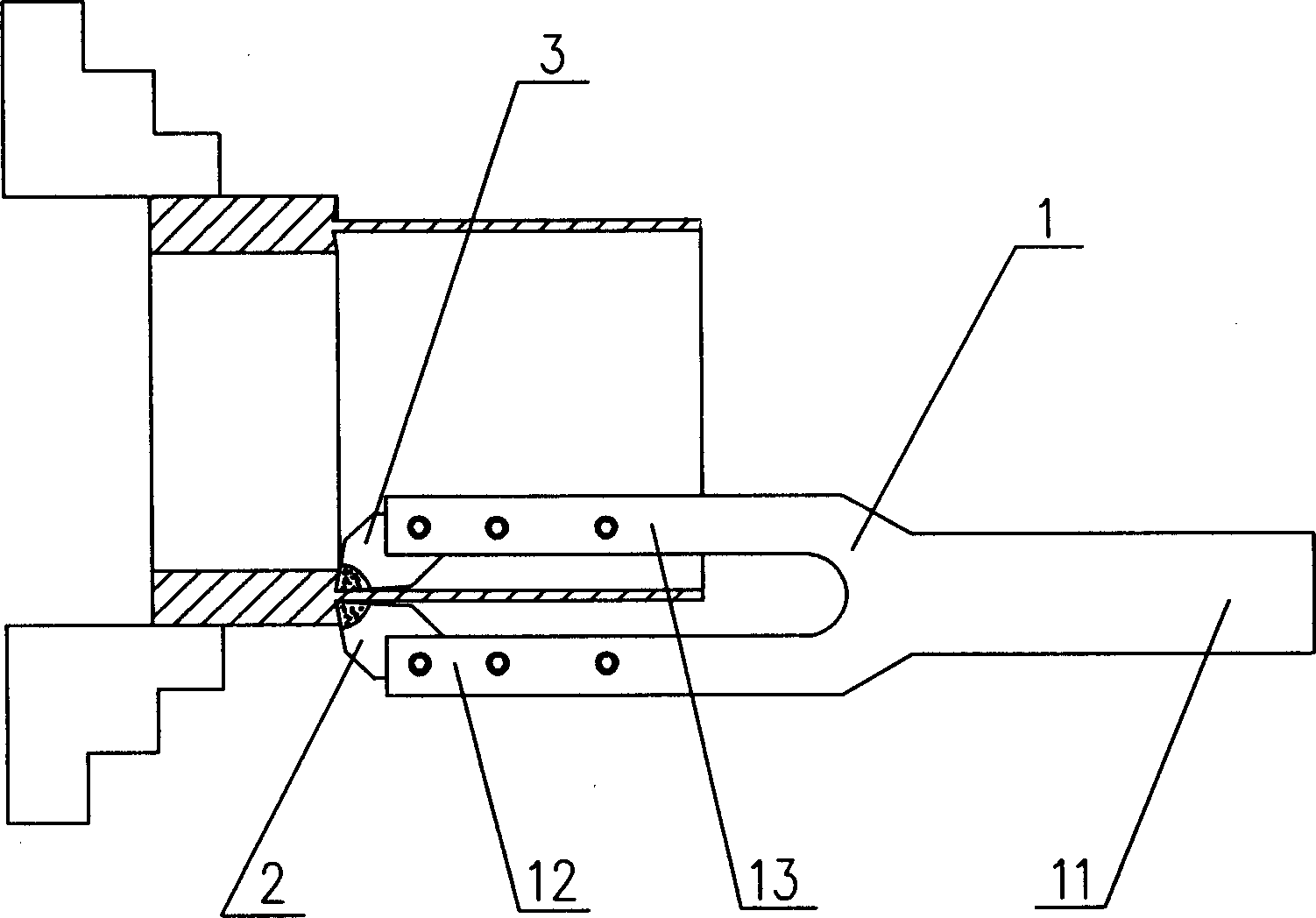

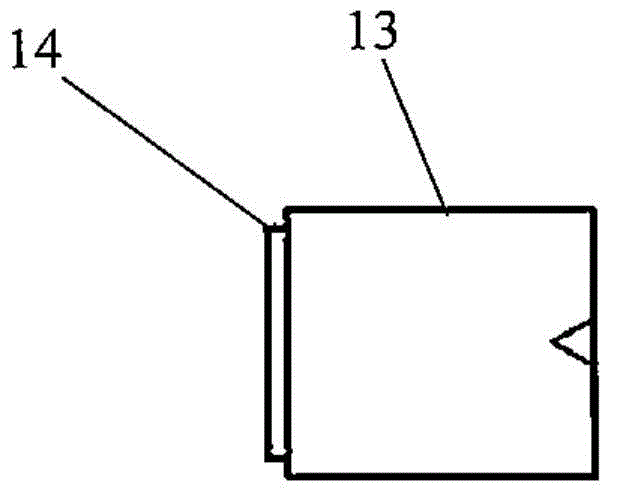

Manual self-centering clamp for thin-walled part

InactiveCN104858463AEasy loading and unloadingLoading and unloadingWorkpiecesBoring/drilling apparatusCircular coneEngineering

Owner:张鸿来

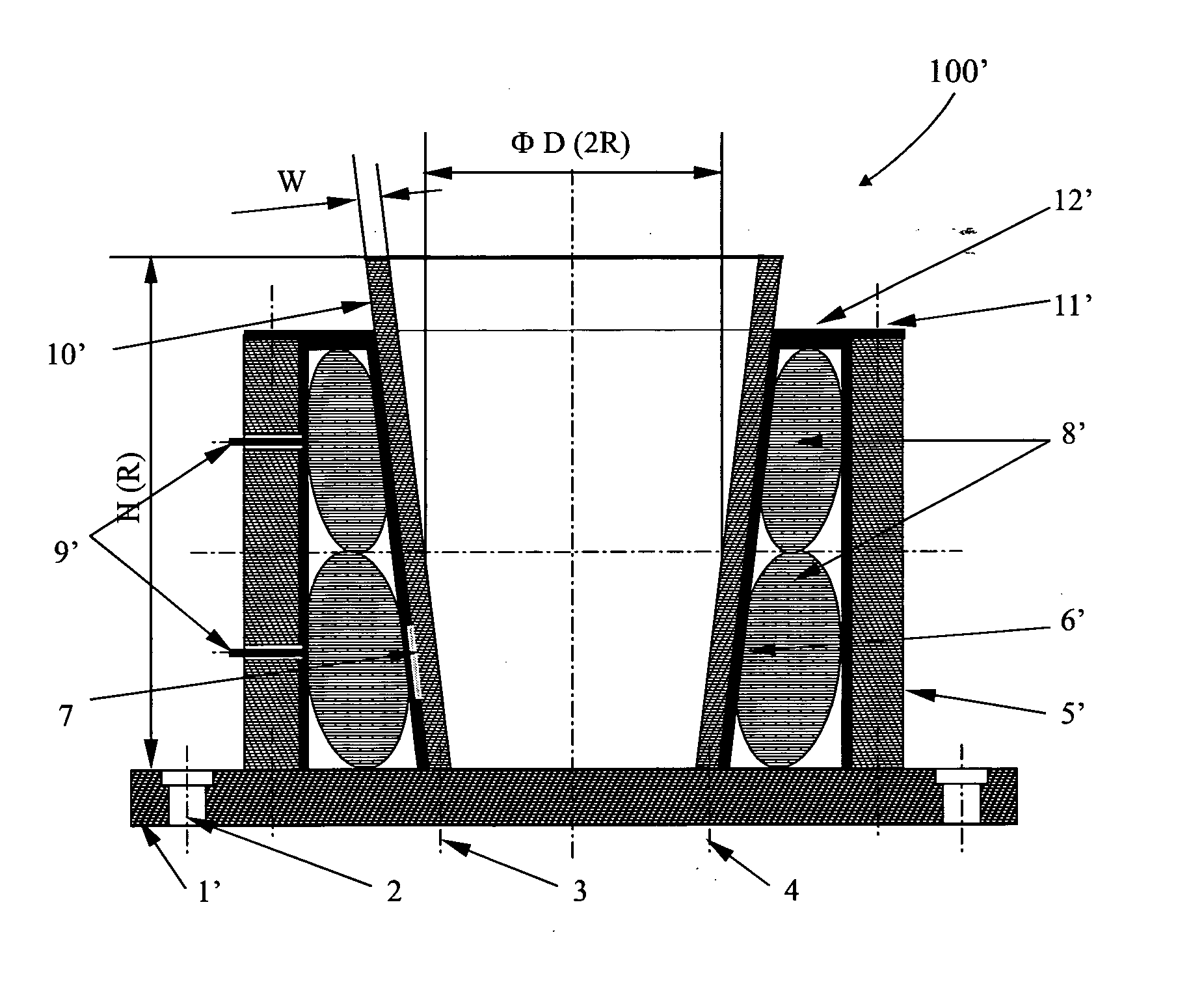

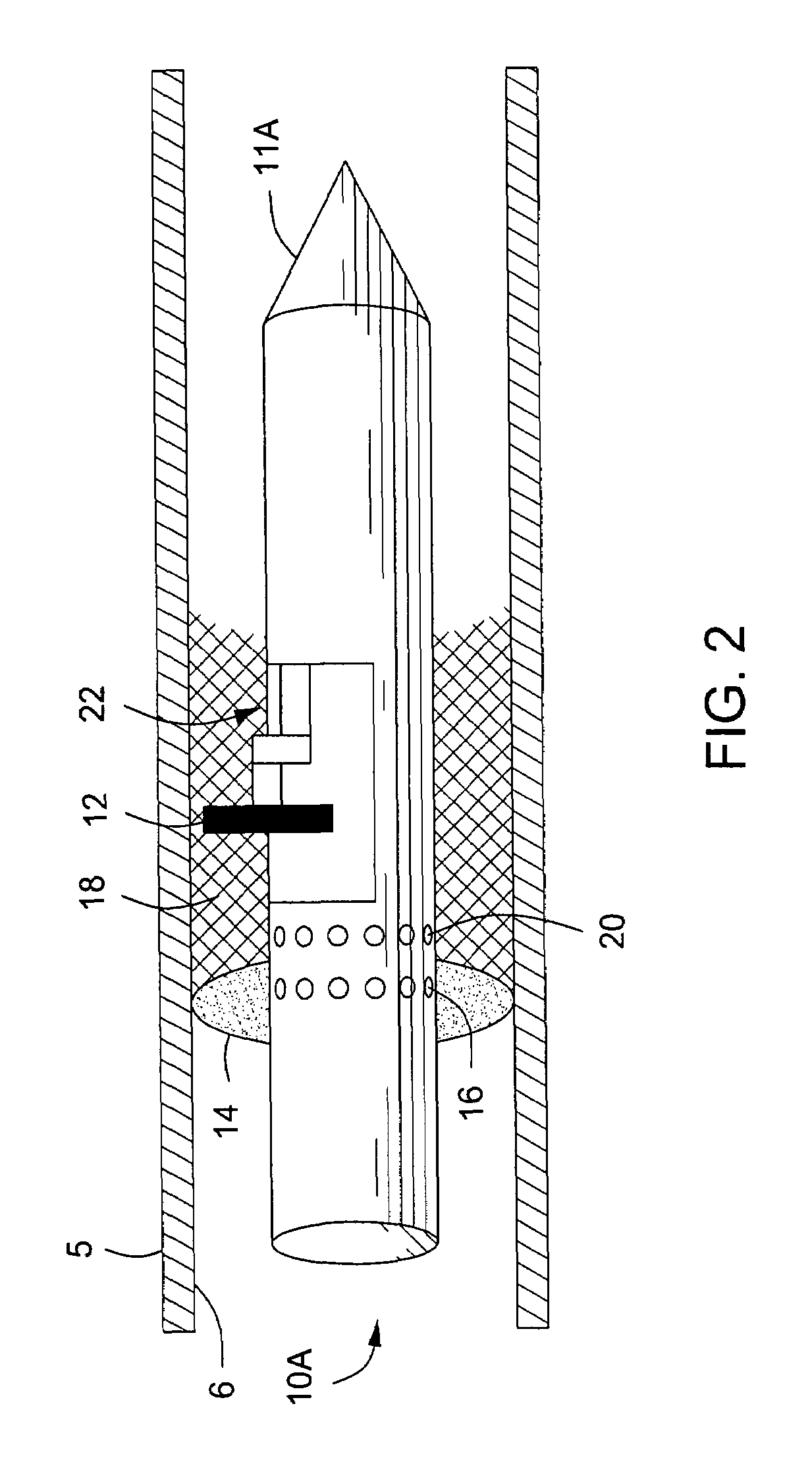

Adaptive design of fixture for thin-walled shell/cylindrical components

InactiveUS20100164187A1Satisfy the demandAvoid exponential growthWorkpiecesBoring/drilling apparatusSurface finishAdaptive design

A group of fixtures for thin-walled shell / cylindrical components (10) while they are being machined internally and externally, has a mounting base (1) having mounting holes, positioning pins and clamps to locate one end of the thin-walled component. A supporting arbour or cylinder (5) is fixed in the base. A circular lid (12) is fixed to the supporting arbour or cylinder and has a wedged step to locate the other end of the cylindrical component for internal and external machining, or the major open end of shell component for internal machining. A pair of modified vehicle wheel inner tubes (8) are disposed around the supporting arbour or cylinder. A multi-layered sacrificial liner (7) surrounds the pressure element and is adapted to fit between it and the thin-walled components. When properly inflated according to the design and validation procedure, the fixture adaptively holds the thin-walled components for machining, with sufficient supporting rigidity and dynamic stability, so as to maintain the machining precision and surface finish to an acceptable engineering standard. Furthermore, a reasonable and practical design and validation procedure is supplied, easily adapted to different sized thin-walled shell / cylindrical components.

Owner:UNIV OF SHEFFIELD

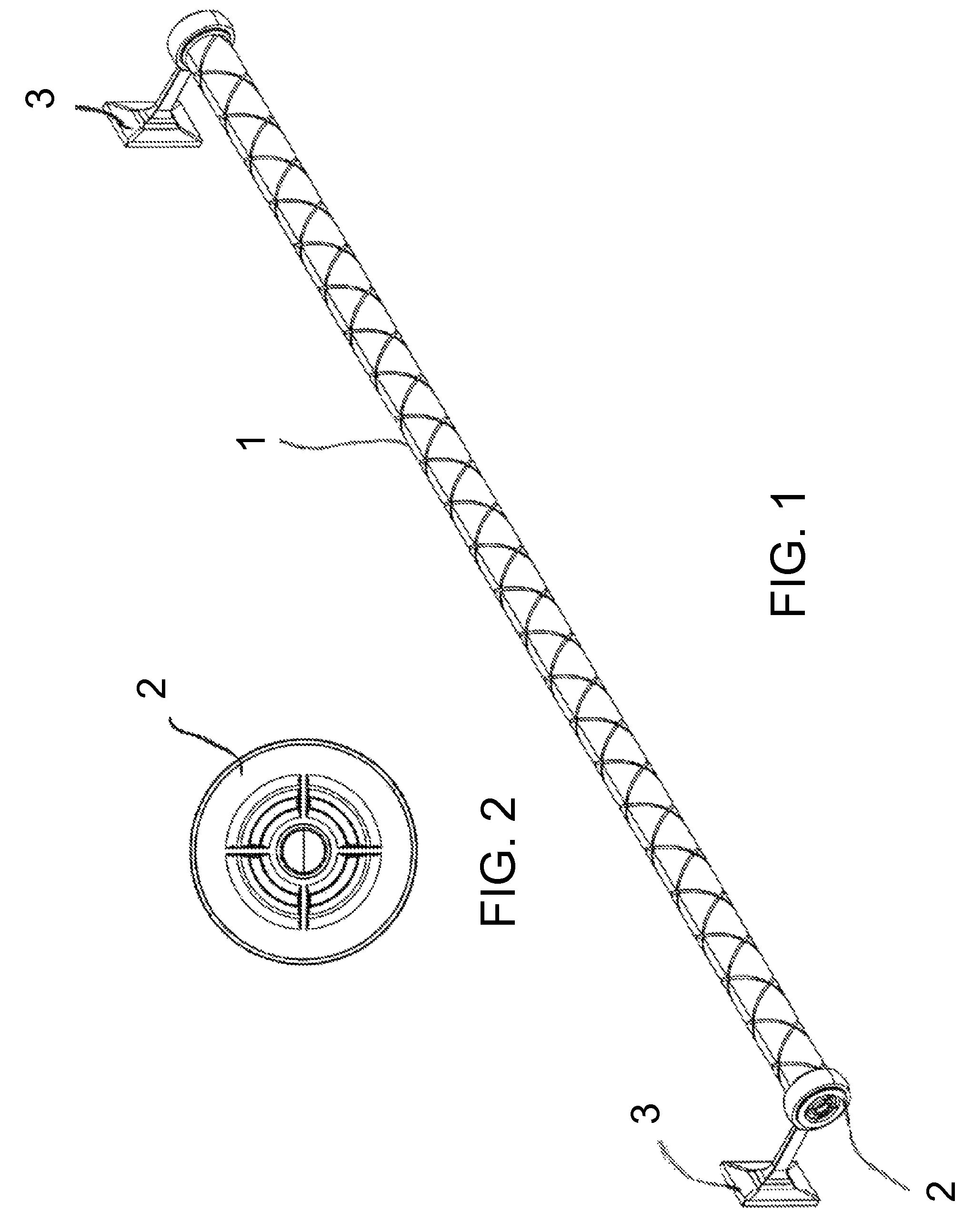

Rotatable drive element for moving a window covering

A curtain assembly comprises a rotatable drive element wherein at least one helical guide structure is formed on, or into, the outer surface of the drive element. A drive attachment element having a structure that communicates with the helical guide structure to move the drive attachment element axially along the drive element when the drive element is rotated. Specific embodiments incorporate either a manual or motor-driven rotation assembly for rotating the drive element. Further specific embodiments involve a helical guide structure that comprises a helical groove and a structure that comprises a tooth that engages with the helical groove.

