Patents

Literature

154results about "Portable lathe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

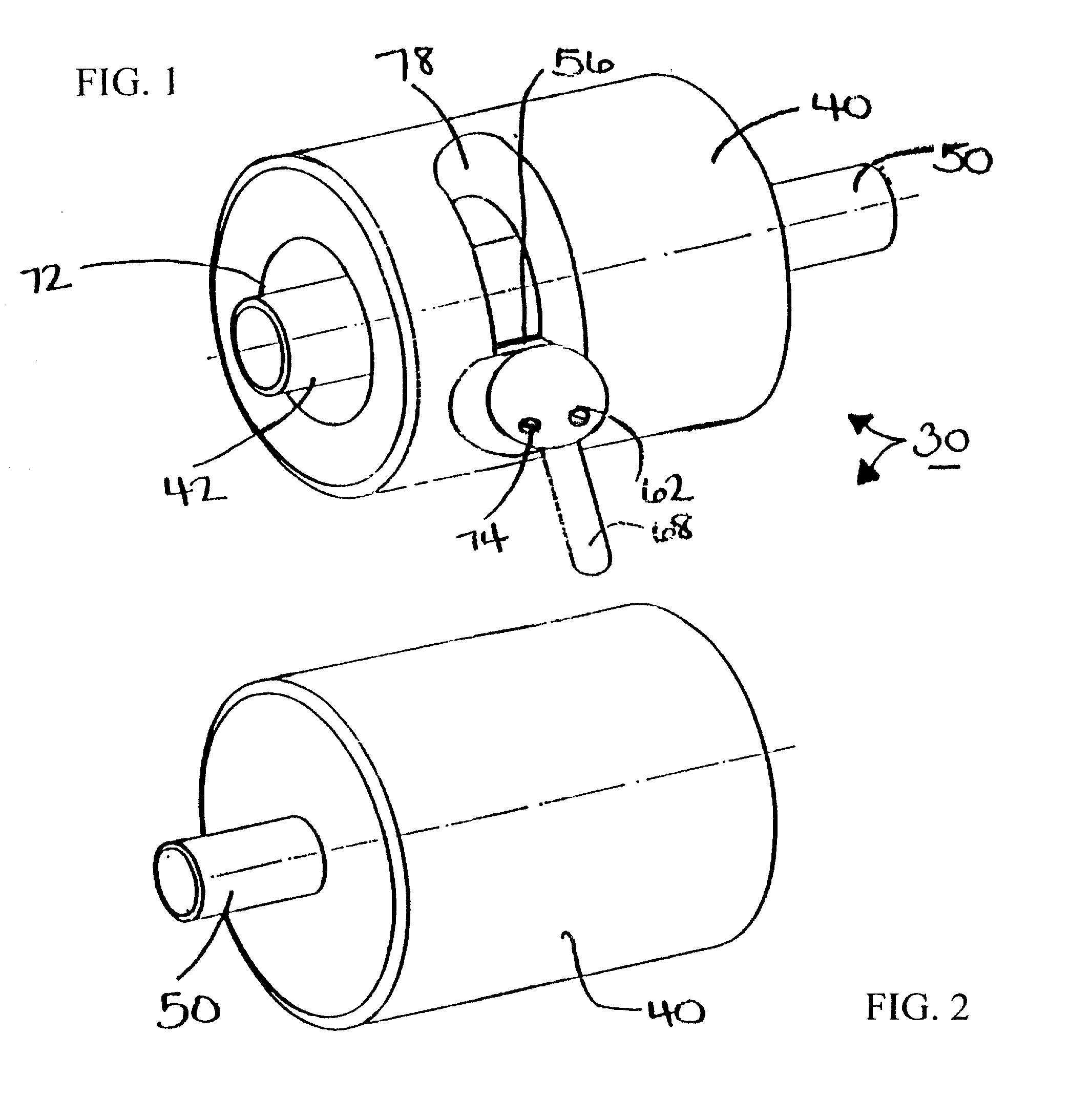

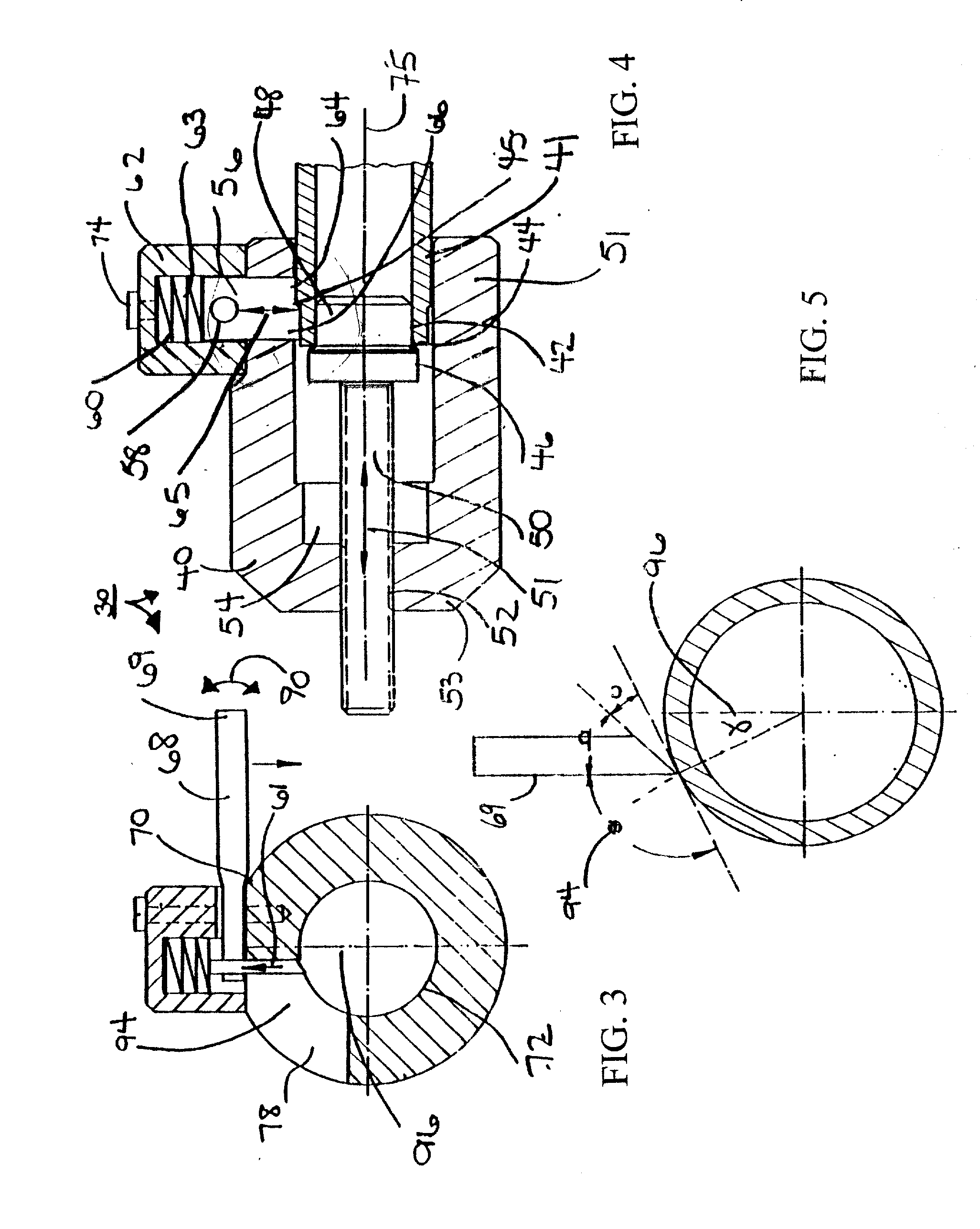

Pipe shaver

The present invention a pipe shaver a pipe shaver for removing a uniform layer of material from the outer diameter of a pipe, the pipe shaving includes a housing including a longitudinal axis; a cutting blade including a blade guide for positioning a front face of said cutting blade at an angle theta of not less than 95 degrees relative to the pipe surface and for mounting said blade to said housing, said blade including a cutting edge; a lifting means for manually urging said blade radially outwardly away from said pipe and inwardly to the outer diameter of the pipe; and a lever for manually urging said blade radially outwardly away from said pipe and a threaded cam for moving said cutting edge longitudinally along the outer diameter of said pipe for shaving a thin substantially uniform layer of material off the outer diameter of the pipe.

Owner:OSWALD FRITZ

Pipe End Machining Device with Axial Autofeed

A device for preparing the end of a pipe includes a non-rotatable mandrel one end of which is attachable to the pipe. A motor rotates a sleeve around the mandrel and the sleeve retains an arm perpendicular to the mandrel for cutting the pipe. A cam surface on the rotating sleeve moves a cam follower. Movement of the cam follower is converted to rotational movement for turning a feed nut threaded on the mandrel. The rate at which the sleeve is advanced by the feed nut is controlled by limiting the movement of the cam follower.

