Pipe cutting and beveling machine

一种管道切割、斜切机的技术,应用在剪管装置、剪切装置、便携式车床等方向,能够解决切割刀片振动、滑动、工作效率和生产率降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

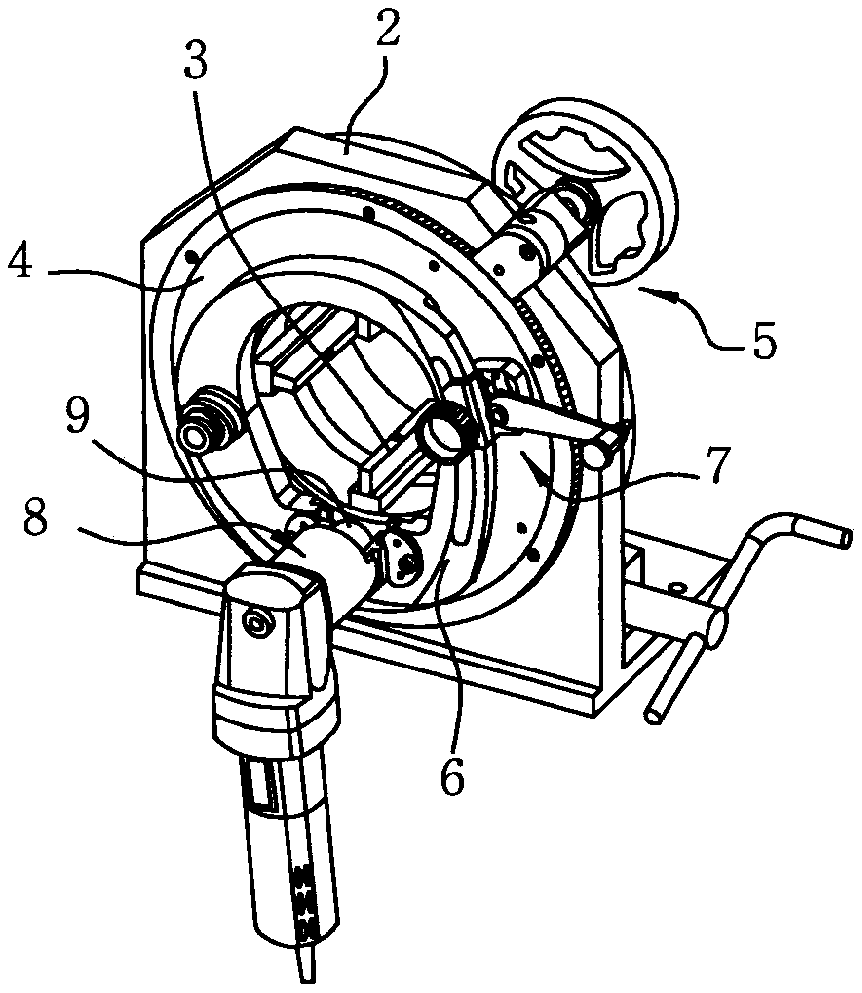

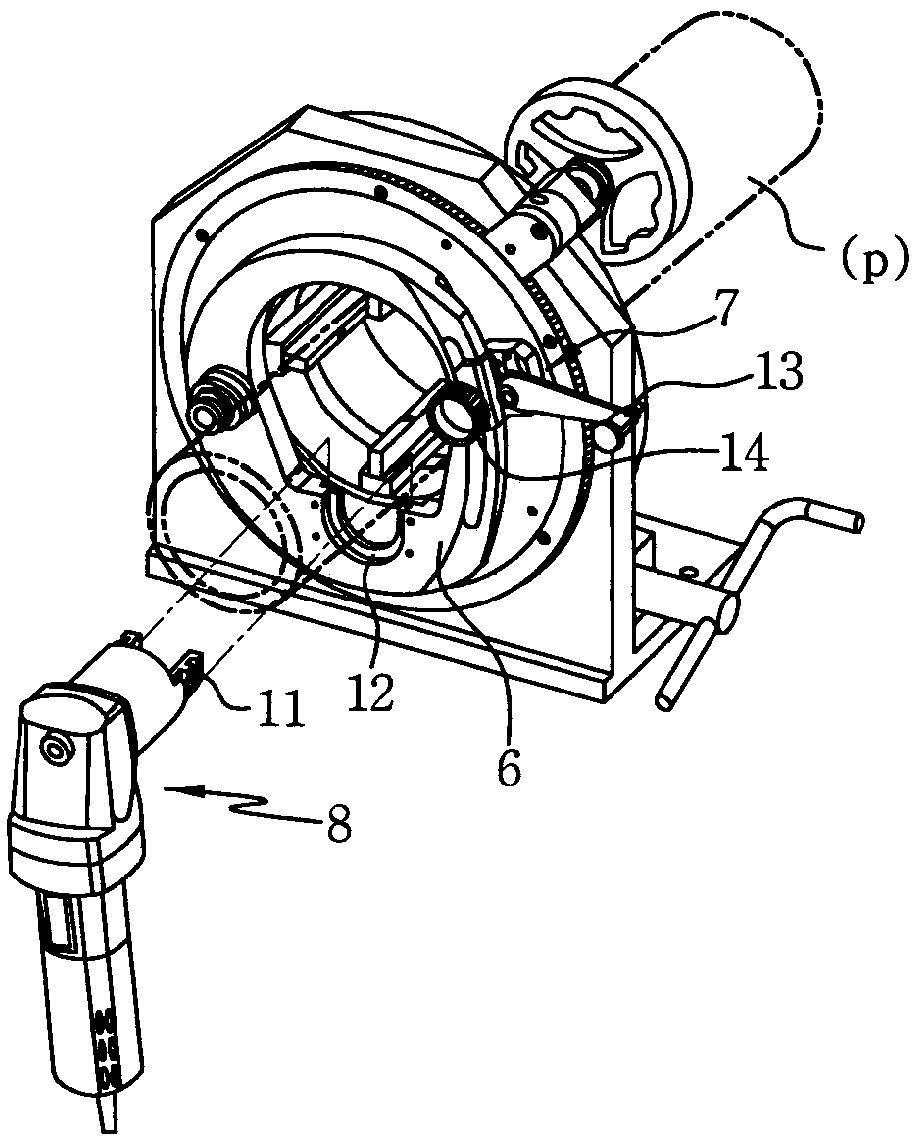

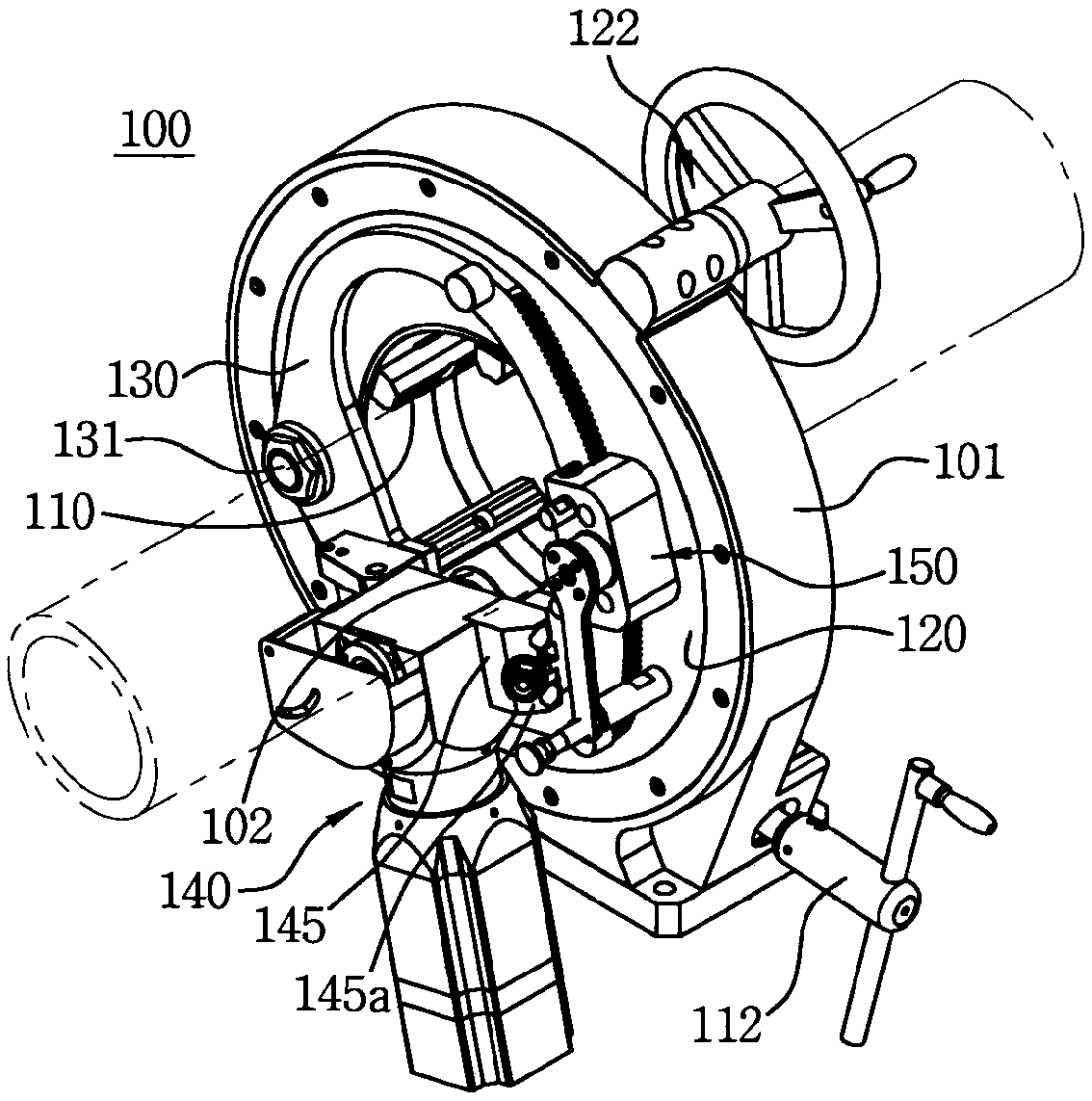

[0036] Hereinafter, a pipe cutting and beveling machine according to an embodiment of the present disclosure will be described in detail with reference to the accompanying drawings.

[0037] Such as image 3As shown, the pipe cutting and beveling machine 100 according to the present disclosure includes a main body 101 standing vertically as a basic skeleton. The main body 101 has a central part through which the pipe p to be cut or beveled passes, the machine means for cutting or beveling the pipe is attached to the front side of the main body 101 and the fixing means for clamping the pipe is attached to the main body 101 the rear side of the

[0038] First, in the apparatus, a rotating plate 120 concentrically rotating around the outer circumference of the fixed pipe p is attached to the main body 101 . The rotating plate 120 is connected to the main body 101 to be freely rotatable without being separated from the main body 101 , and the apparatus further includes a rotatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com