Owner:CURRENT PROD CORP

Pipe machining apparatuses and methods of operating the same

Owner:ILLINOIS TOOL WORKS INC

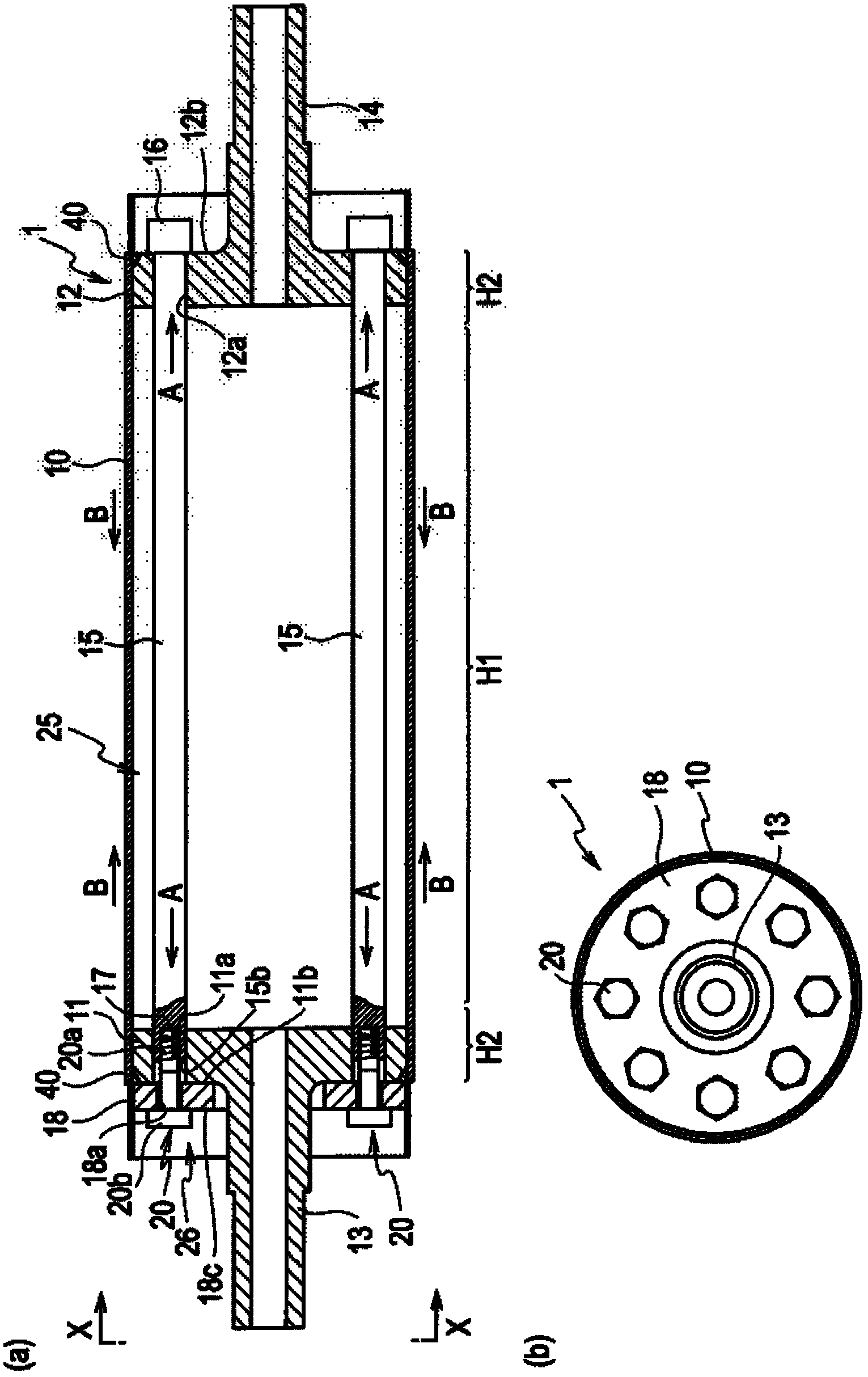

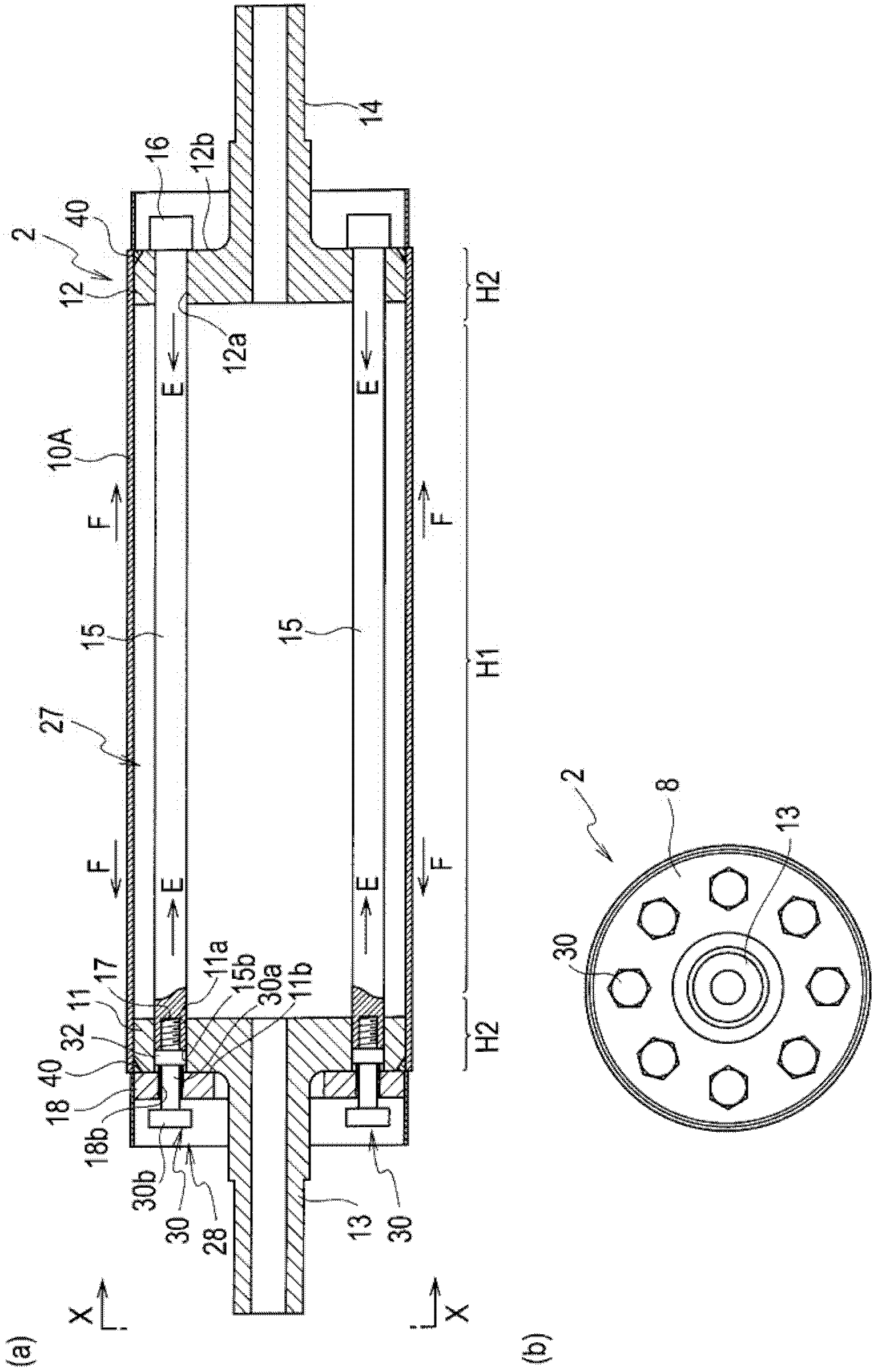

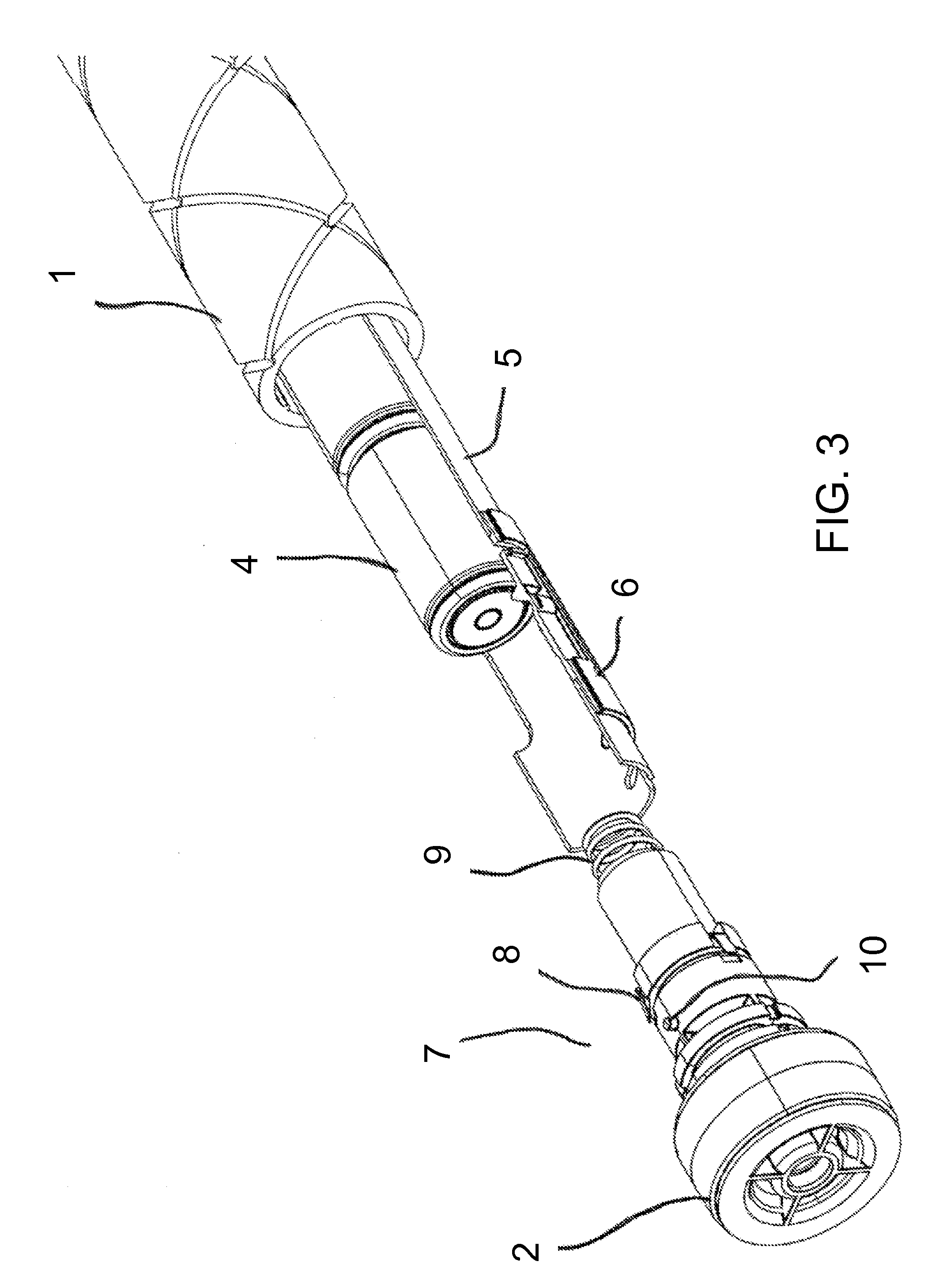

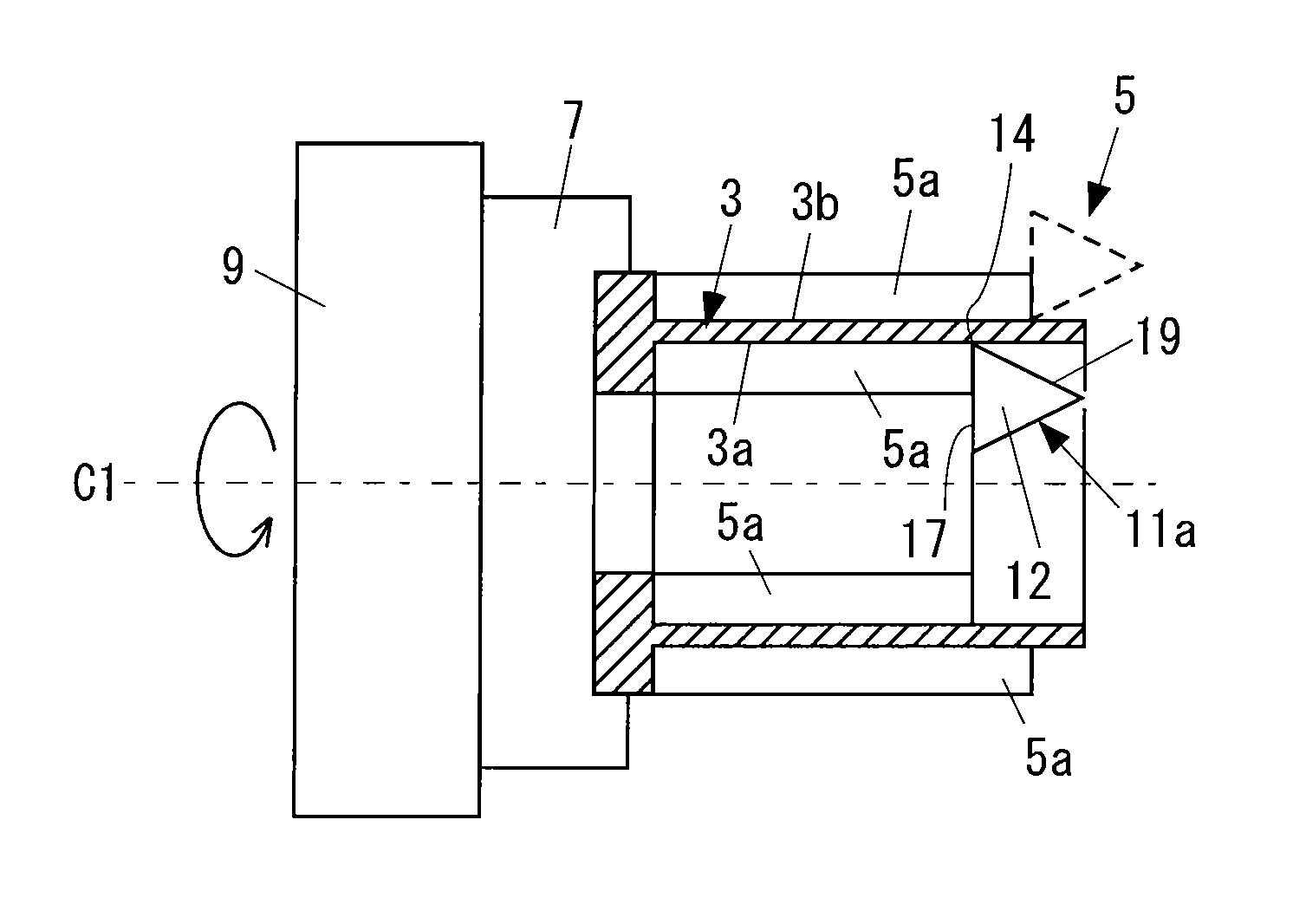

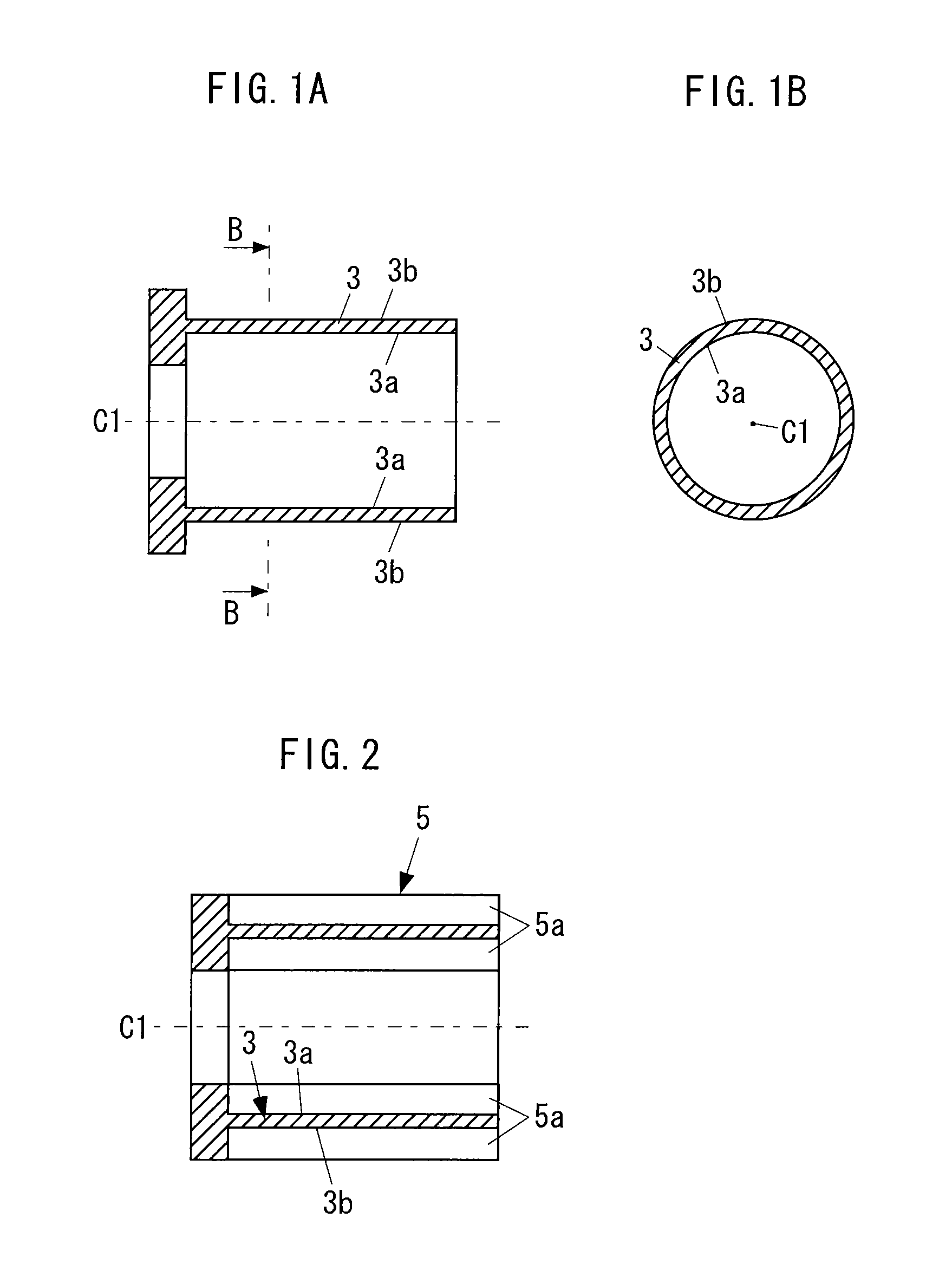

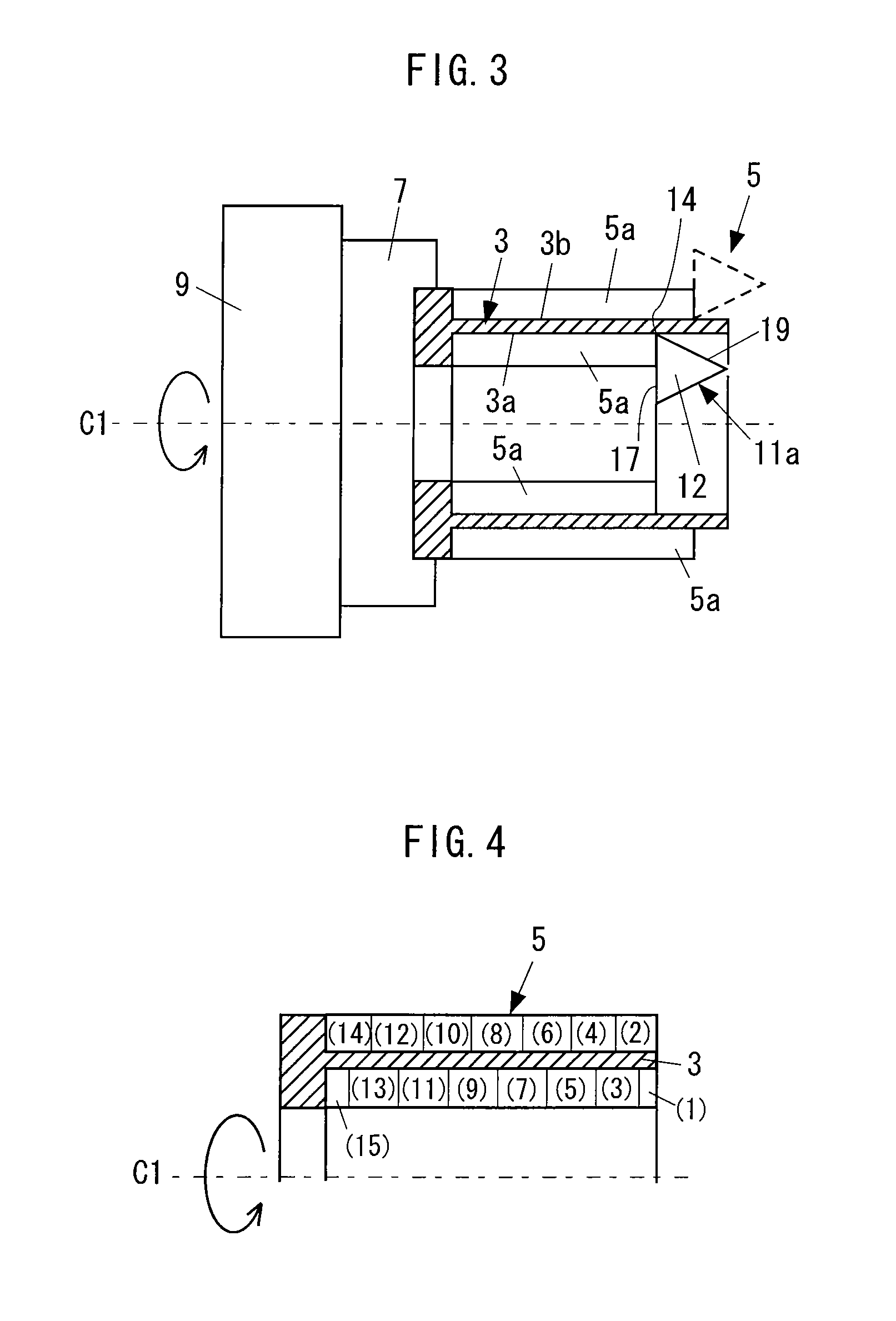

Jig for holding thin cylindrical work, method for processing thin cylindrical work, and sheet film forming roll

InactiveCN102427903AImprove cylindricityImprove surface roughnessSleeve/socket jointsWorkpiecesSheet filmEngineering

A holding jig (1, 2, 3) for a thin cylindrical work (W) includes a holding member (10, 10A, 10B) which holds the work (W) from an inner peripheral side and a diameter changing unit (25, 27) which changes a diameter of the holding member (10, 10A, 10B). The holding member (10, 10A, 10B) is made of metal and has a cylindrical shape and an elastically expandable or contractible diameter. The holding member (10, 10A, 10B) is configured with an outside diameter of the holding member (10, 10A, 10B) being held smaller than an inside diameter of the work (W) at the time of insertion into an