Owner:ILLINOIS TOOL WORKS INC

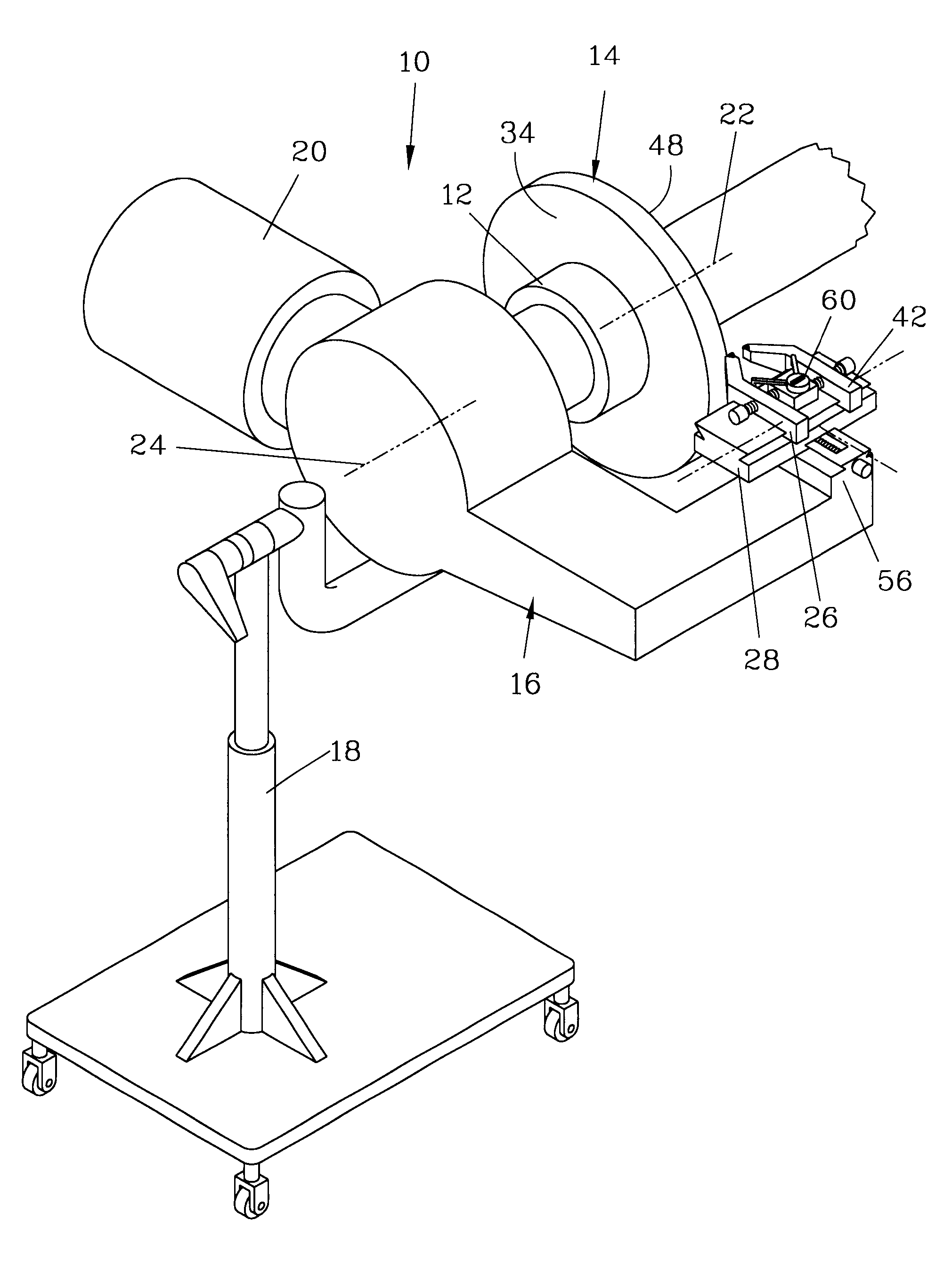

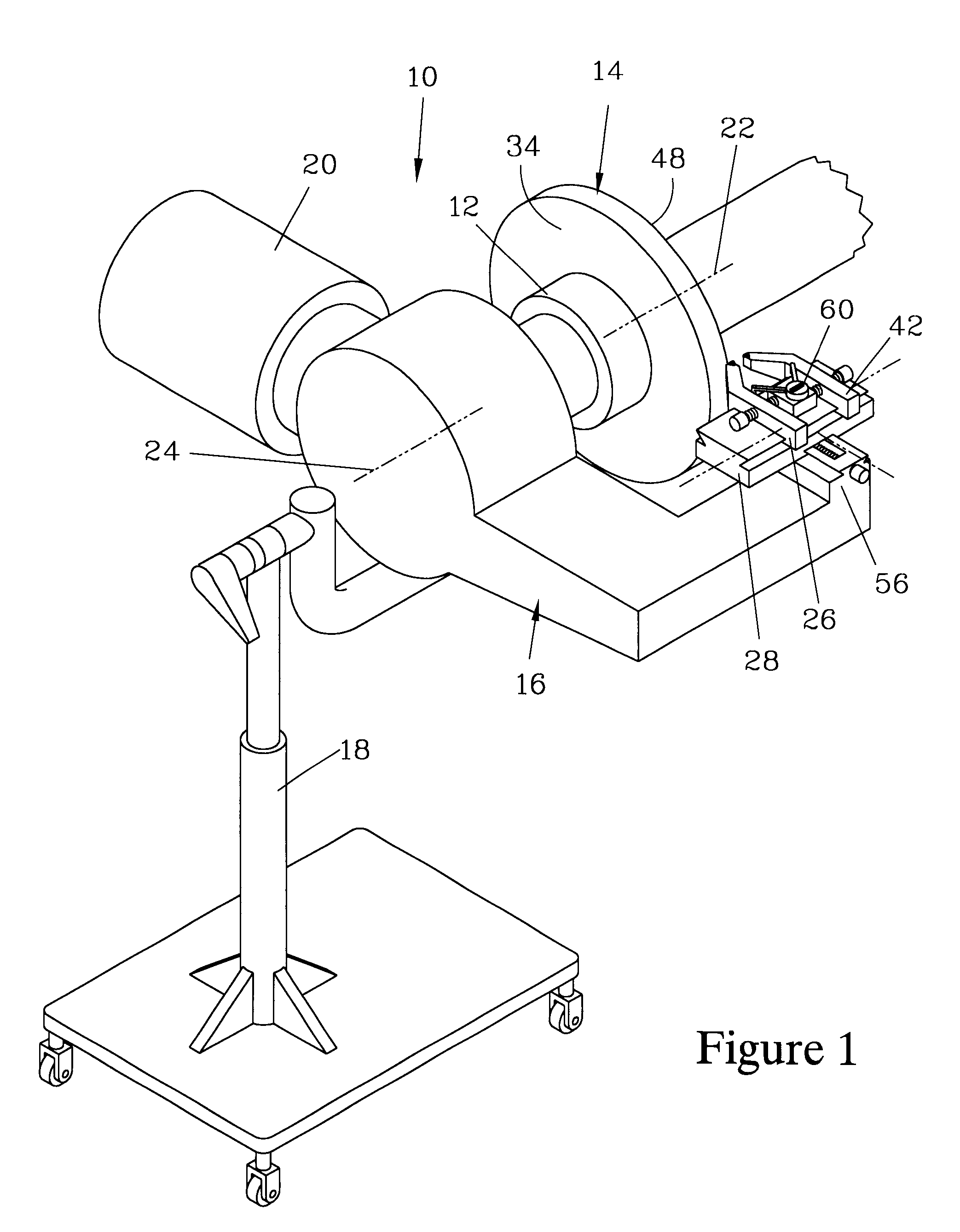

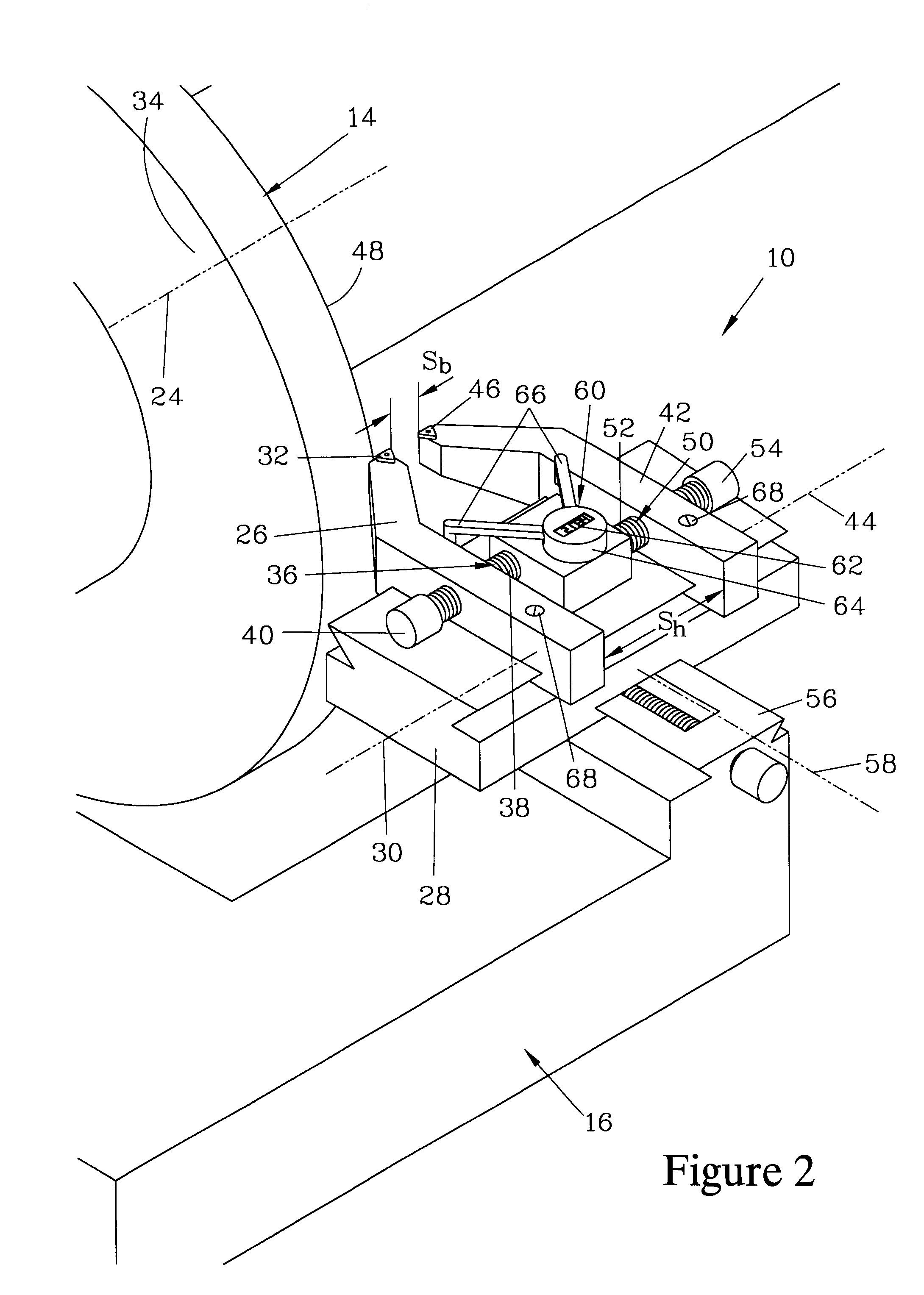

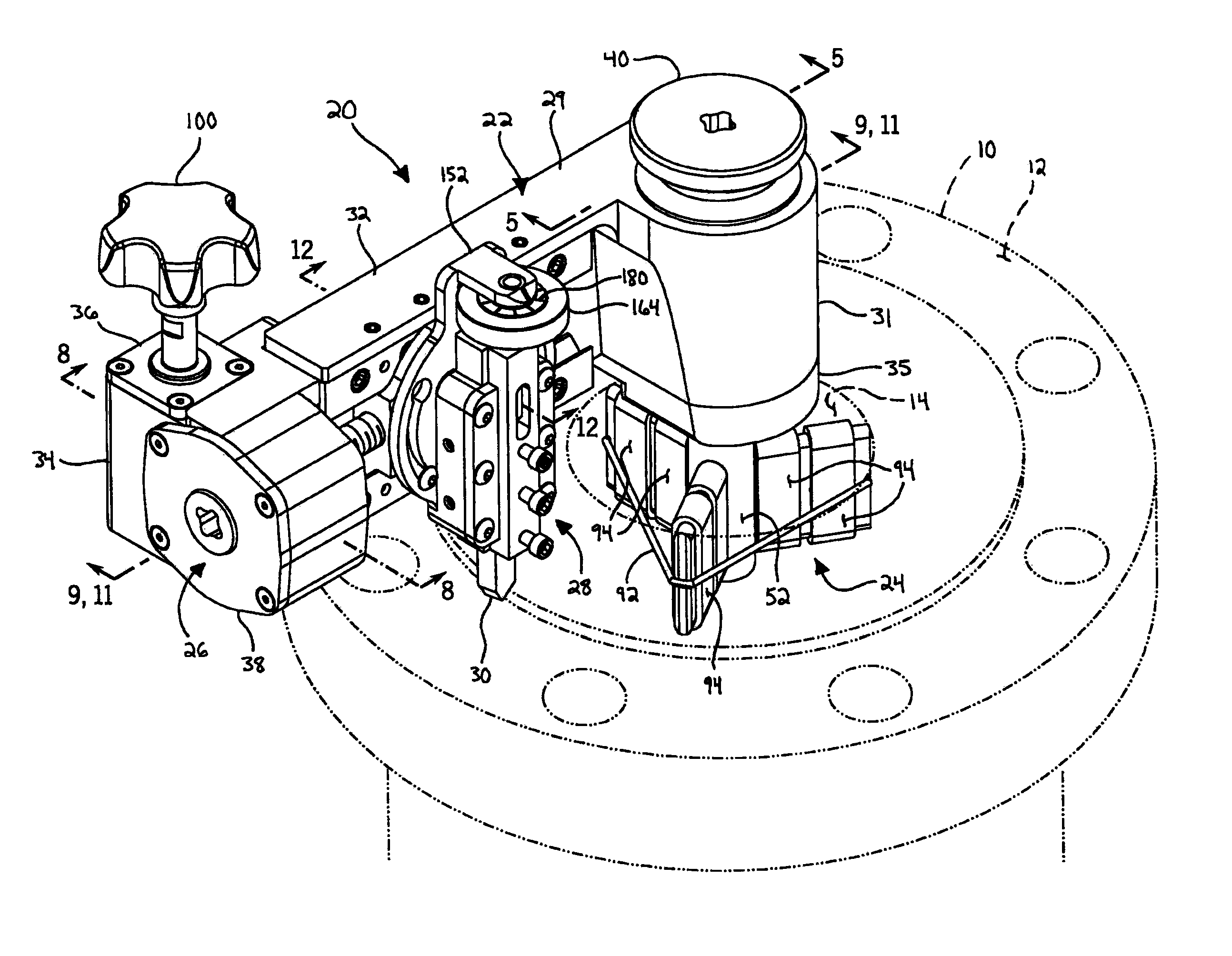

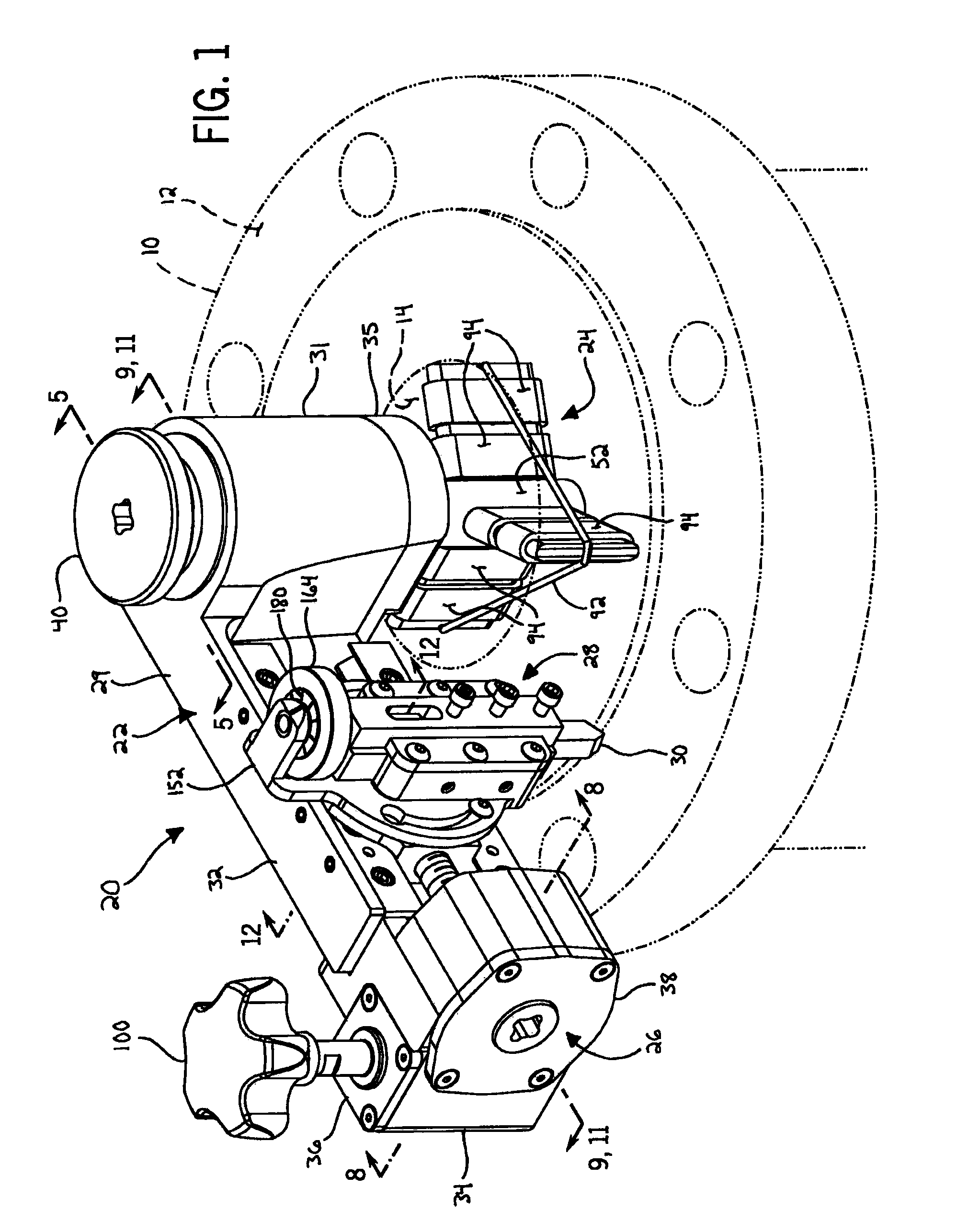

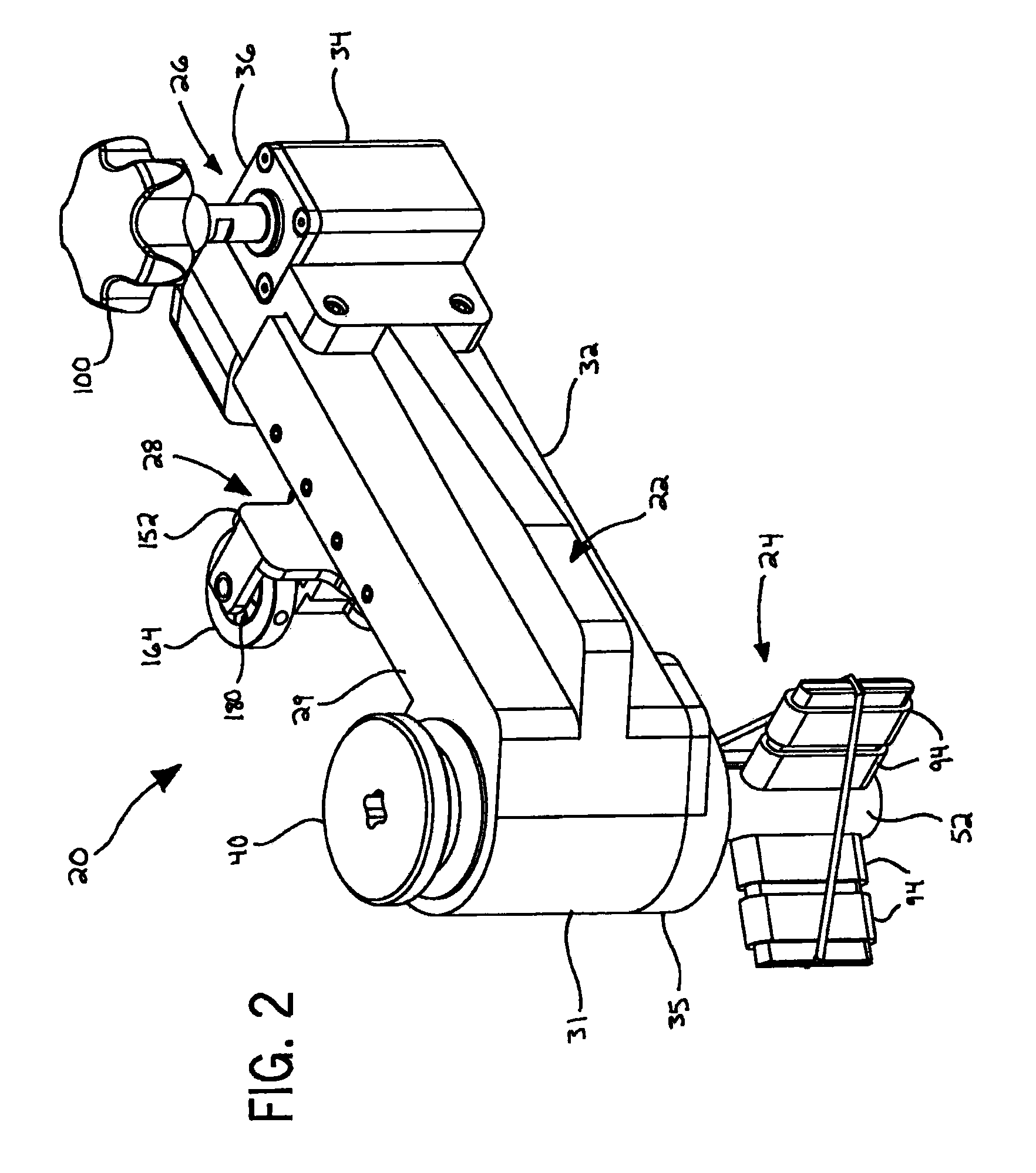

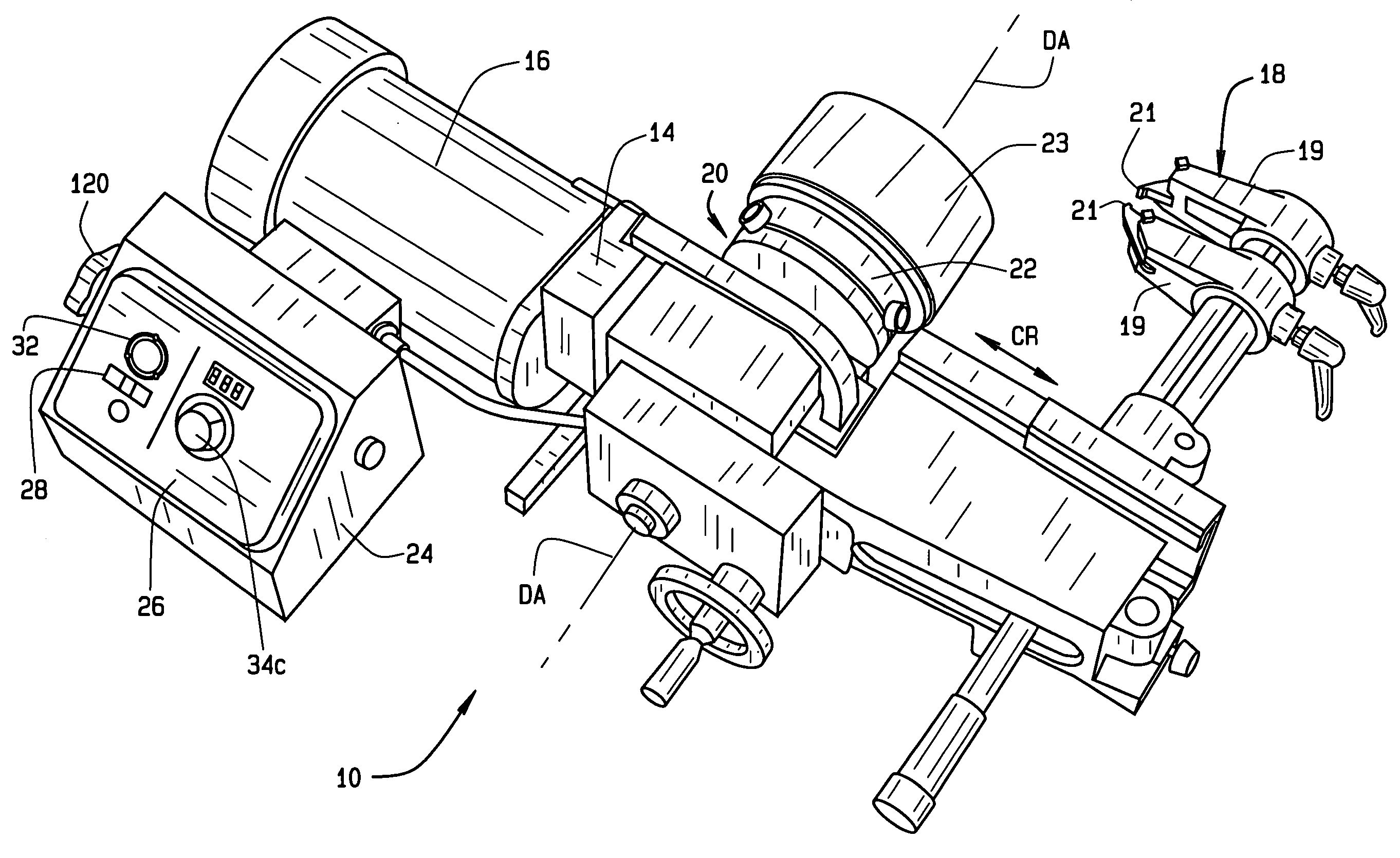

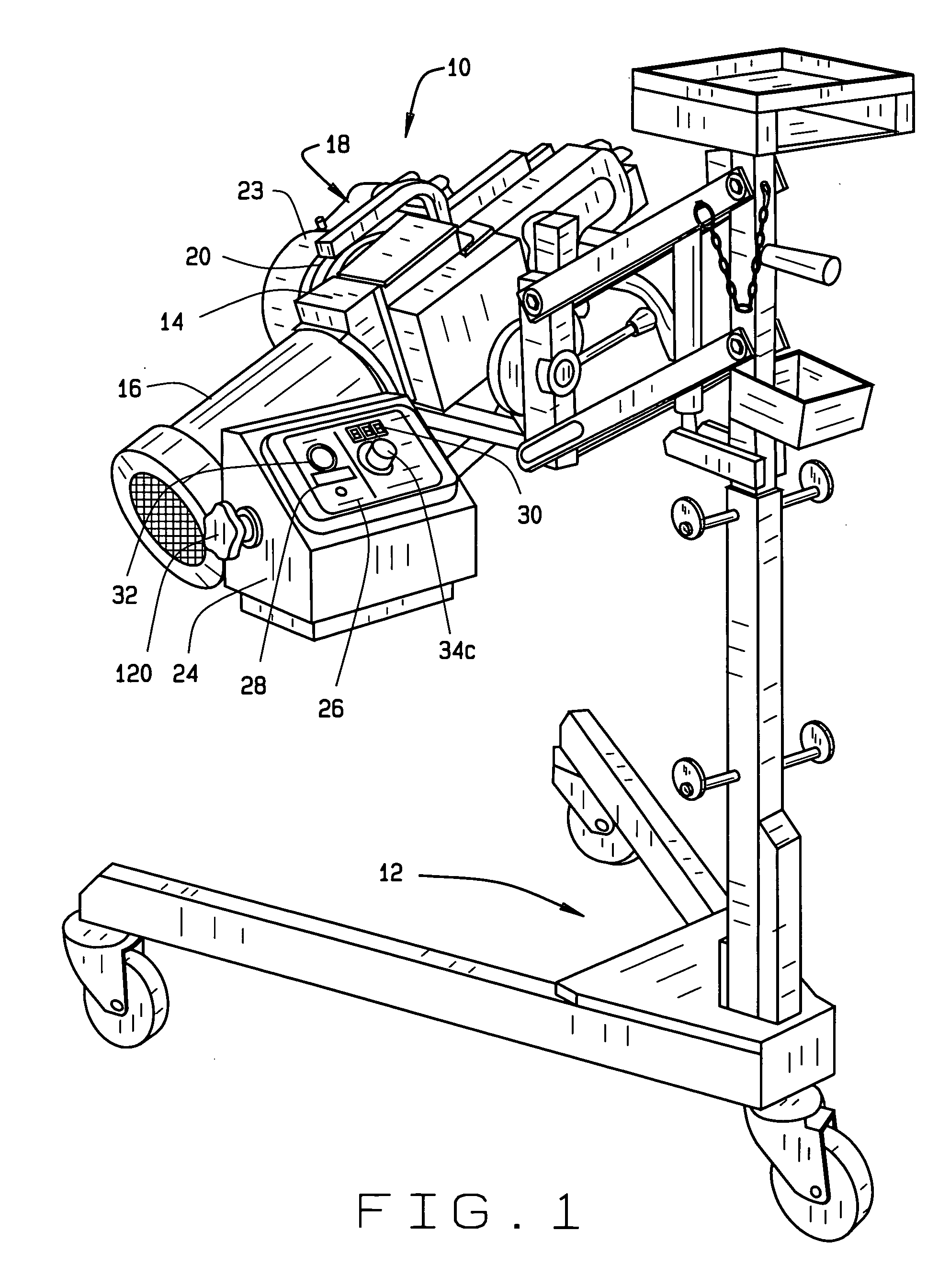

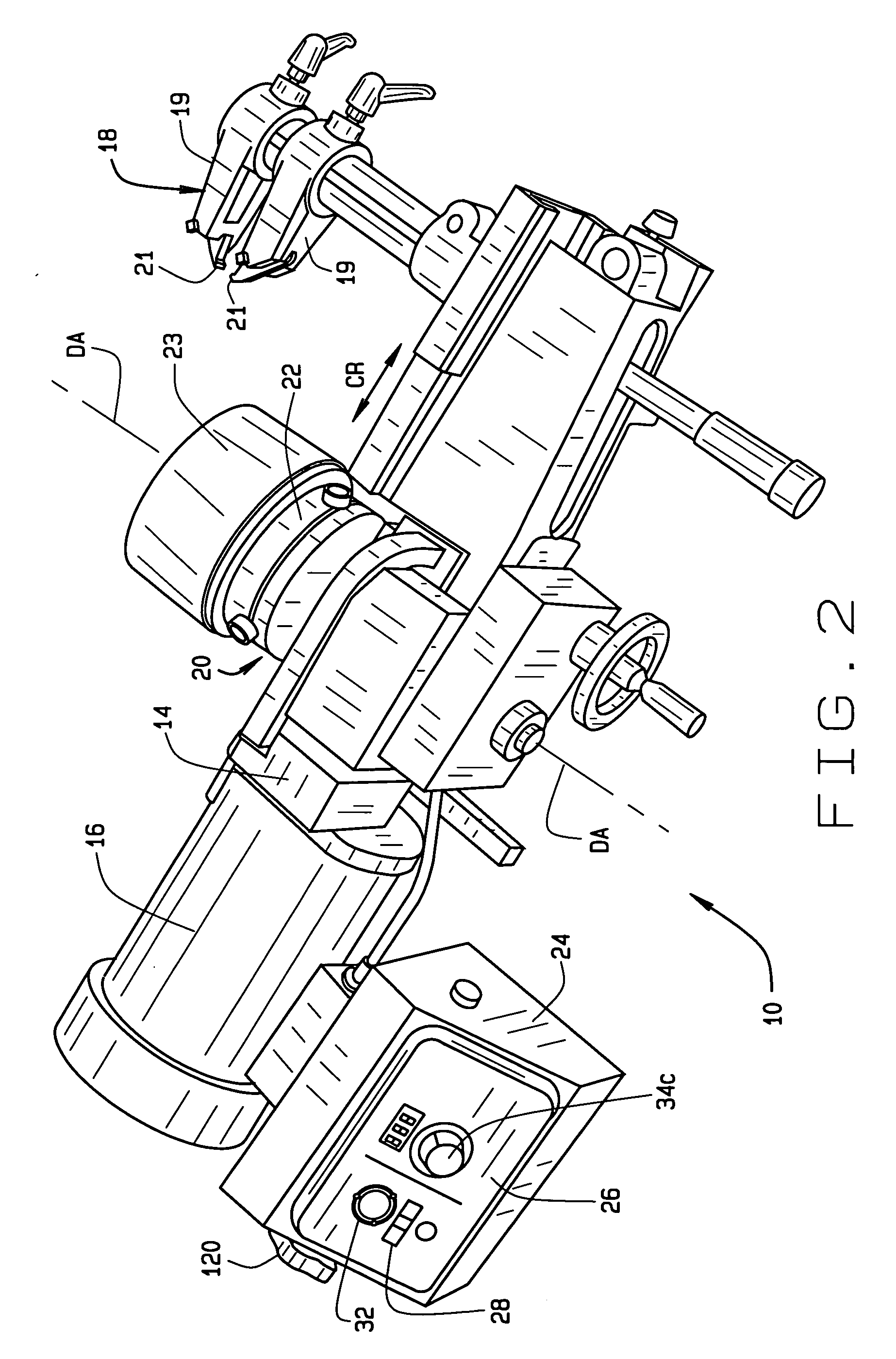

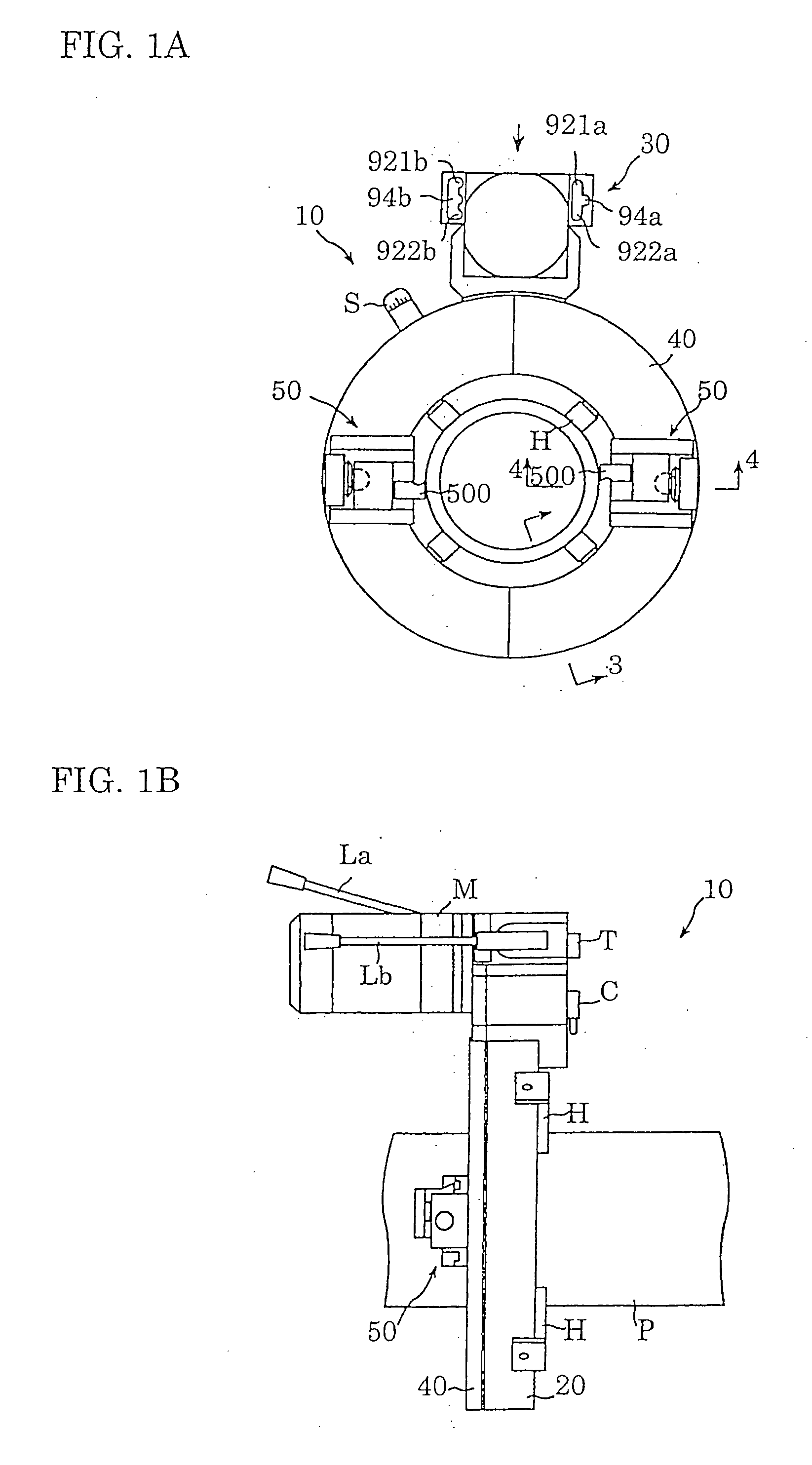

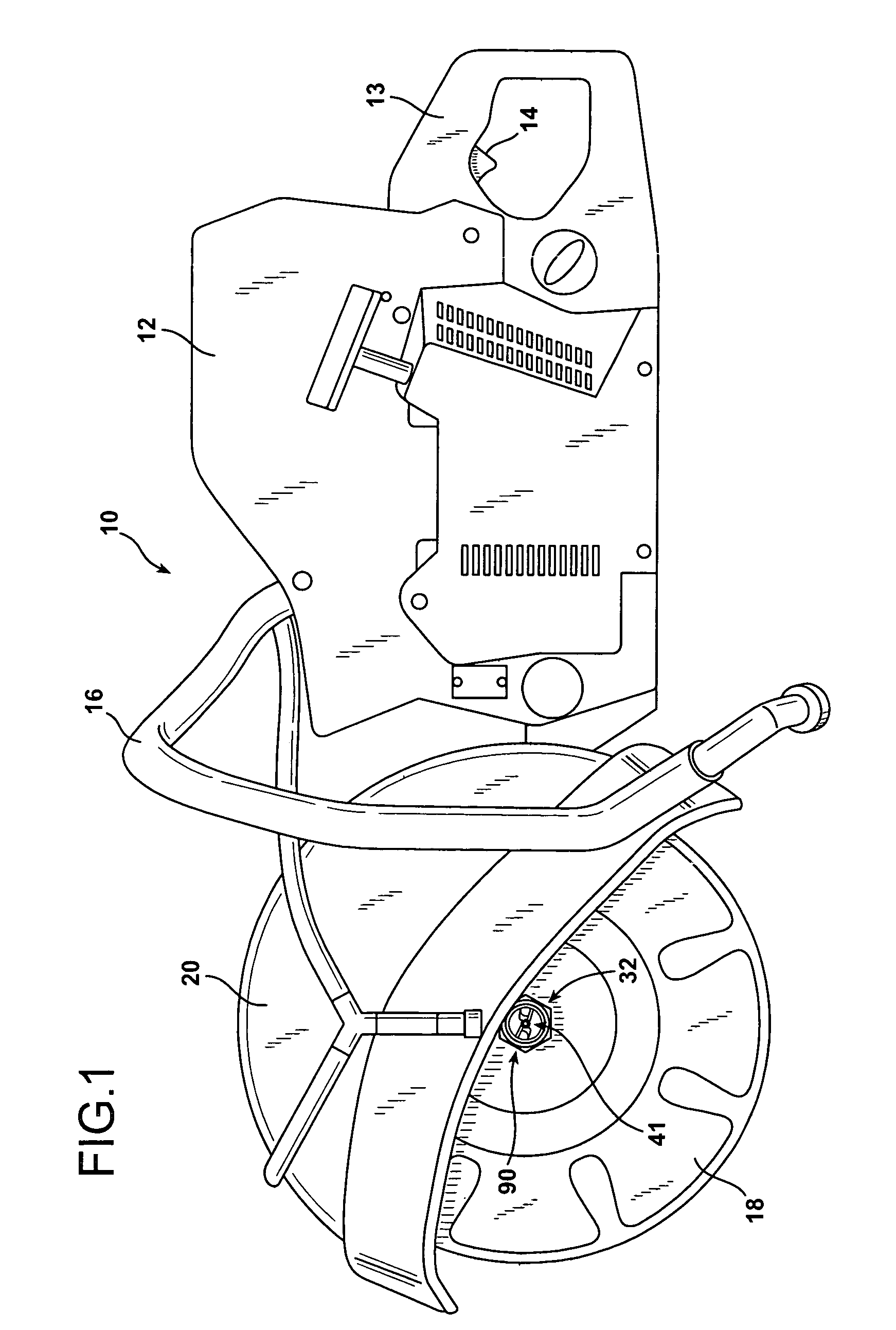

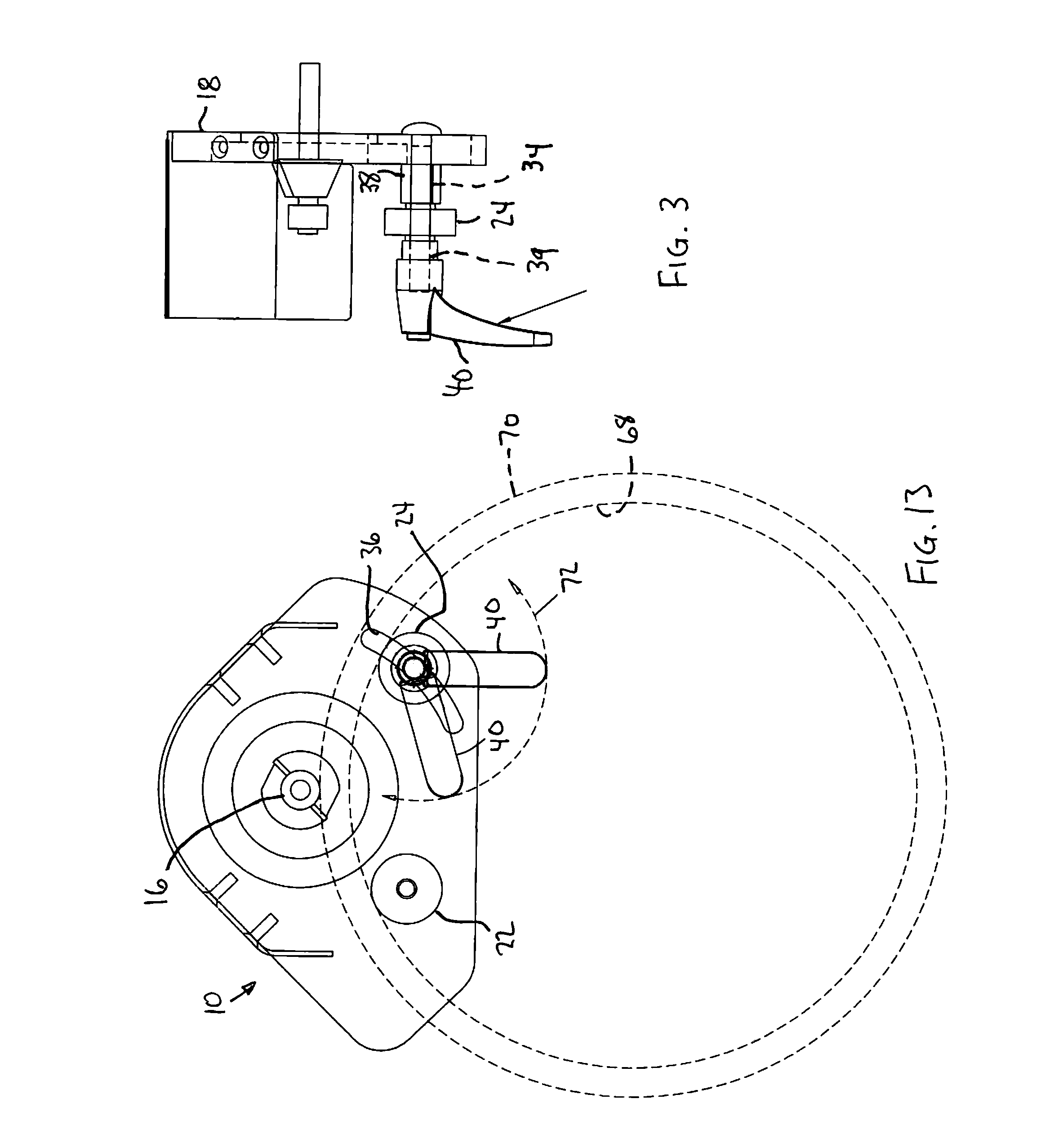

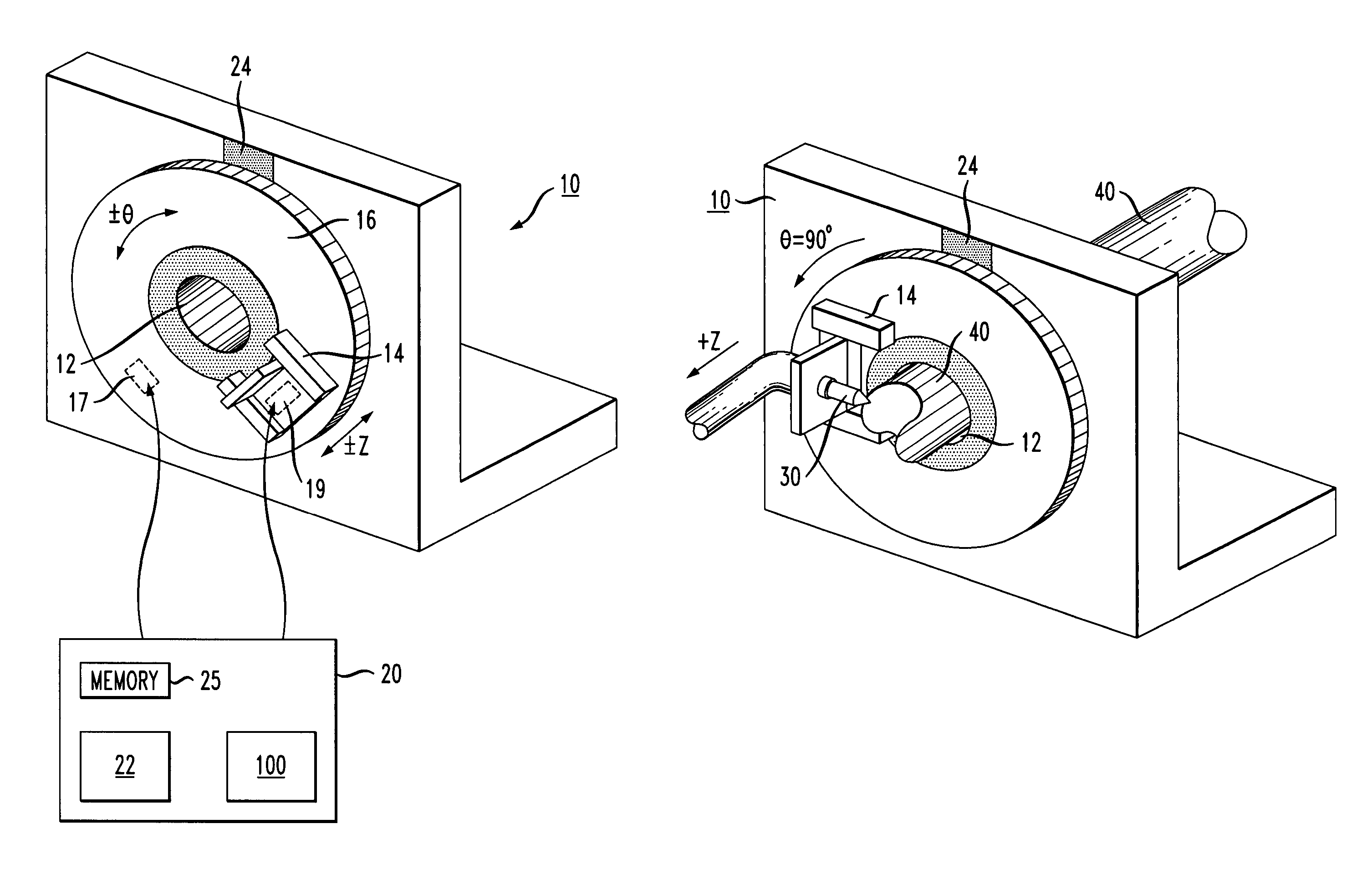

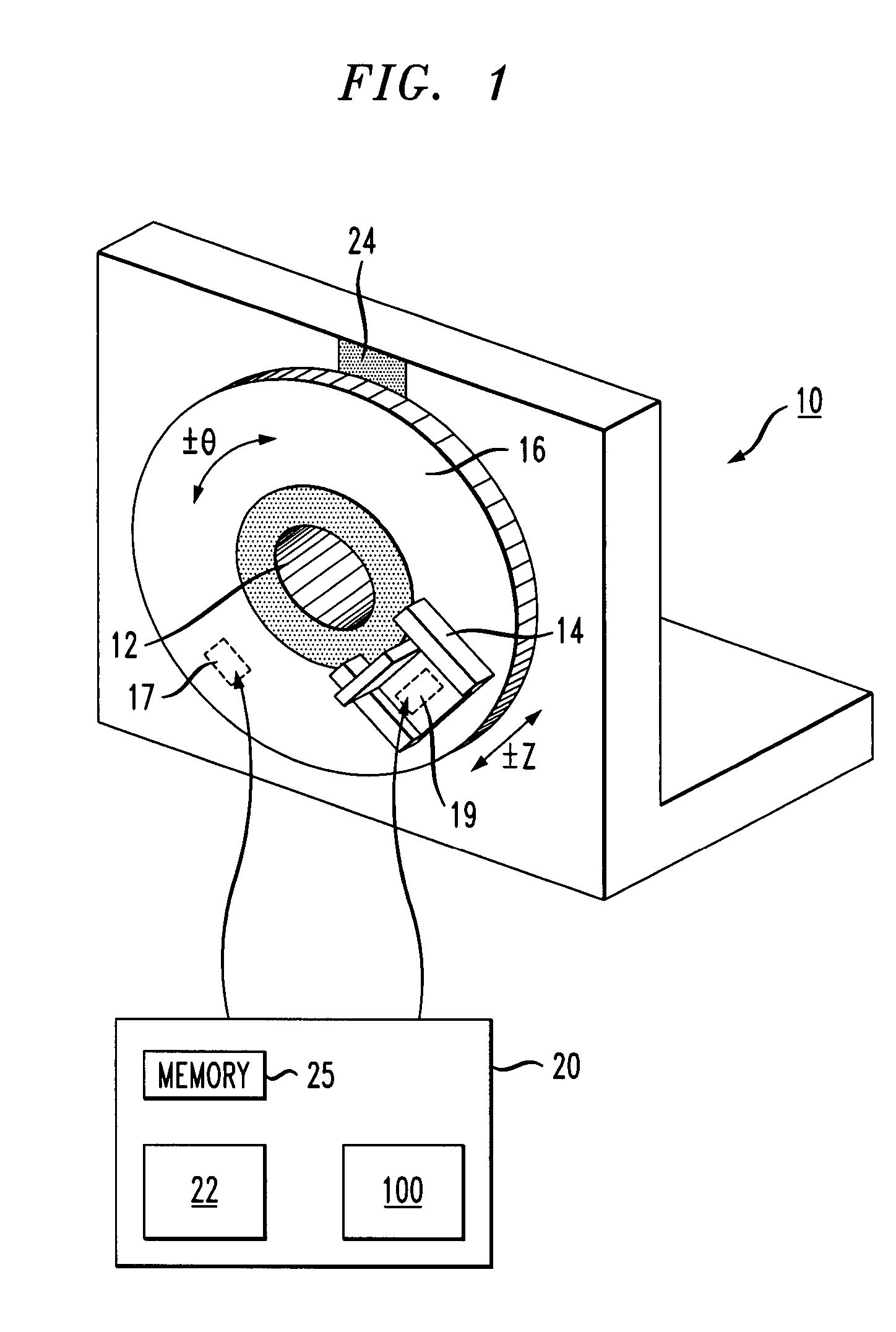

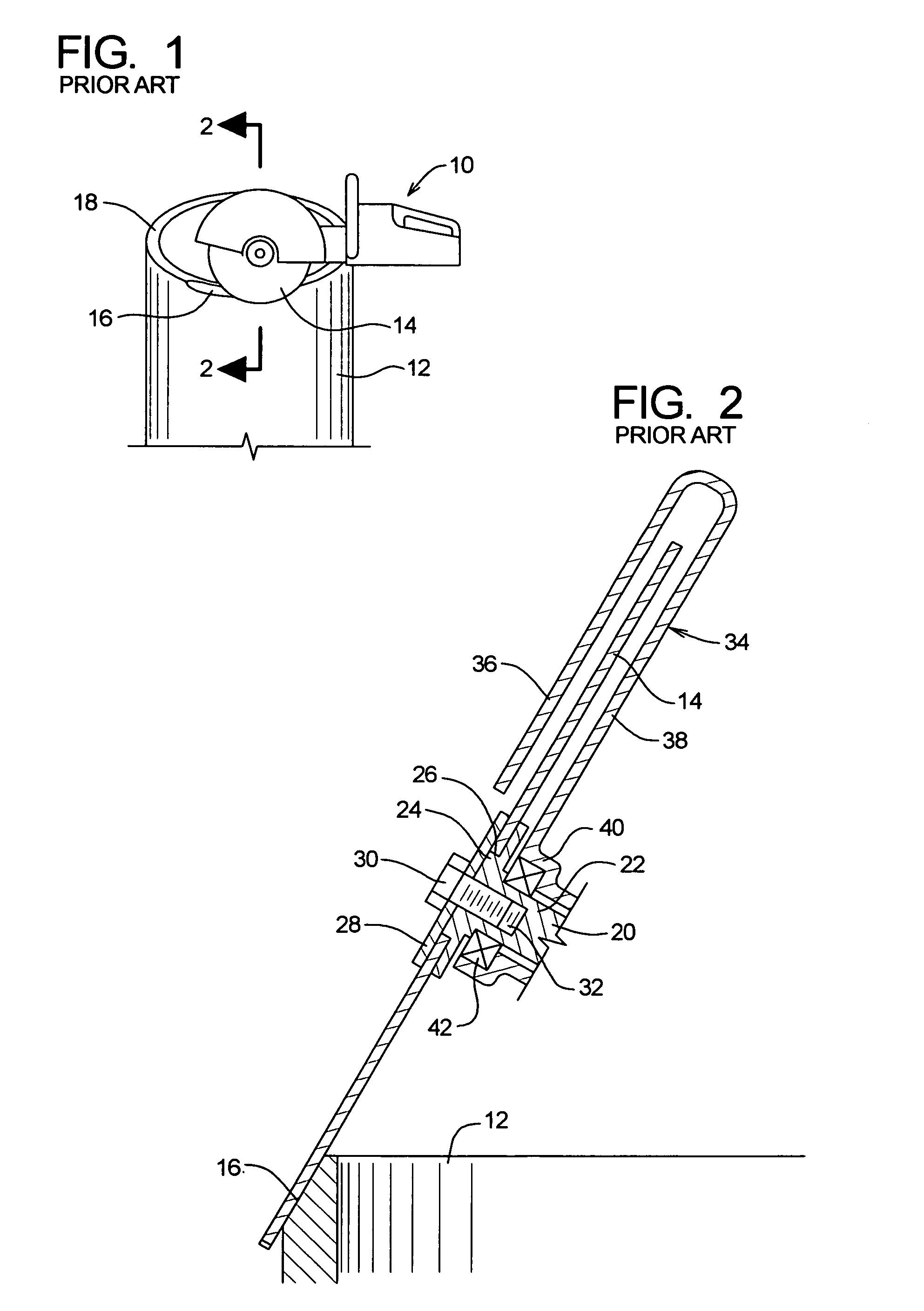

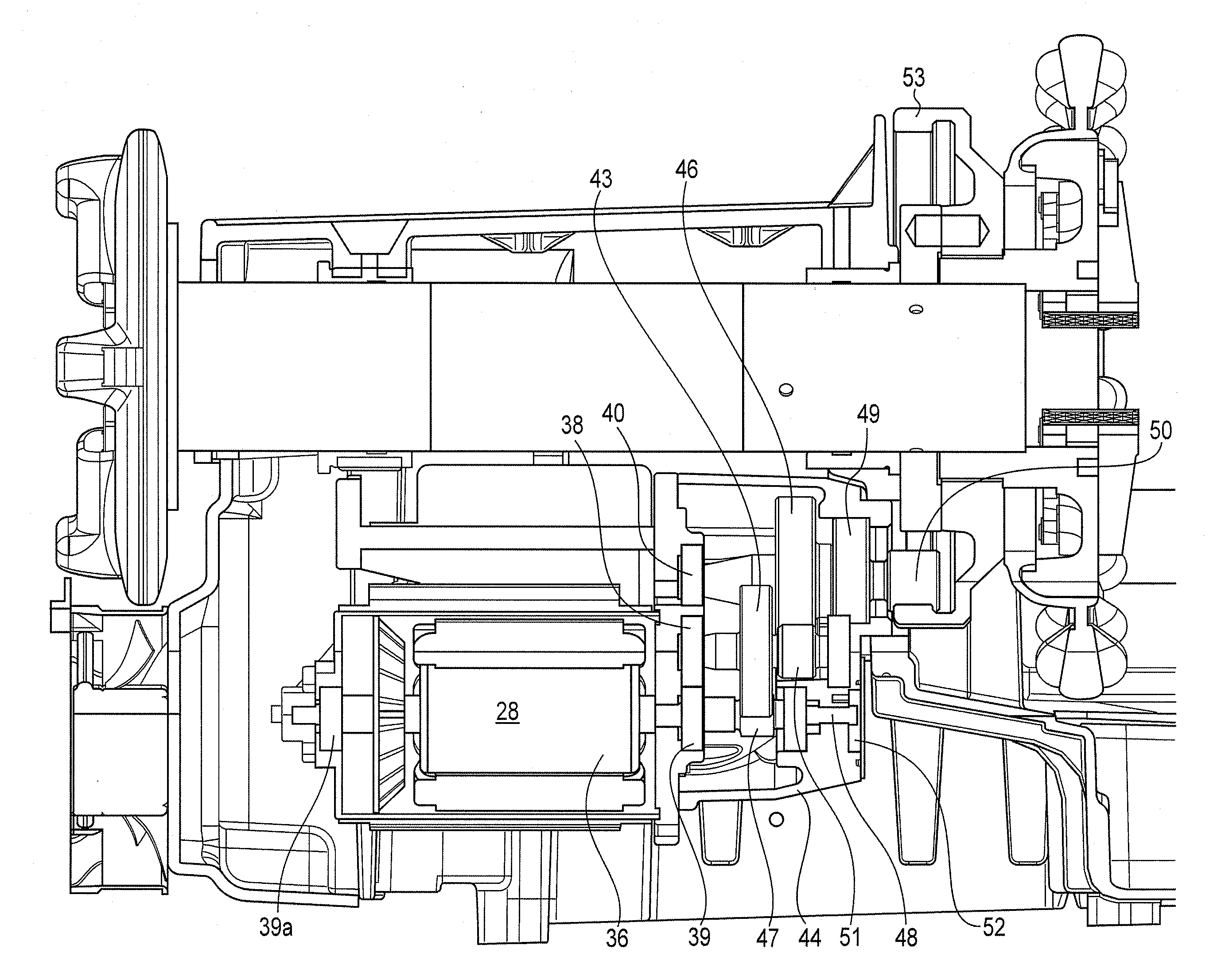

On-vehicle disk brake lathe

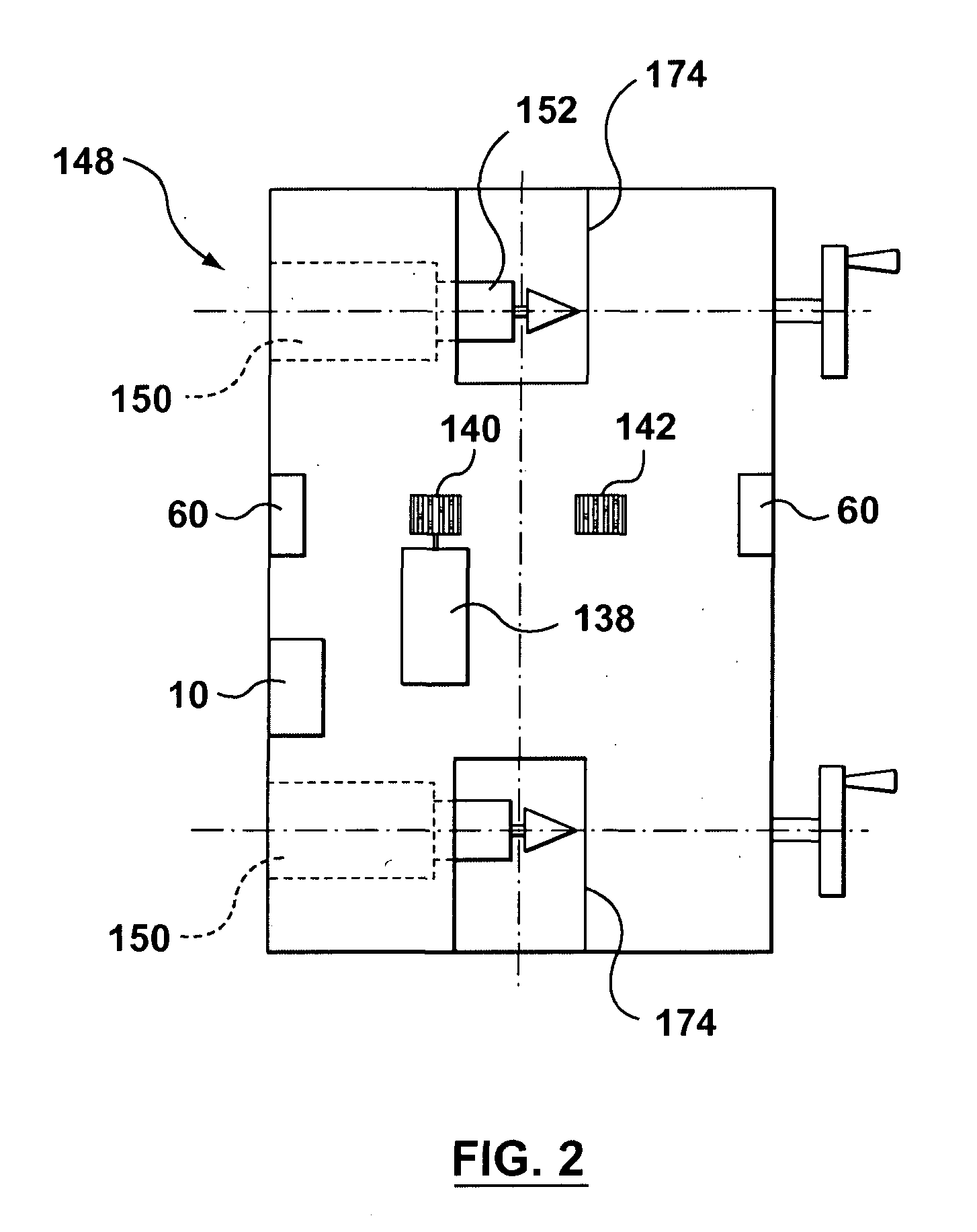

InactiveUS6363821B1Easy to adjustEasy to measureTurning machine accessoriesMeasurement/indication equipmentsTool bitEngineering

A disk brake lathe has a pair of tool bits mounted to tool holders which are translatable parallel to a lathe axis to adjust the separation of the tool bits from a brake disk. A displacement gauge responds to changes in the separation between the tool holders. When the tool bits are in continuous contact with the disk, the separation indicates the thickness which would result from machining the disk. This separation can be compared to a specification to determine whether to machine or discard the disk. A method for machining a disk starts by mounting and aligning the lathe to a wheel hub on which the disk is mounted. The tool bits are each advanced until they are in continuous contact the disk surfaces, when the separation of the tool bits is measured and preferably compared to a specification. When the tool bits are sequentially advanced, variation in the separation can be used to determine depth of cut for each tool bit. A system employing a brake lathe has a microprocessor which receives signals responsive to the separation between the tool bits of the lathe. One or more contact sensors indicate contact of the tool bits with the other tool bit or the brake disk, and the microprocessor can implement instructions to practice the above method. A surface displacement gauge can be employed to allow the system to measure the thickness and lateral run-out of the disk prior to machining.

