Method and apparatus for linked horizontal drapery panels having varying characteristics to be moved independently by a common drive system

a technology of horizontal drapery panels and drive systems, applied in the direction of curtain suspension devices, door/window protective devices, shutters/movable grilles, etc., can solve the problems of increasing assembly costs and adding complexity to the assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment

Method and Apparatus for Linked Horizontal Drapery Panels Having Varying Characteristics to be Moved Independently by a Common Drive System

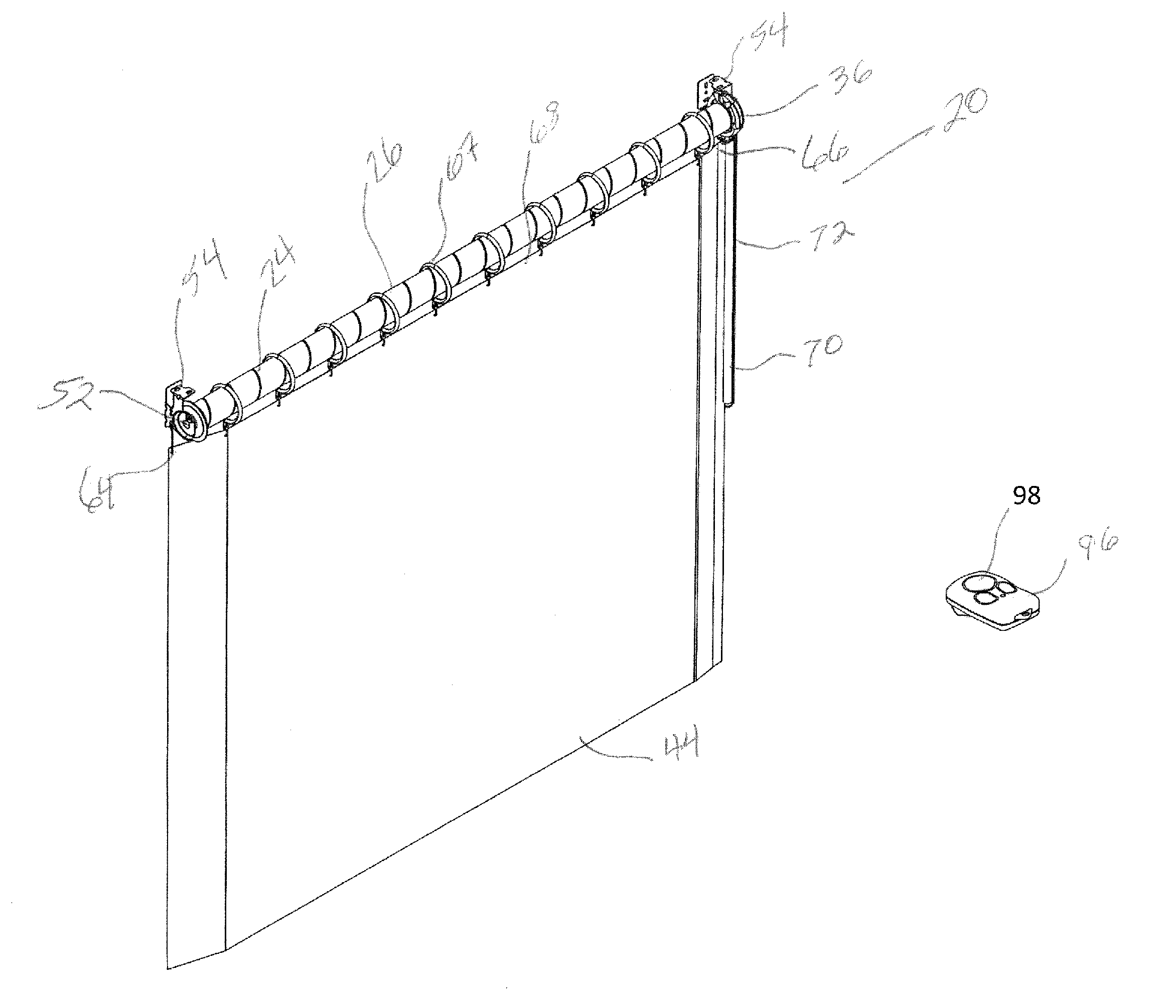

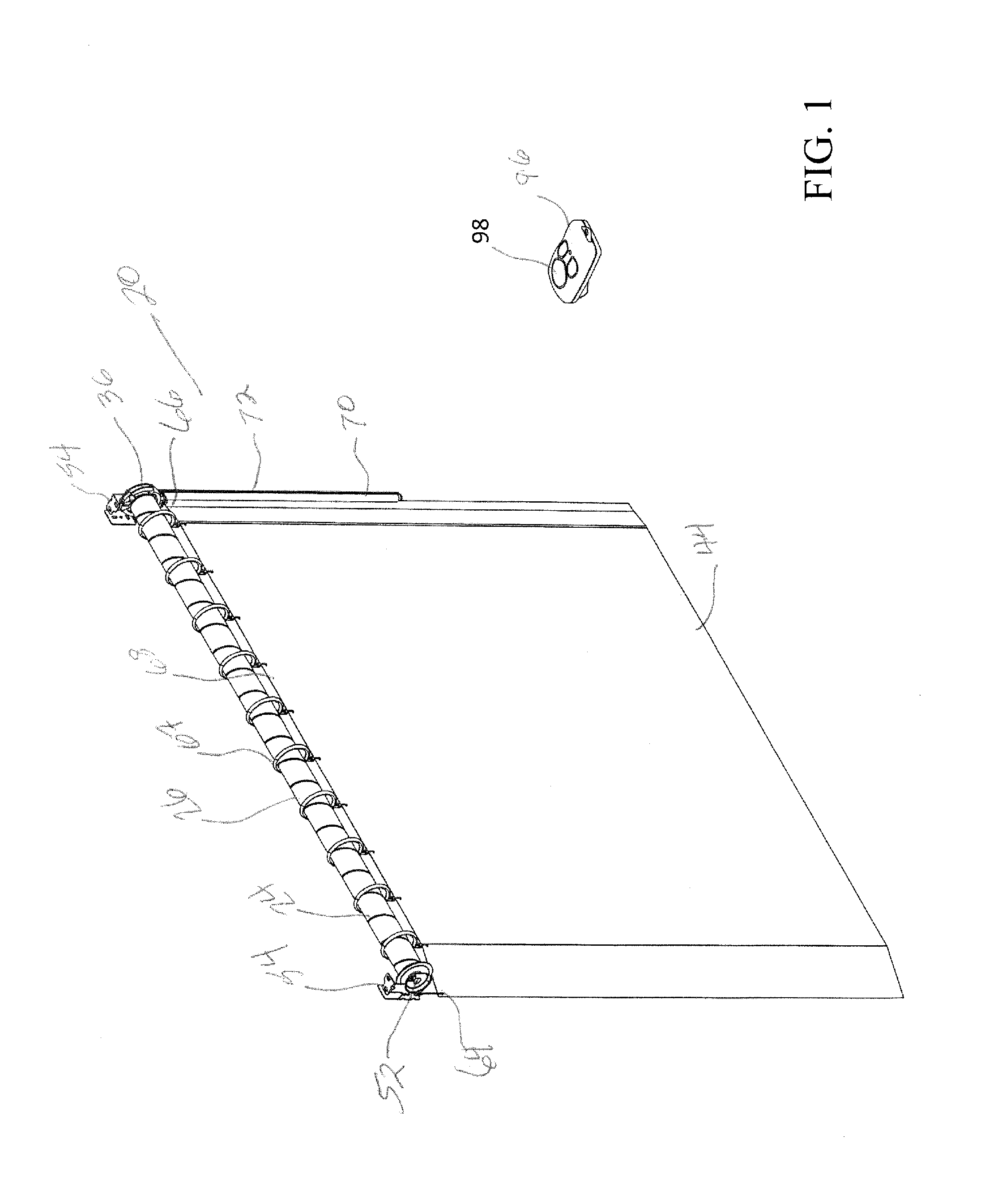

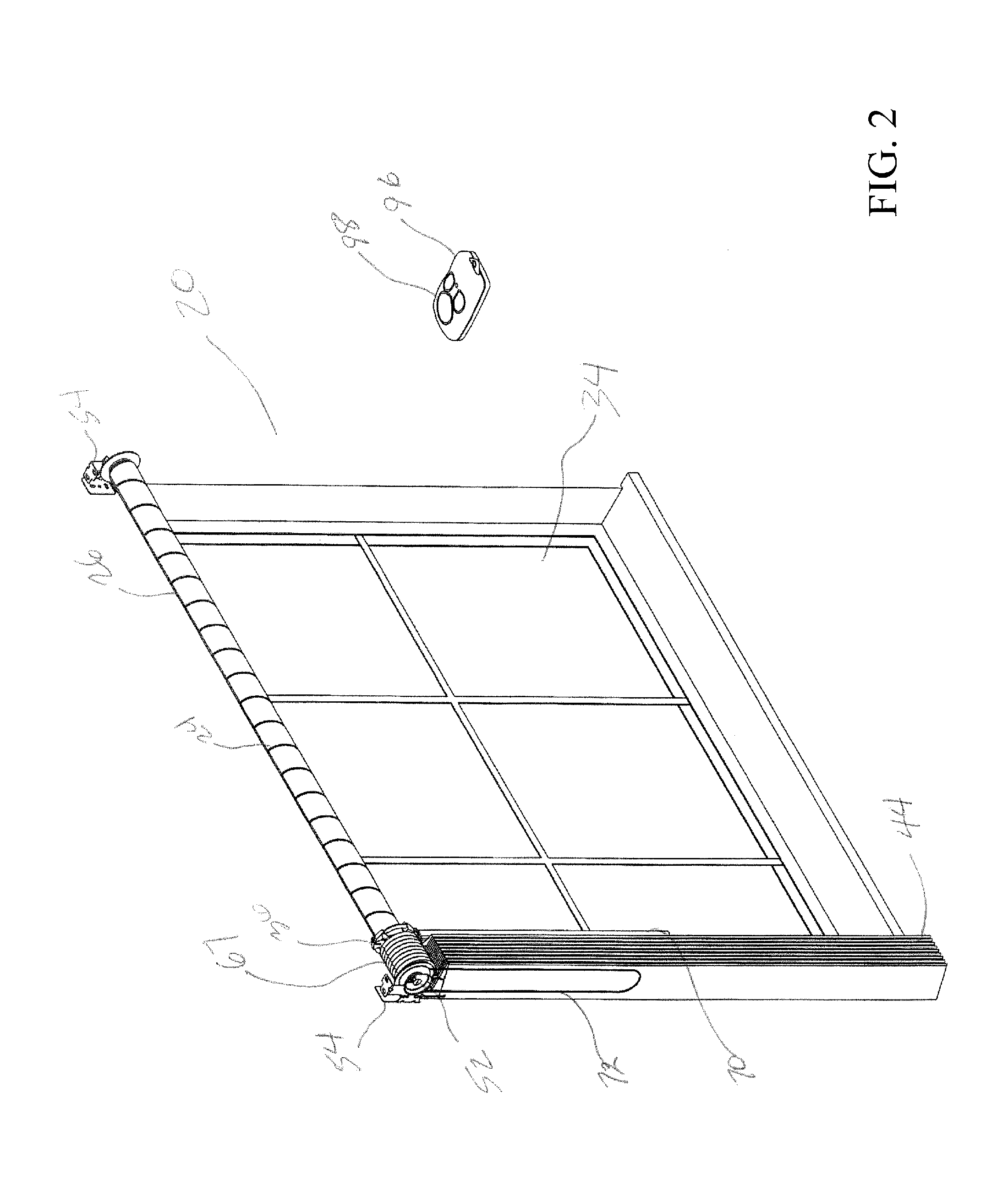

[0211]A system having two horizontal moving curtains or draperies made from dissimilar materials can display each of the two curtains individually, using a common drive system. The drive system can be operated manually by, for example, a pull cord or a draw rod, and can be motorized. In the embodiment, shown in FIGS. 64-77, the horizontal movement of the curtain or drapery is accomplished by one or more grooves, such as one or more helical grooves, formed on the outer surface of a rotating element, such as a roll shade tube, to move the curtain or drapery horizontally when the tube rotates. The drive element can also utilize a sleeve over a tube, such that the sleeve has the one or more grooves and rotating the tube rotates the sleeve. The sleeve and tube can be the same material or different materials. A sleeve made of non-metallic material over...

PUM

| Property | Measurement | Unit |

|---|---|---|

| outer diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

| outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com