inner periphery of the work (W) and being expanded after inserted into the inner periphery of the work (W) to hold the work (W) from an inner peripheral side of the work (W) with an outer peripheral surface in close contact with an entire inner peripheral surface of the work (W). The diameter changing unit (25, 27) applies at least one of an axial external force in a compressing direction or an axial external force in a tensile direction to both ends of the holding member (10. 10A, 10B) to change the diameter of the holding member (10, 10A, 10B).

Owner:TOSHIBA MASCH CO LTD

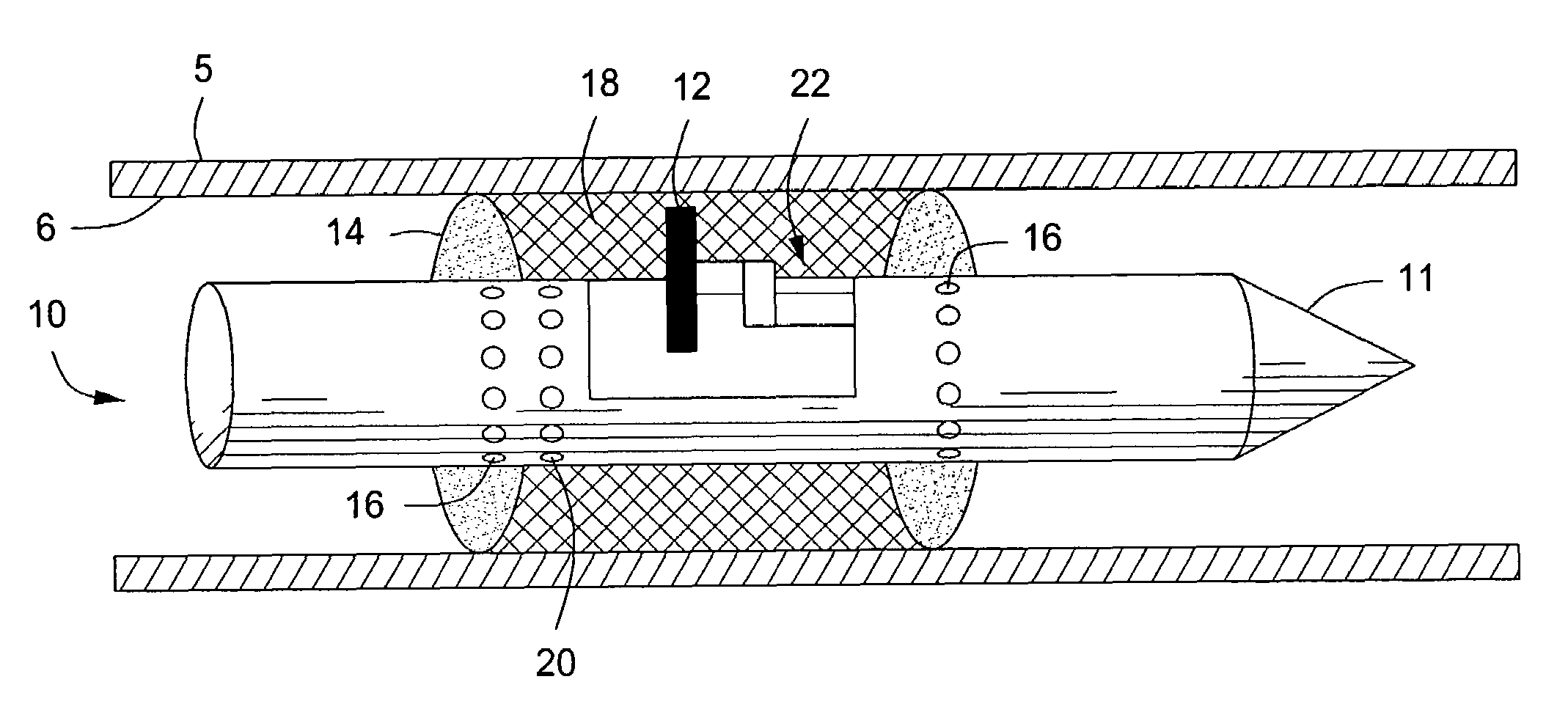

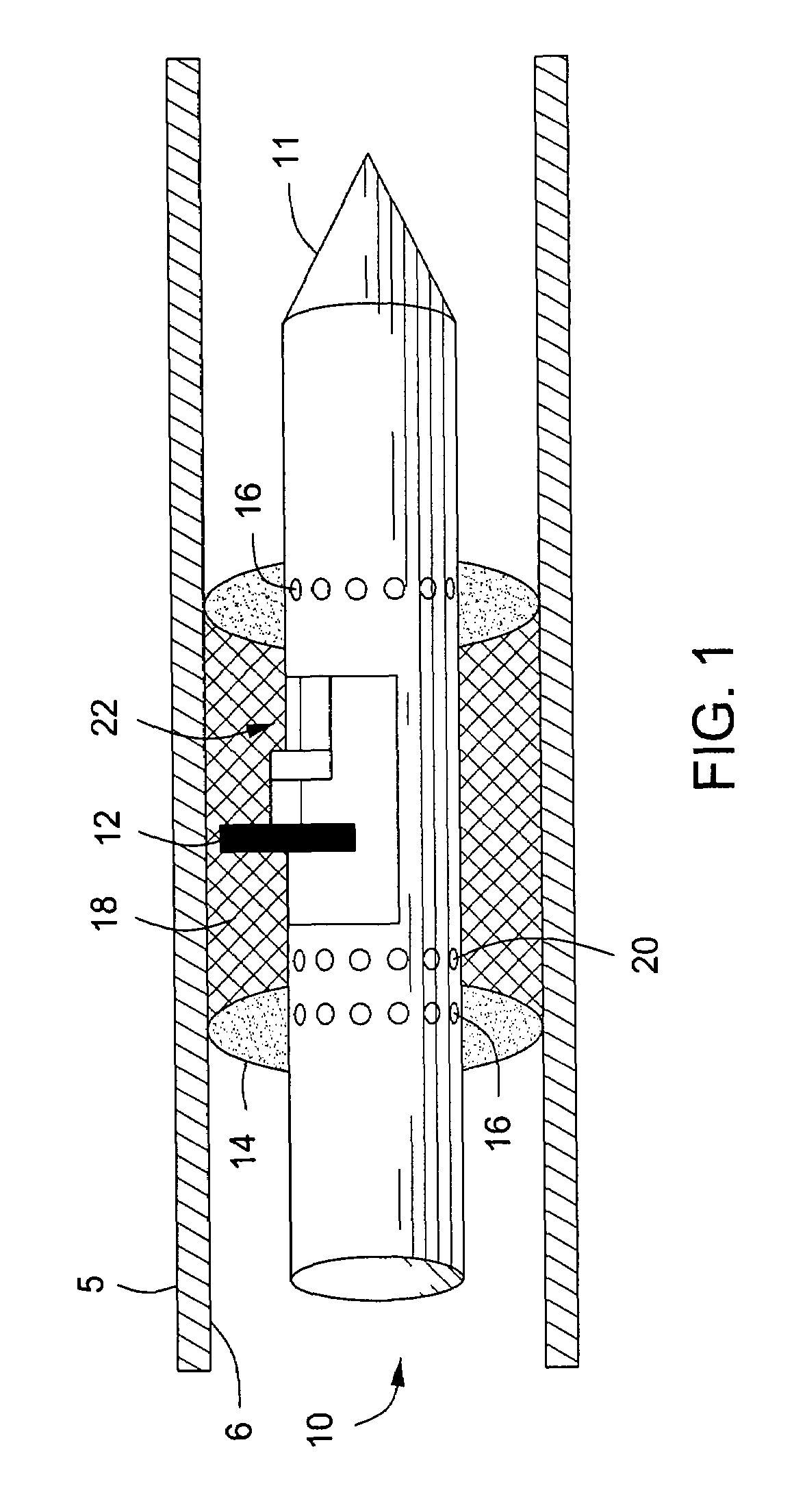

Optimized machining process for cutting tubulars downhole

The tubular cutter disclosed herein is useful for severing downhole tubulars and comprises a drive system, a pivoting system, a cutting head, and a cutting member. Cutting is accomplished by rotatingly actuating the cutting head with an associated motor, and then radially extending the cutting blade away from the cutting head. In one embodiment, the cutting head includes a cutting member that pivotally extends from the cutting head upon rotation of the cutting head.