Owner:BONITA IP

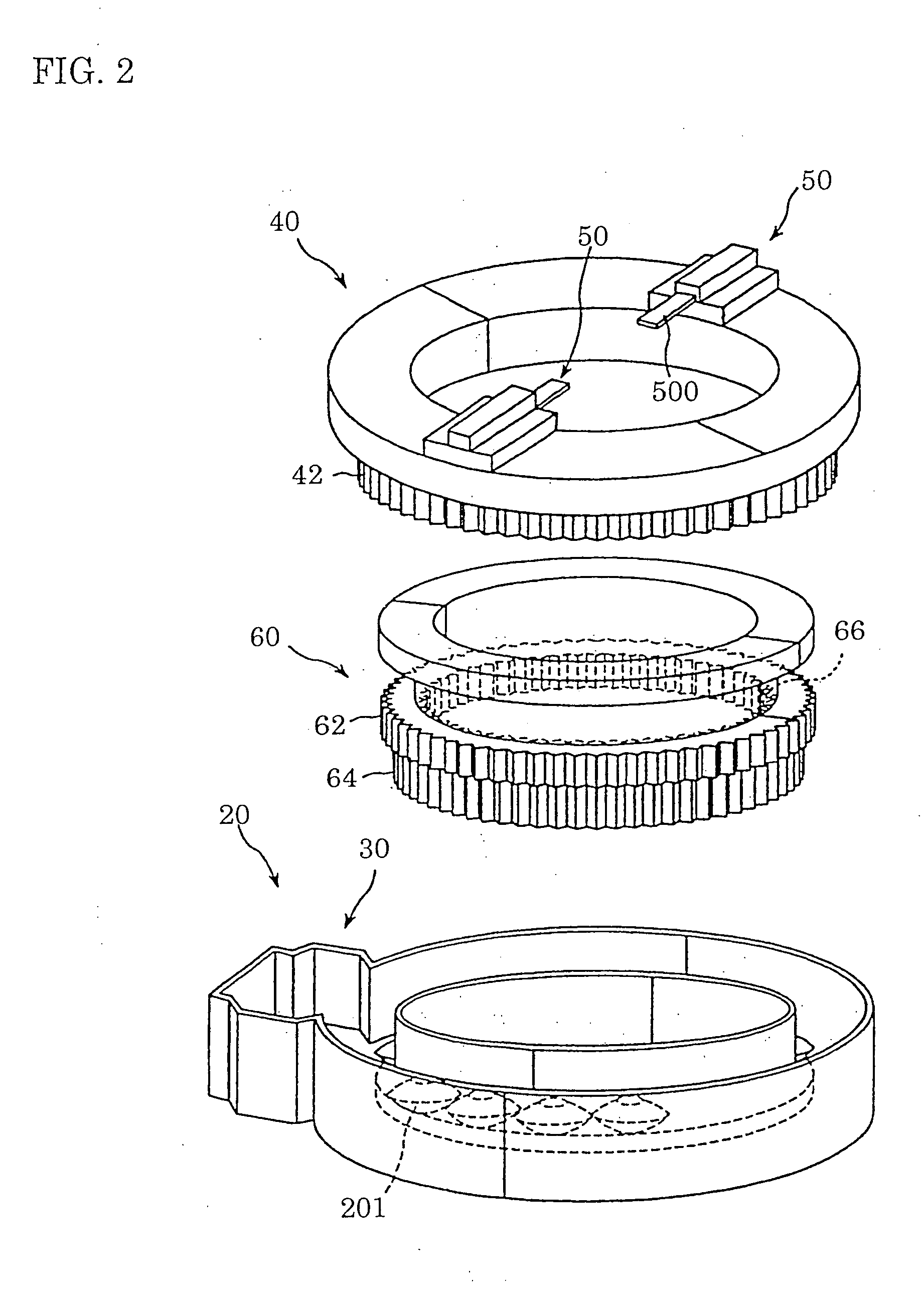

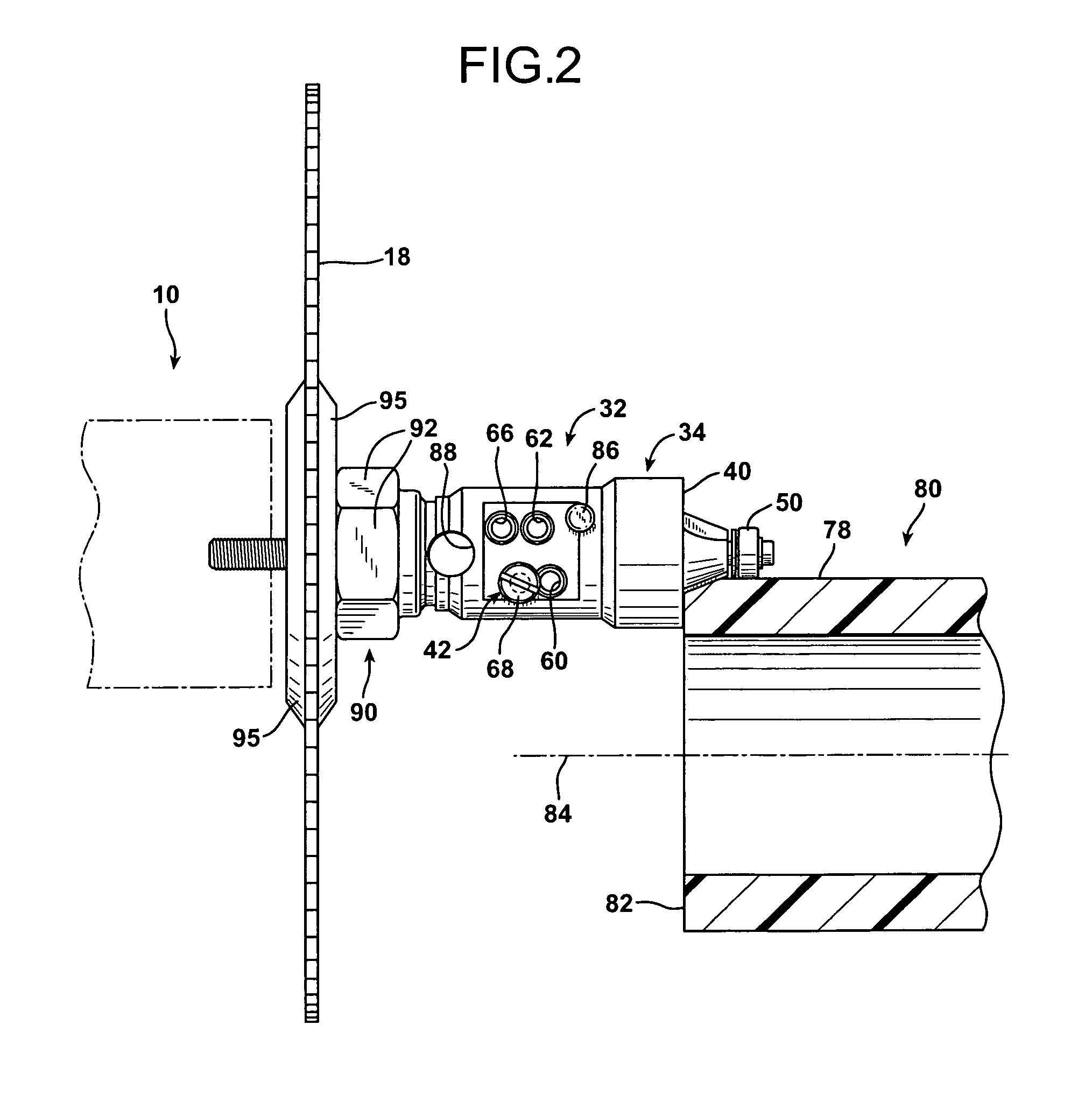

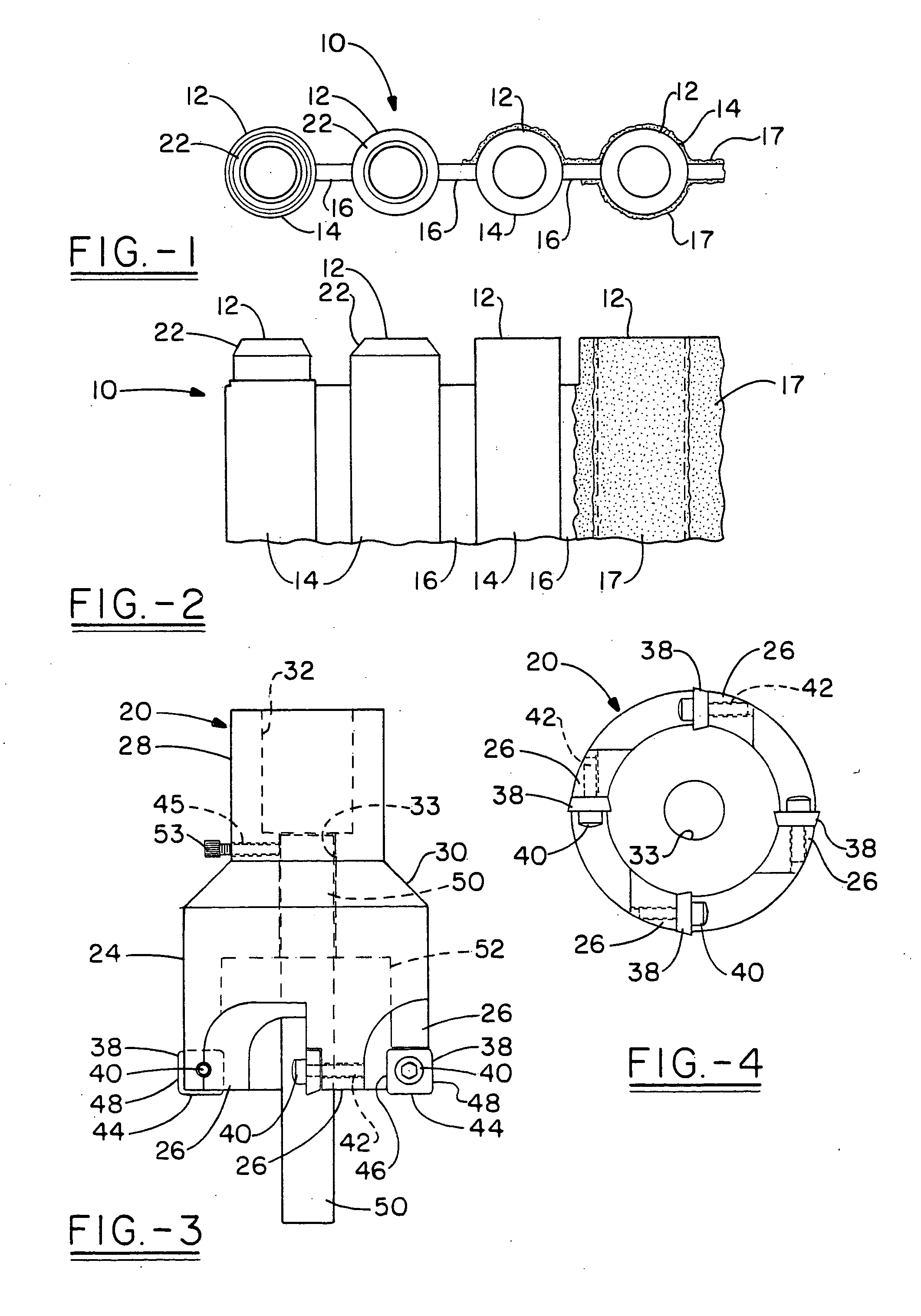

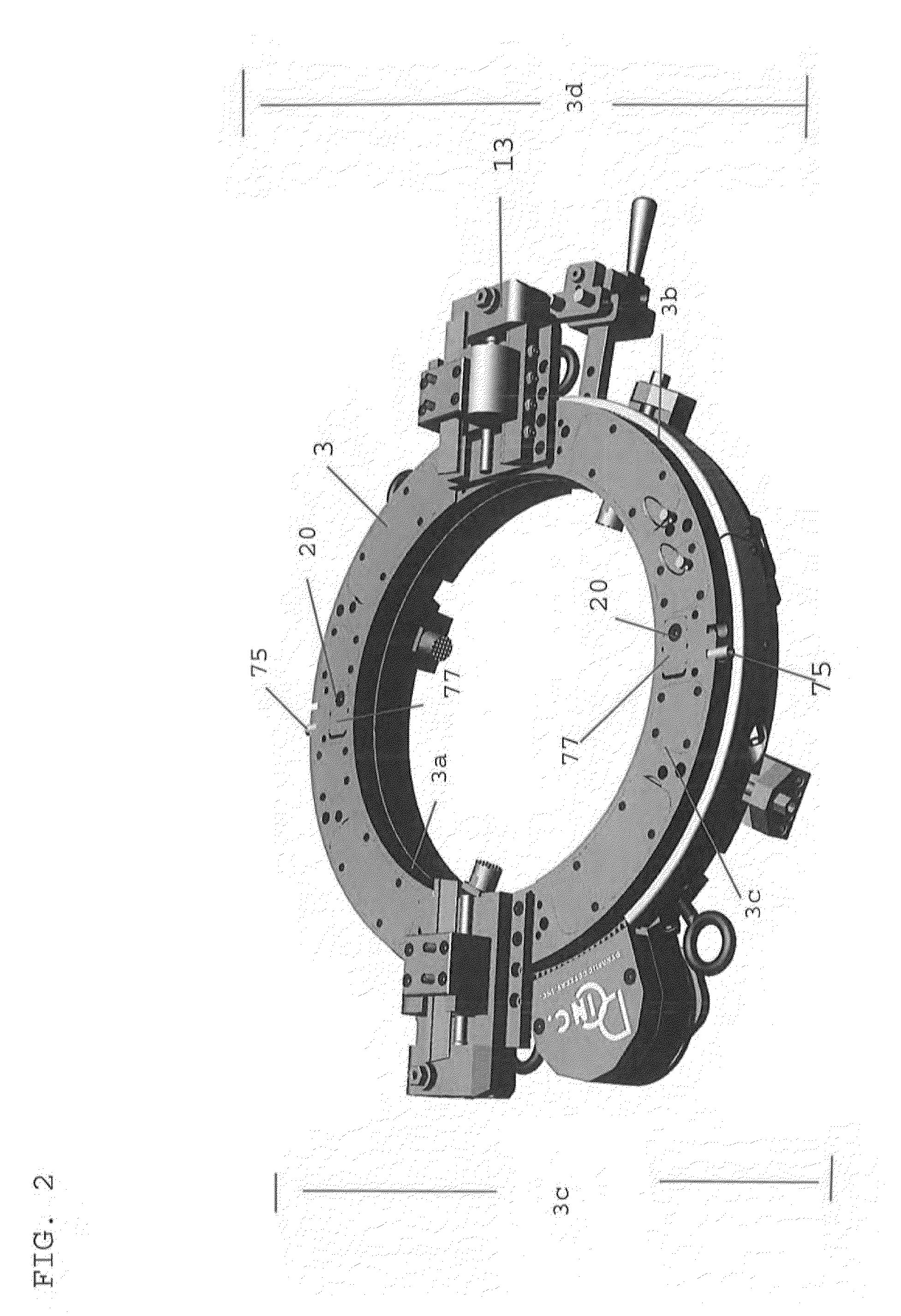

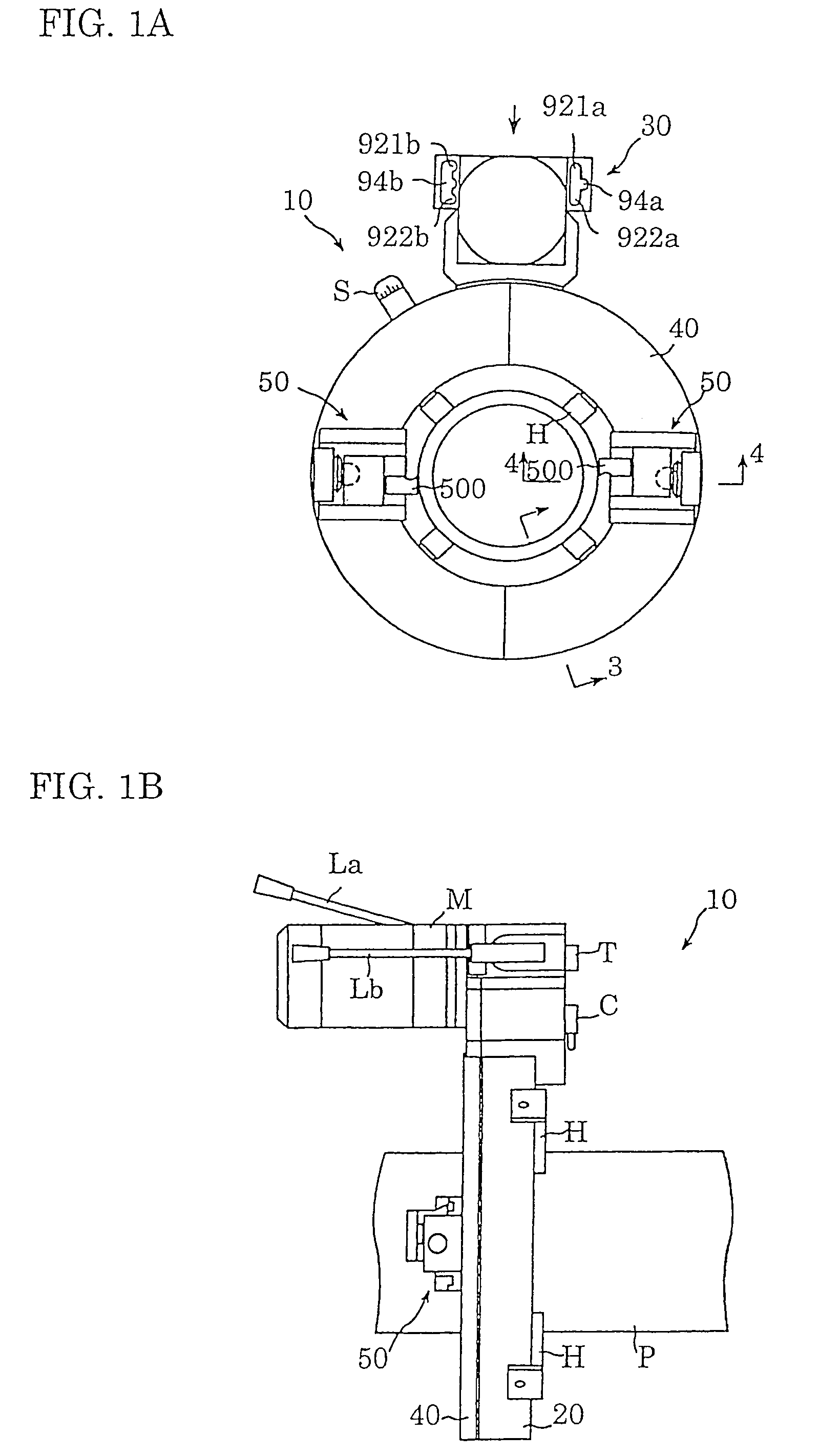

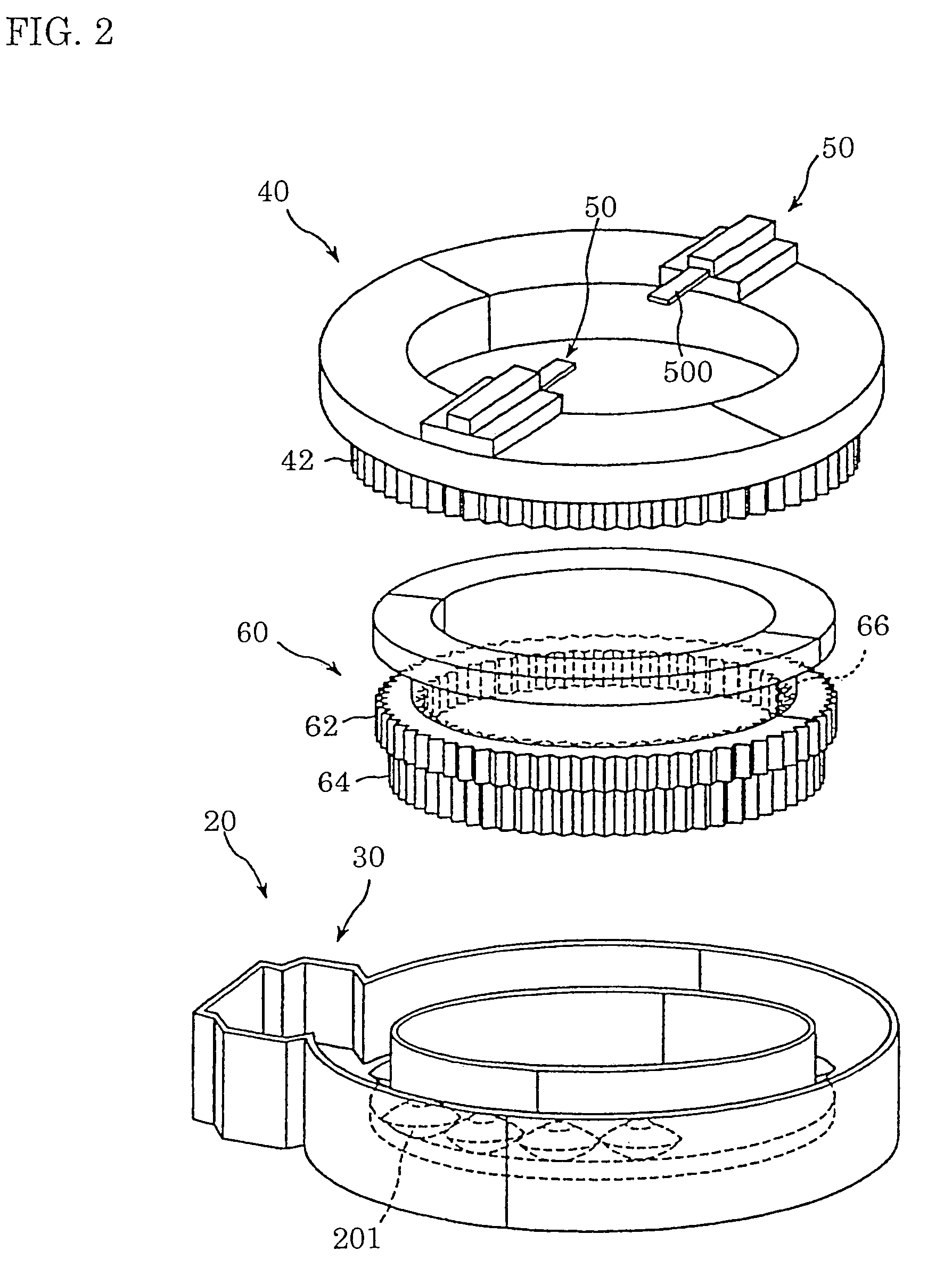

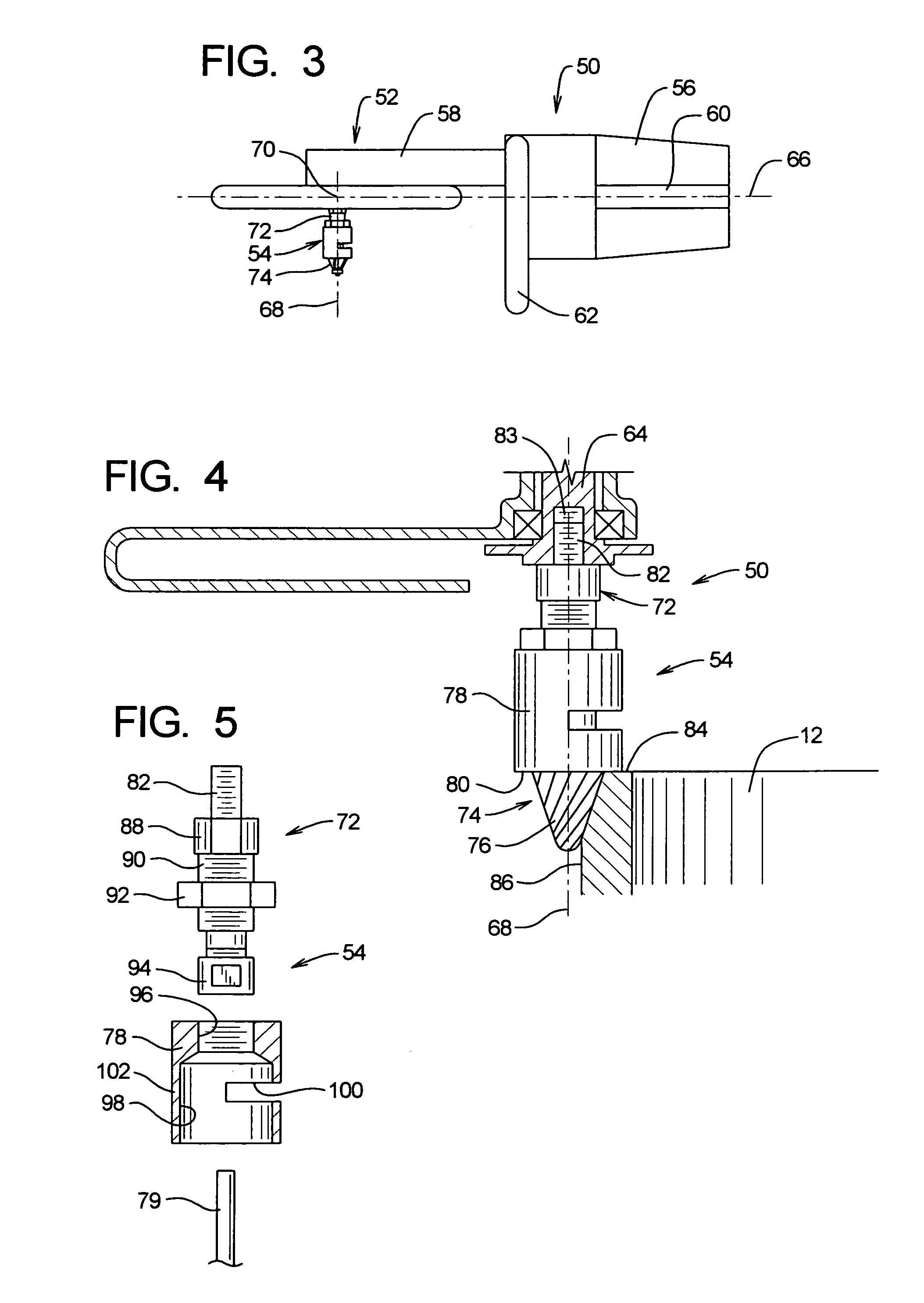

Rotating Pipe Machining Device

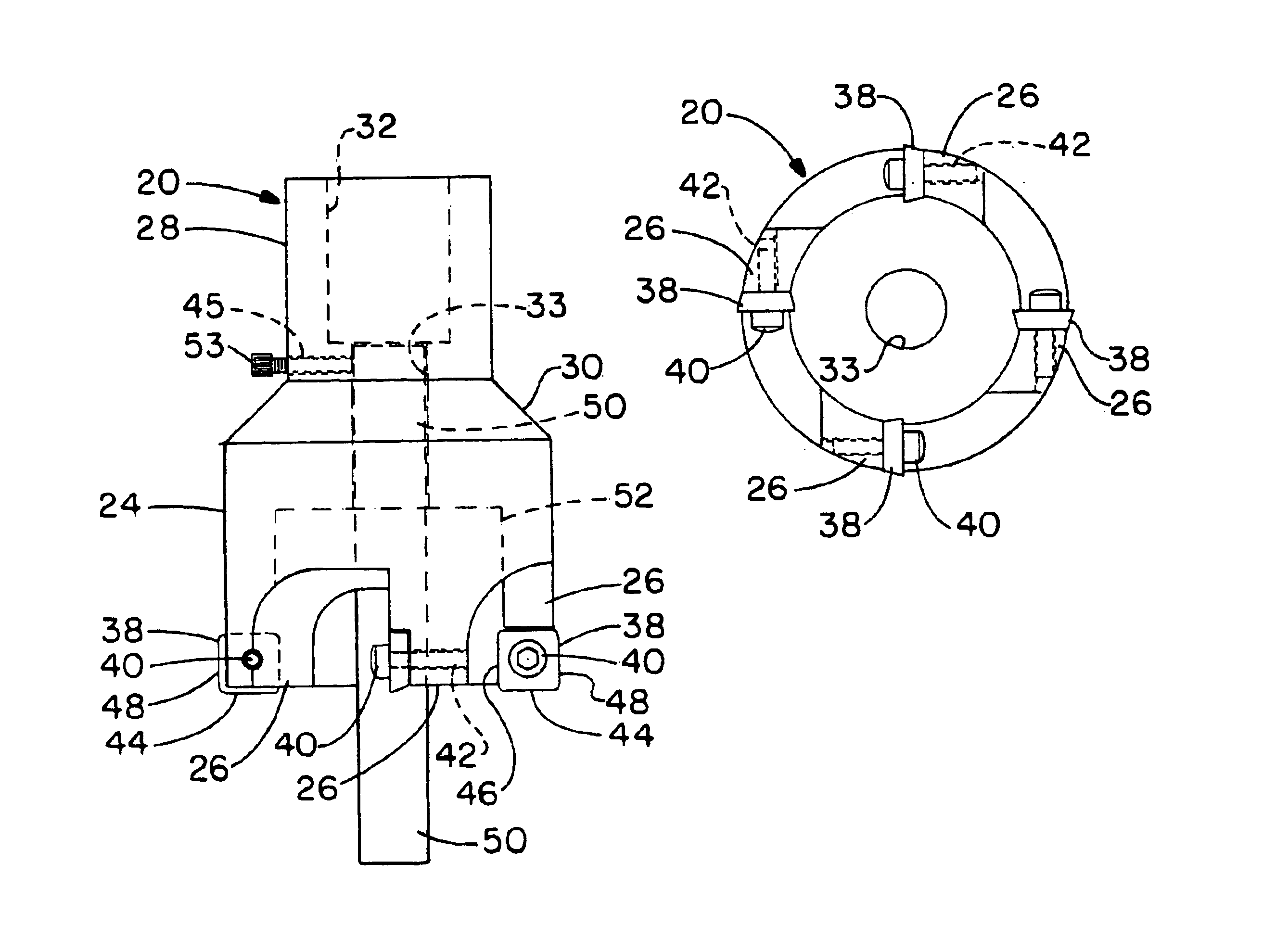

ActiveUS20110219920A1Automatic/semiautomatic turning machinesRolling contact bearingsEngineeringMachining

A machining device has a stationary member and a rotating member. A plurality of bearings on one of the members engages a surface of the other. At least one of the bearings is radially fixed, while the remainder of the bearings are radially adjustable. In another aspect of the invention, the bearings are rotatable on a first cylindrical portion of a mounting shaft that has a second cylindrical portion attachable to the machine. A radial undercut is provided around a flange between the first cylindrical portion and the second cylindrical portion.

