Finish turning clamp for machining high-precision thin-wall part

A thin-walled parts, high-precision technology, applied in the direction of workpieces, manufacturing tools, metal processing equipment, etc., can solve the problems of excessive shape accuracy, part size, poor shape accuracy, etc., to eliminate clamping deformation and reduce turning scrap rate , The effect of increasing market share

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

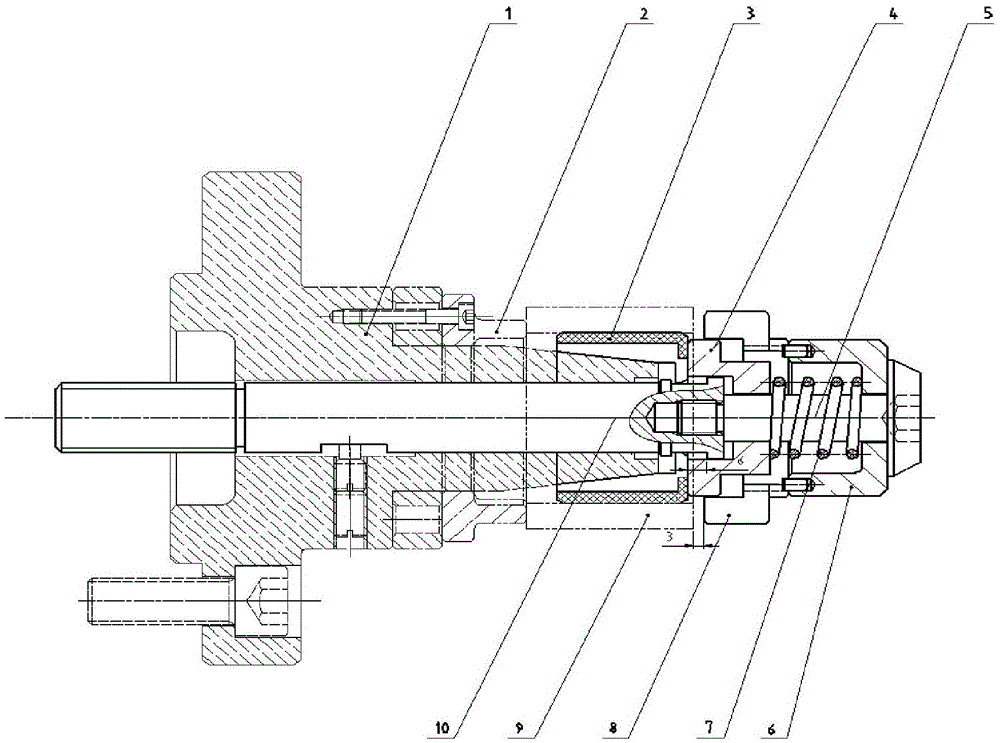

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] as follows figure 1 As shown, the present invention is a precision turning fixture for processing high-precision thin-walled parts, including a body 1, a quick-change flat pad 2, an adhesive expansion sleeve 3, a gasket 4, an extension rod 5, a gland 6, a compression spring 7, an opening Pad 8, workpiece 9 and tie rod 10. Among them, the main body 1 is used to connect with the transition plate of the machine tool, and its end surface supports the quick-change flat pad 2, and its tapered surface can force the adhesive expansion sleeve 3 to spread evenly.

[0024] The quick-change flat pad 2 is interposed between the main body 1 and the workpiece 9 to support the workpiece 9 .

[0025] The positioning hole of the bonding expansion sleeve 3 and the annular groove of the pull rod 10 belong to a clearance fit, and its inner tapered surface cooperates with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com