Owner:BAKER HUGHES HLDG LLC

Drapery tube incorporating batteries within the drapery tube, with a stop for facilitating the loading and unloading of the batteries

ActiveUS9095907B2Easy to changeEasy to replaceCurtain suspension devicesLight protection screensSpring forceEngineering

A motorized window covering is presented having an elongated hollow rod. A battery tube is positioned within the hollow rod. The battery tube has a hollow interior with an elongated spring therein and a stop positioned adjacent an open end of the battery tube. An end cap closes the open end of the battery tube. A plurality of batteries are inserted in end-to-end alignment into the hollow interior of the battery tube. As each battery is inserted, the stop deflects thereby allowing the battery past the stop. Once each battery passes the stop, the stop moves into a stop position thereby holding the battery within the battery tube. To remove each of the plurality of batteries, the stop is deflected and the spring forces the battery out of the hollow interior of the battery tube. The battery tube is electrically connected to a motor that when activated rotates the rod thereby operating the window covering.

Owner:CURRENT PROD CORP

Pipe machining apparatuses and methods of operating the same

Pipe machining apparatuses are provided. In some aspects, a pipe machining apparatus may include a hinge to allow two sections of the pipe machining apparatus to move relative to one another. In another aspect, a support member may be provided to support a pipe machining apparatus on a surface. In a further aspect, a support member may be provided that allows lifting of a pipe machining apparatus in either a horizontal position or a vertical position.

Owner:ILLINOIS TOOL WORKS INC

Thin wall processing technology and its special-purpose knife tool

InactiveCN1876295AImprove processing efficiencyImprove qualified product rateWorkpiecesTurning toolsMachining processBiomedical engineering

The invention relates to a mechanical preparing technology, especially to a thin wall preparing process and private knife device. The process comprises following steps: (1) grasping work piece blank; (2) fixing private knife for thin wall preparation on feed knife carrier, and the two cutting points of outer and internal diameter cutter head is vertical to feeding direction; (3) cutting; (4) cutting blank. Said knife device comprises knife handle, left front fork and right front fork, the left and right front fork extends forwardly to form U shape and they are equipped with outer diameter processing cutter head and internal diameter processing cutter head, the distance between two knife head cutting point is corresponding to the thickness required by thin wall element. The invention is characterized by high thin-walled processing efficiency and stable quality of thin-walled element.