Owner:ILLINOIS TOOL WORKS INC

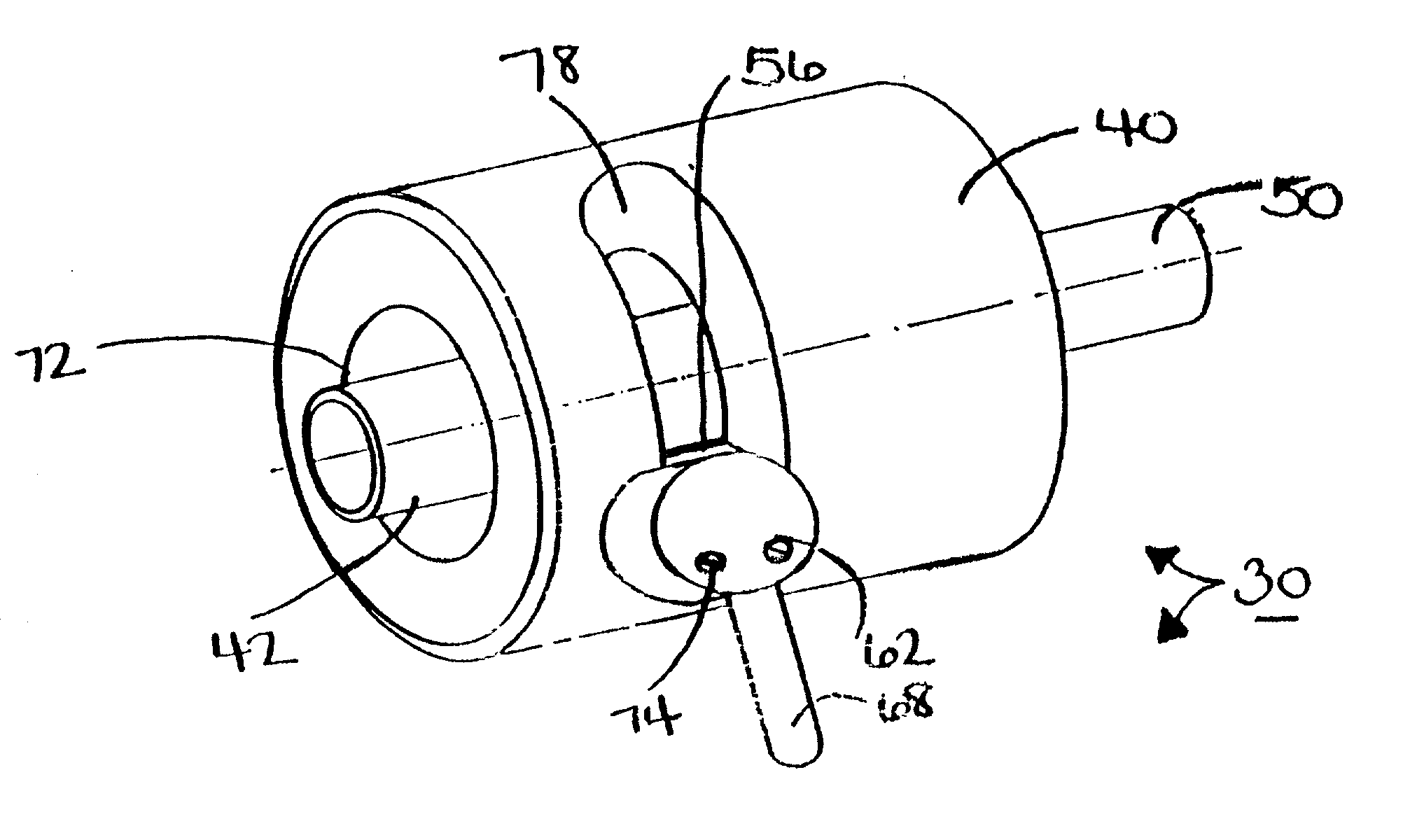

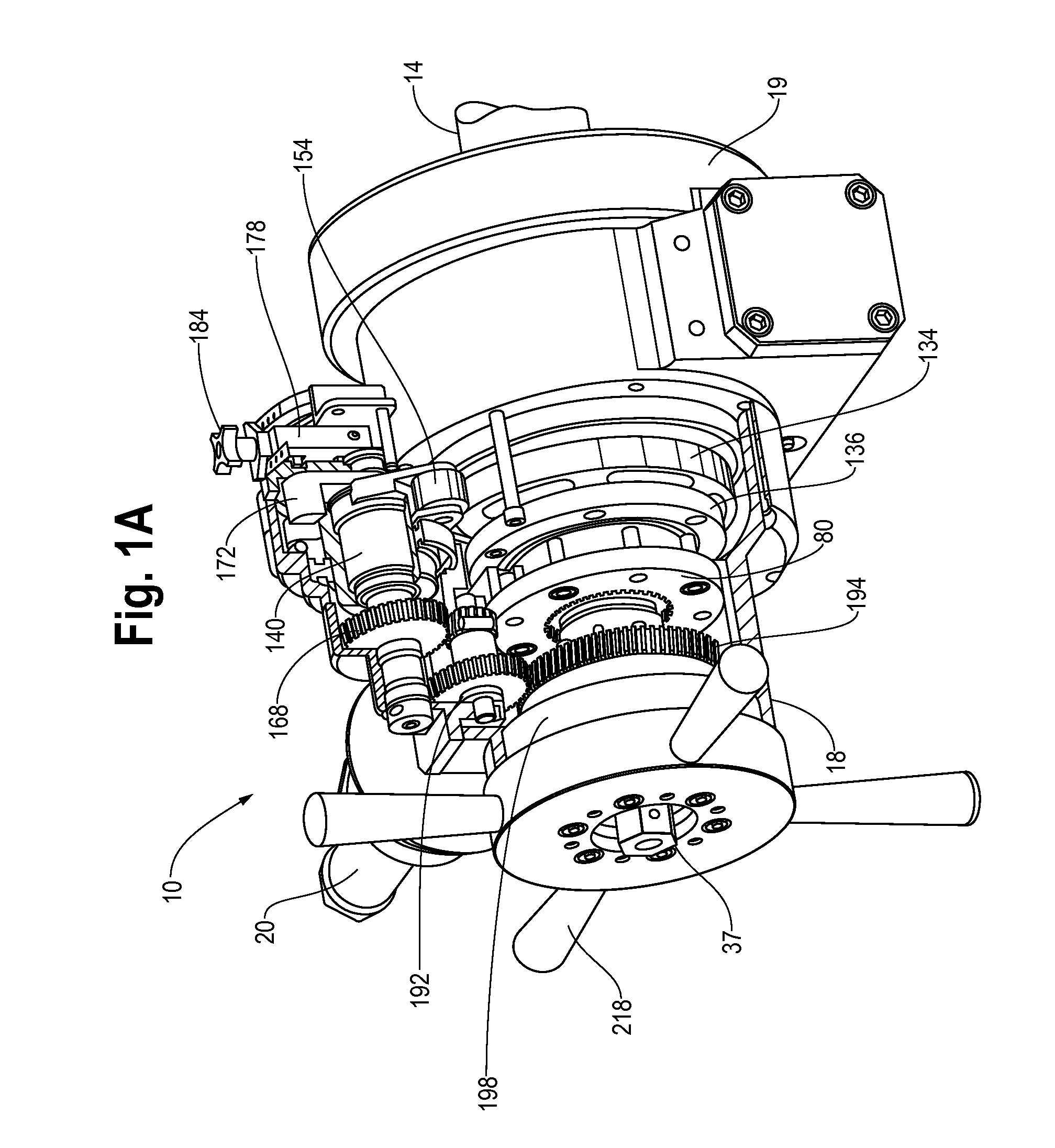

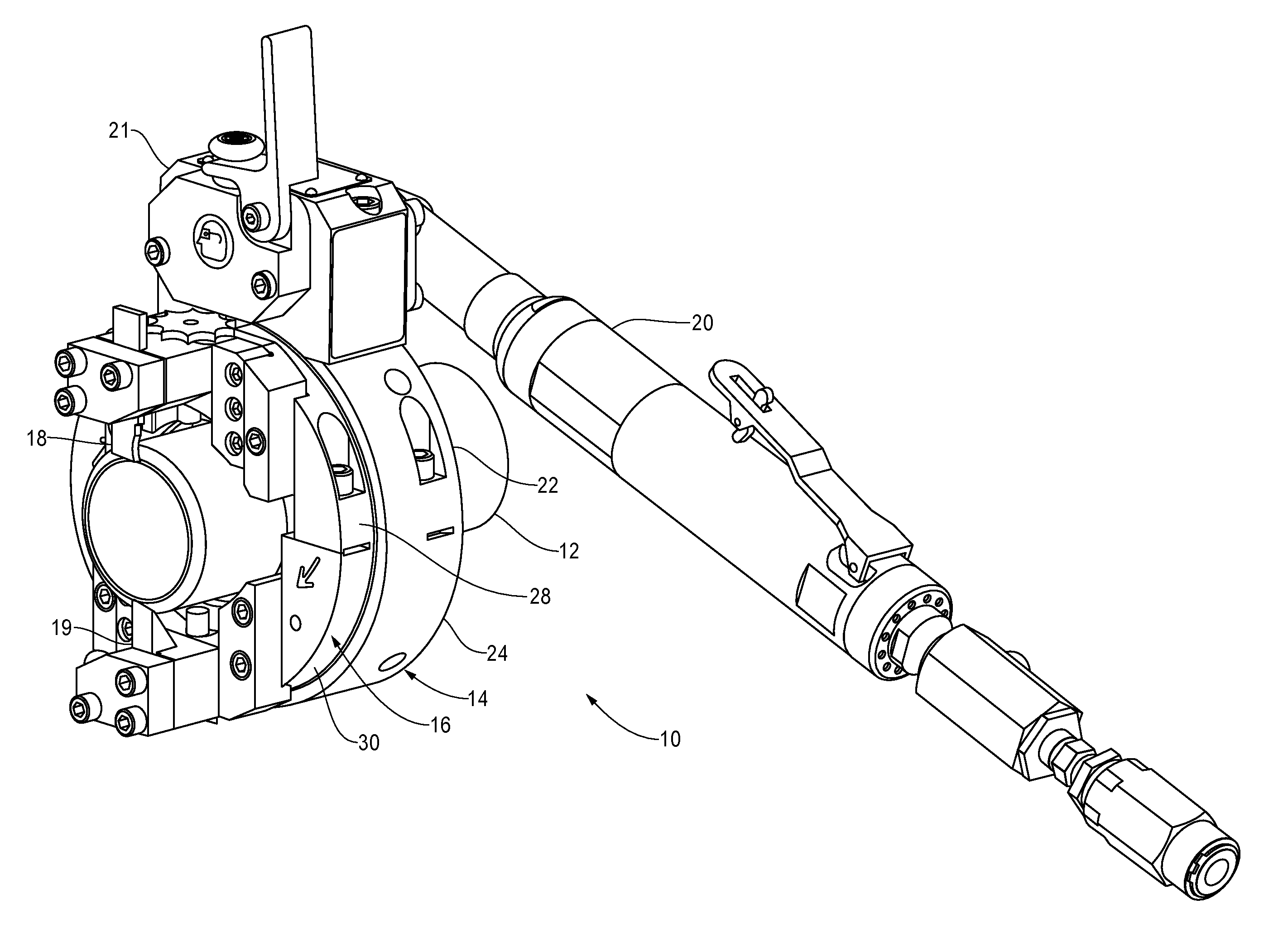

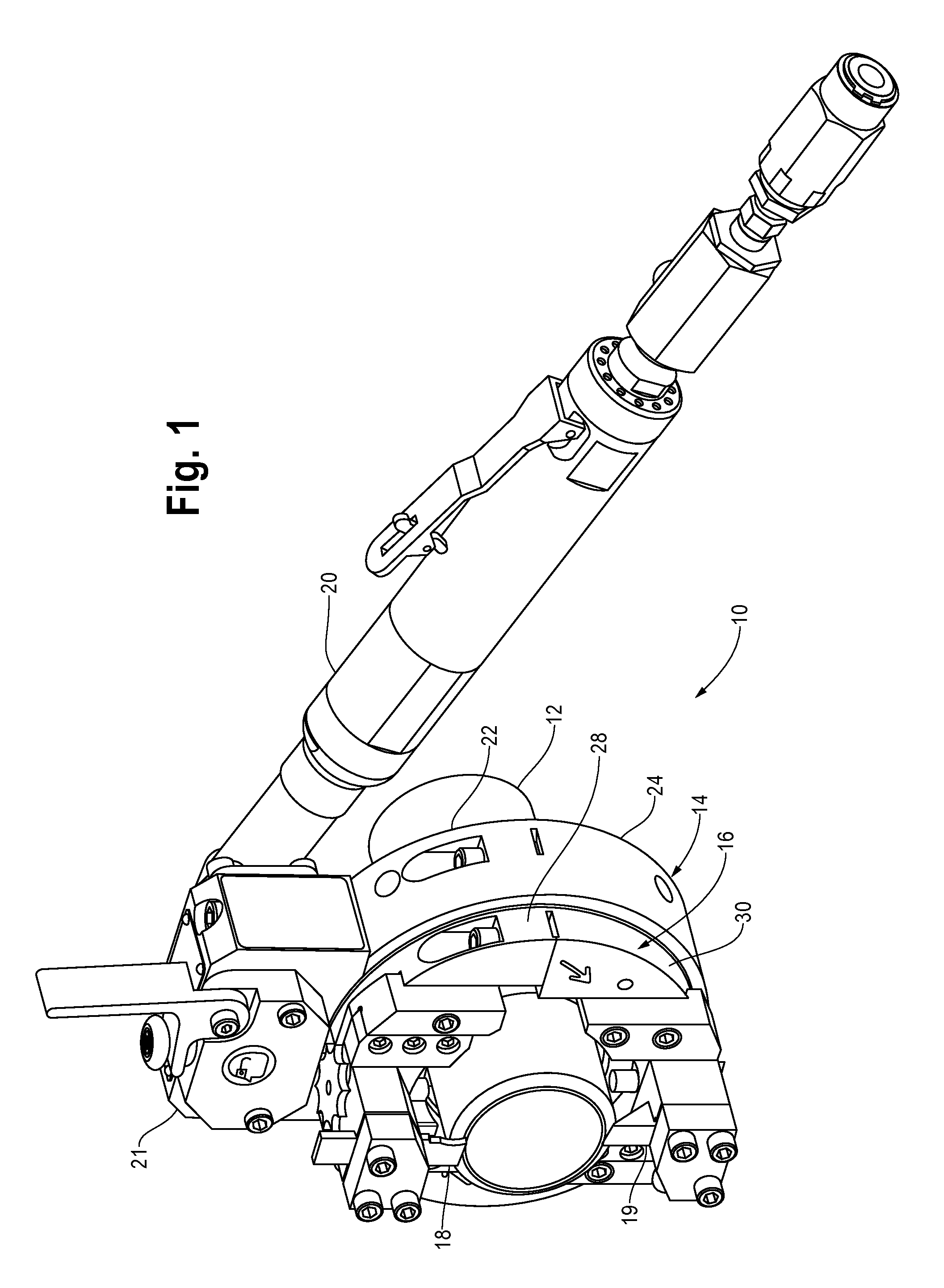

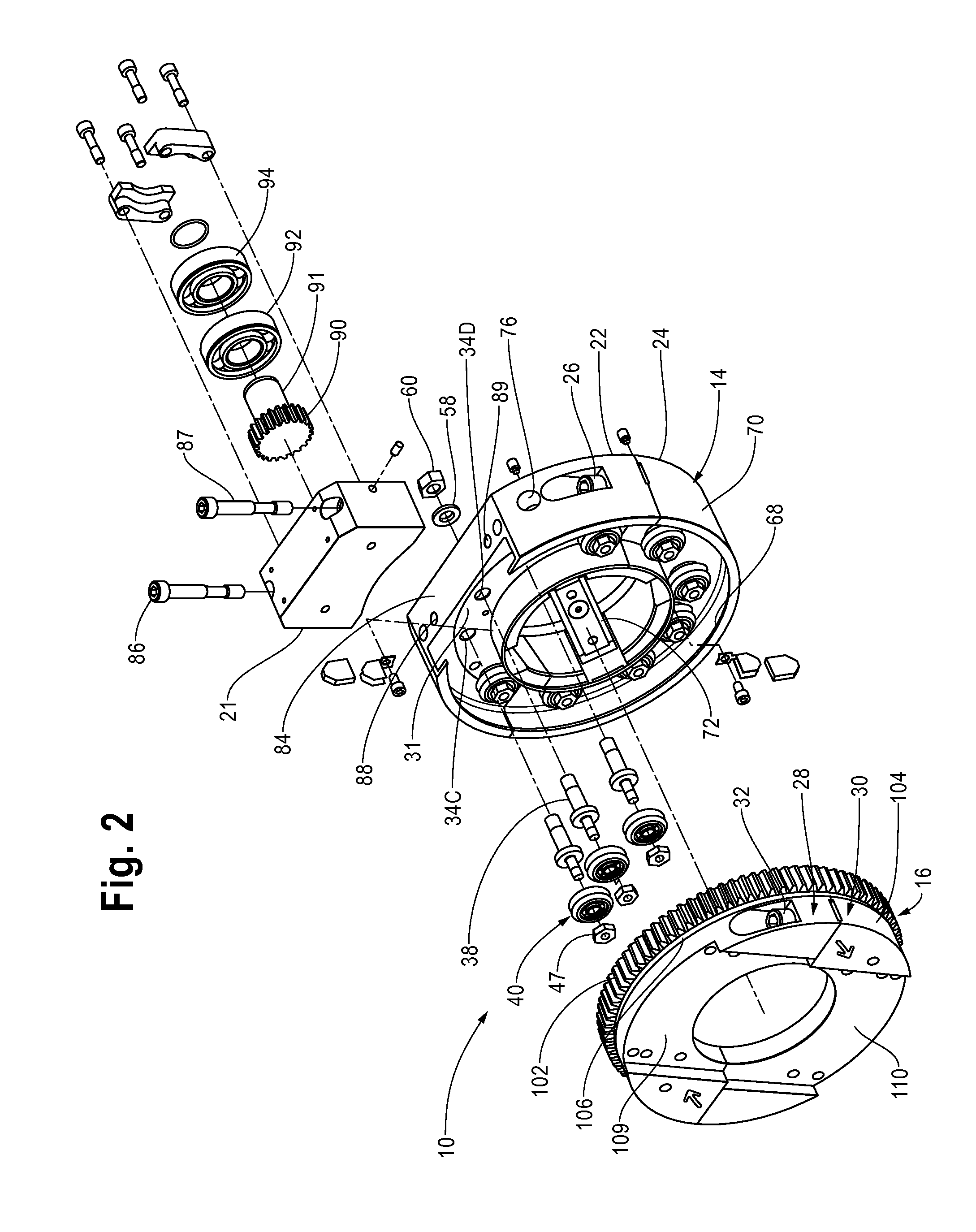

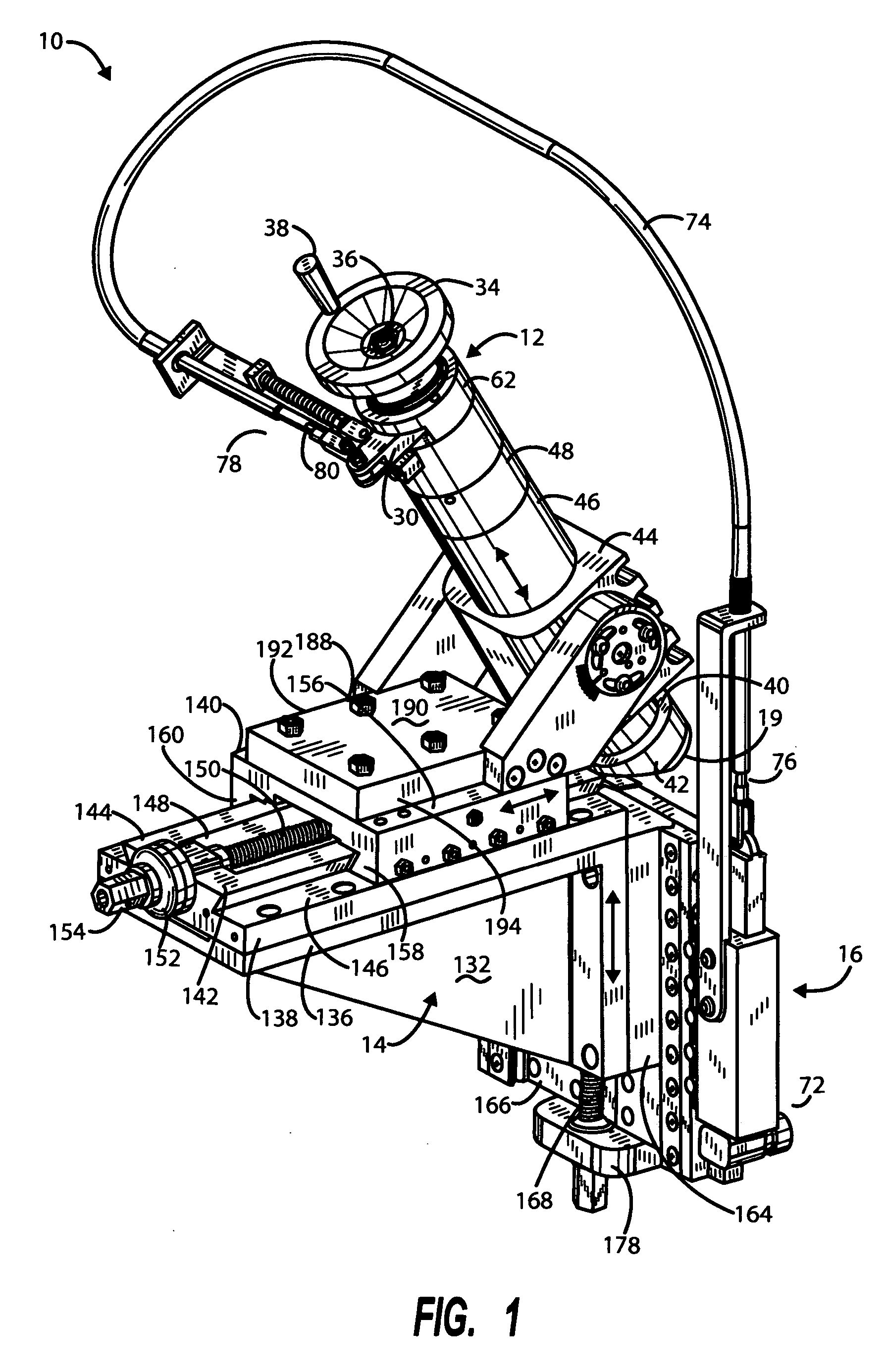

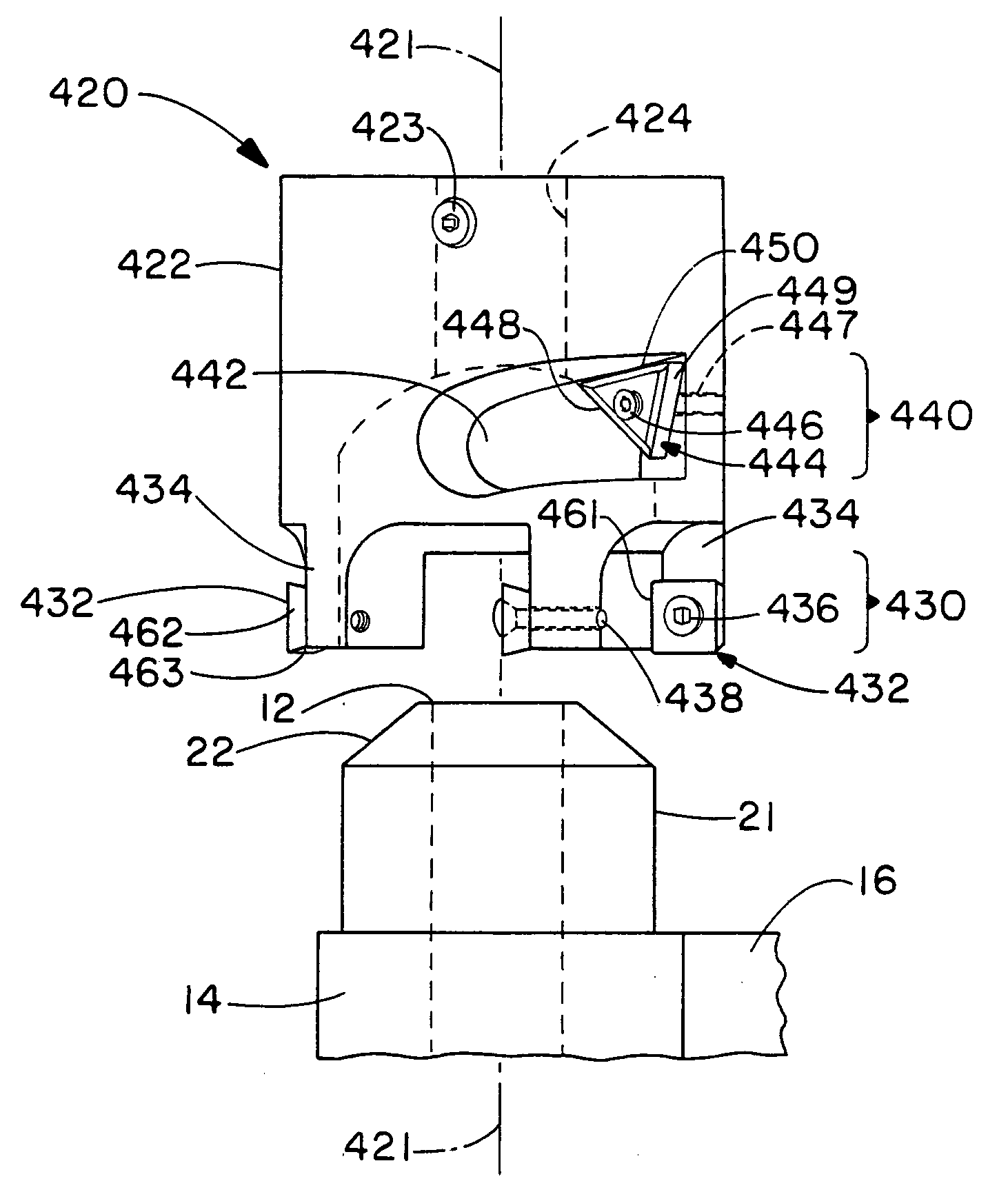

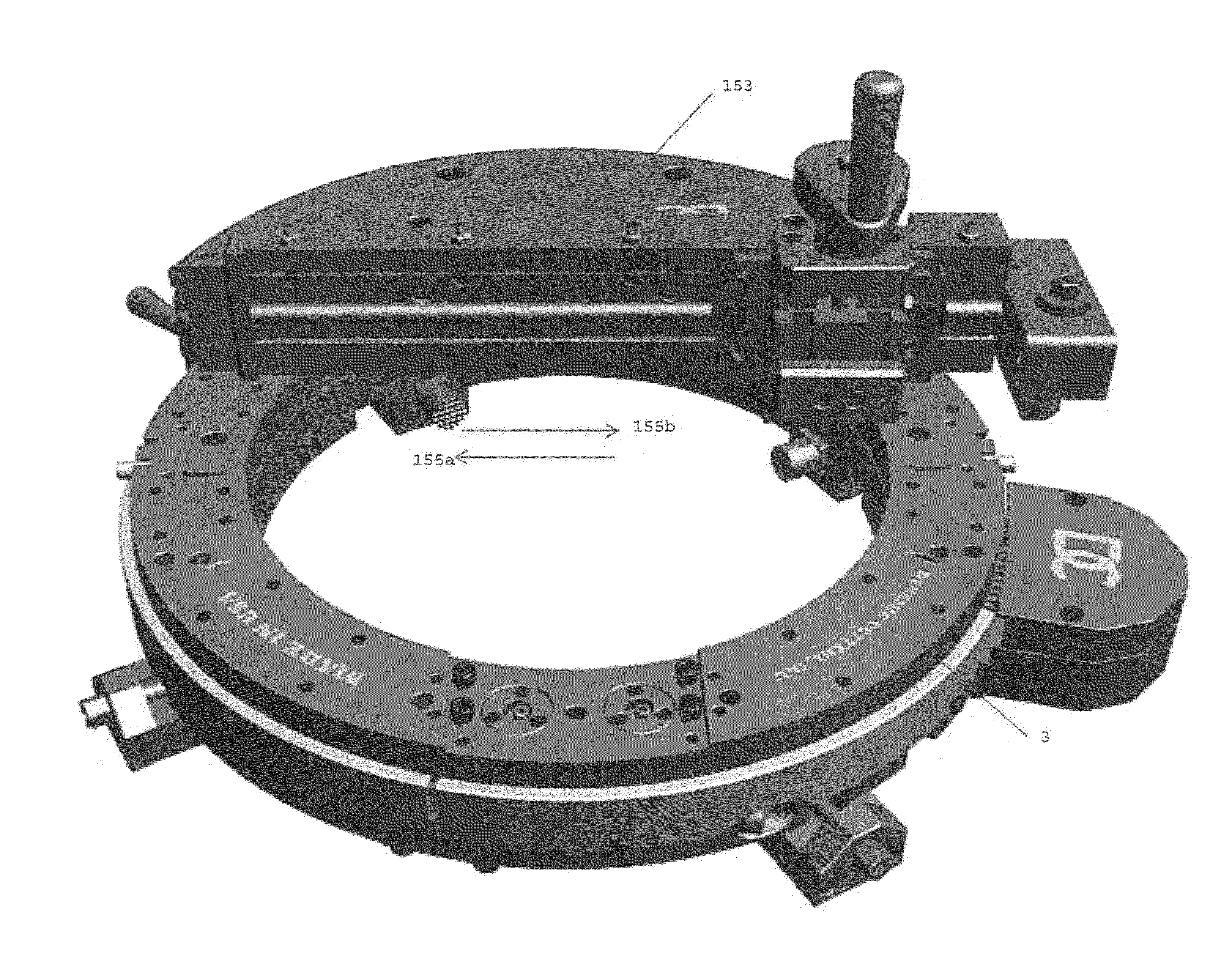

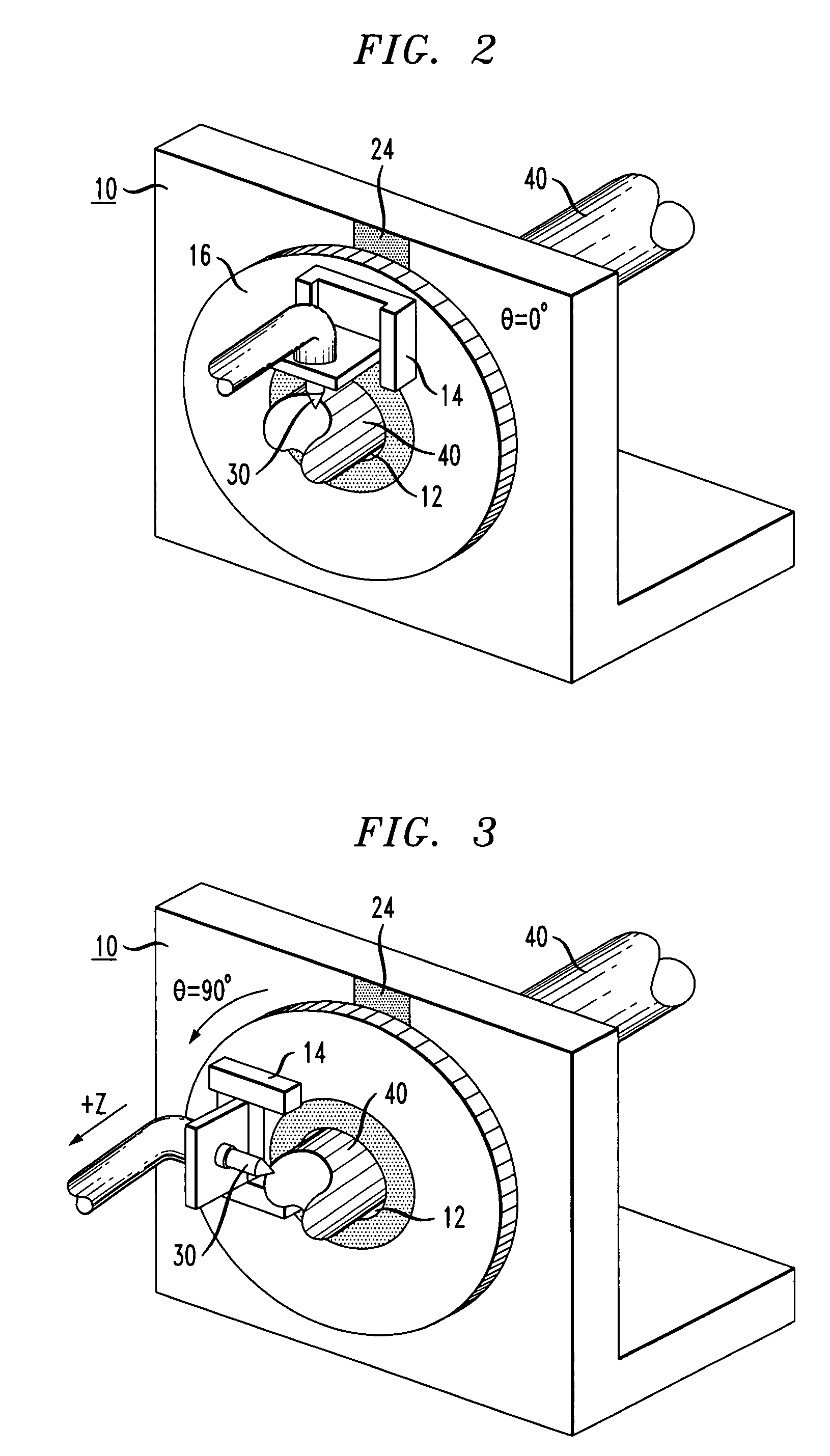

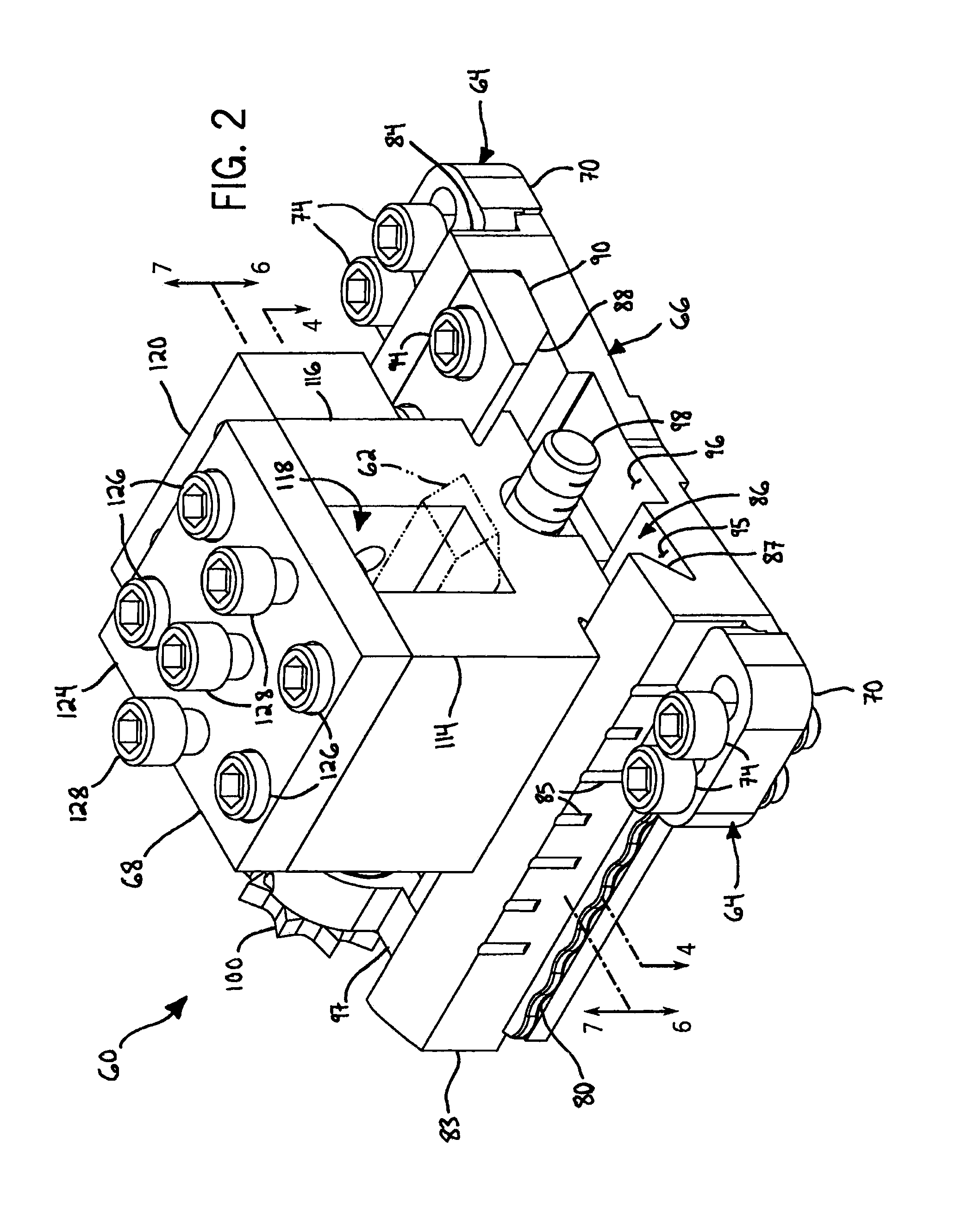

Swivel head module for a clamshell lathe

A swivel head assembly for a clamshell lathe is provided. The swivel head module includes an adjustable tool head assembly. The adjustable tool head assembly has a tool for machining a work piece, and is capable of being incrementally advanced in a radial direction against the work piece. The swivel head assembly further includes a means for positioning the metal working tool along an x-axis, y-axis, and z-axis. A tripper assembly is operatively coupled to the tool head assembly to incrementally urge the tool head against the work piece upon each revolution of the clamshell ring. The tripper assembly incorporates a solenoid for selectively incrementally advancing the tool against the work piece.

Owner:DONATO L RICCI +1

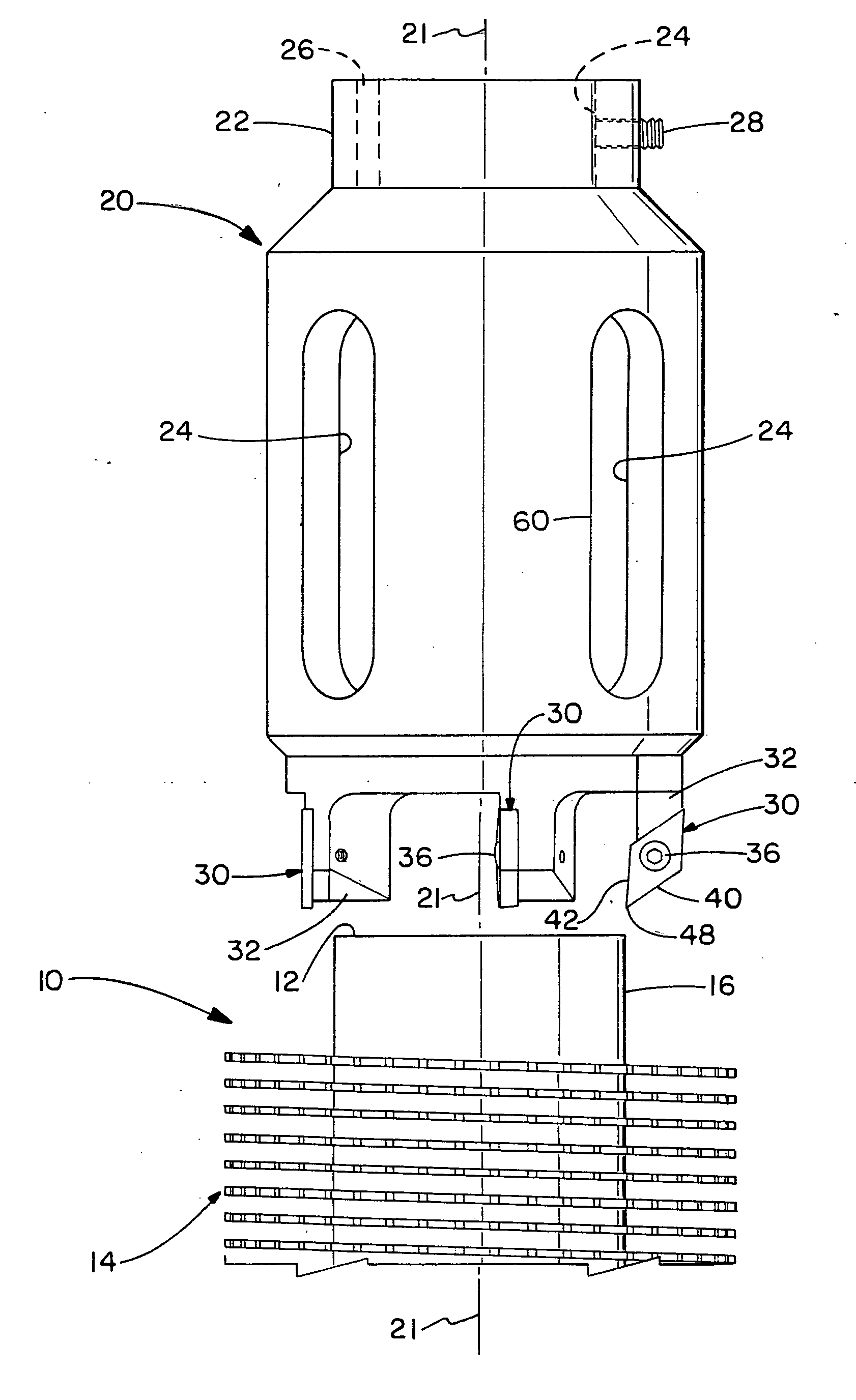

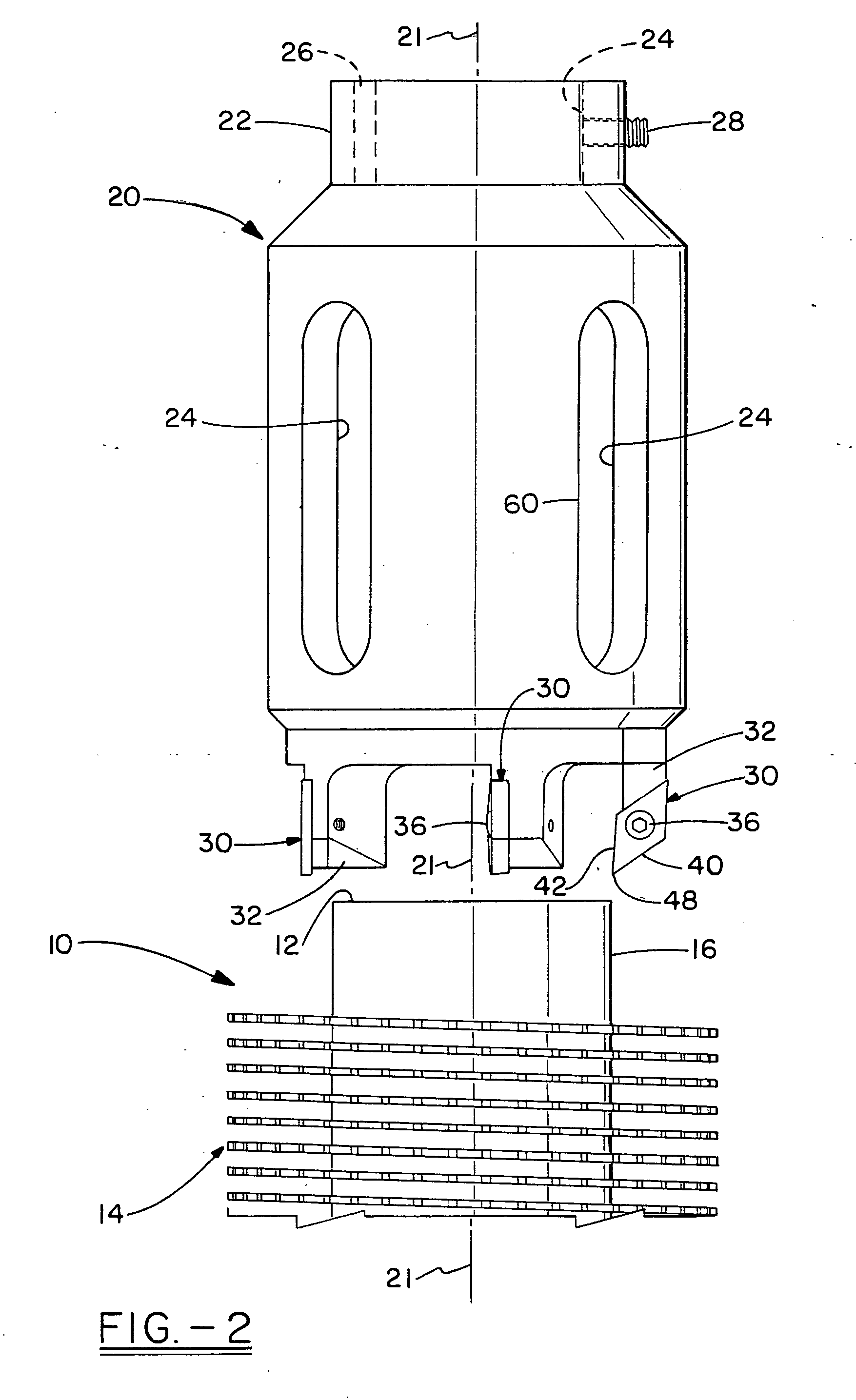

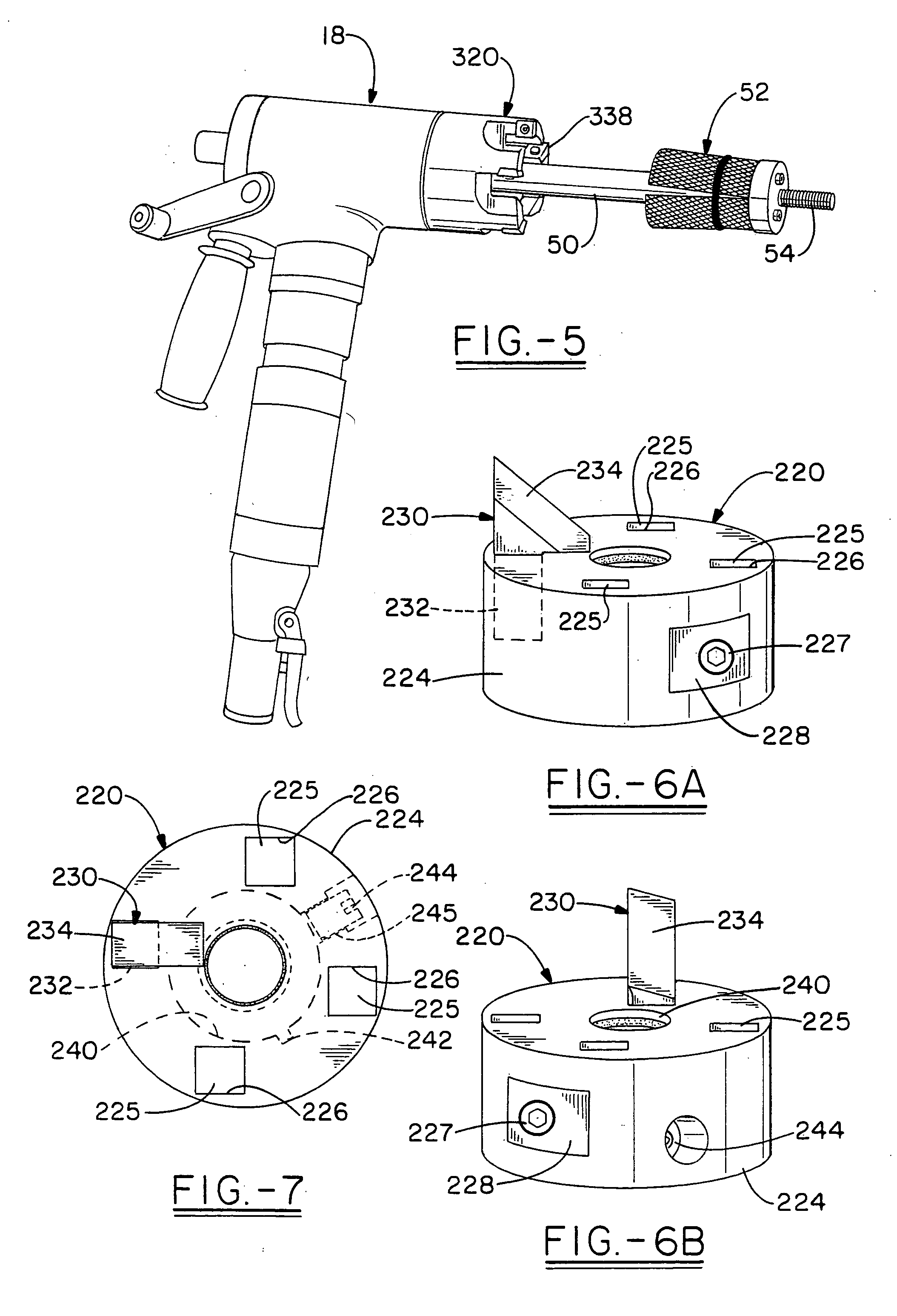

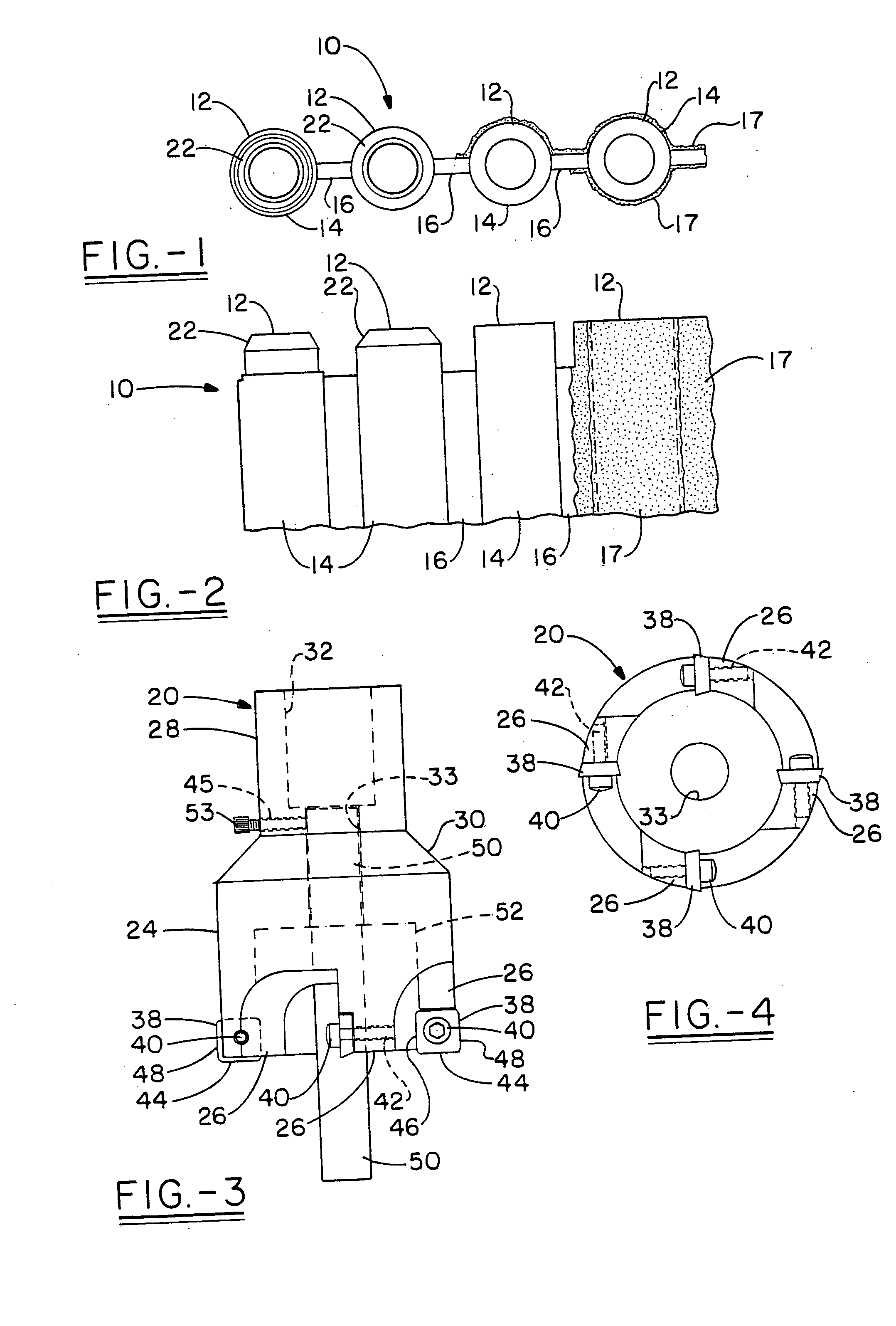

Milling head for removing heat dissipating elements from a tube

ActiveUS20070098509A1Complete efficientlyMilling cuttersAttachable milling devicesHeat exchangerTube length

A milling head for a milling device, particularly a rotary milling device, wherein the milling head is capable of imparting a desired finish on a tube, preferably of a heat exchanger tube. The milling head includes one or more milling elements capable of cutting and / or removing heat dissipating elements connected to an outer surface of the tube. The heat dissipating elements are removed from the tube in a longitudinal direction along the tube length. In one embodiment, the milling head also includes a bevel milling element. Methods for milling a tube having heat dissipating elements are also described.