Owner:CRRC QISHUYAN CO LTD

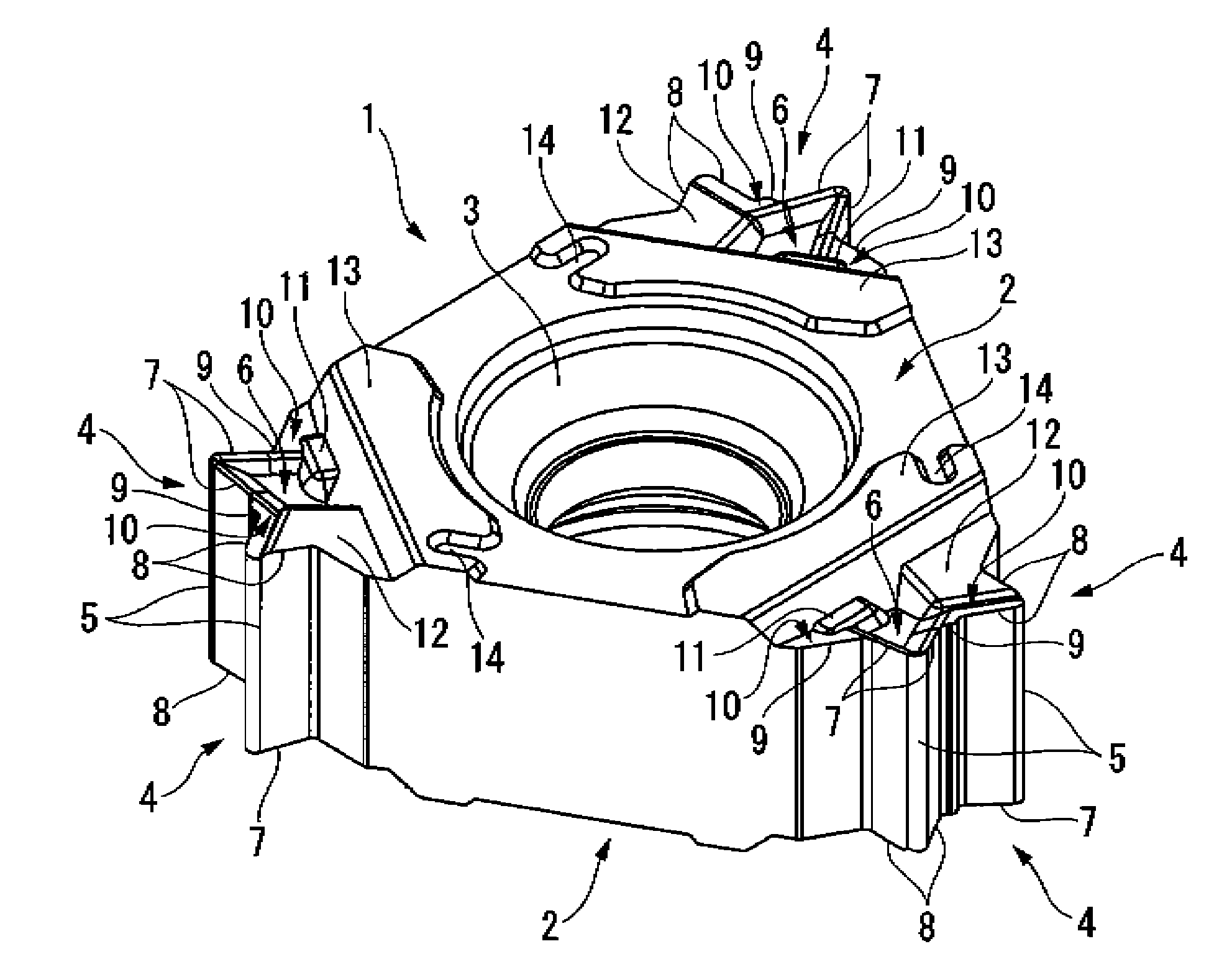

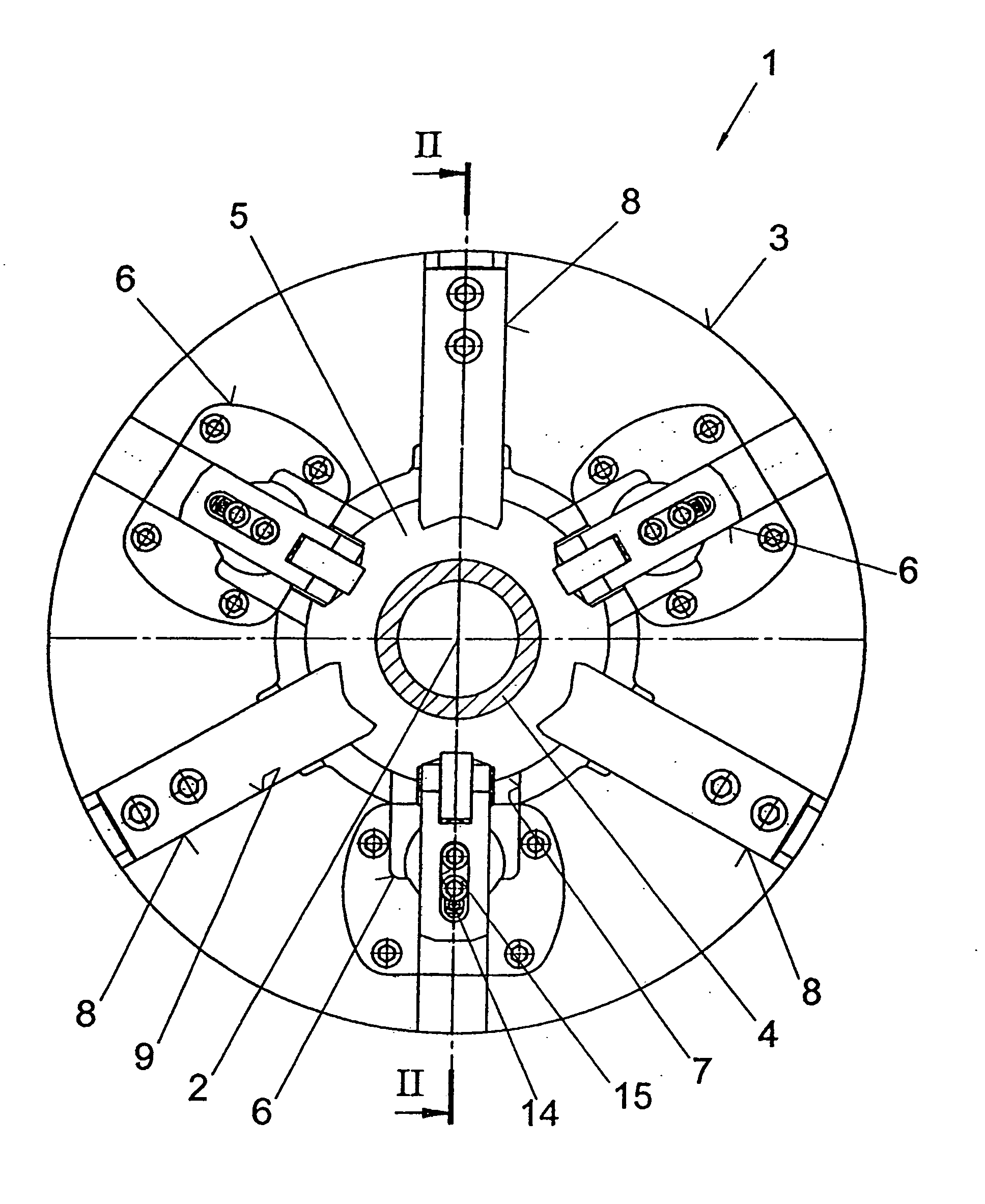

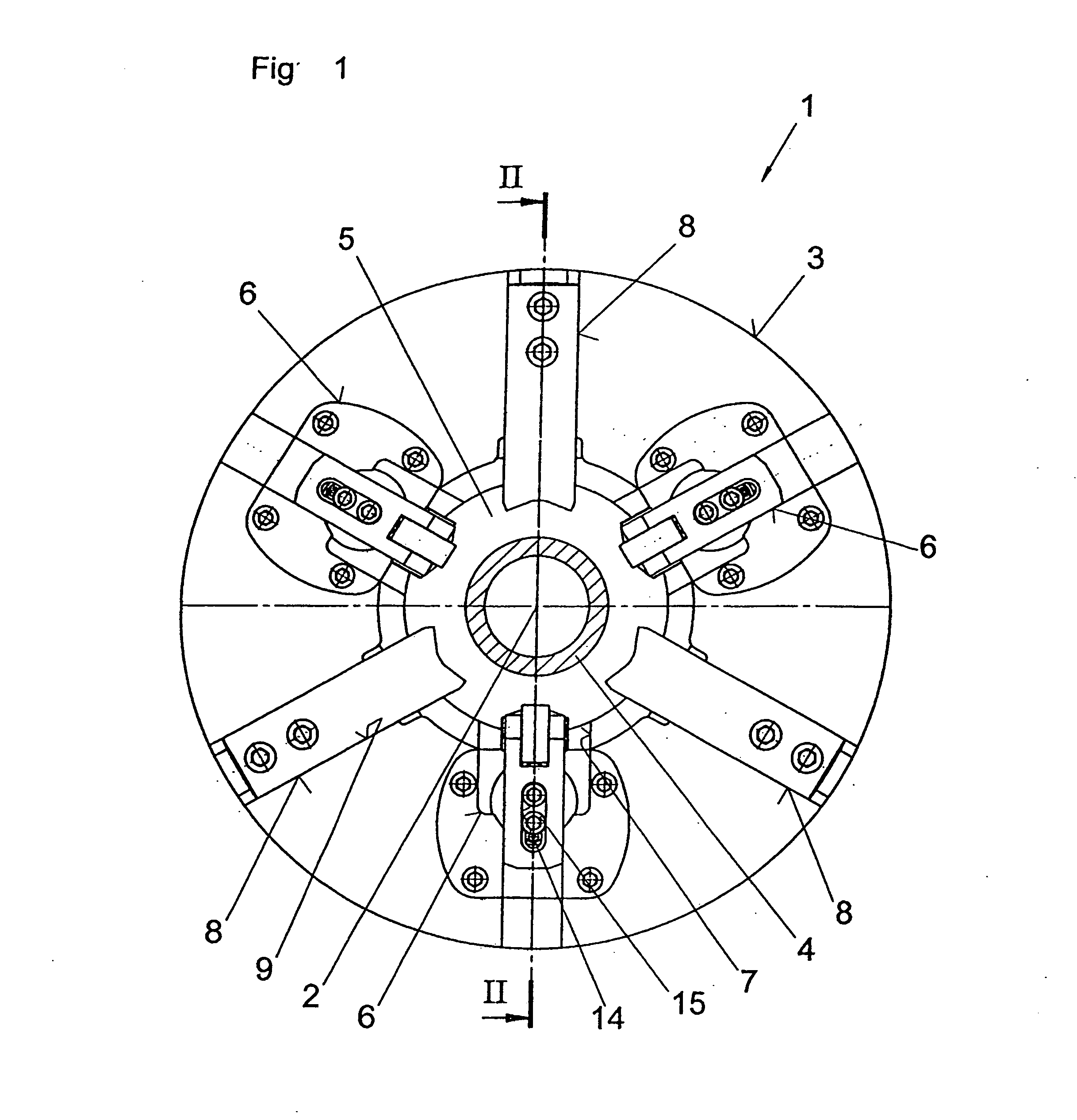

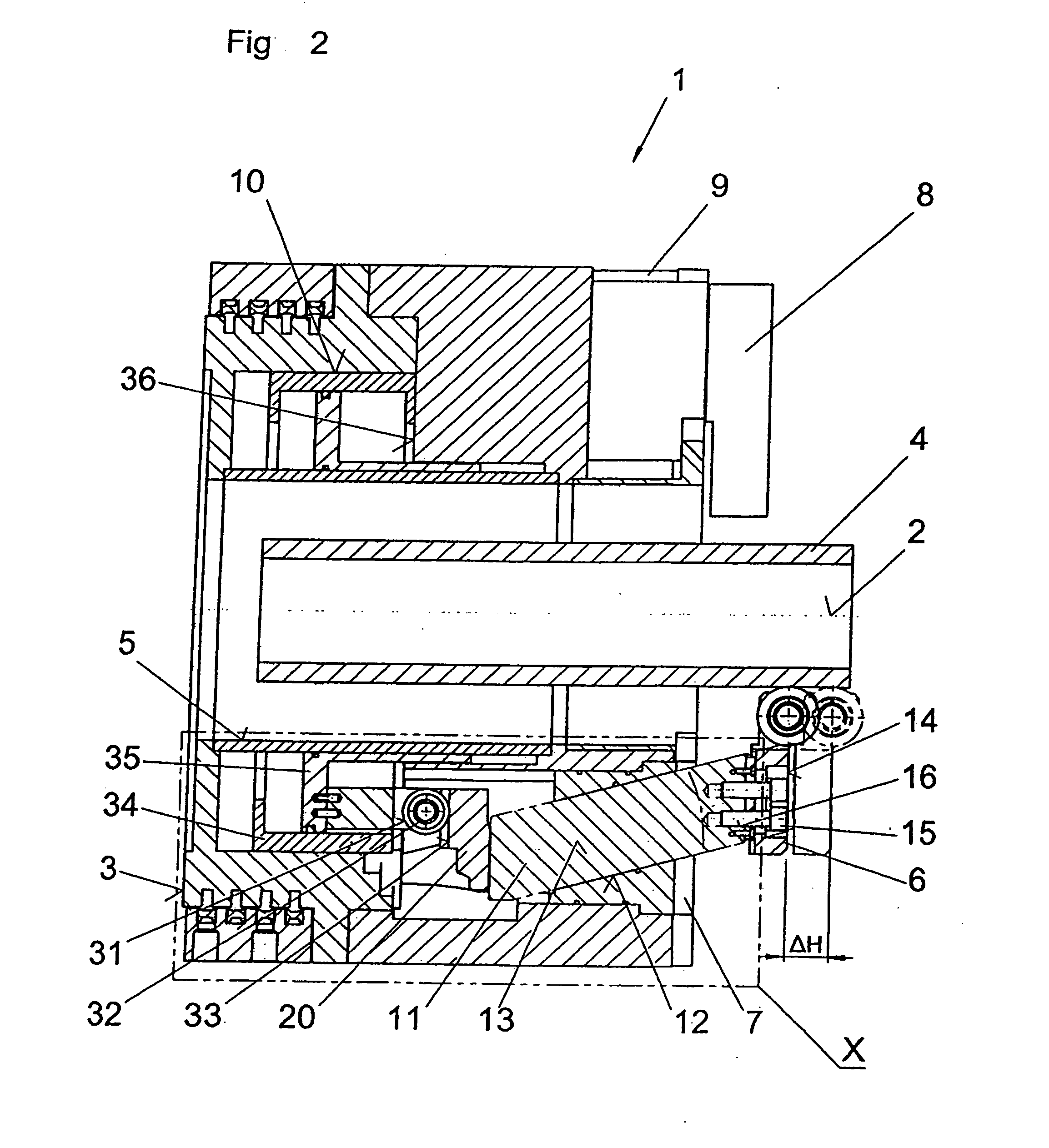

Power operated chuck

ActiveUS20140001712A1Increase the itineraryIncrease freedomSleeve/socket jointsWorkpiecesMechanical engineeringEngineering

A chuck assembly for supporting cylindrically shaped workpieces to be machined at their ends, the assembly comprisinga body having a passage in its lengthways axis,a driving for providing an actuation force absorbed by an actuating pin axially movable in the body,a guide hole in the body having the actuating pin therein, andcentring jaws, mounted in a guide groove in the chuck body and moveable radially toward the workpiece, each in a driving arrangement an actuating pin.A roller provided on the driving means facing the actuating pin, a contact surface is on a free end of the pin at right angles to the lengthways axis of the chuck body. The contact surface and the roller interacting such that forces of driving means transfer onto the contact surface axially, and simultaneously a movement at right angles to the lengthways axis of the chuck body is released between the contact surface of the actuating pin and the roller.

Owner:SMW AUTOBLOK SPANNSYST GMBH

Cutting technology for thin-wall titanium alloy part

InactiveCN104227019AIncreased durabilityAvoid vibrationWorkpiecesTurning toolsDeformation effectTitanium alloy

The invention relates to a cutting technology for a thin-wall titanium alloy part. According to the cutting technology for the thin-wall titanium alloy part, tool materials, angles and cutting factors suitable for machining of titanium alloy materials are selected, the machining durability of tools is improved, the deformation effect of workpieces is reduced remarkably, and the machining quality of the workpieces is improved. A machining result of 1000 workpieces in multiple batches shows that the qualified rate of the workpieces is only 70 percent before the technology is improved, and the qualified rate of the workpieces is increased to about 97 percent after the technology is improved.

Owner:无锡市森信精密机械厂

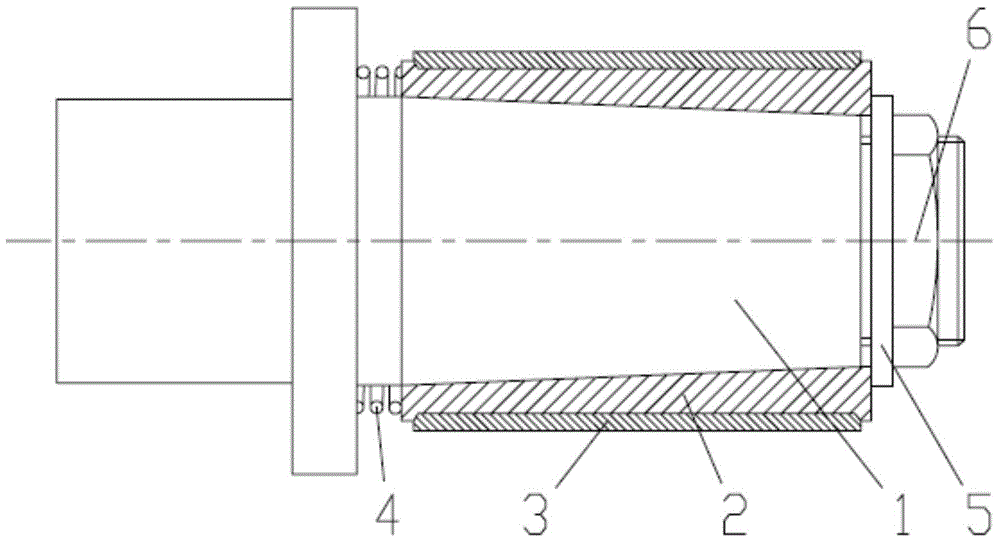

Self-centering clamp for thin-walled part

InactiveCN104858694AEasy loading and unloadingLoading and unloadingWorkpiecesBoring/drilling apparatusEngineeringMachining process

The invention relates to a self-centering clamp for a thin-walled part. The self-centering clamp comprises a mandrel, an expanding sleeve, an adjusting nut and a retaining ring, wherein the mandrel adopts a conical body; the inner wall of the expanding sleeve adopts a conical surface matched with the outer wall of the mandrel, and the outer wall of the expanding sleeve is a cylindrical surface; the expanding sleeve is matched and connected with the conical body of the mandrel through the conical surface of the inner wall; the front end of the expanding sleeve is connected with the step end surface at the rear end of the mandrel through a spring; the rear end of the expanding sleeve is contacted and connected with the adjusting nut through the retaining ring, and the adjusting nut is screwed at the threaded end of the mandrel; the expanding sleeve is sleeved with a flexible positioning sleeve. The self-centering clamp for the thin-walled part is simple in structure, workpieces are convenient to load and unload, self-centering can be realized, particularly, after the flexible positioning sleeve is used, the deformation of the thin-walled part is small in the machining process of clamping the thin-walled part, the machining precision is improved, and the coaxiality and the perpendicularity of the machined thin-walled part can be guaranteed; the expanding sleeve is loosened by the spring, so that the part is convenient to load, unload and machine.

Owner:张鸿来

Centric clamping device

InactiveUS20130205957A1Long distanceFreedom of movementLathesSleeve/socket jointsMechanical engineeringShape formation

Owner:KARLEIN BIRGITT

Finish turning clamp for machining high-precision thin-wall part

ActiveCN105562748AUnaffected by drawbarReduce Turning Scrap RateWorkpiecesBoring/drilling apparatusHydraulic cylinderMachine tool

The invention provides a finish turning clamp for machining a high-precision thin-wall part. The finish turning clamp comprises a body, a pull rod and an extension rod, wherein a circular through hole is formed in the center of the body; the pull rod is arranged in the circular through hole of the body, and also capable of stretching and retracting freely in the circular through hole; one end of the body is connected to a machine tool transition disc, while the other end of the body is provided with an end face and an outer conical surface; a quick-change flat washer sleeves the body, and the end face of the body is used for supporting the quick-change flat washer, and a sticking power lock sleeves the outer conical surface of the body; one end of the pull rod is connected to a machine tool hydraulic cylinder, while the other end of the pull rod is connected with one end of the extension rod; a gland is arranged on the other end of the extension rod; a washer and a slotted washer orderly sleeve the pull rod from one end to the other end, and the slotted washer is fitted with the gland; further, a compression spring sleeves the extension rod, and is located between the washer and the gland; during working, a workpiece sleeves the sticking power lock between the quick-change flat washer and the slotted washer. The finish turning clamp for machining the high-precision thin-wall part structurally reduces and eliminates elastic deformation resulting from clamping.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

Method of cutting thin-walled material

A method is provided to cut a thin-walled member without causing chattering vibration, without using a chattering vibration preventing retainer, that performs the following: (A) preparing a material having much stock for obtaining a thin-walled material, (B) while rotating the material about a center axis, cutting the inner round surface of the material within a predetermined range by feeding a cutting tool relative to material by the desired distance from one end side to the other end side of the material along the center axis, (C) while rotating the material about the center axis, cutting the outer round surface of the material within a predetermined range by feeding the cutting tool relative to the material by the desired distance from the one end side to the other end side of the material along the center axis, and (D) alternately repeating (B) and (C) to finish cutting the material.

Owner:IHI CORP

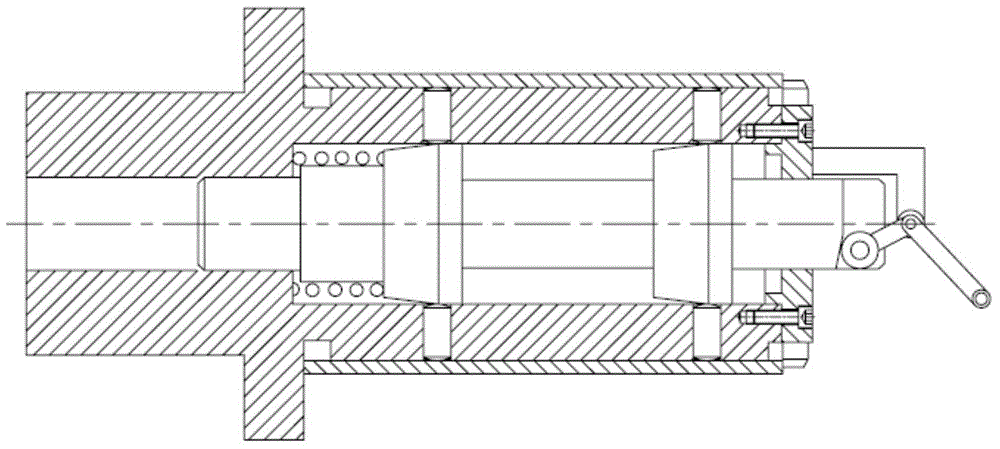

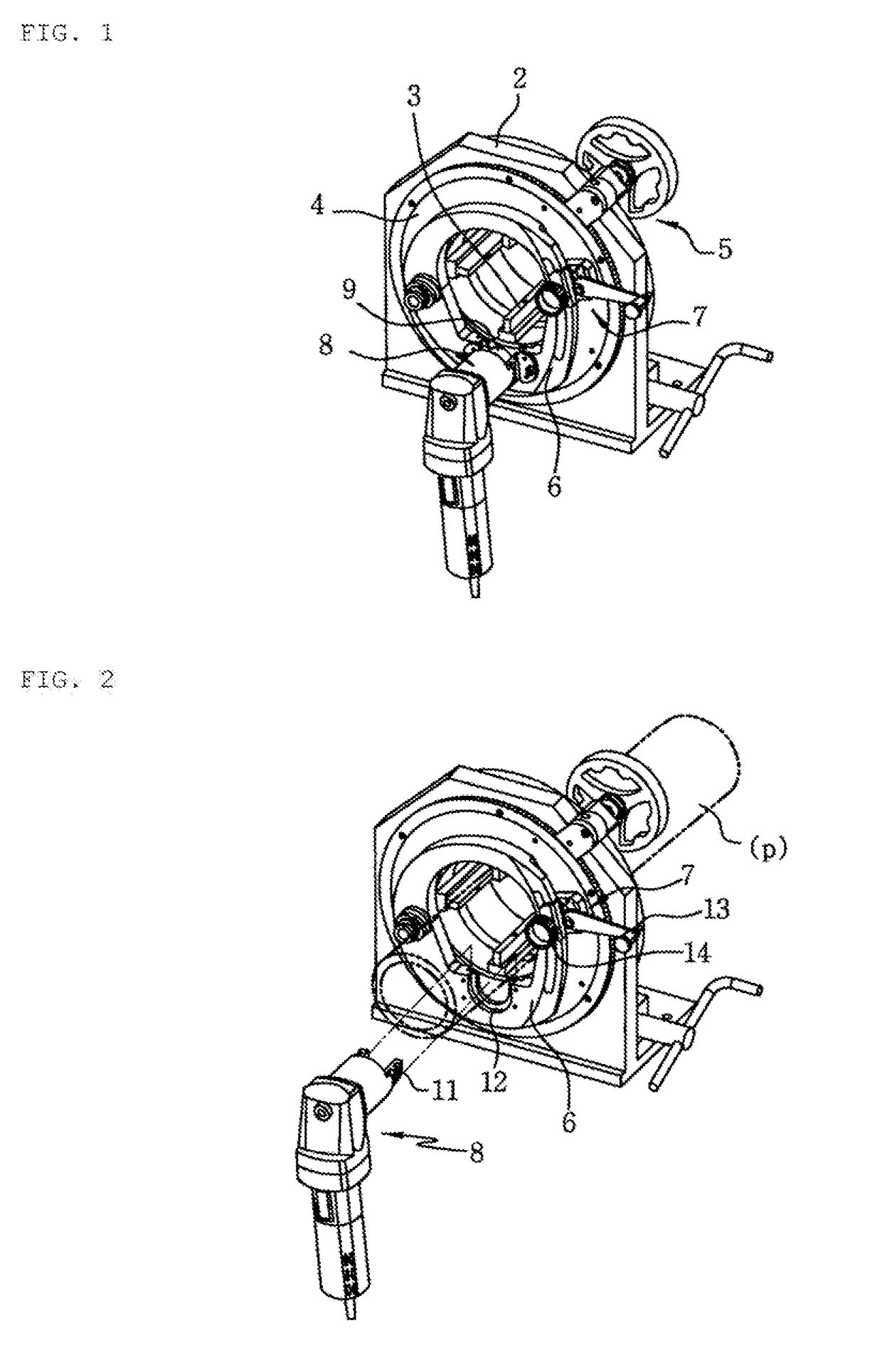

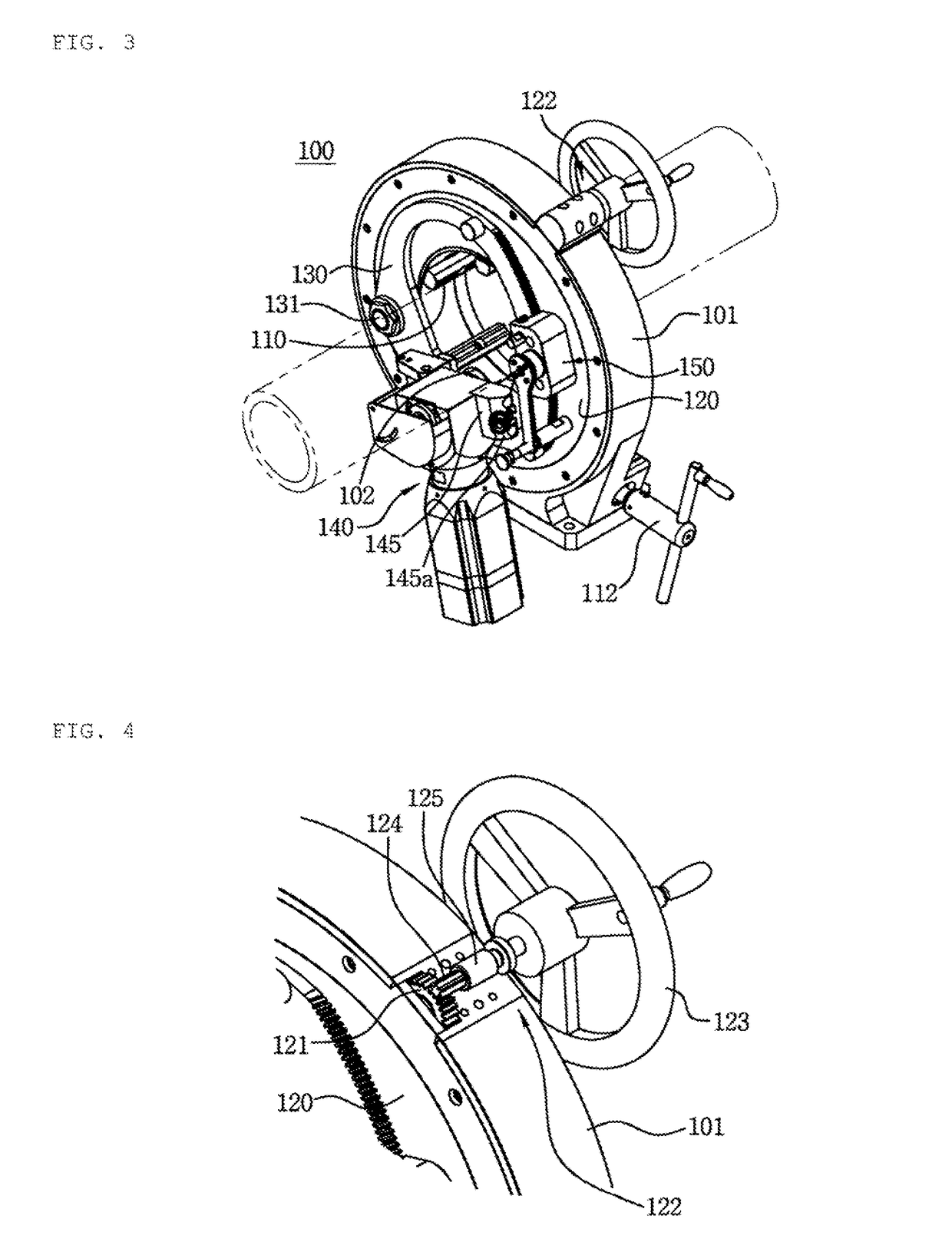

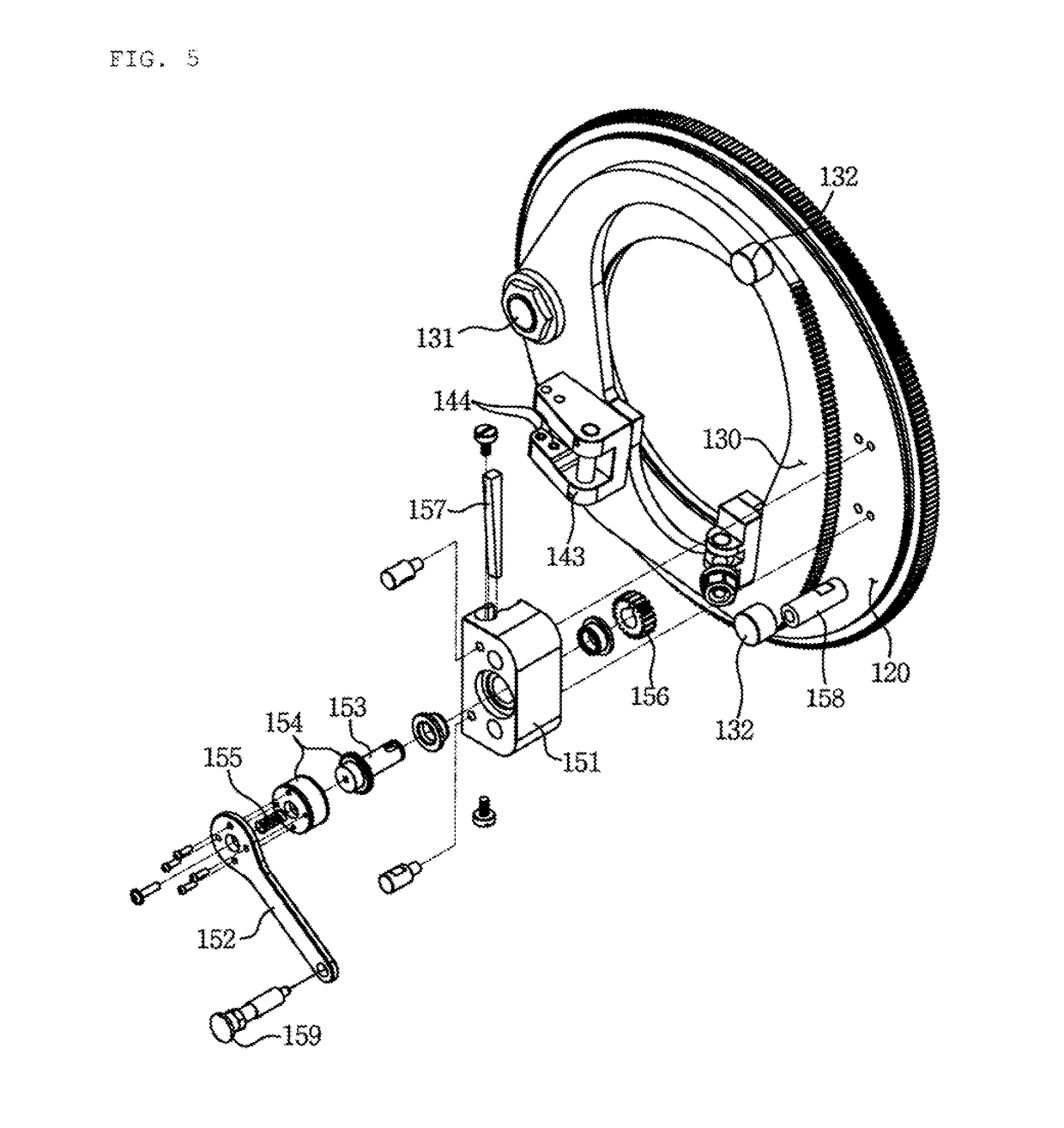

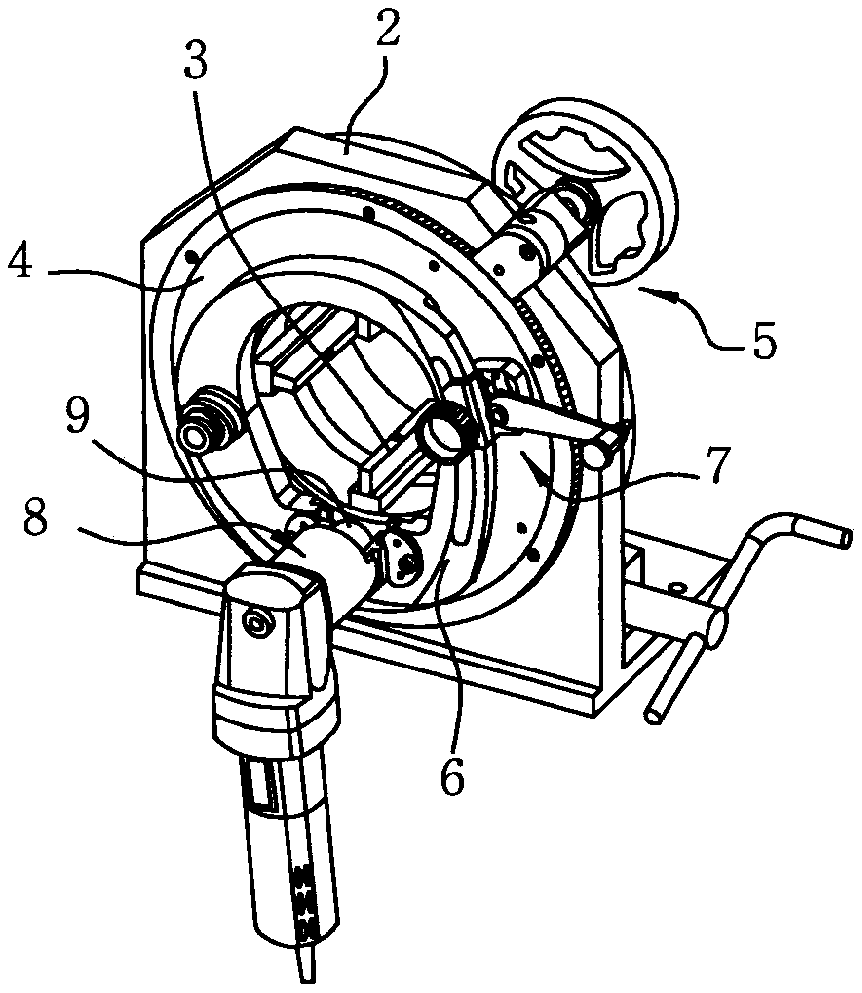

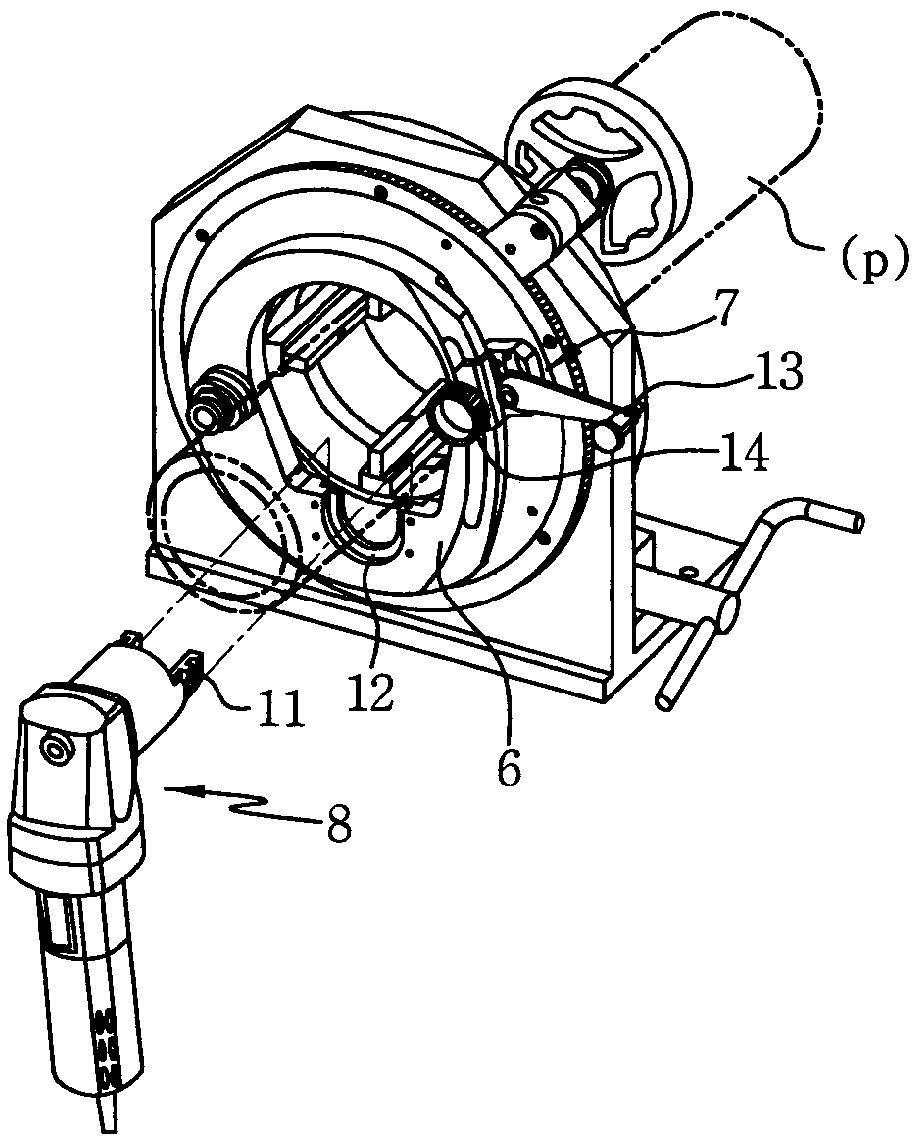

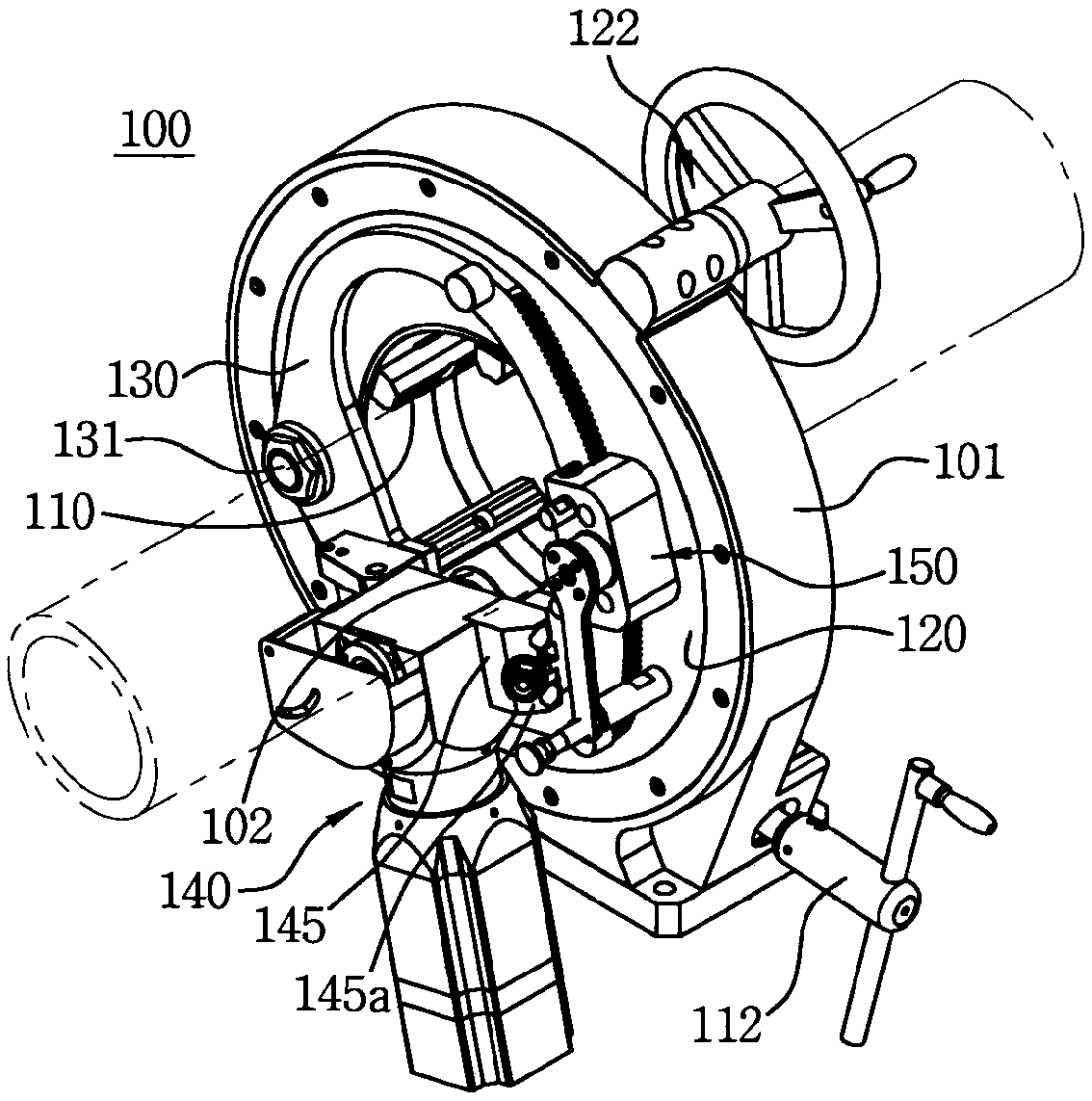

Pipe cutting and beveling machine

ActiveUS20190022773A1Quickly and conveniently replacedSimple structureTurning machine accessoriesWorkpiecesUnit operationEngineering

A machine for cutting or beveling a pipe. A cutter unit rotates around the pipe while cutting any surface of the pipe after gripping and fixing the pipe. The machine includes: a main body which a pipe passes through the center portion thereof to be fixed; and a cutter unit coupled to the main body unit rotates around the fixed pipe to cut or bevel the pipe. The cutter unit may have a rotating unit on one side to pull the cutter unit aside and a locking unit on the other side to restrain or release the cutter unit. An entry control unit operating the cutter unit includes: a lever gear-engaged with an outer side surface of an entry control plate; and a clutch formed on a rotation shaft of the lever such that the restraint is released when the lever is lifted or pressed in the axial direction.