Owner:CLIMAX PORTABLE MACHINE TOOLS

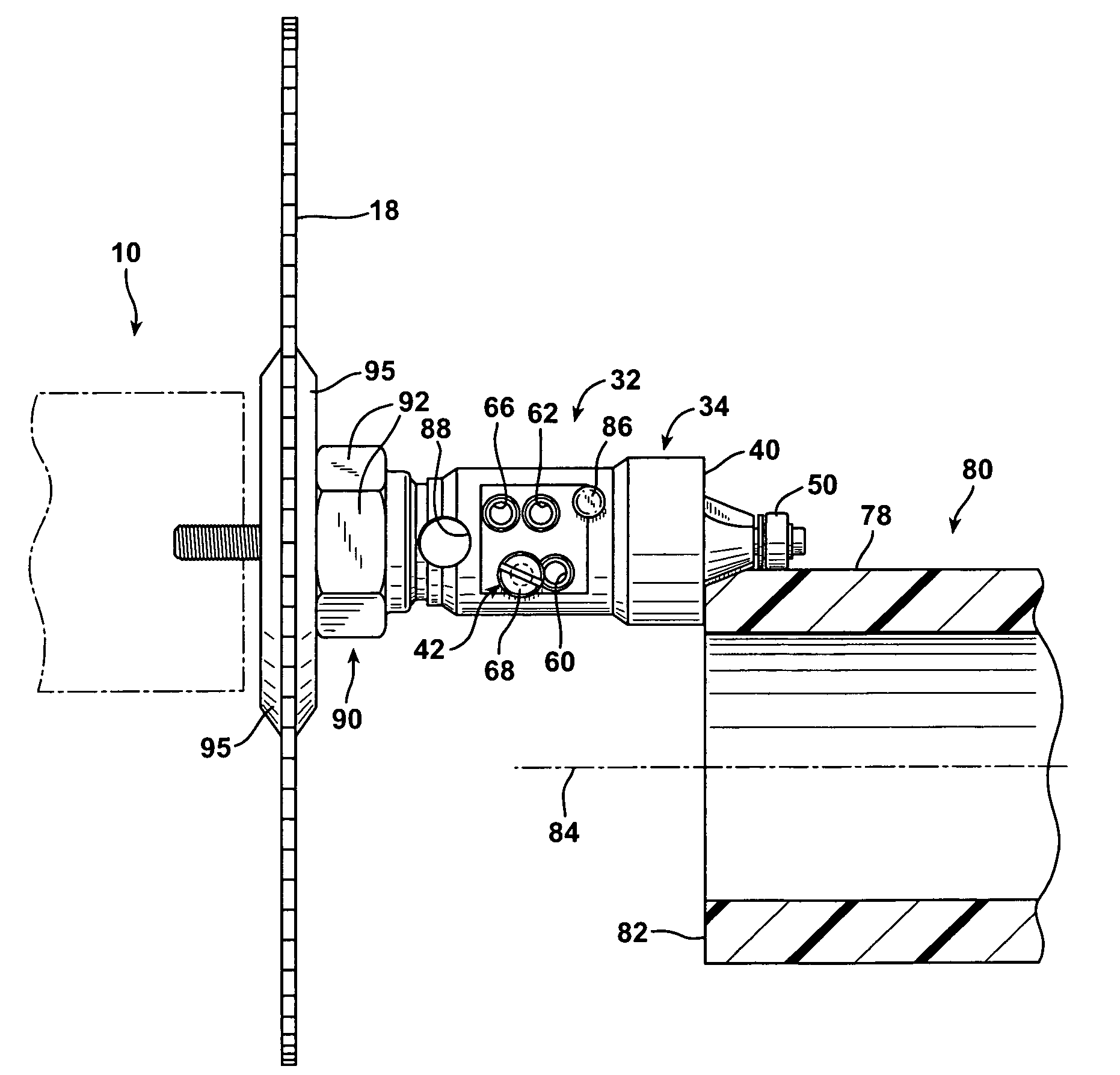

Pipe Flange Facing Apparatus and Method

An apparatus for facing a flange of a pipe comprises a housing and an anchor assembly rotatably supported by the housing. The anchor assembly is configured to engage an inner surface of the pipe. The apparatus further comprises a tool holder translatably supported by the housing. The tool holder is configured to support a facing tool for facing the flange of the pipe. The apparatus further comprises a drive shaft that is rotatable relative to the housing to translate the tool holder relative to the housing. The housing is rotatable relative to the anchor assembly about a first axis in a first direction and the drive shaft is simultaneously rotatable relative to the housing about a second axis in a second direction opposite the first direction to move the tool holder along a spiral path and thereby face the flange of the pipe.