Owner:DCSENG CO LTD

High-accuracy thin-wall bush machining method

InactiveCN104476117AQuality assuranceSolve sizeTurning machine accessoriesWorkpiecesEngineeringMachining

The invention provides a high-accuracy thin-wall bush machining method. The high-accuracy thin-wall bush machining method comprises the following steps of (1) rough machining which comprises enabling the excircle size of a bush to be provided with the margin of 1 to 1.5mm and enabling the inner hole size of the bush to be provided with the margin of 0.3 to 0.5mm; (2) finish machining an inner hole; (3) semi finish machining the excircle, clamping the bush through a first core rod and enabling the excircle size after semi finish machining to be provided with the margin of 0.1 to 0.15mm; (4) finish machining the excircle, clamping the bush through a second core rod and enabling an insertion end of the head of the second core rod to be provided with the gradient from 0 to 0.041 degree. The high-accuracy thin-wall bush machining method can effectively solve the influences generated by pressure when a lathe chuck clamps the bush to the bush size and the coaxiality and accordingly the quality of the batch production thin wall bush when the machining accuracy requirement is high.

Owner:SHANGHAI AIRCRAFT MFG +1

Pipe cutting and beveling machine

ActiveCN108698245AWon't interfereWill not be disturbedTurning machine accessoriesWorkpiecesRotational axisGear wheel

Disclosed is a dedicated machine capable of cutting or beveling a pipe, such as a circular pipe or bar, in such a manner that a cutter unit rotates around the pipe while cutting any one surface of thepipe after gripping and fixing the pipe. A pipe cutting and beveling machine, according to the present invention, comprises: a main body unit in which a pipe passes through the center portion thereofso as to be fixed; and a cutter unit which is coupled to the main body unit so as to cut or bevel the pipe by means of a cutting blade while rotating around the fixed pipe, wherein the cutter unit may be provided with a rotating unit on one side thereof so as to pull the cutter unit aside and a locking unit on the other side thereof so as to restrain or release the cutter unit from being pulled aside. In addition, an entry control unit, which operates the cutter unit to move forward or backward, may comprise: a lever which is gear-engaged with an outer side surface of an entry control plate;and a clutch which is formed on a rotation shaft of the lever such that the restraint thereof is released when the lever is lifted or pressed in the axial direction.

Owner:DCSENG CO LTD

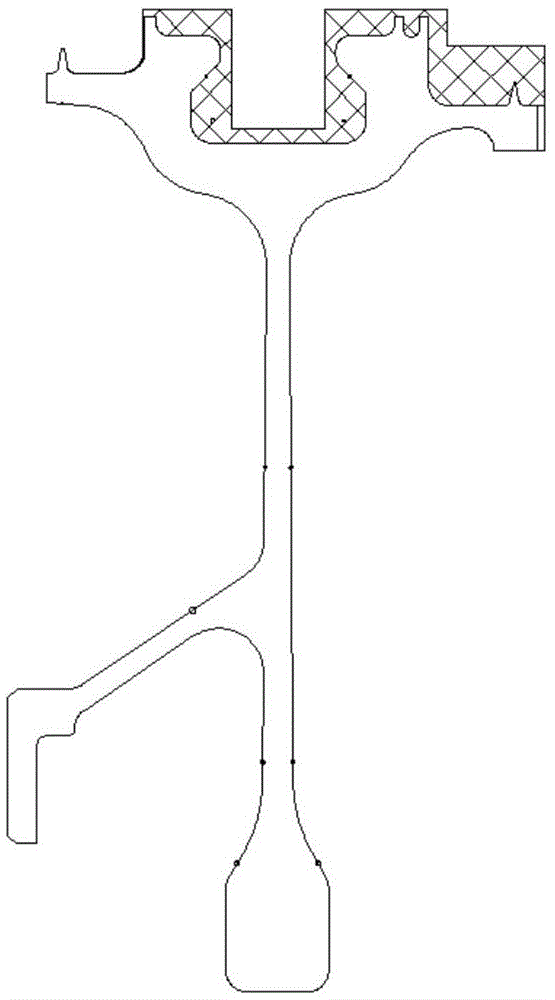

Method and apparatus for cutting one or more grooves in a cylindrical element

InactiveUS20140076115A1Reduce tool changePrecise alignmentCurtain suspension devicesLight protection screensEngineering

Embodiments of the subject invention relate to a method and apparatus for cutting one or more grooves in a cylindrical element. In specific embodiments, the one or more grooves are cut into an outer surface of the cylindrical element. The cylindrical element can be solid, or can have one or more hollow portions. In a specific embodiment, the cylindrical element is a hollow tube. Embodiments also pertain to a cylindrical element having one or more grooves cut in an outer surface of the cylindrical element. Further specific embodiments are directed to cylindrical elements having one or more grooves that can be utilized as a drapery or curtain tube, where the one or more grooves, in combination with rotation of the cylindrical element, can be used for moving the drapery to one or more positions along the tube, such as from an open position for the drapery or curtain to a closed position for the drapery or curtain, by engaging an interconnecting element between the drapery or curtain and the one or more grooves while rotating the tube.

Owner:QMOTION

Double-headed automatic chamfering machine for pipe fittings

InactiveCN106001617AReduce labor intensityImprove work efficiencyTurning machine accessoriesWork clamping meansPipe fittingEngineering

The invention provides a double-headed automatic chamfering machine for pipe fittings. The double-headed automatic chamfering machine comprises a machine base, a feeding mechanism, a clamping mechanism and chamfering mechanisms; the feeding mechanism is located on the machine base, the clamping mechanism is arranged opposite to the feeding mechanism, the chamfering mechanisms comprise the first chamfering mechanism and the second chamfering mechanism which are located on the two sides of the clamping mechanism respectively. According to the double-headed automatic chamfering machine for the pipe fittings, work such as automatic feeding, clamping, chamfering and discharging can be achieved automatically, the work efficiency can be improved, a worker does not need to operate manually and only needs to stack workpieces to be machined in a feeding hopper, the rest of the work can be completed automatically through the machine, the labor intensity of workers is reduced, and the pipe fittings with different specifications can be chamfered by adjusting the positions of hand wheels and chamfering cutters.

Owner:天津博瑞泰机械零部件股份有限公司

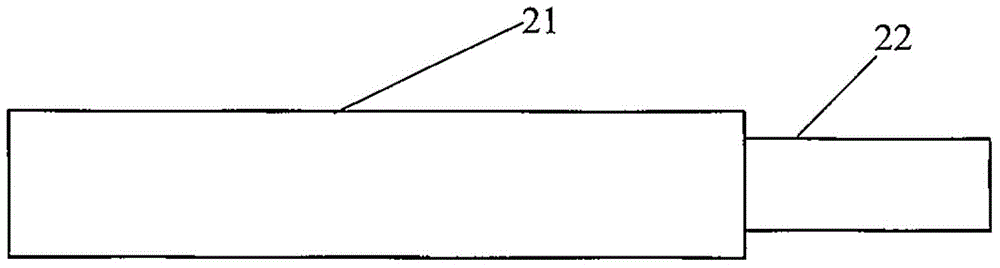

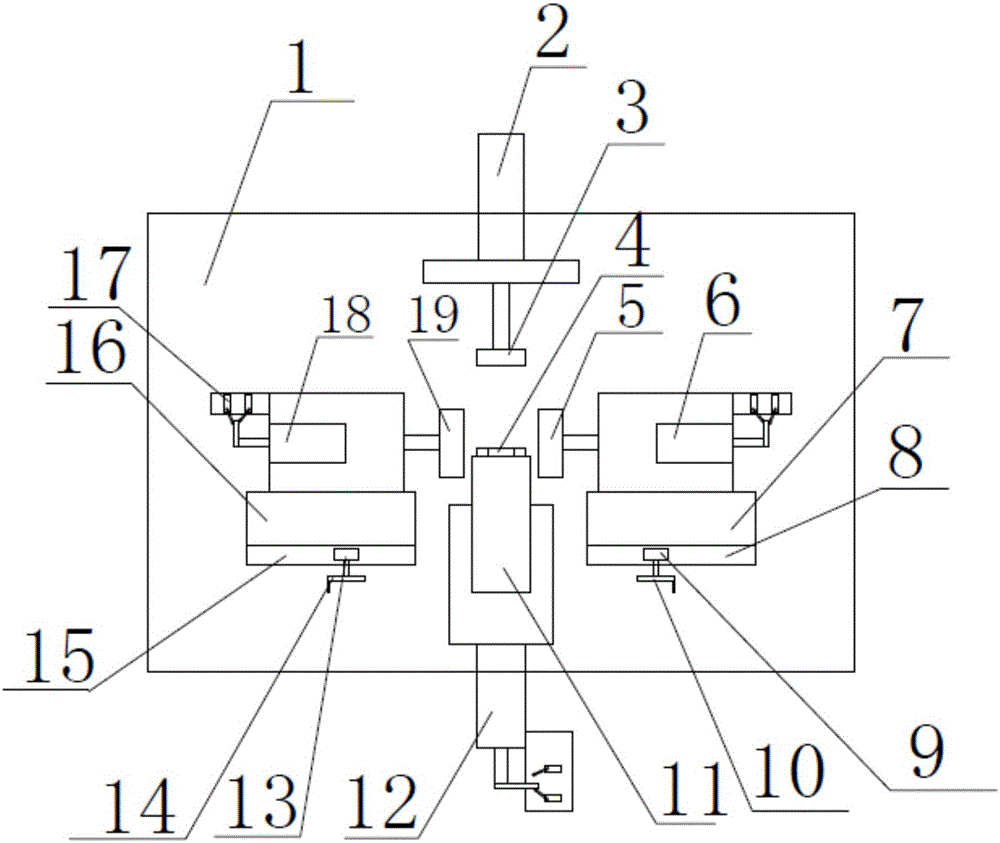

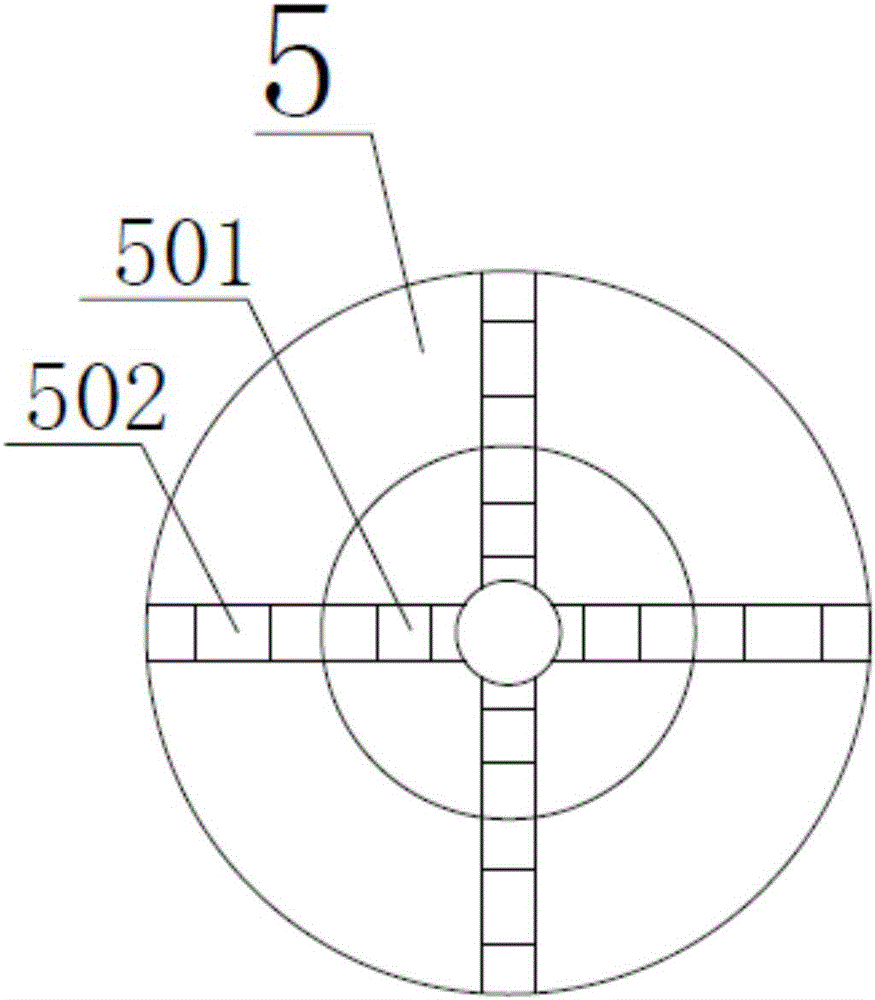

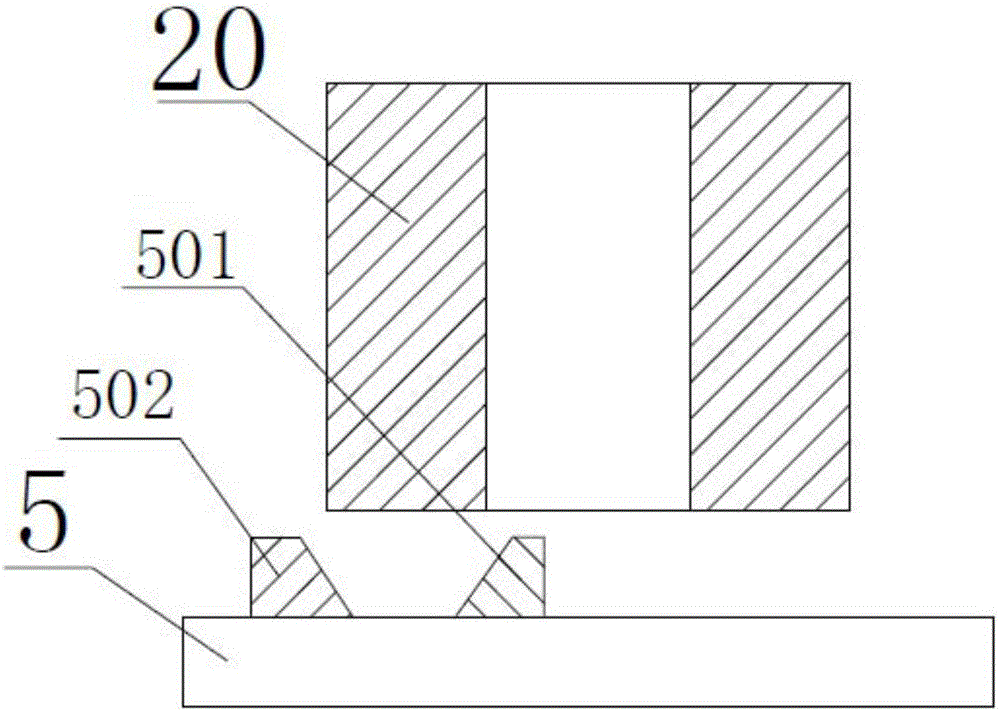

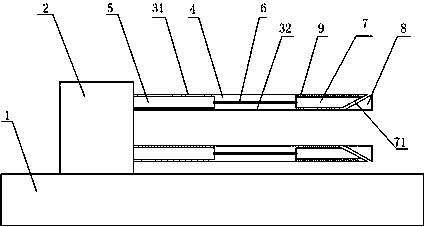

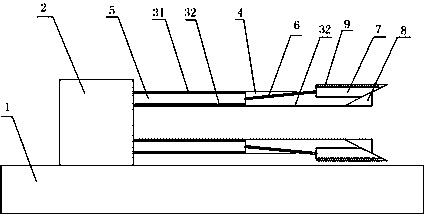

Machining tool used for thin-wall barrel type part

ActiveCN104759653AAvoid clamping deformationWorkpiecesBoring/drilling apparatusManufacturing technologyEngineering

The invention discloses a machining tool, in particular to a machining tool used for a thin-wall barrel type part and belongs to the technical field of machining technology, assembly, design and manufacturing. By means of the machining tool used for the thin-wall barrel type part, large machining errors in the machining process of the thin-wall part due to clamping reasons can be effectively avoided. The machining tool comprises a base frame and clamping support components, and the base frame is sleeved with the clamping support components in an expansible and contractible mode in the radial direction; the thin-wall barrel type part is fixed onto the machining tool in an expansible mode through the clamping support components, and the machining tool is installed on machining equipment for the thin-wall barrel type part in a clamped mode through the base frame.

Owner:CHINA 19TH METALLURGICAL CORP

Pipe stabilizing and rotating device

ActiveCN105499623ARealize targeted promotionAchieve a biteWorkpiecesWork holdersMachining processMechanical engineering

The invention discloses a pipe stabilizing and rotating device. The pipe stabilizing and rotating device comprises a base, and a motor arranged on the base; a rotating shaft of the motor is connected with a hollow main shaft; the main shaft includes an outer cylinder and an inner cylinder; an annular gap is formed between the outer cylinder and the inner cylinder; an electric push rod, a connecting rod, a slide block and a stopper are arranged in the annular gap; the two ends of the connecting rod are respectively hinged with the electric push rod and the slide block; the stopper is fixed at the end part of the annular gap; the surface of the stopper is a curved surface gradually inclined outwards from the inner cylinder to the outer cylinder in the main shaft extending direction; and the slide surface of the slide block is matched with the surface of the stopper. The invention aims to provide the pipe stabilizing and rotating device, solves the problem of inconvenience for clamping and rotation in the pipe processing process in the prior art, and realizes the purpose of conveniently and quickly stabilizing a pipe to be processed while rotating.

Owner:LUZHOU YUANCHENG ENG MACHINERY CO LTD

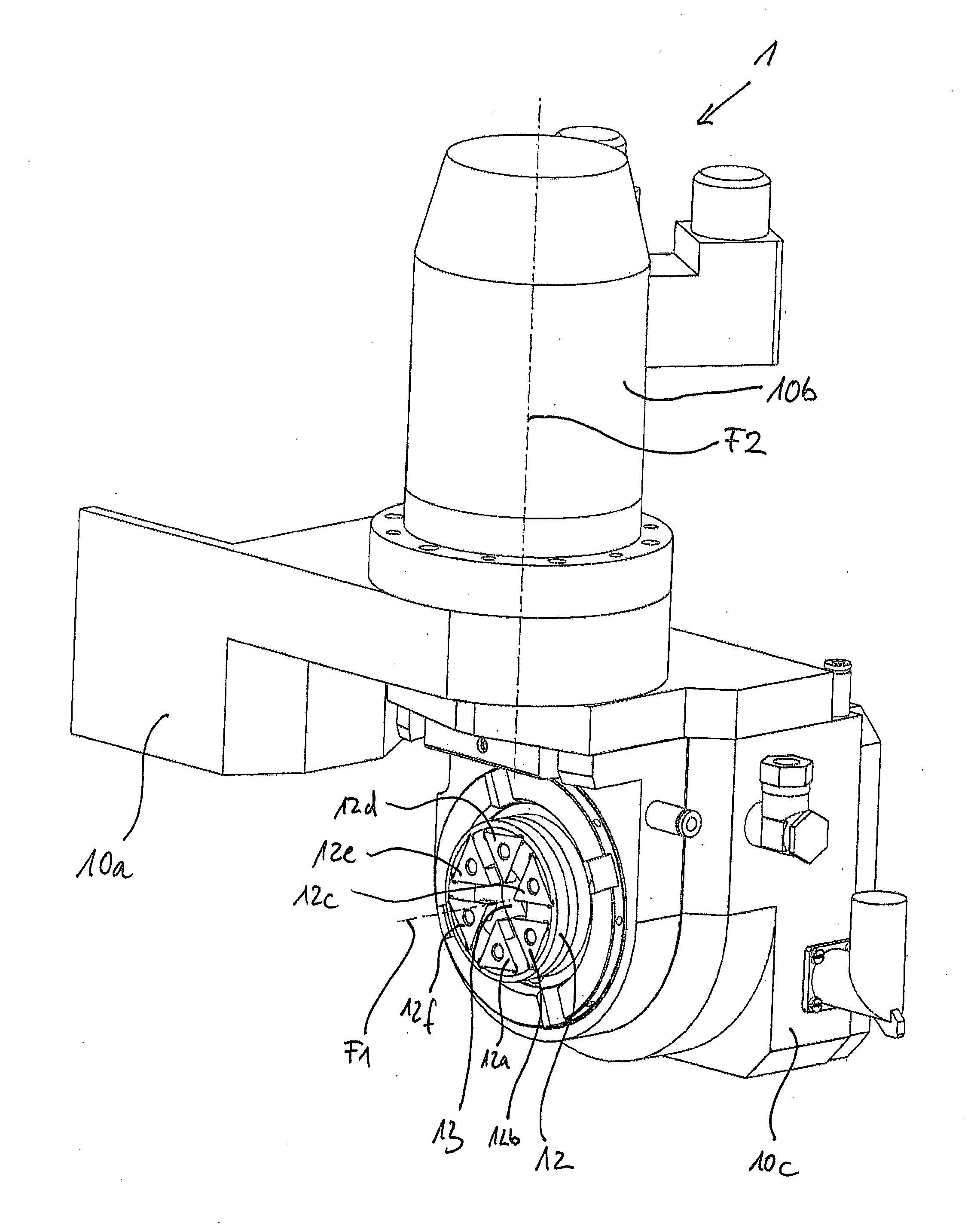

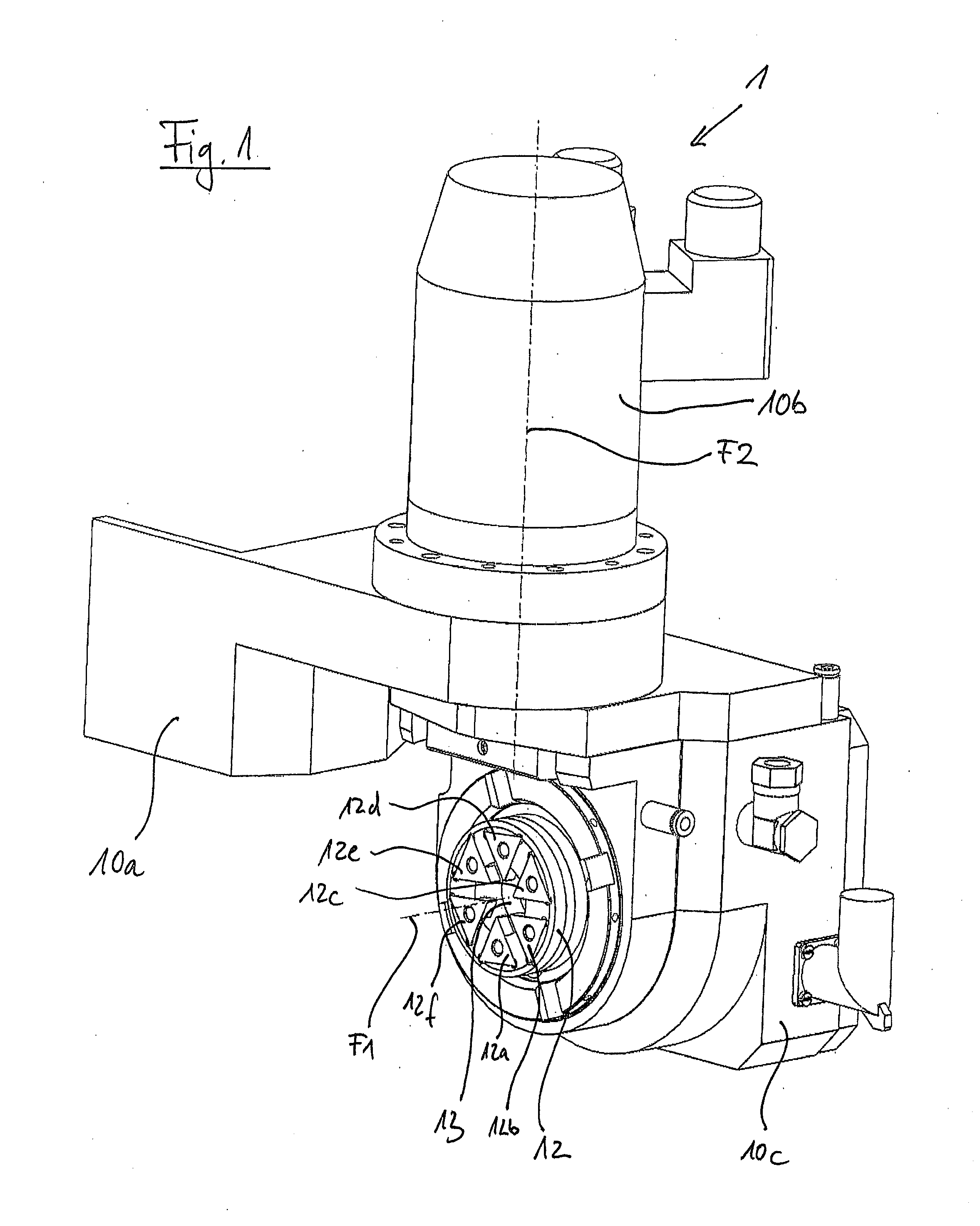

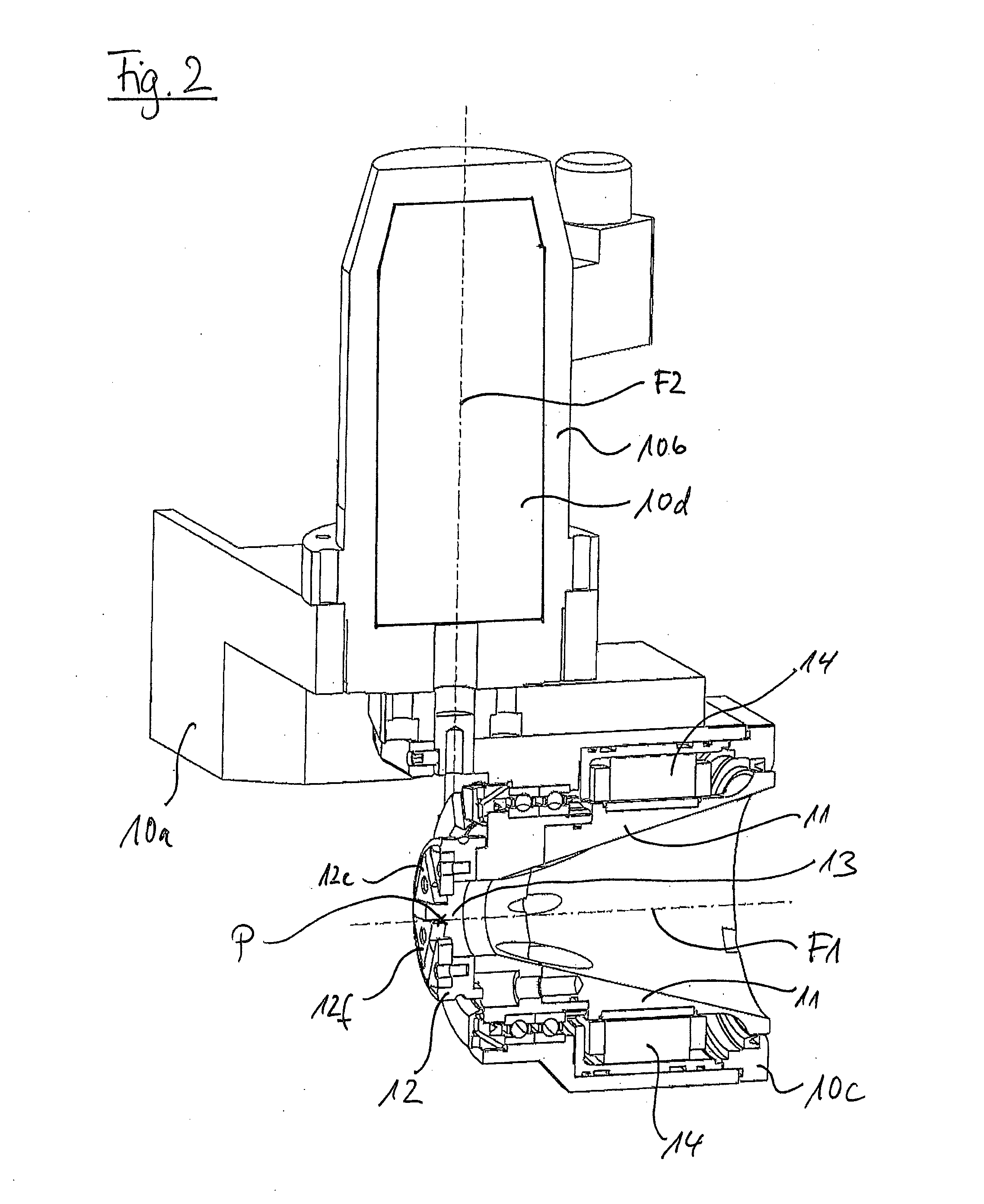

Thread whirling device and turning machine comprising a thread whirling device

ActiveUS20140318330A1Simple wayImprove time efficiencyLathesAutomatic/semiautomatic turning machinesEngineeringScrew thread

A thread whirling device for producing a thread on a workpiece on a numerically controlled turning machine by a thread whirling method, having a retention structure for fitting the thread whirling device to the turning machine, a whirling head which is retained on the retention structure, has an opening and carries one or more cutters which are arranged peripherally on the edge of the opening, having a first drive device which is configured to drive the whirling head in a rotational manner about a first rotation axis which extends through the opening. The thread whirling device further includes a second drive device which is configured to drive the whirling head in a rotational manner about a second rotation axis which extends transversely relative to the first rotation axis, in order to orientate an angle between the first rotation axis and the spindle axis of the turning machine work spindle.

Owner:GILDEMEISTER ITALANA

Centric clamping device

Owner:KARLEIN BIRGITT

Numerical control finish turning processing method of annular Omega-shaped groove of titanium alloy thin wall disc ring piece

InactiveCN104475766ADevelopment and production went smoothlyMeet the design requirementsAutomatic/semiautomatic turning machinesTurning machine accessoriesNumerical controlProcess efficiency

The invention provides a numerical control finish turning processing method of an annular Omega-shaped groove of a titanium alloy thin wall disc ring piece. The numerical control finish turning processing method of the annular Omega-shaped groove of the titanium alloy thin wall disc ring piece includes: confirming an allowance in each finish turning processing stage of the annular Omega-shaped groove of the titanium alloy thin wall disc ring piece; confirming a processing scheme of the finish turning stages of the annular Omega-shaped groove of the titanium alloy large diameter thin wall disc ring piece; compiling a numerical control turning program of the finish turning stages of the annular Omega-shaped groove of the titanium alloy large diameter thin wall disc ring piece; controlling a processing route of each numerical control finish turning processing stage of the annular Omega-shaped groove of the titanium alloy thin wall disc ring piece. The numerical control finish turning processing method of the annular Omega-shaped groove of the titanium alloy thin wall disc ring piece breaks a technical bottleneck in processing of a titanium alloy piece of special structure, improves processing efficiency on the premise of meeting processing technology requirements of the annular Omega-shaped groove of the titanium alloy large diameter thin wall disc ring piece in numerical control turning of a titanium alloy material supercharging first stage disc, achieves high efficiency processing of the annular Omega-shaped groove of the titanium alloy large diameter thin wall disc ring piece, solves the problems that the annular Omega-shaped groove of the titanium alloy large diameter thin wall disc ring piece is low in processing efficiency and long in machine occupying time, and alleviates production bottlenecks in machining of a vertical lathe.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com