Owner:ENERPAC TOOL GRP CORP

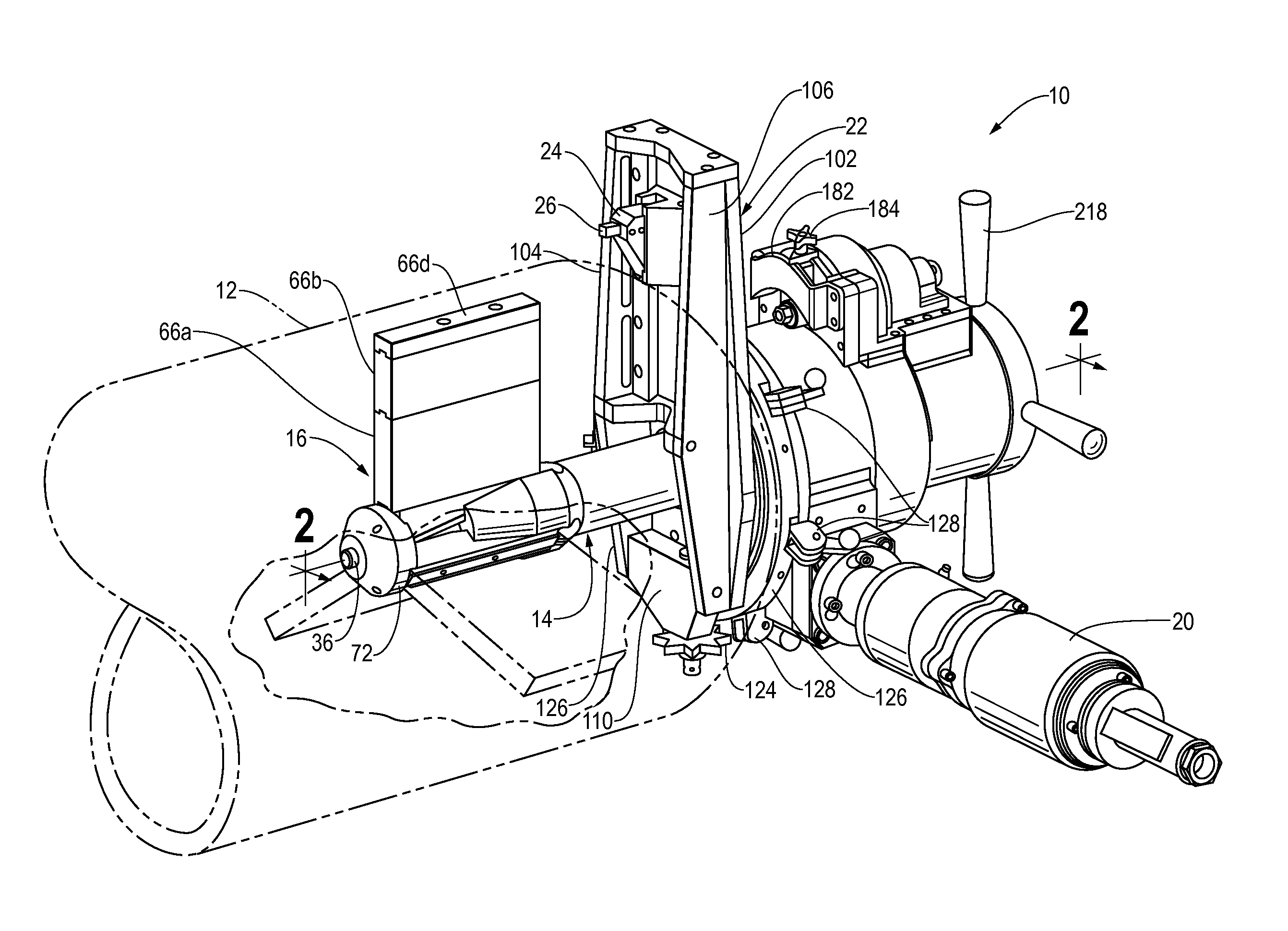

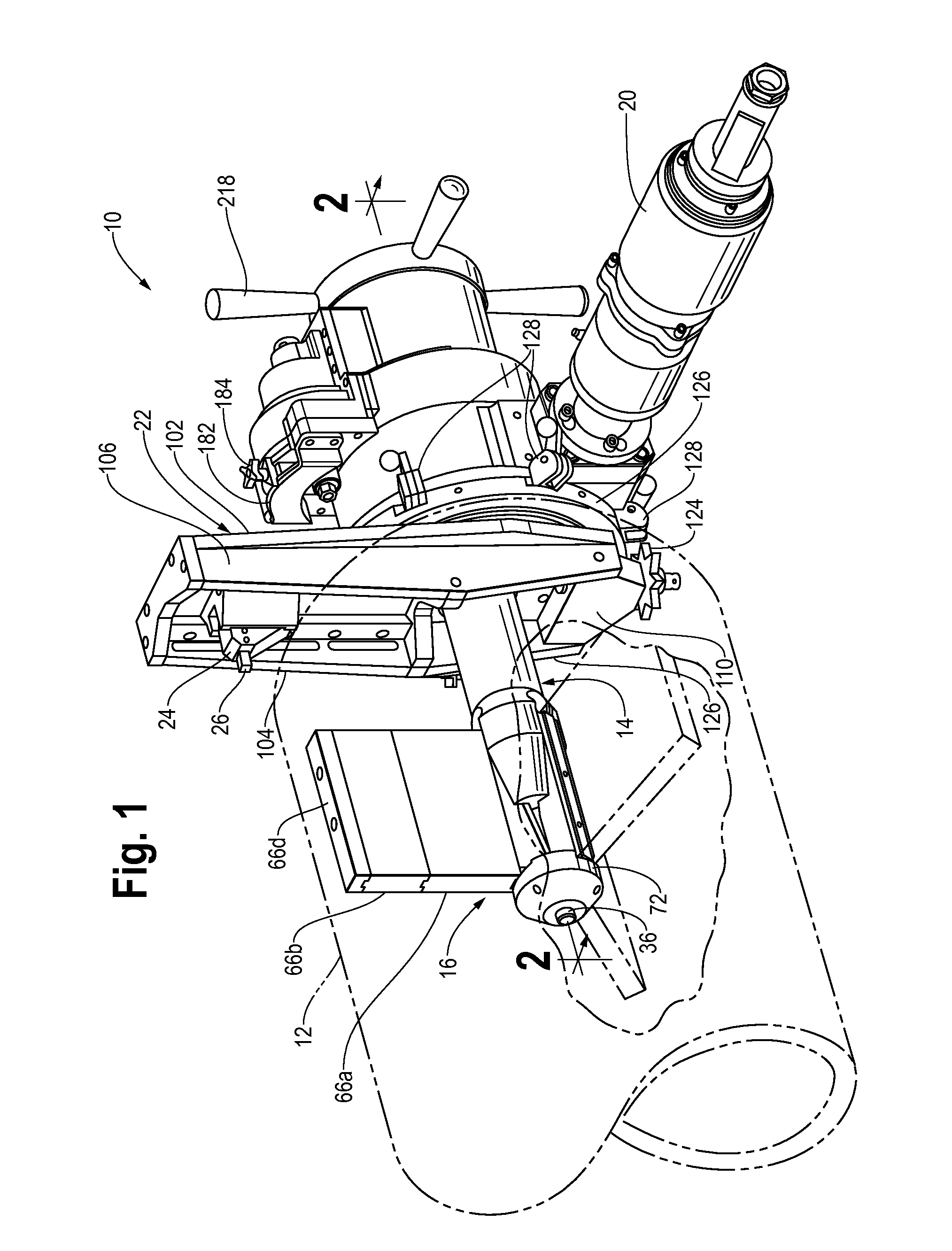

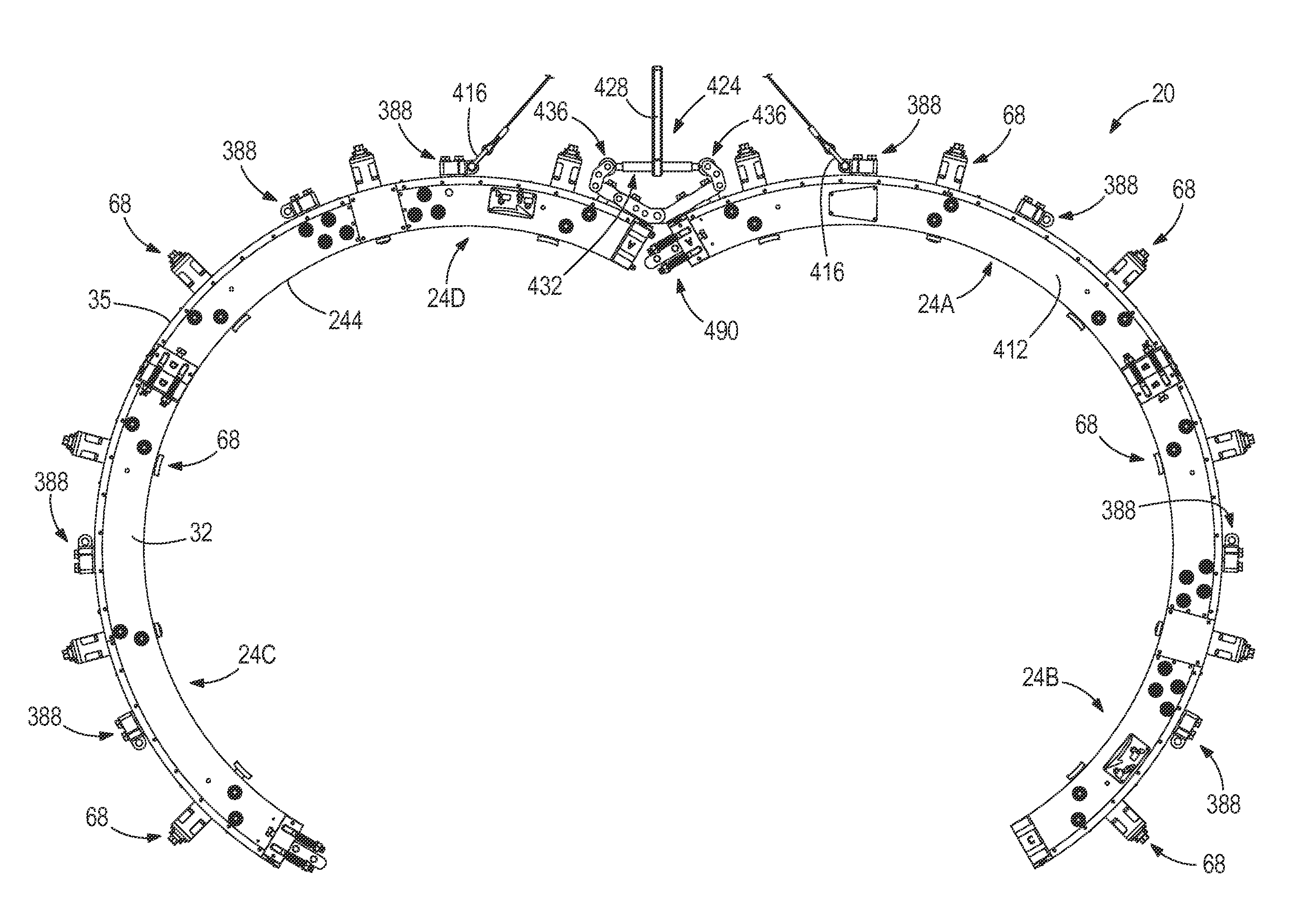

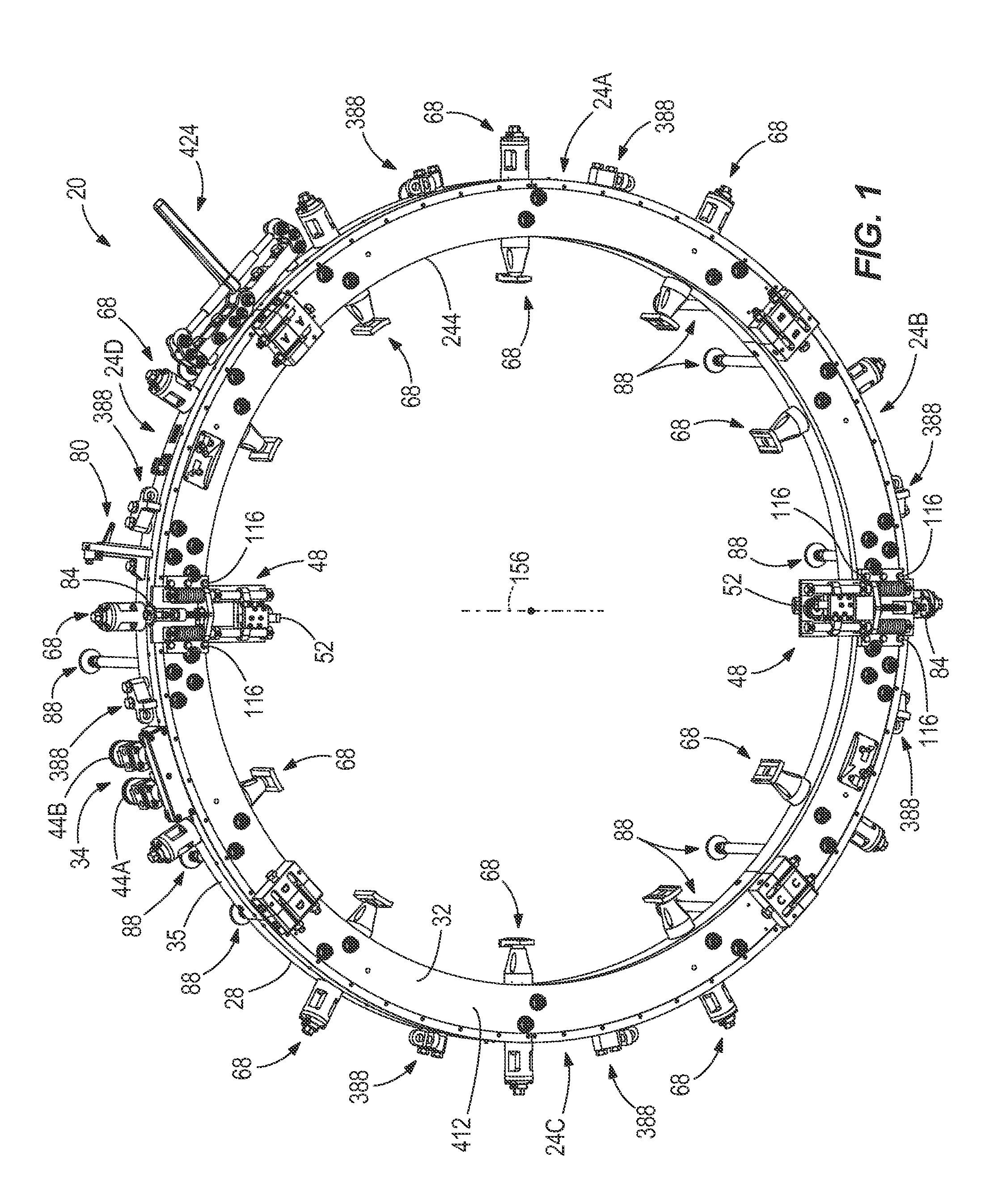

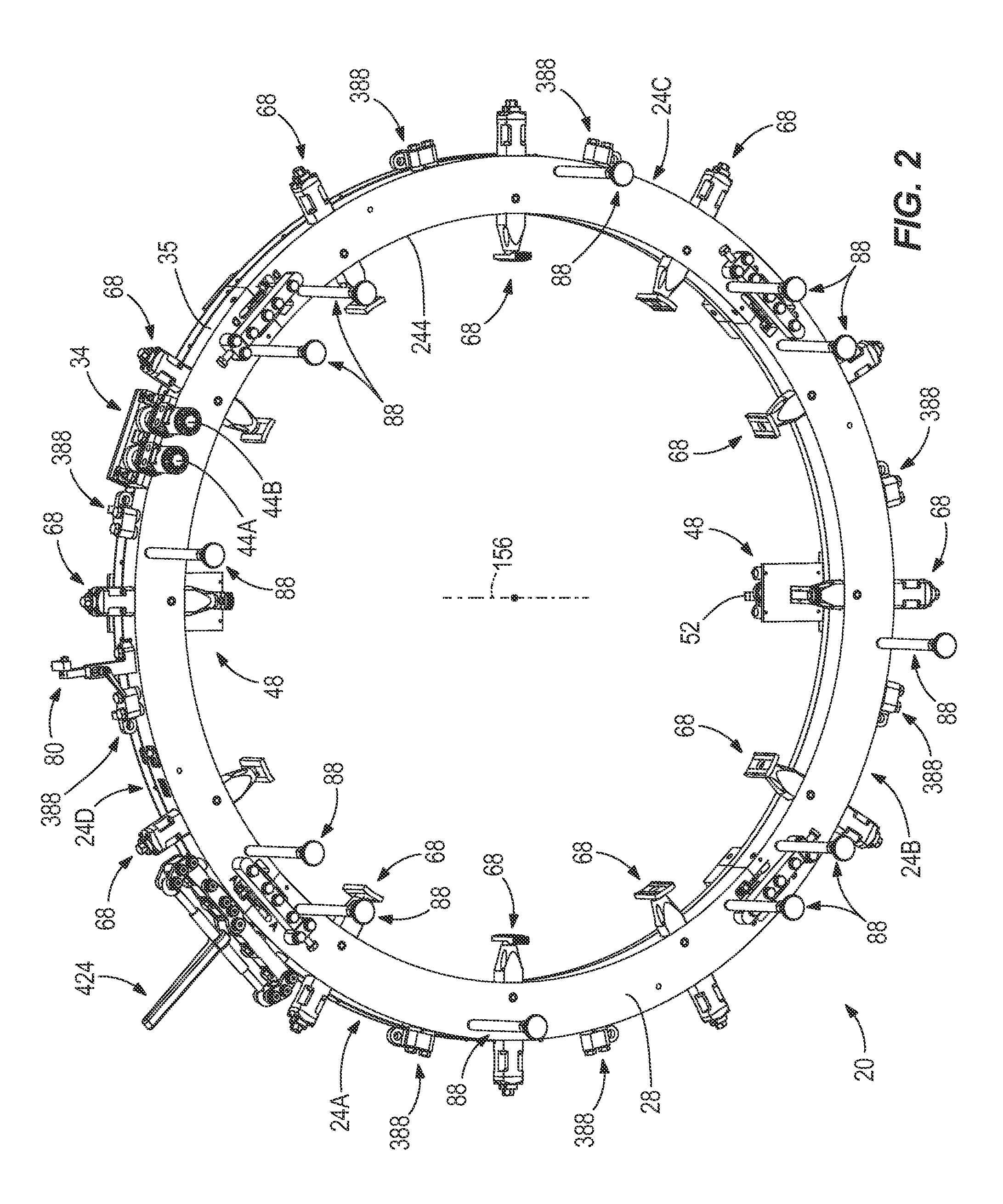

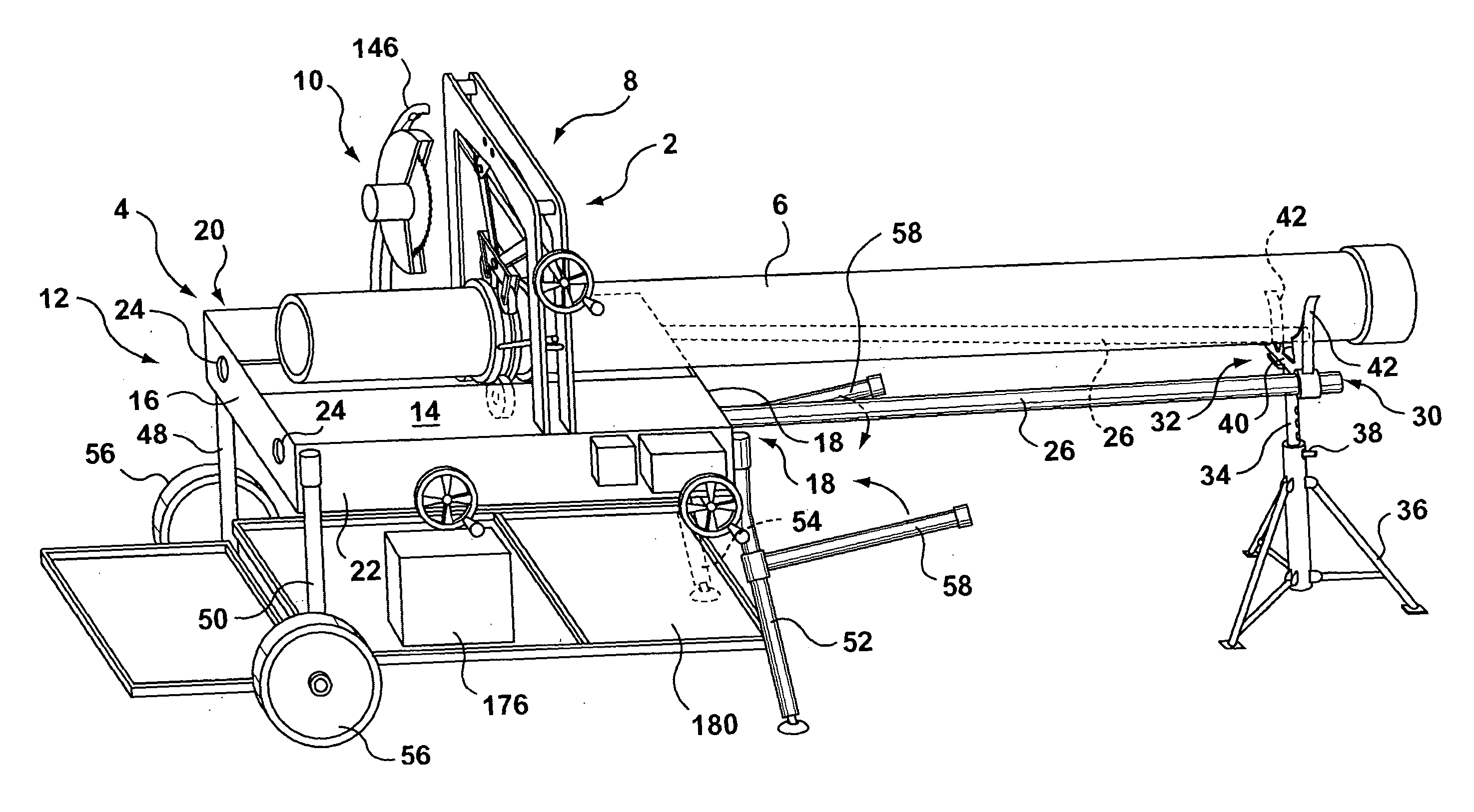

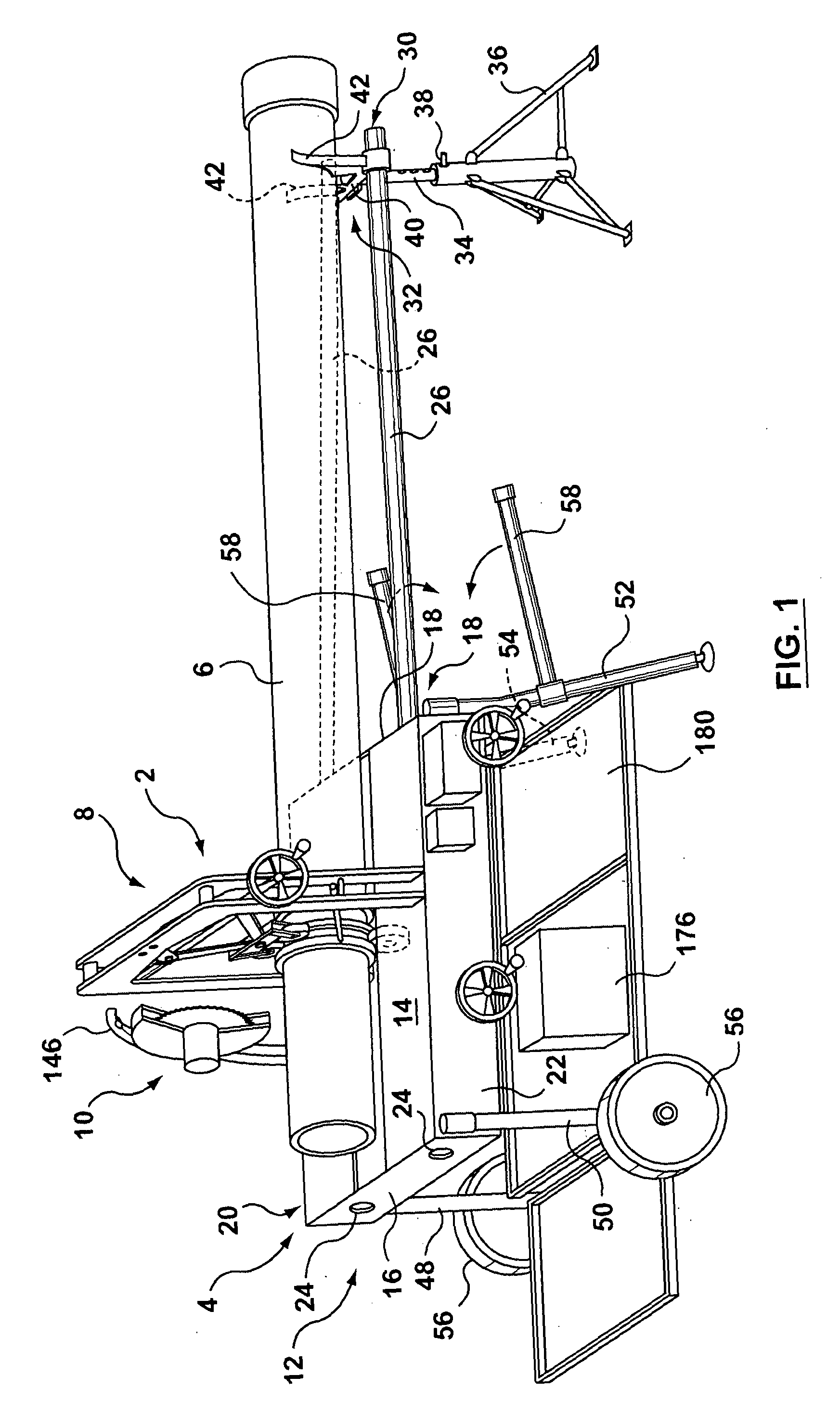

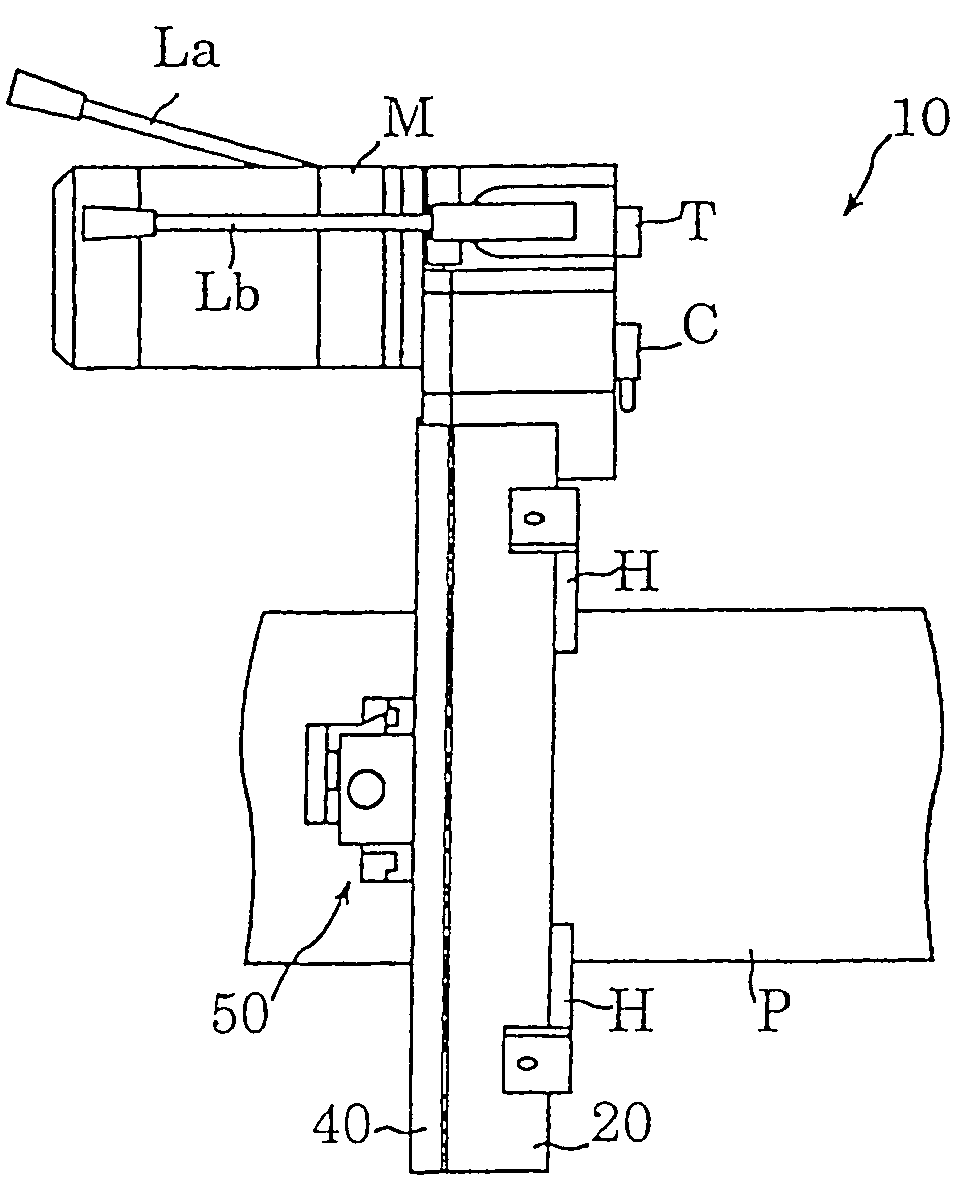

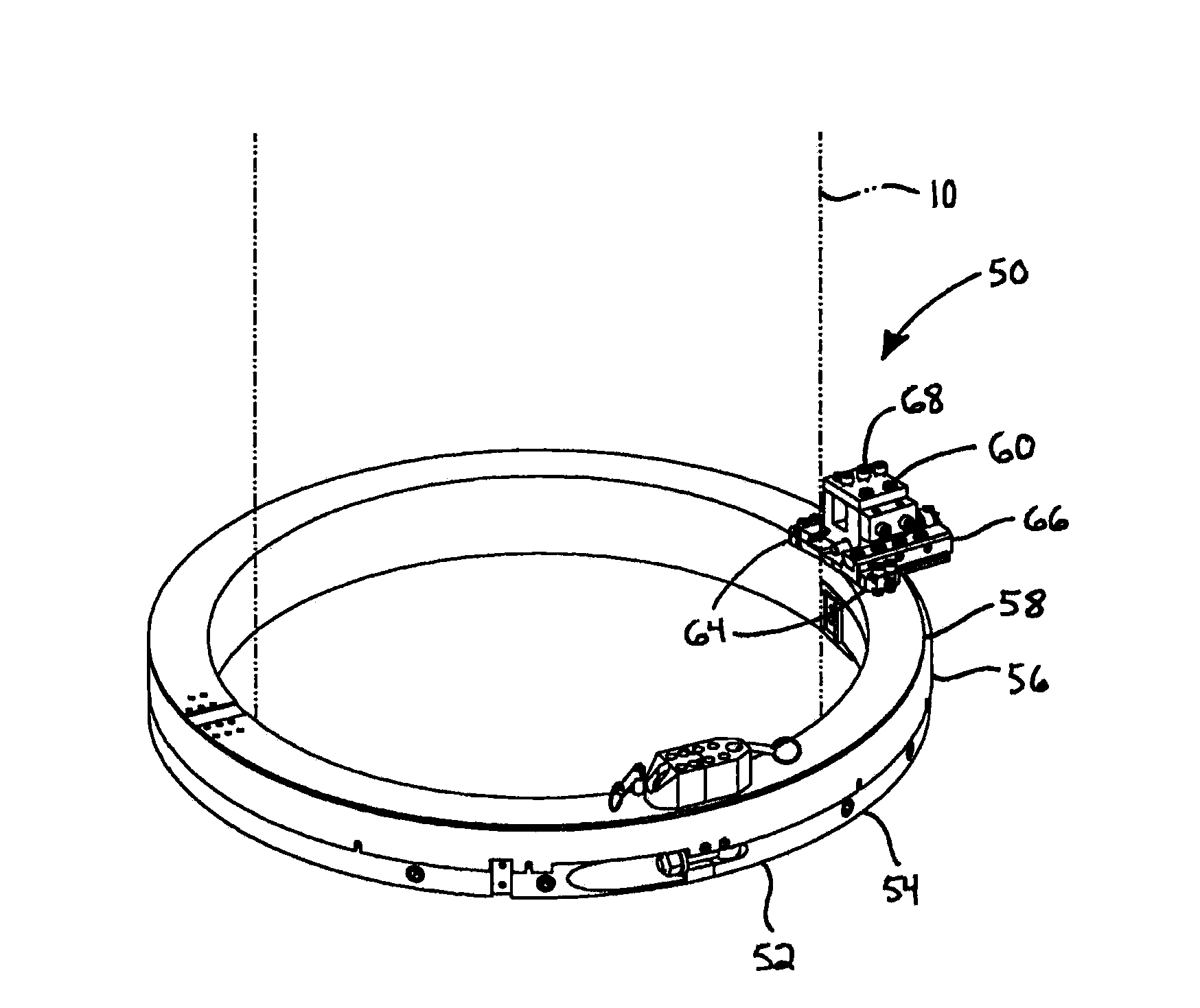

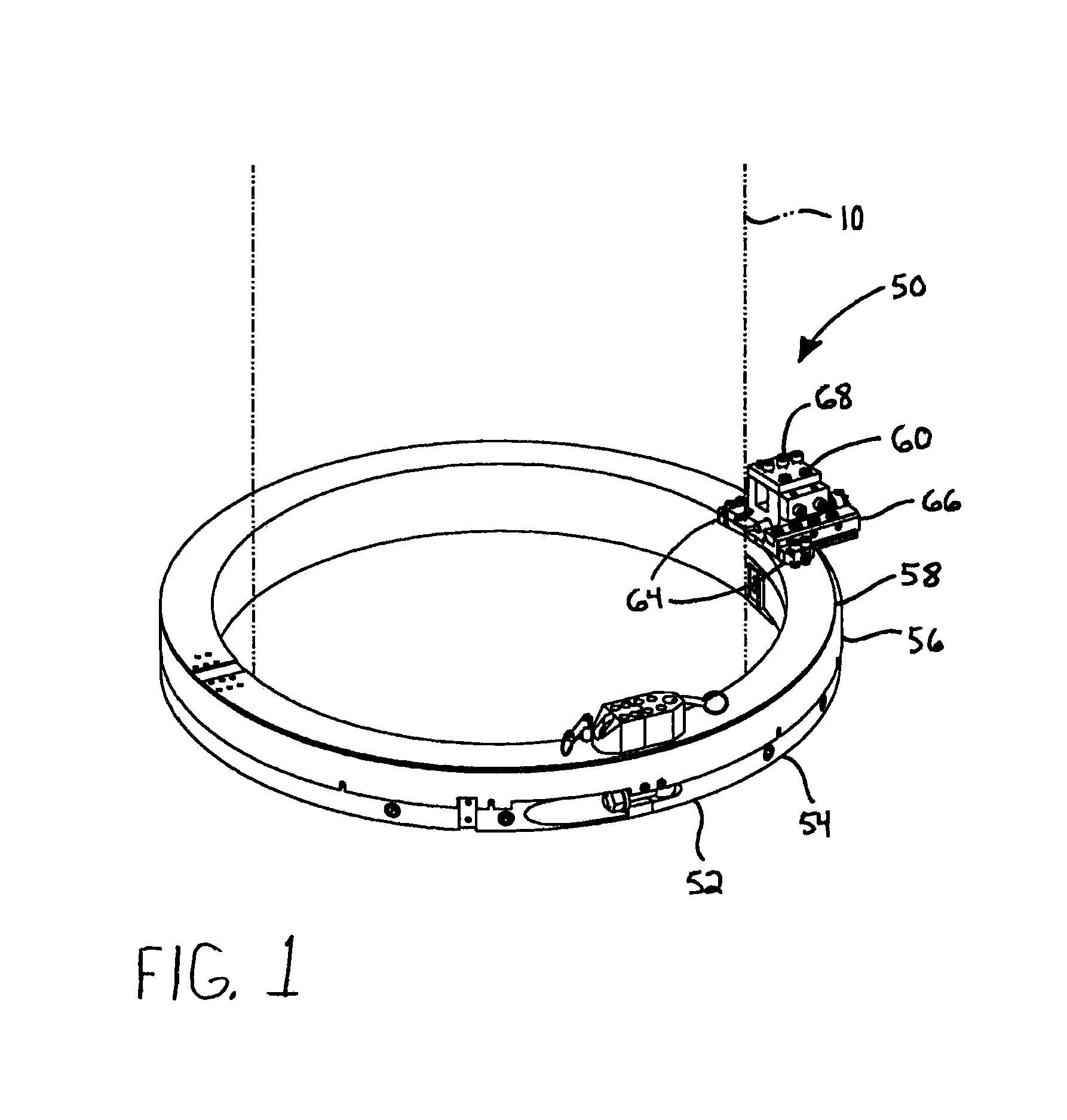

Pipe machining apparatuses and methods of operating the same

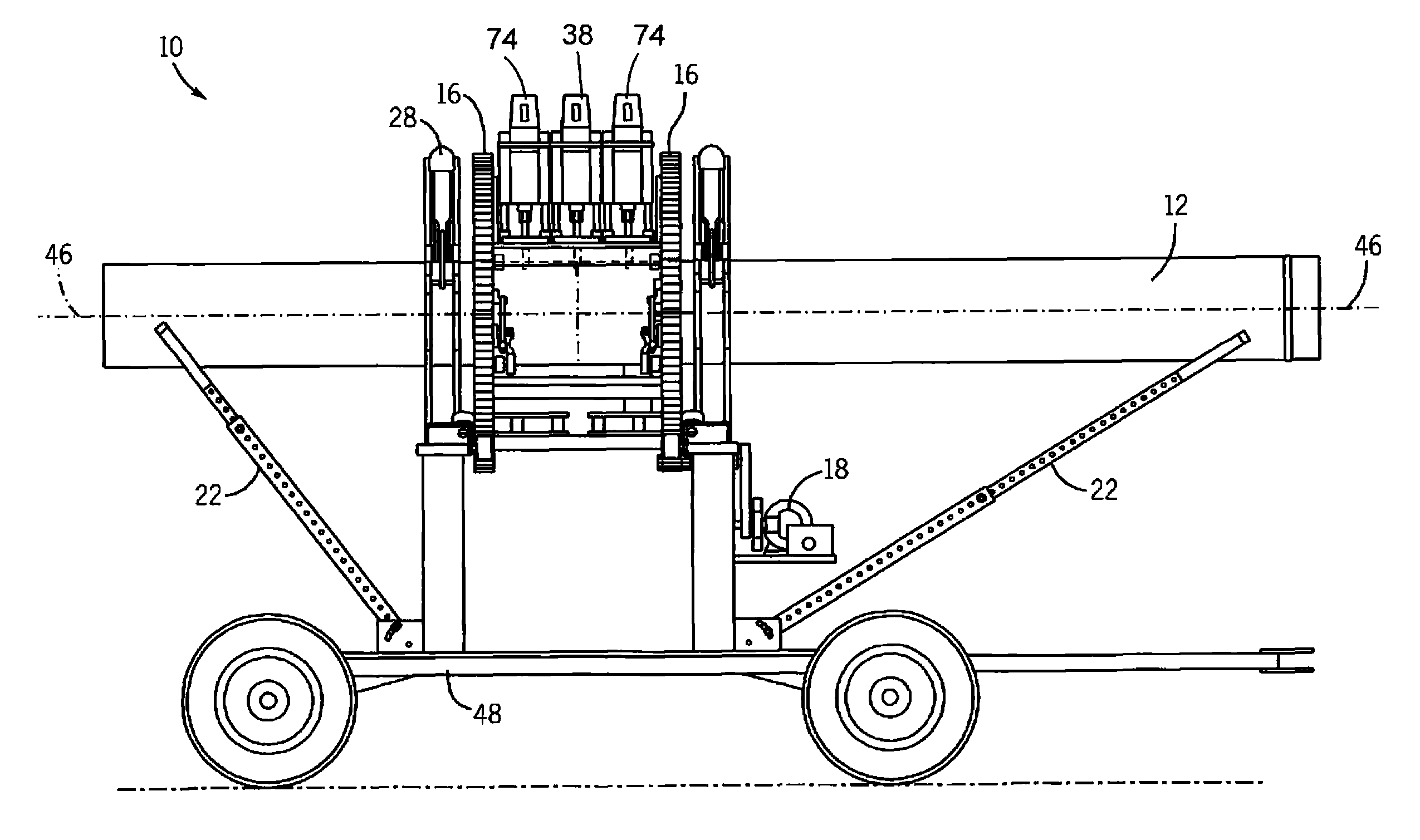

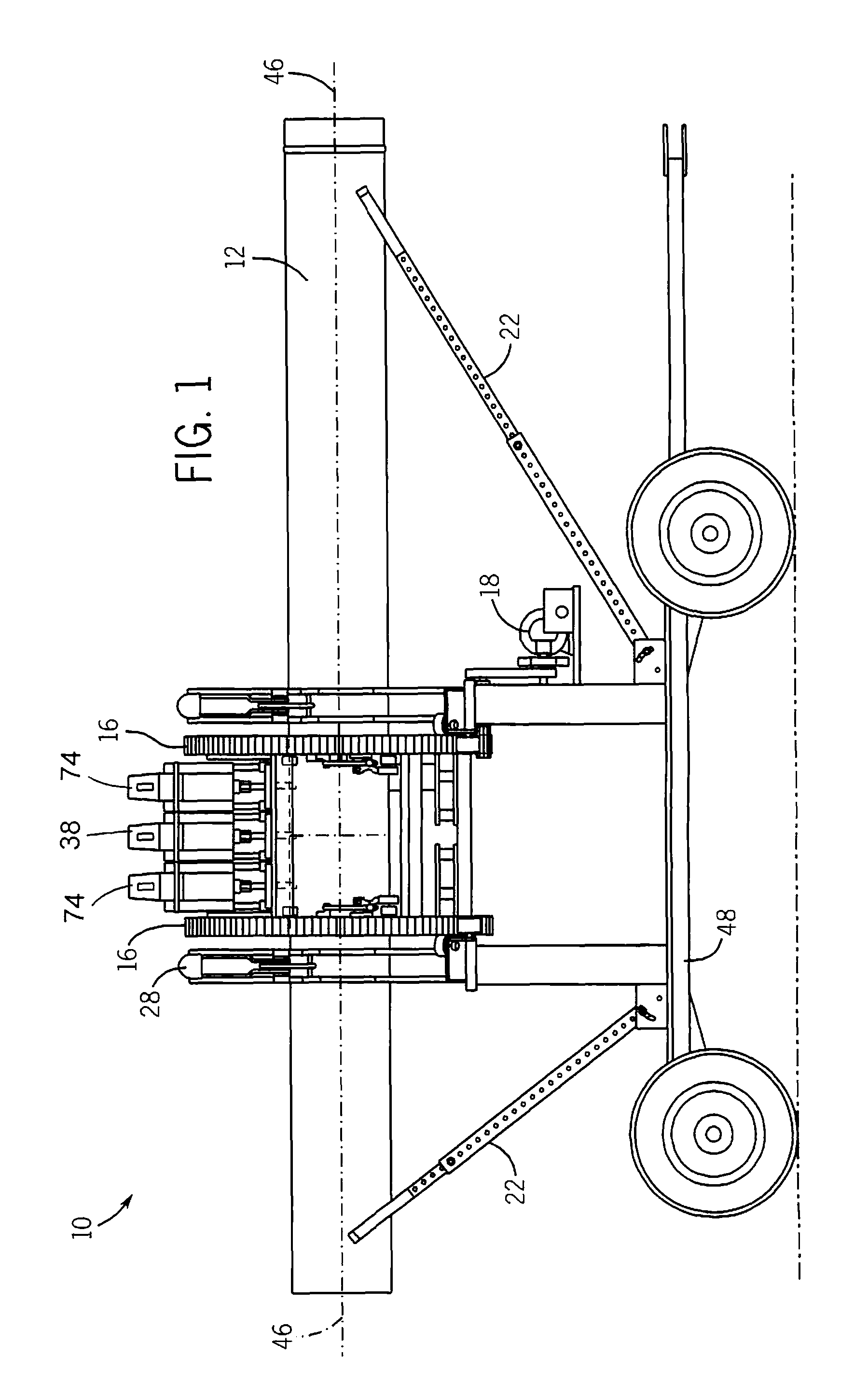

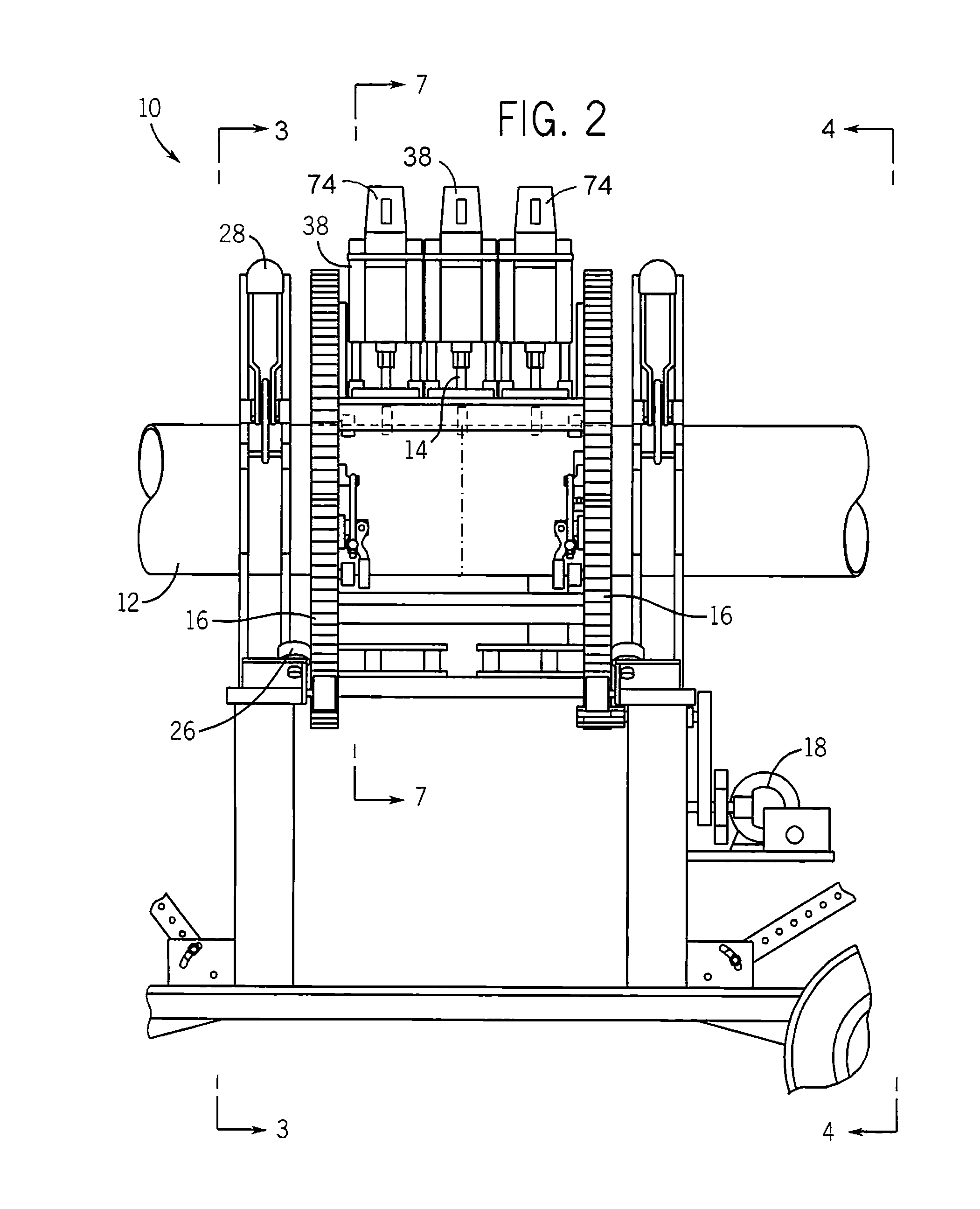

Pipe machining apparatuses are provided. In some aspects, a pipe machining apparatus may include a hinge to allow two sections of the pipe machining apparatus to move relative to one another. In another aspect, a support member may be provided to support a pipe machining apparatus on a surface. In a further aspect, a support member may be provided that allows lifting of a pipe machining apparatus in either a horizontal position or a vertical position.

Owner:ILLINOIS TOOL WORKS INC

Method and apparatus for resurfacing brake rotors

The present invention relates to automotive vehicle brake lathes configured for resurfacing brake rotor components, and in particular, to an improved on-car brake lathe apparatus and a method for compensating for runout between an on-car brake lathe and a vehicle wheel hub to which the on-car brake lathe is secured for a brake rotor resurfacing operation

Owner:HUNTER ENG

Out of round tool bit holder assembly

A tool slide assembly mounted on a clamshell lathe where the clamshell lathe is used to machine an out-of-round work piece. The tool slide assembly generally comprises a base mounted on the rotatable ring of the clamshell lathe and a tool bit holder. The tool bit holder comprises a follower member and a tool block adapted to hold a tool bit, where the follower member is urged against an outer surface of the out-of-round work piece by a plurality of springs. The tool block is incrementally translated such that the tool bit gets fed into the out-of-round work piece.

Owner:HYDRATIGHT OPERATIONS

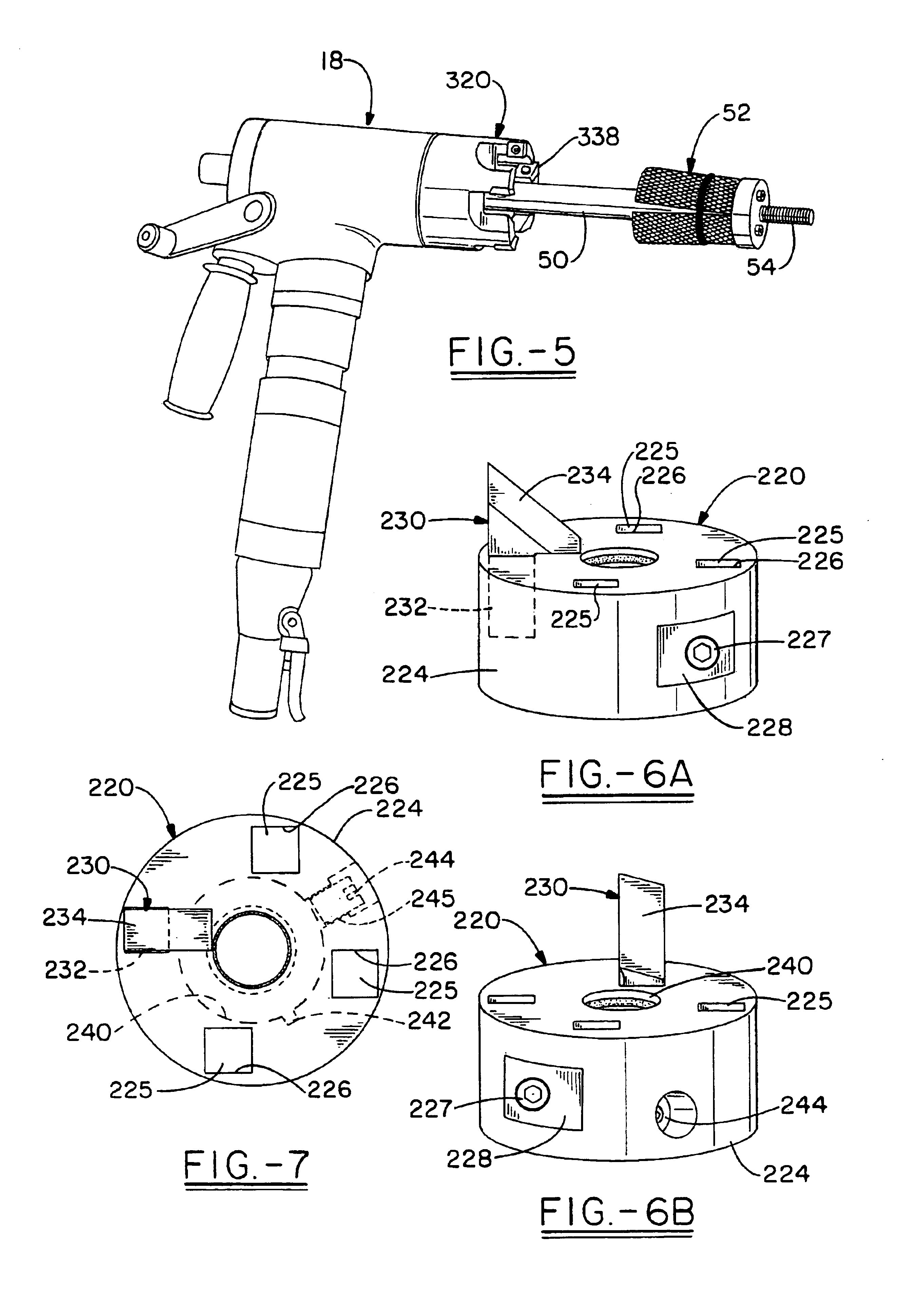

Cutting, profiling, and edge-preparing apparatus

InactiveUS20050247171A1Formed in shape with easeImprove accuracyPortable latheMetal working apparatusEngineeringFeeding mode

An apparatus for cutting and / or profile machining an edge of a pipe is provided. The apparatus includes a housing, a rotatable faceplate mounted on a front surface of the housing, and a tool holder mounted on the faceplate and holding a cutting tool. In a first embodiment, a cutting apparatus includes gearing that permits the tool holder to be moved relative to a surface of a pipe in a rapid-feed mode, a slow-feed mode and a rapid-return mode. In second and third embodiments, a profile machining apparatus includes a carriage having a profiling roller or shaft that advances (or retracts) relative to a pipe along a path defined by a template. The carriage to which the cutting tool is mounted is pivoted about a support shaft permitting the carriage and tool to change its angle and orientation relative to the pipe while advancing or retracting.

Owner:MORI KENICHI

Pipe beveling system

InactiveUS7082656B1Good adhesionEasy detachmentEdge grinding machinesSleeve/socket jointsMechanical engineeringEngineering

A tool for beveling the end of a pipe is comprised of a hollow, tubular body having a central, longitudinal axis of rotation, an inboard coupling end, and an opposite outboard working end. A plurality of longitudinally spaced, transversely directed latching pin bores of equal size are defined through the wall of the tubular body. A core member is disposed coaxially within the tubular body. The core member includes a beveling cutter head and a longitudinal stem having a radially inwardly directed, circumferential latch position groove. A transversely oriented latching pin is engaged in a selected one of the latching pin bores in the body and with the latch position groove of the core stem. This allows alternative selection of each of the latch position bores for insertion of the latching pin. The particular bore selected determines the longitudinal position of the core stem latch position groove within the body that will be aligned with the latching pin. This, in turn, determines the extent of protrusion of the core member cutter head from the outboard end of the tubular body, and thus the depth of the beveling cut in the pipe.

Owner:DUNCAN C WARREN +2

Portable beveling tool

InactiveUS8297157B1Low costEasy constructionWood turning toolsTransportation and packagingEngineeringMechanical engineering

A portable beveling tool that is attached to a power tool having a rotary cutter for beveling pipe. The beveling tool includes a base, two rollers extending away from the base, and a tool mount that rotatably mounts the power tool to the base. The rollers and the cutter cooperate to locate the beveling tool on the pipe and to guide movement of the beveling tool around the pipe. The position of one of the rollers is adjustable to accommodate pipes of different diameters and wall thicknesses. An operator can move the beveling tool around the end of the pipe without changing his or her grip on the power tool.

Owner:TKM TOOLS

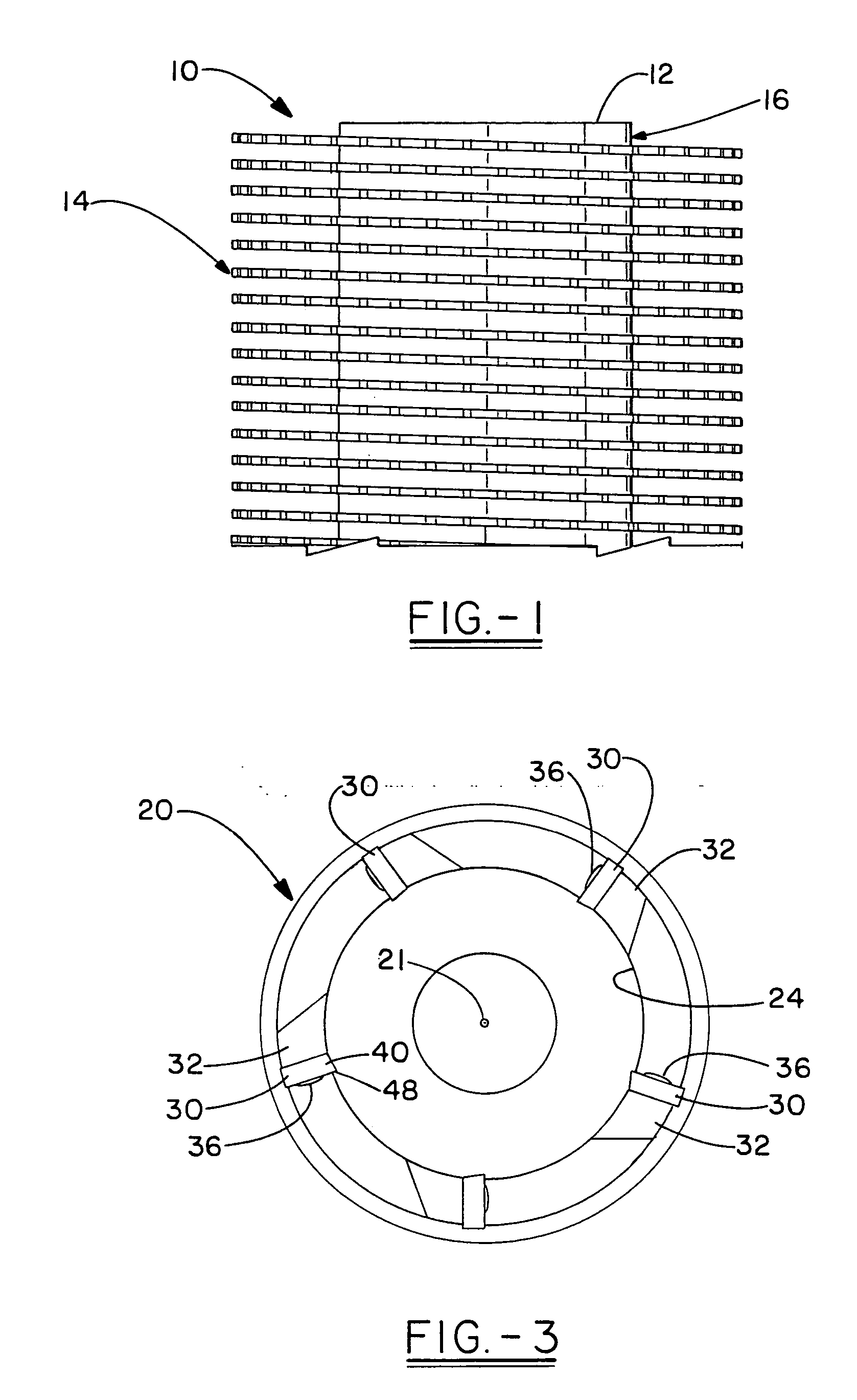

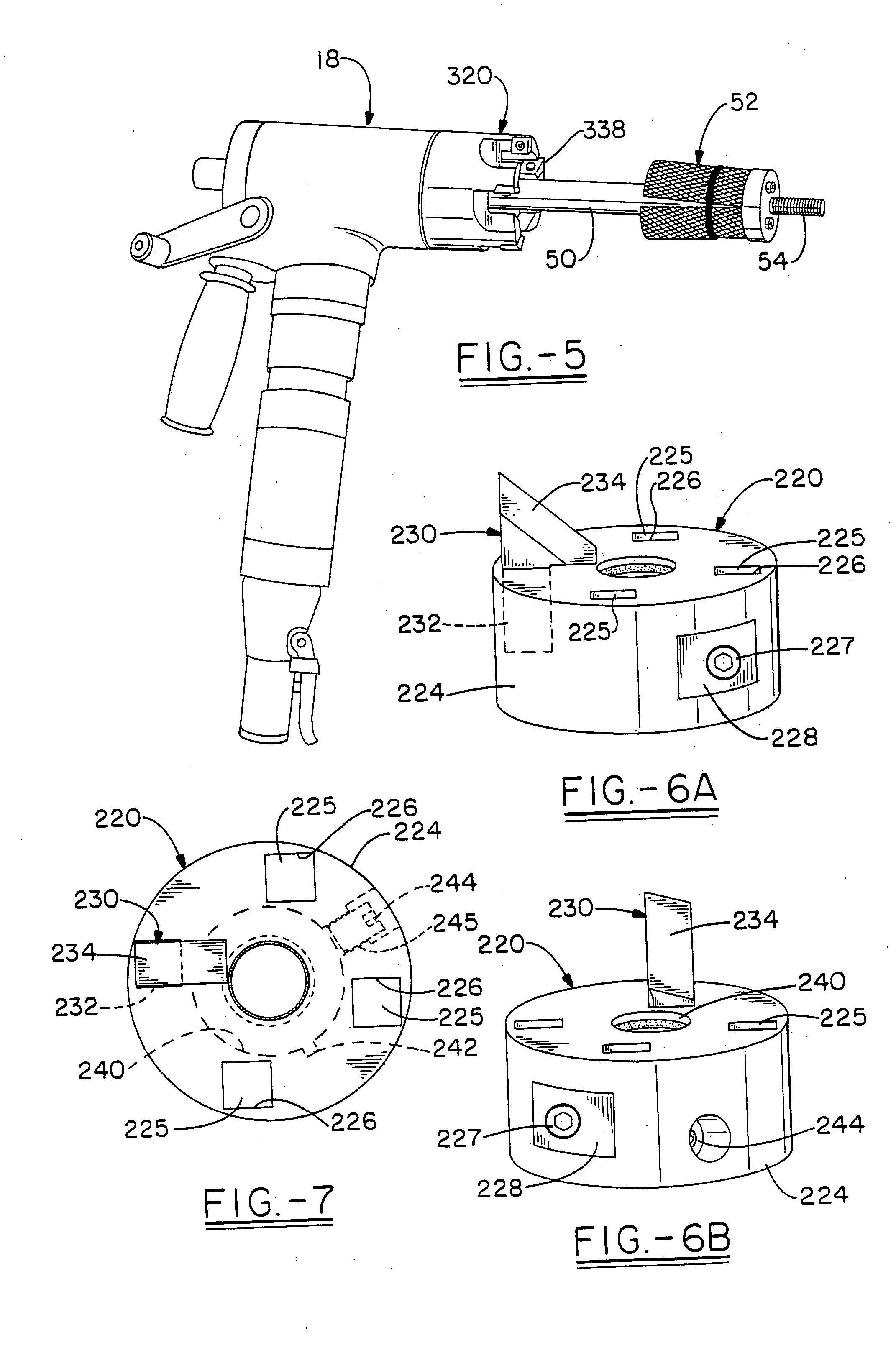

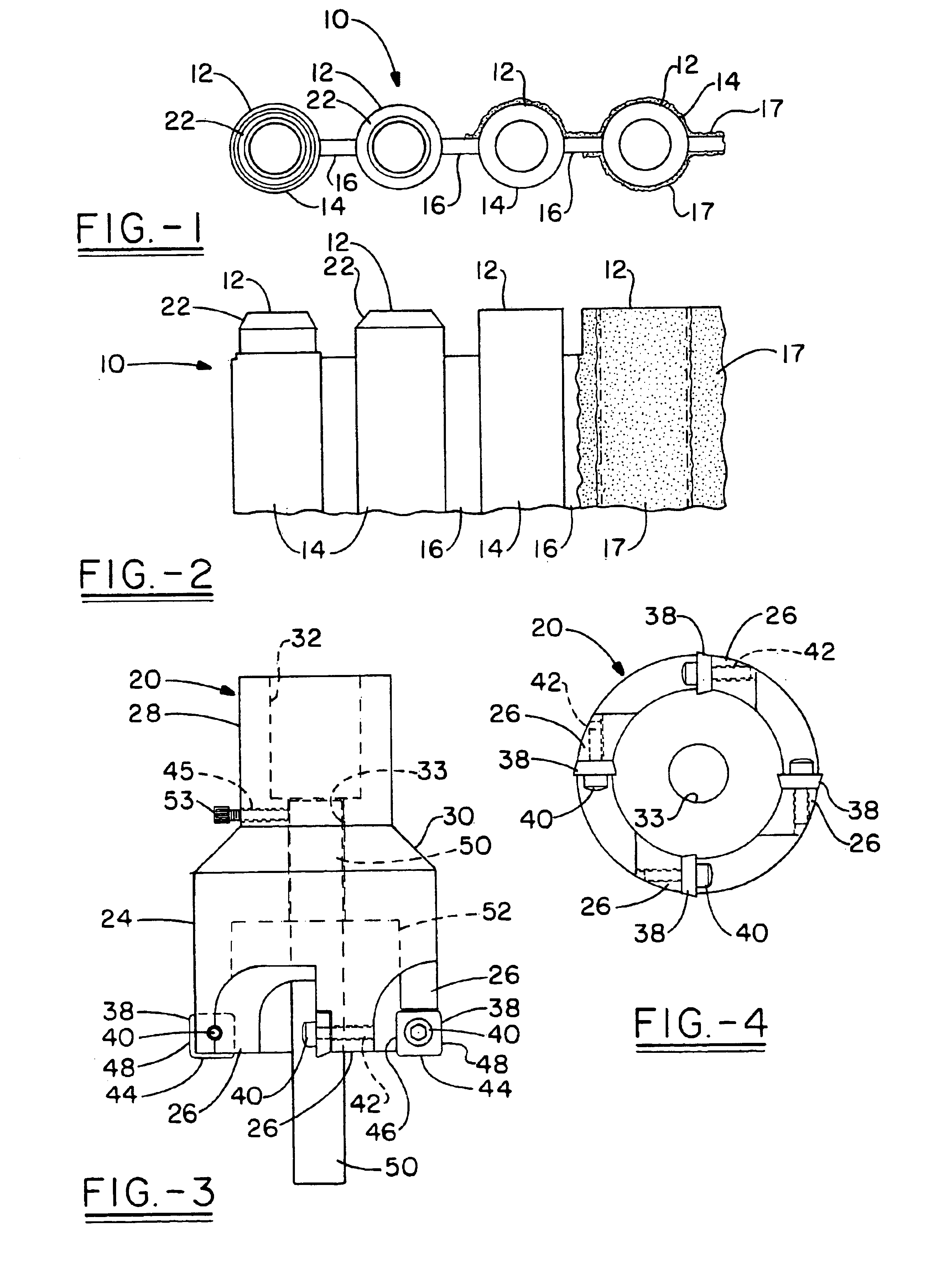

Tube milling head

ActiveUS20050053432A1Improve relationshipSave downtimeMilling cuttersWorkpiecesEngineeringKnife blades

Tube ends such as those of boiler tube banks, are prepared utilizing any of various combinations of processes which include a step of micro-diameter tube film removal from a portion of a tube end, including an area below a beveled segment, or segment to be beveled. The micro-diameter film removal step provides the tube with an exposed, clean metal surface which is conducive to a subsequent welding or bonding operation performed on the tube. Preferably, the process is performed with a tube milling tool having interchangeable milling or cutting heads. A specialized milling head is also disclosed and, in one embodiment, is at least used to perform the micro-diameter tube film removal step. Advantageously, the tube film removal milling head also removes a weld overlay on one or both sides of a tube in one embodiment. The tube film removal milling head includes an attached blade having a planar face configuration which enables tube film removal.

Owner:CLIMAX PORTABLE MACHINE TOOLS

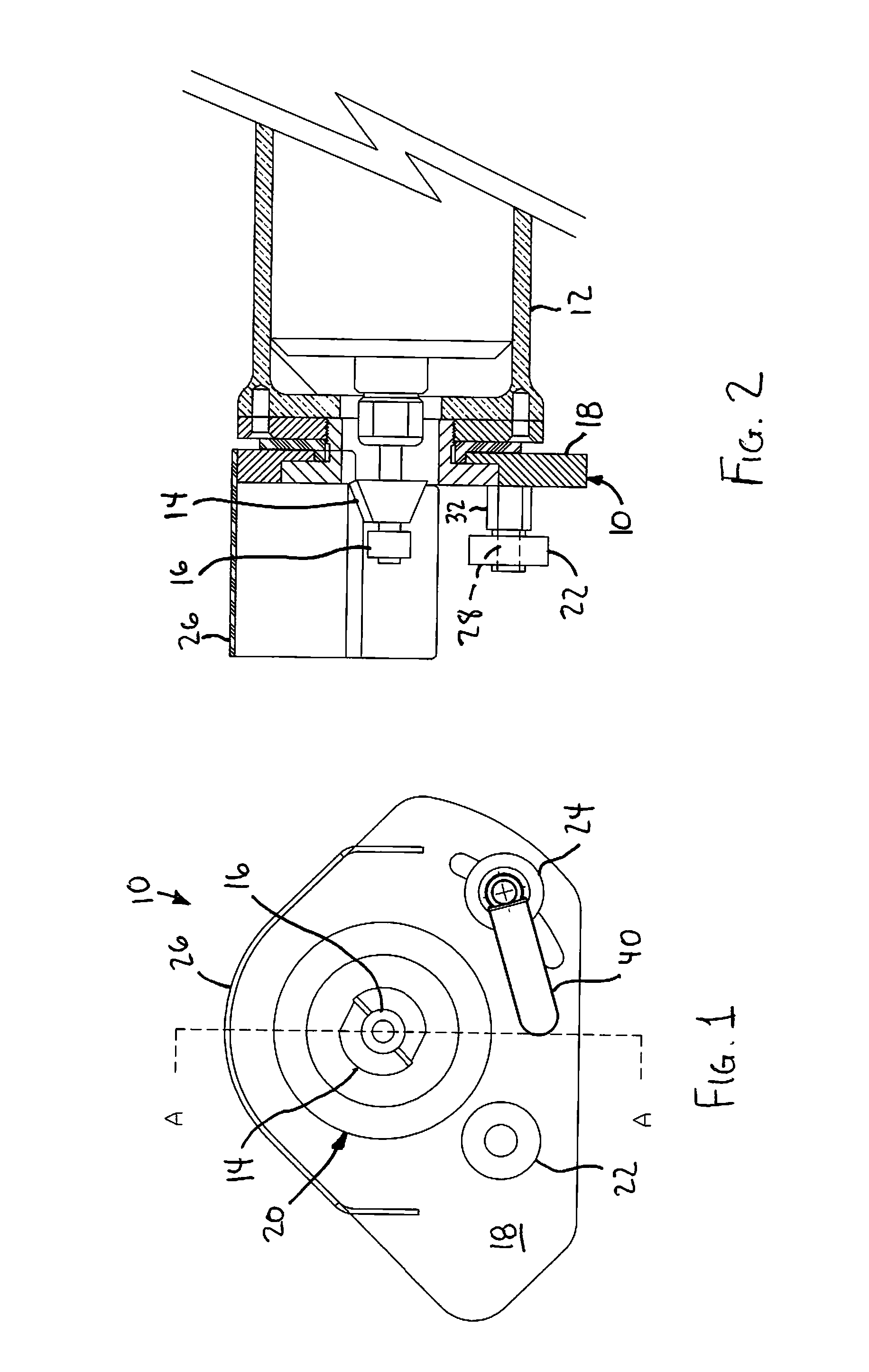

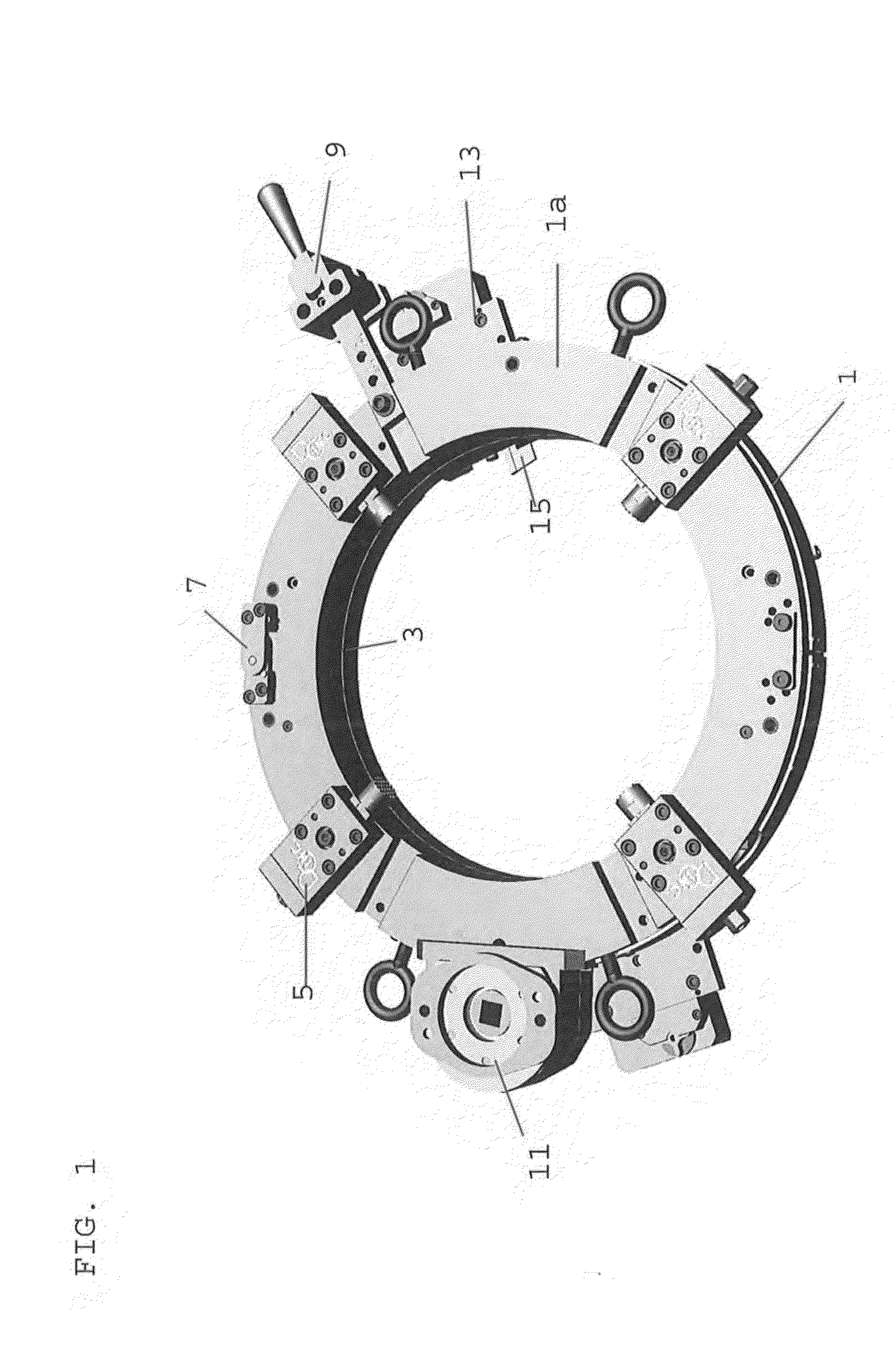

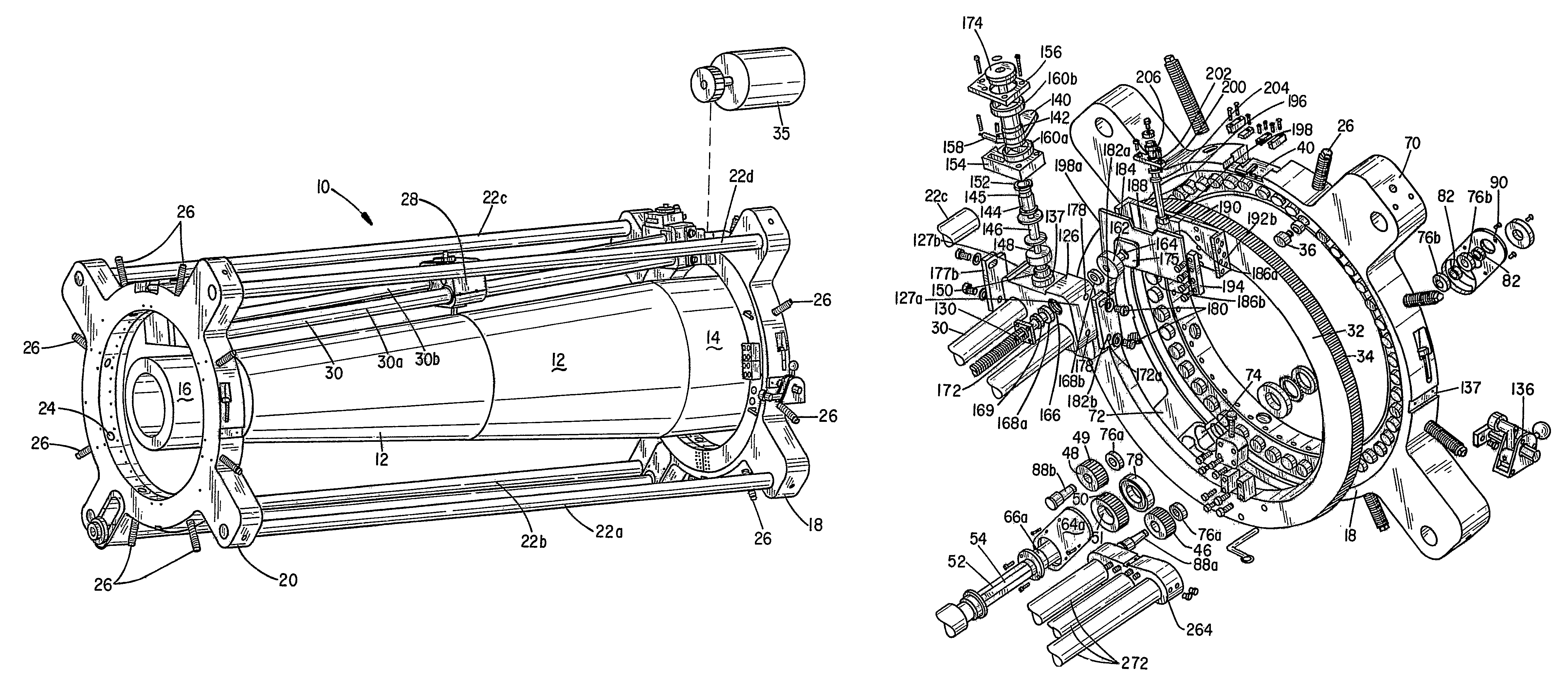

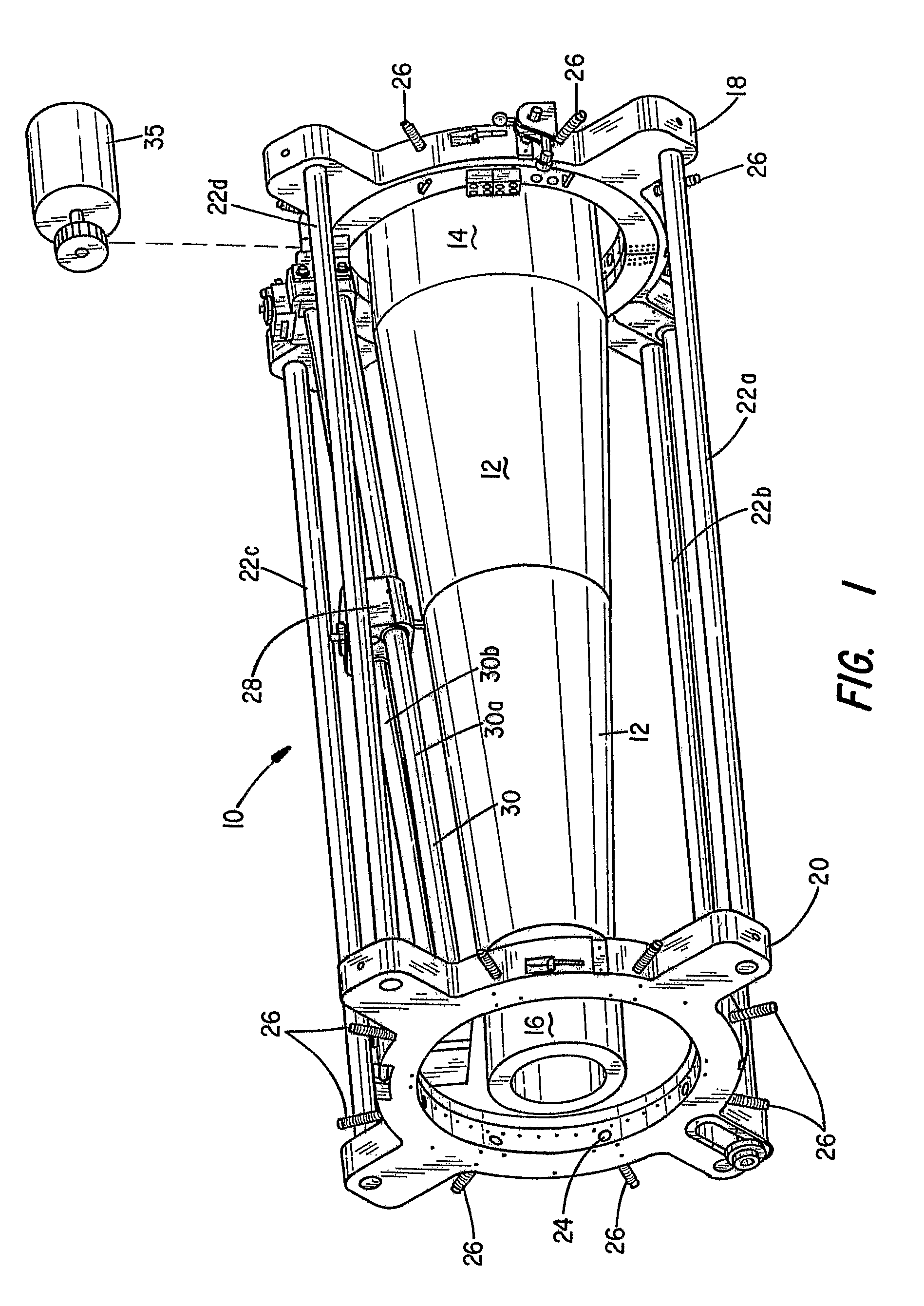

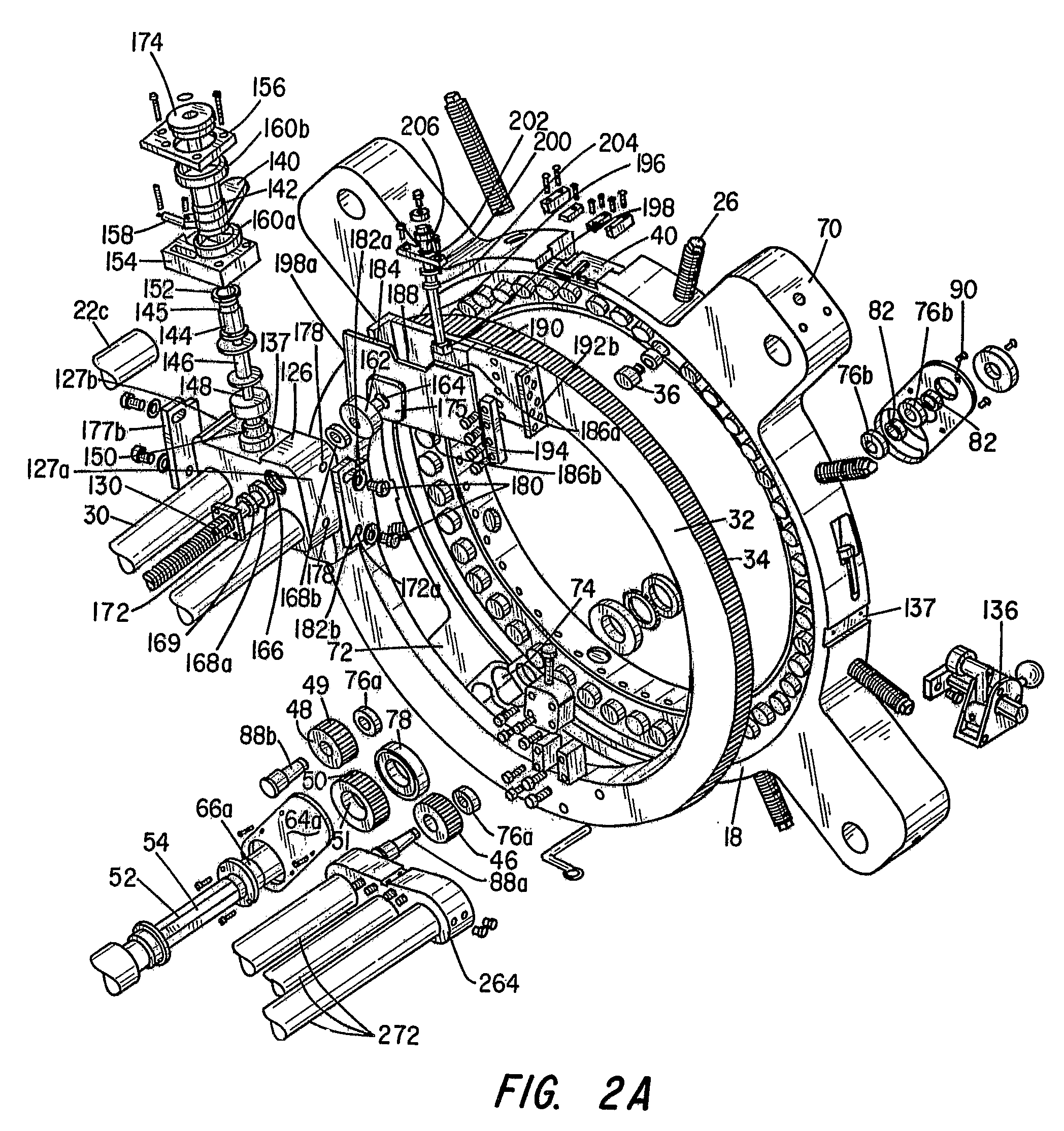

Split Frame Lathe

A split frame lathe having improved locking, cutting and adjustment capabilities is disclosed. The split frame lathe includes an embodiment having a plurality of internal bearing systems where each internal bearing system includes an eccentric bushing, a bearing pin and a v-bearing. Another embodiment of the split frame lathe may include adjustable leg systems. The split frame lathe may also include a star gear connected to a gear ring where the star gear can be rotated in a first direction and, alternatively, in an opposite second direction. In another embodiment the split frame lathe includes a trip system to prevent damage to the lathe and harm to the operator. The split frame lathe may also include improved locking mechanisms for the gear and base ring and a hinge system. The split frame lathe also may include a counter bore and flange facer attachment.

Owner:WOKAN MIROSLAW +3

Method for tube end preparation and milling head therefore

InactiveUS20050053440A1Improve relationshipSave downtimeThread cutting toolsTransportation and packagingEngineeringMetal

Tube ends such as those of boiler tube banks, are prepared utilizing any of various combinations of processes which include a step of micro-diameter tube film removal from a portion of a tube end, including an area below a beveled segment, or segment to be beveled. The micro-diameter film removal step provides the tube with an exposed, clean metal surface which is conducive to a subsequent welding or bonding operation performed on the tube. Preferably, the process is performed with a tube milling tool having interchangeable milling or cutting heads. A specialized milling head is also disclosed and, in one embodiment, is at least used to perform the micro-diameter tube film removal step. Advantageously, the tube film removal milling head also removes a weld overlay on one or both sides of a tube in one embodiment. The tube film removal milling head includes an attached blade having a planar face configuration which enables tube film removal.

Owner:CLIMAX PORTABLE MACHINE TOOLS

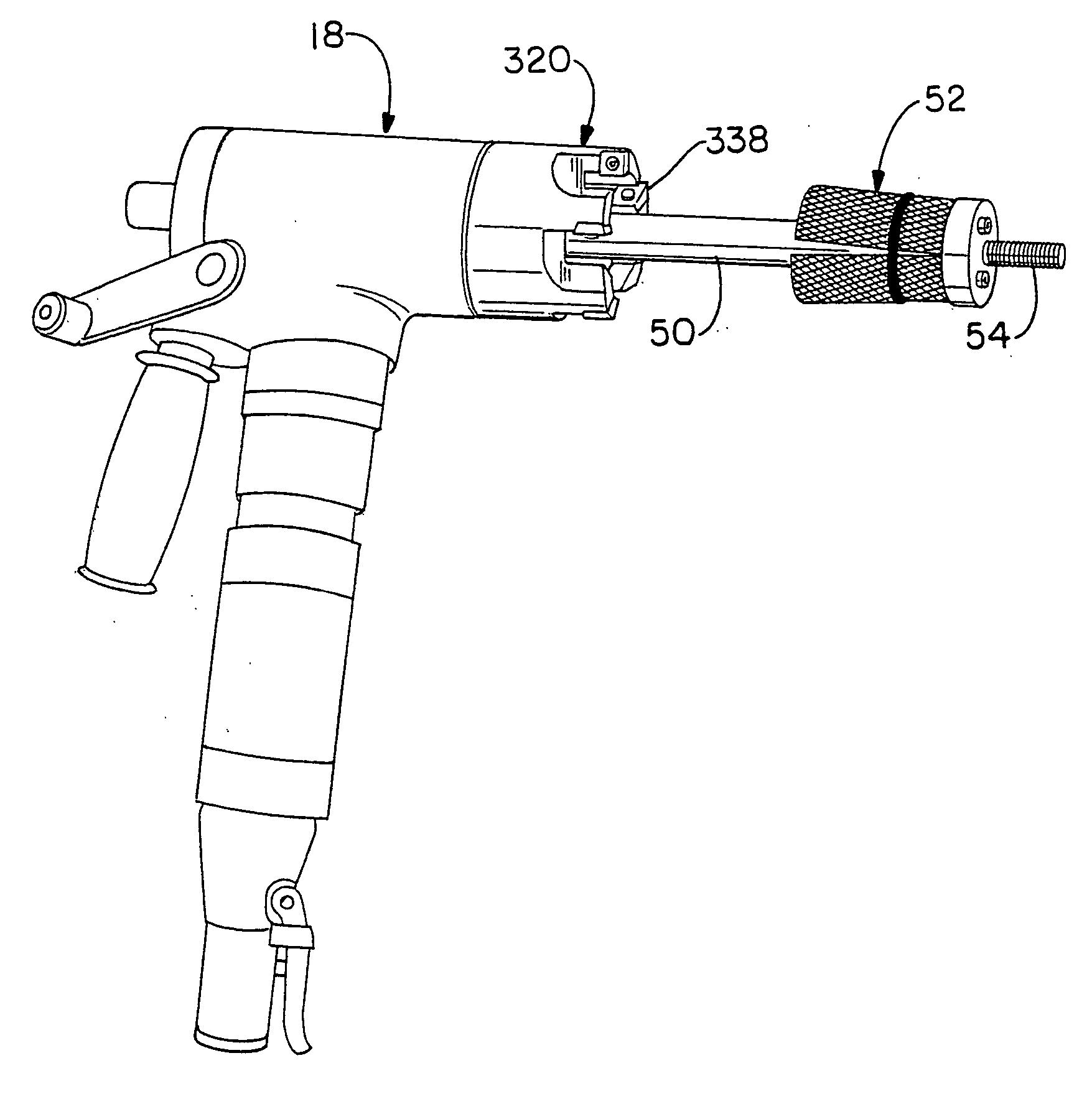

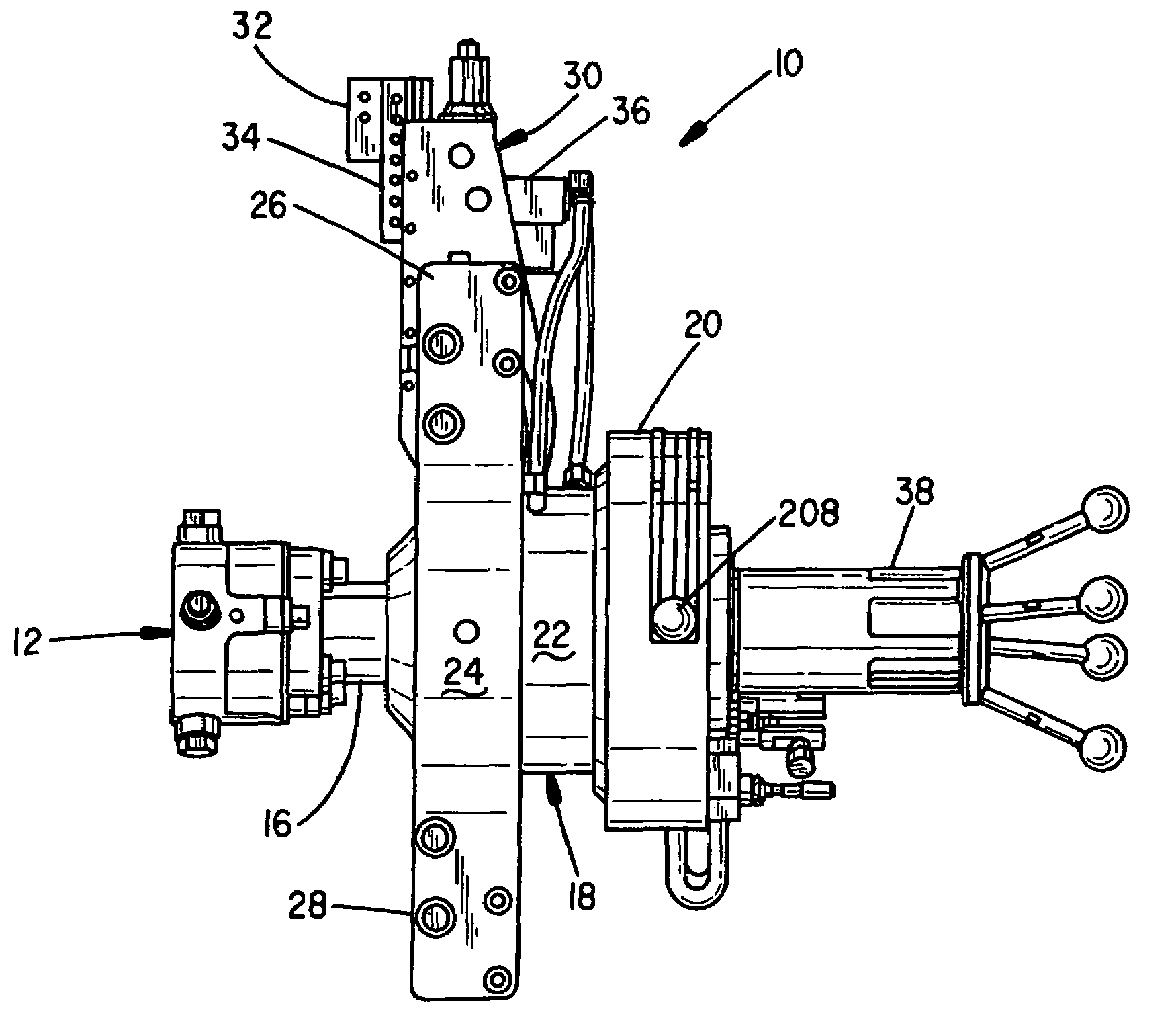

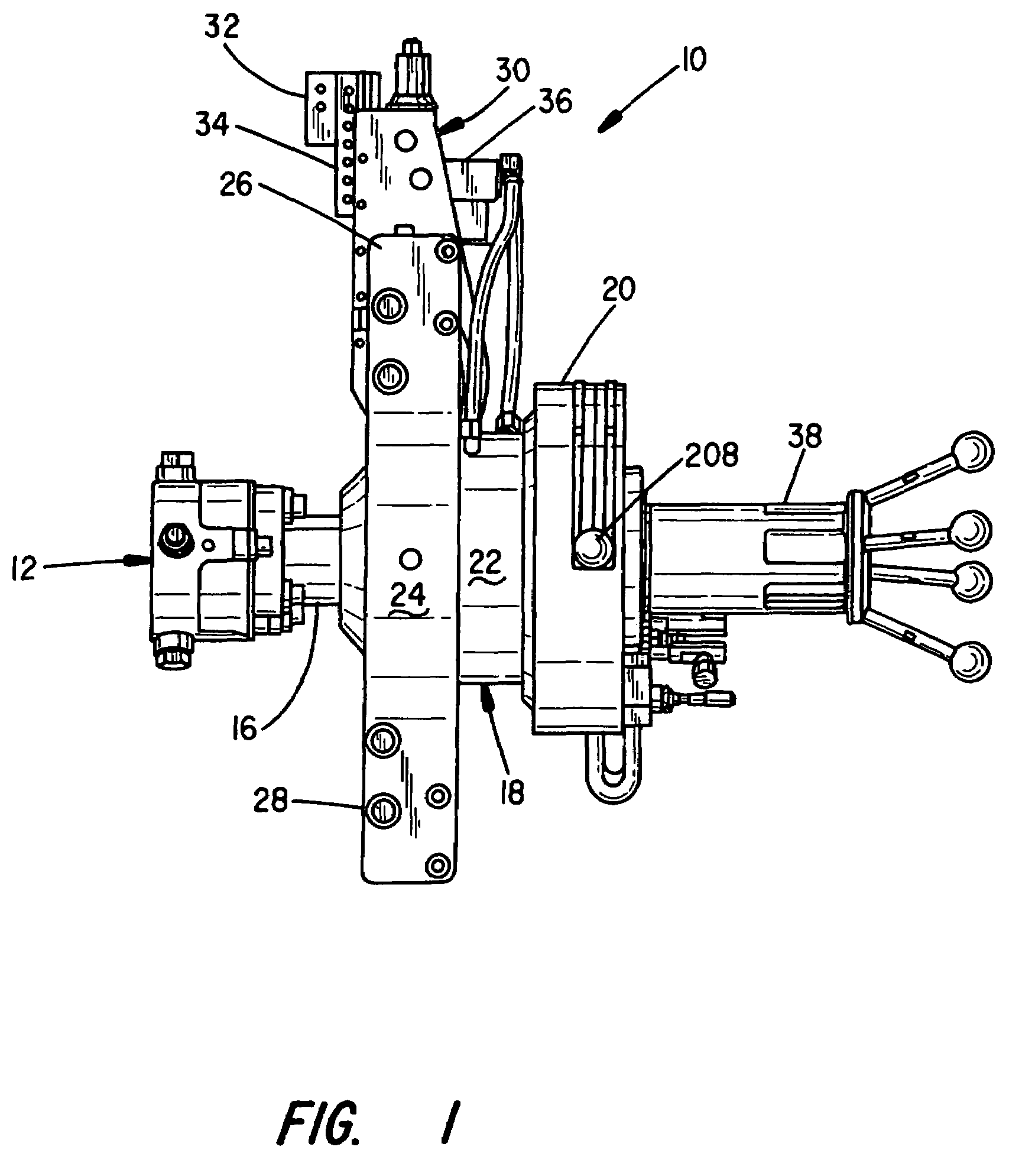

Air-operated end prep machine

An end prep tool with a pneumatically driven tool slide assembly comprises a mandrel mountable to the internal diameter of a tubular work piece. Mounted on the mandrel are a rotational head assembly and a rotatable housing that are longitudinally displaceable along the mandrel. The rotational head assembly carries either one or two tool feed assemblies thereon for orbital movement around the work piece. The tool slide assemblies are driven by a pneumatic motor to provide a true phonographic finish with no tripper marks.

Owner:HYDRATIGHT OPERATIONS INC

Tube milling head

Tube ends such as those of boiler tube banks, are prepared utilizing any of various combinations of processes which include a step of micro-diameter tube film removal from a portion of a tube end, including an area below a beveled segment, or segment to be beveled. The micro-diameter film removal step provides the tube with an exposed, clean metal surface which is conducive to a subsequent welding or bonding operation performed on the tube. Preferably, the process is performed with a tube milling tool having interchangeable milling or cutting heads. A specialized milling head is also disclosed and, in one embodiment, is at least used to perform the micro-diameter tube film removal step. Advantageously, the tube film removal milling head also removes a weld overlay on one or both sides of a tube in one embodiment. The tube film removal milling head includes an attached blade having a planar face configuration which enables tube film removal.

Owner:CLIMAX PORTABLE MACHINE TOOLS

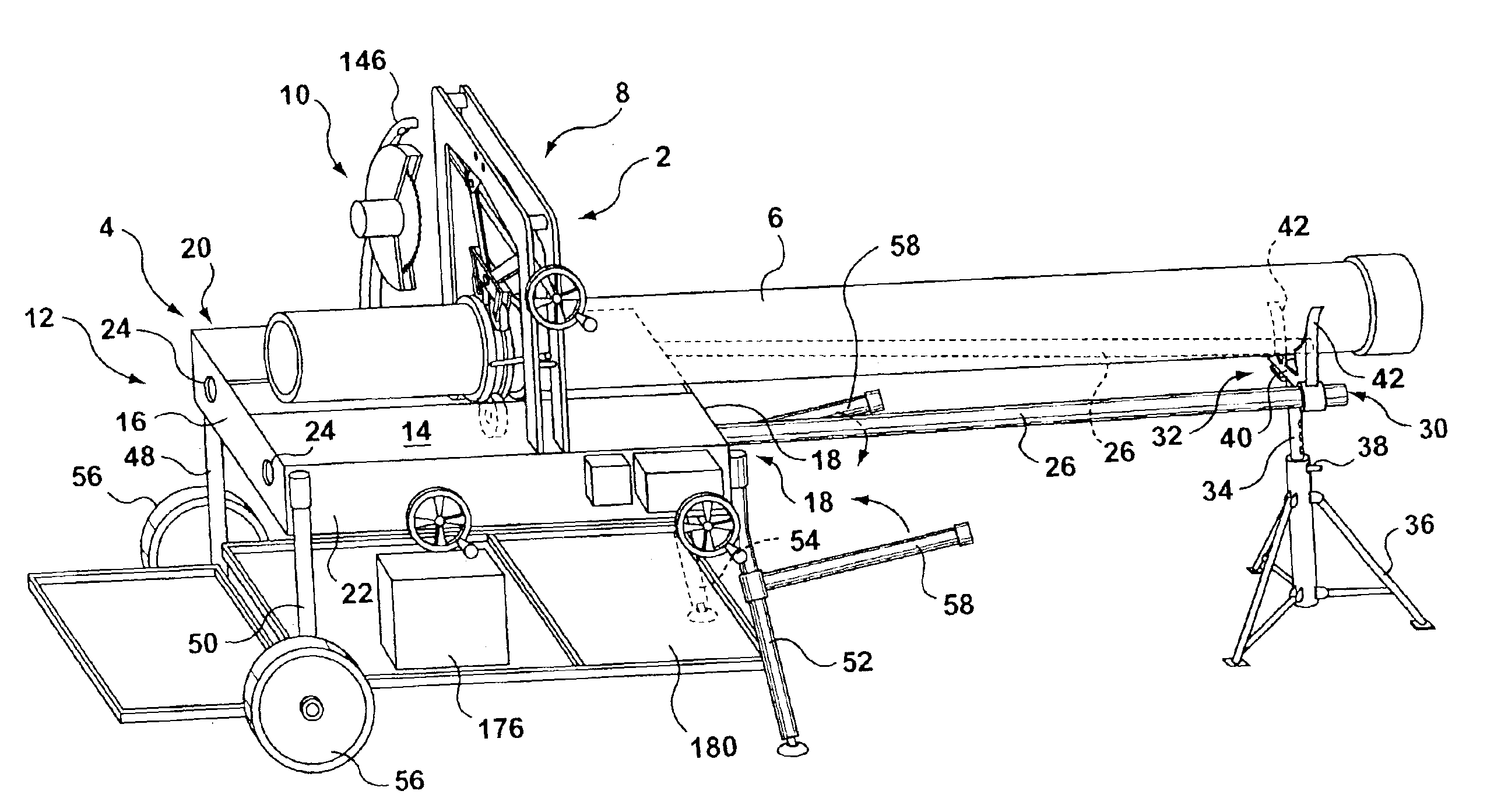

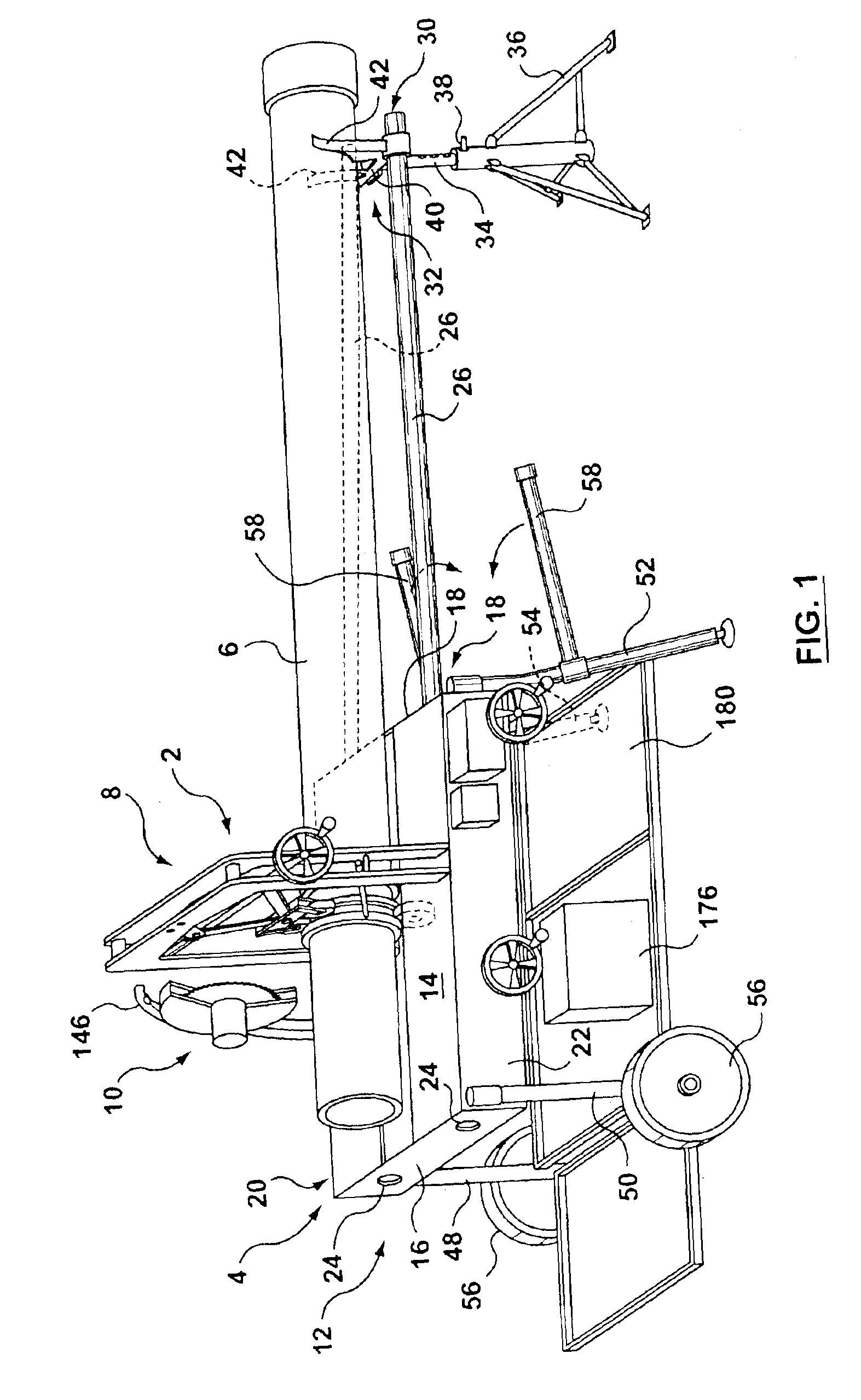

Simultaneous pipe cutting, chamfering and grooving device

InactiveUS7811034B1Efficient and easy to useAutomatic/semiautomatic turning machinesMilling machinesDrive motorEngineering

A mobile device for simultaneously cutting, chamfering and grooving a pipe. The device having a frame, at least one pipe collet-clamp attached to the frame and defining a principal axis, a split carriage rotatably mounted with respect to the frame about the axis and adjacent to the clamp(s), a router affixed to the split carriage and having a cutting-chamfering bit, a grooving router and a drive motor for rotating the carriage. The routers orbit around the pipe and simultaneously cuts the pipe into two chamfered pipes with grooves. A method is also provided for cutting through a pipe, chamfering the cut ends thereof and grooving the pipe.

Owner:KAROW PHILIP

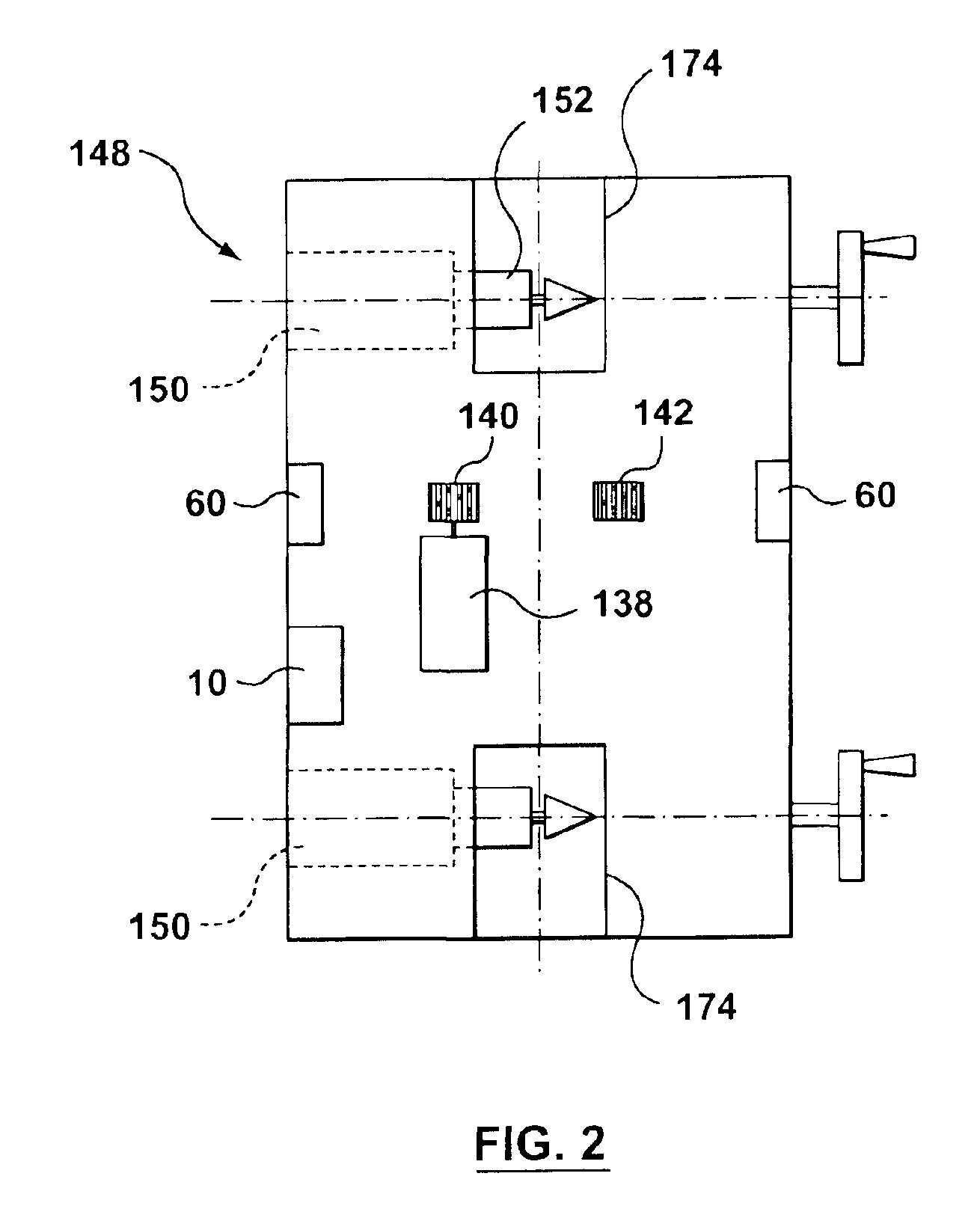

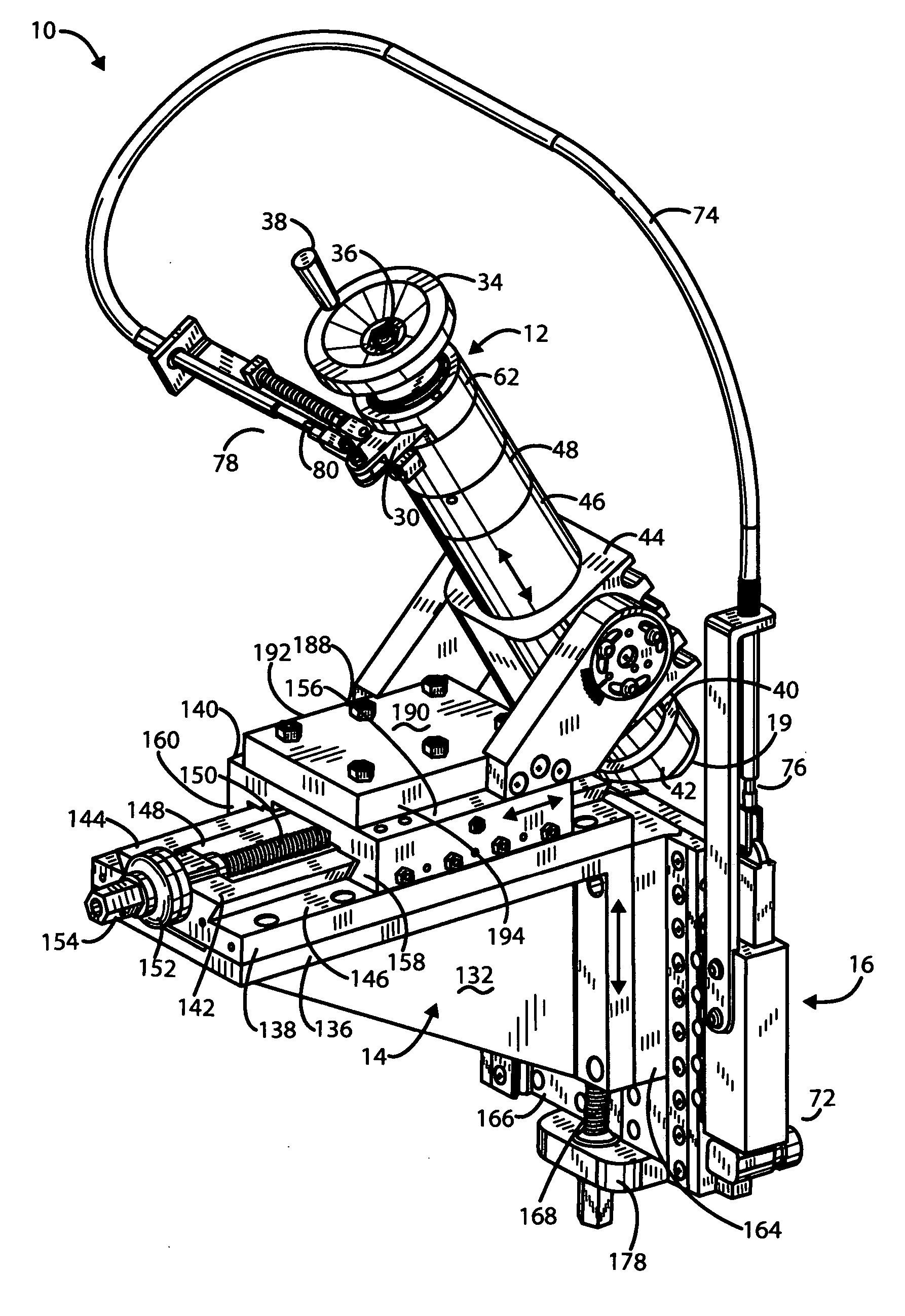

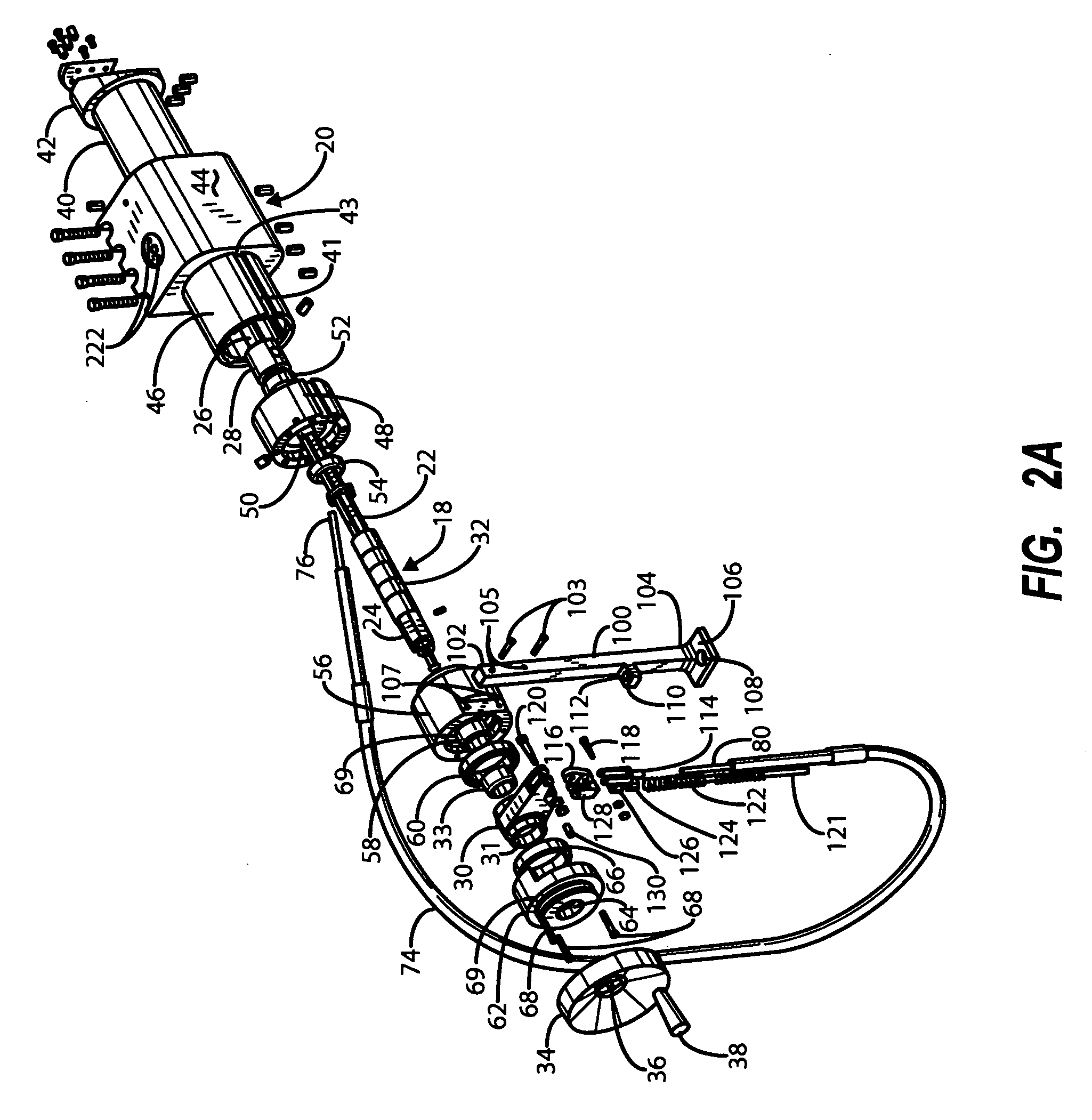

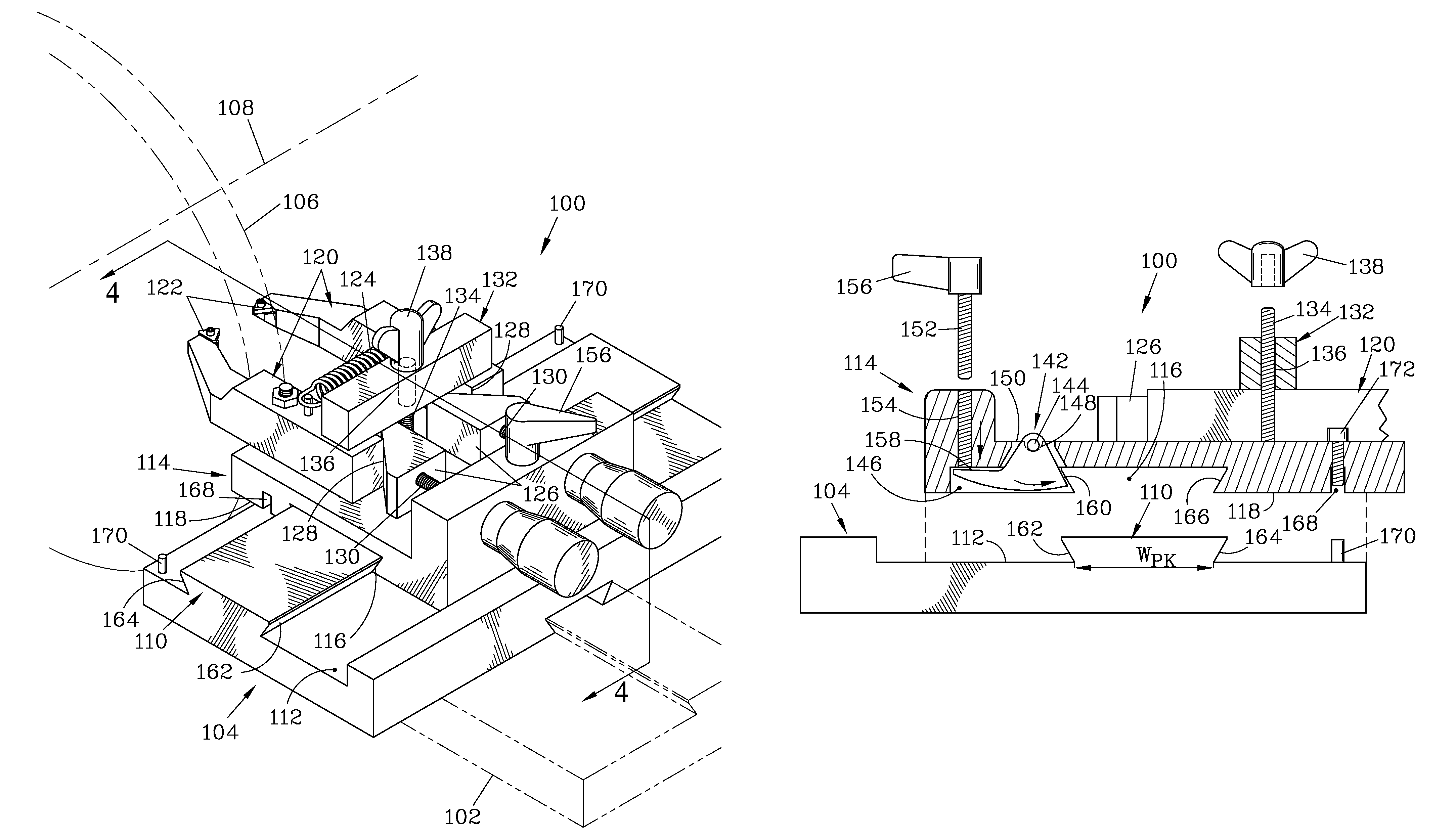

Tapered turning lathe

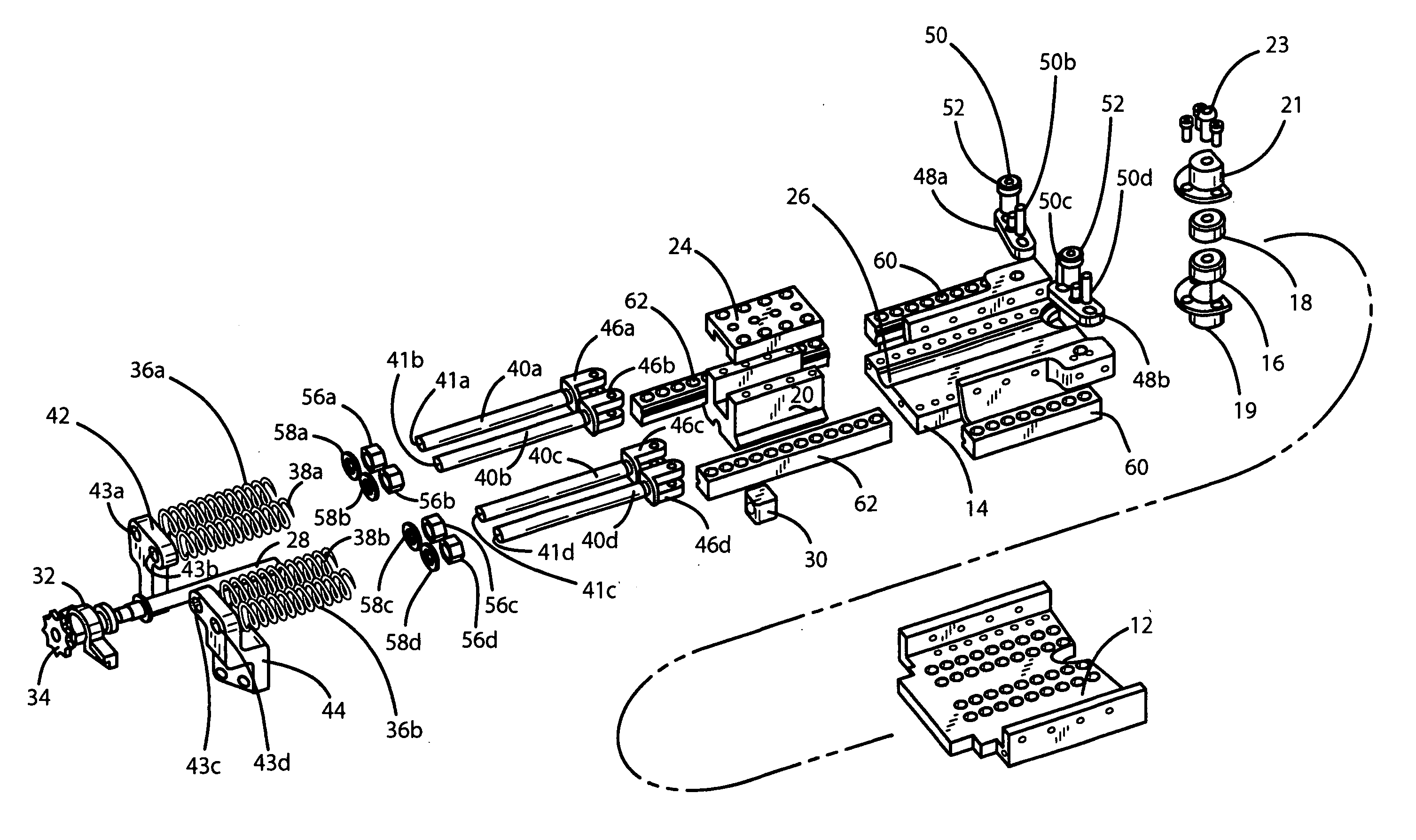

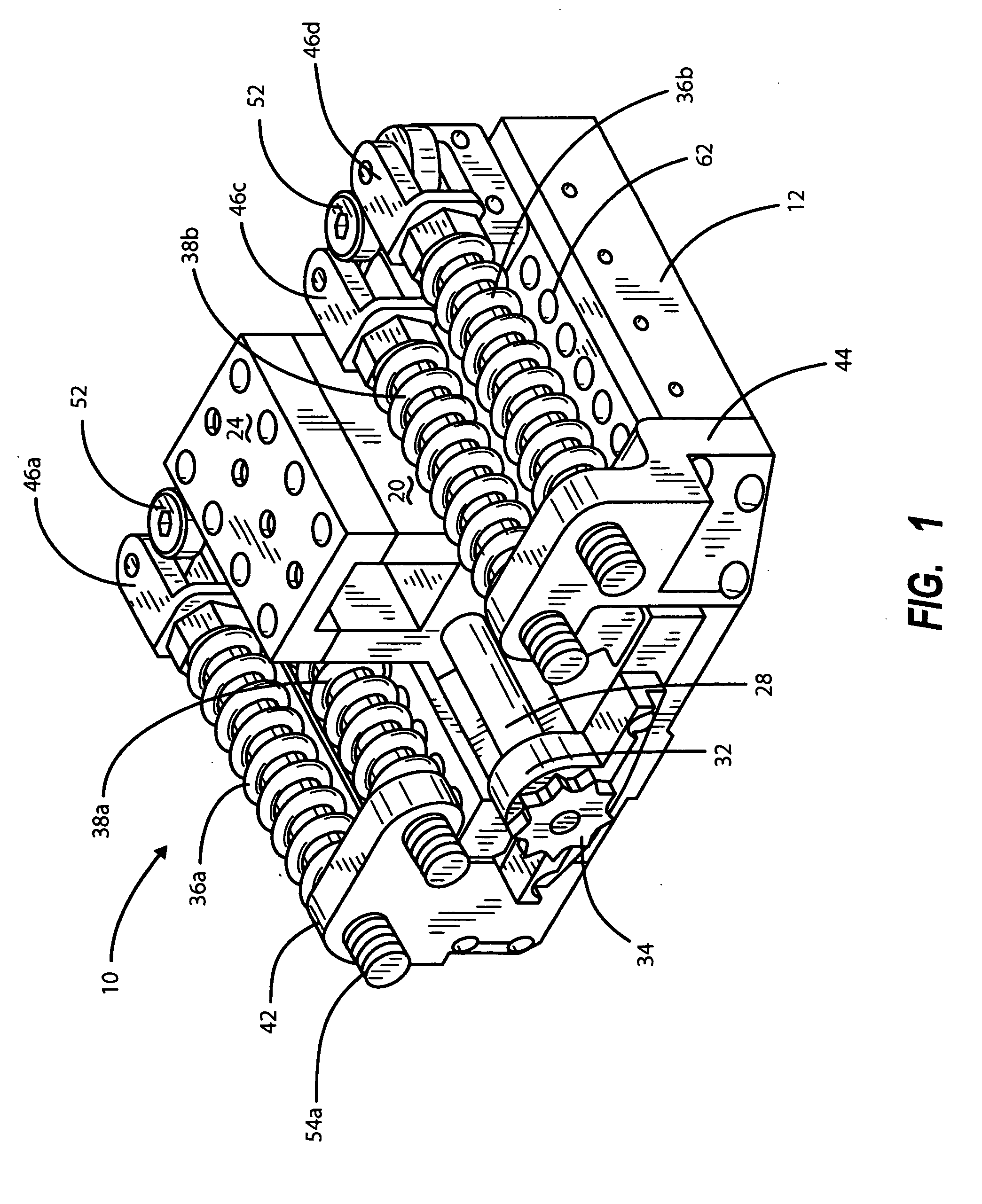

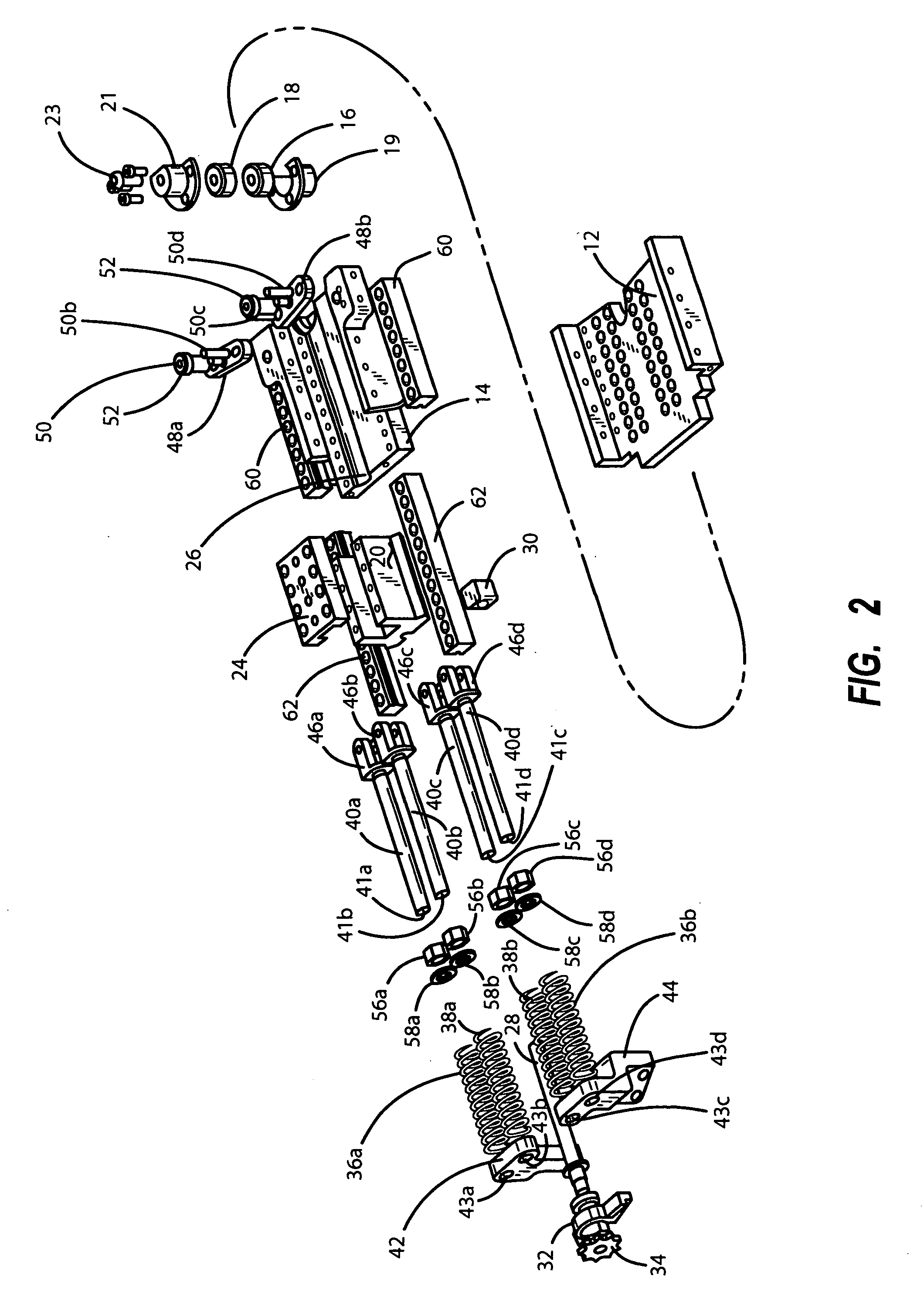

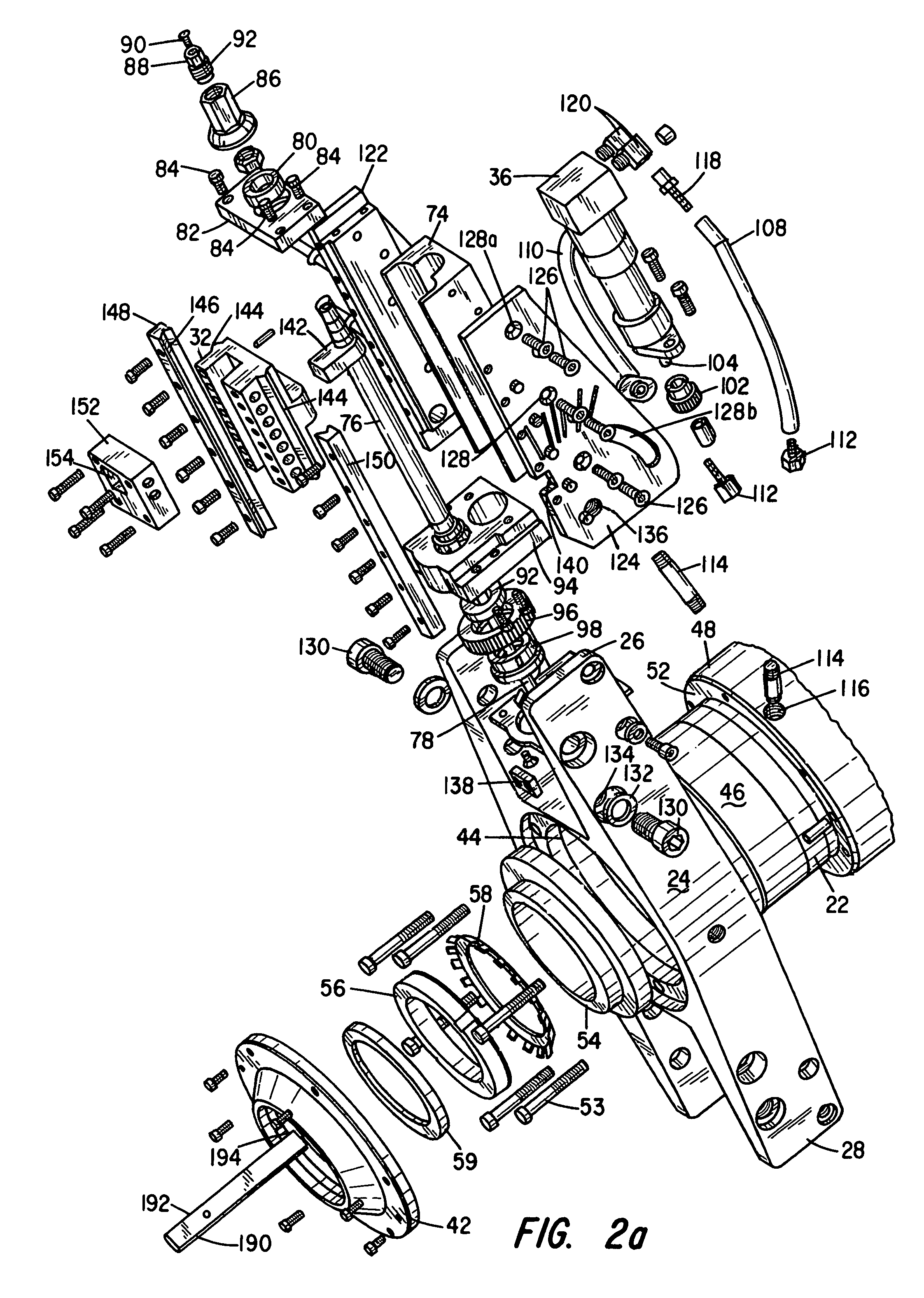

A radially adjustable drive bracket (126) is affixed to, and rotatable with the drive gear (32), and a radially adjustable support bracket (128) is affixed to, and rotatable with the driven gear (42). A pair of parallel slide rails (30) are coupled at opposite ends to the drive bracket (126) and support bracket (128). A cutting head assembly (28) is slidably mounted on the slide rails (30), wherein a threaded lead screw (124) carrying a traveling nut (134) thereon causes longitudinal displacement of the cutting head assembly (28) along the slide rails (30). A cam arm (140) coupled through a one-way clutch to the lead screw (124) and adapted to be actuated by a tripper assembly (136) mounted so as to engage the cam arm (140) during orbiting movement of the drive and driven gear (32,42).

Owner:HYDRATIGHT OPERATIONS INC

Pipe cutting apparatus and method of using the same

An apparatus for cutting a pipe includes a housing with a central aperture for holding the pipe in a fixed position. A rotatable collar is mounted on the outer surface of the fixed housing, with a cutting head attached to the collar. The cutting head is configured to translate forward and backward such that the combination of the rotational movement of the collar and the translational movement of the cutting head is capable of performing complex cuts without ever moving the pipe. A number of different cutting tools (laser, plasma, etc.) may be attached to the cutting head, and a variety of different tasks may be performed including cutting completely through the entire pipe, inscribing on the pipe surface, forming through-holes along the pipe, and the like.

Owner:MARPLE MELVYN JAMES +1

Cutting, profiling, and edge-preparing apparatus

InactiveUS7320268B2Formed in shape with easeImprove accuracyPortable latheMetal working apparatusEngineeringKnife holder

An apparatus for cutting and / or profile machining an edge of a pipe is provided. The apparatus includes a housing, a rotatable faceplate mounted on a front surface of the housing, and a tool holder mounted on the faceplate and holding a cutting tool. In a first embodiment, a cutting apparatus includes gearing that permits the tool holder to be moved relative to a surface of a pipe in a rapid-feed mode, a slow-feed mode and a rapid-return mode. In second and third embodiments, a profile machining apparatus includes a carriage having a profiling roller or shaft that advances (or retracts) relative to a pipe along a path defined by a template. The carriage to which the cutting tool is mounted is pivoted about a support shaft permitting the carriage and tool to change its angle and orientation relative to the pipe while advancing or retracting.

Owner:MORI KENICHI

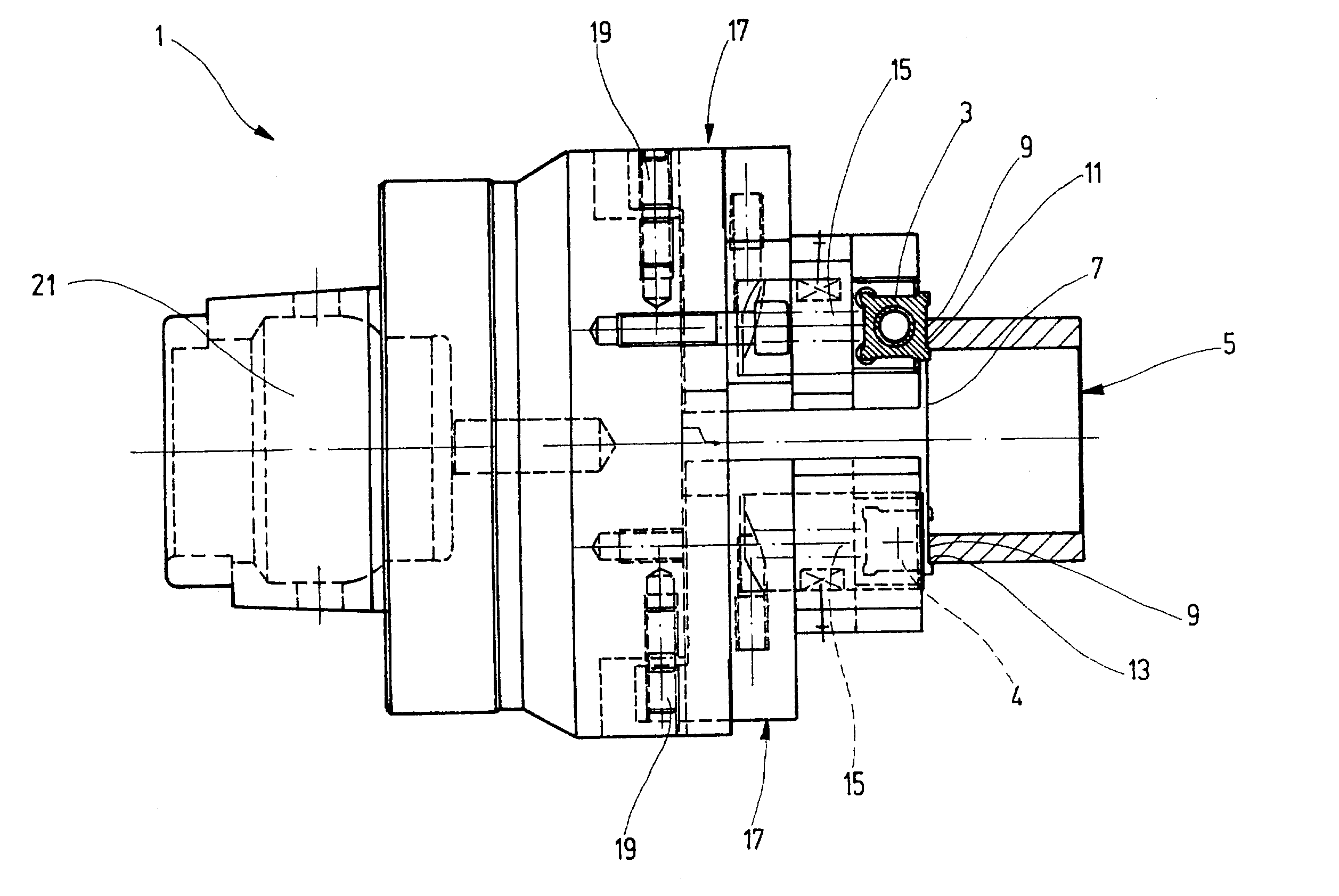

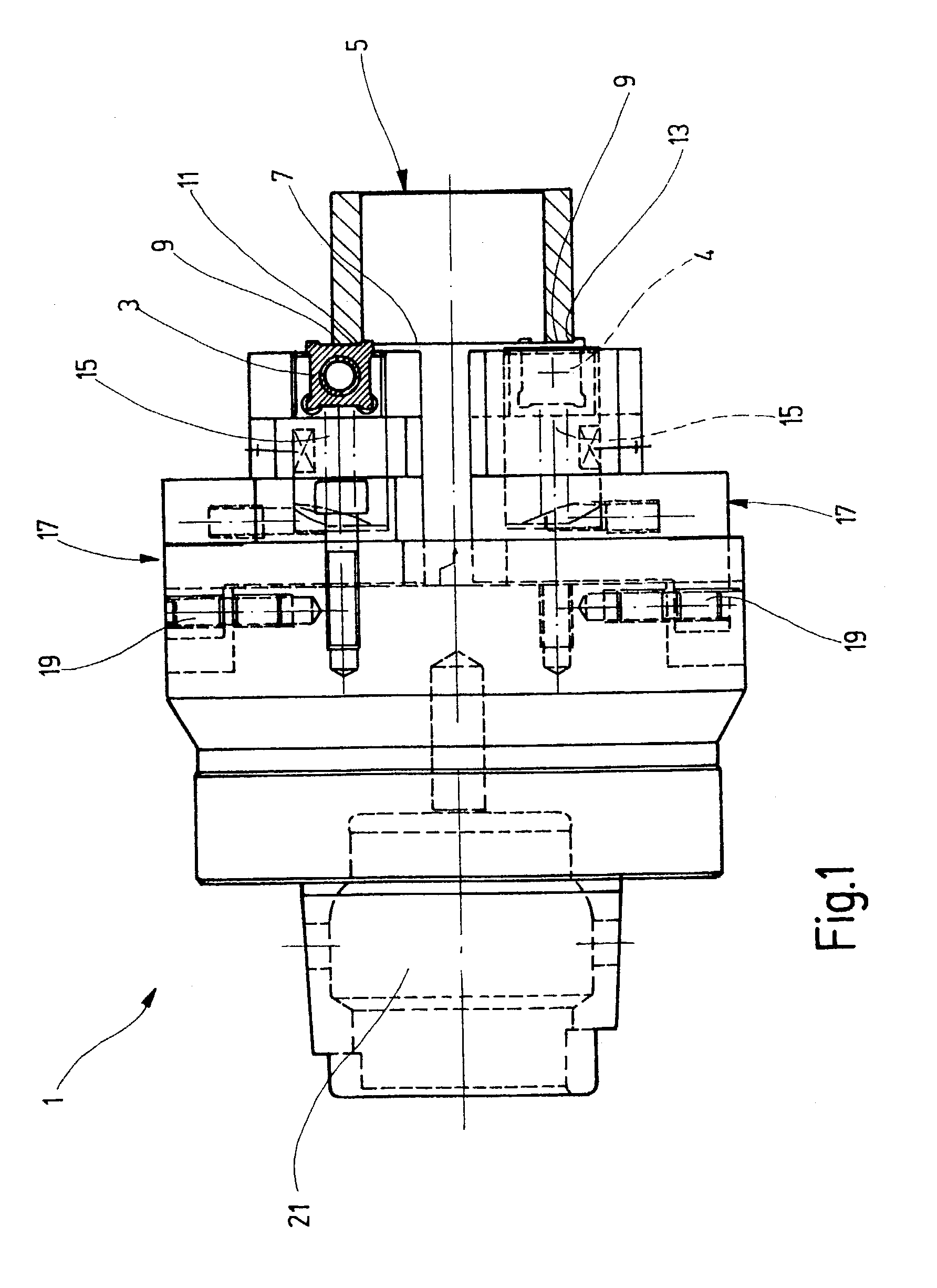

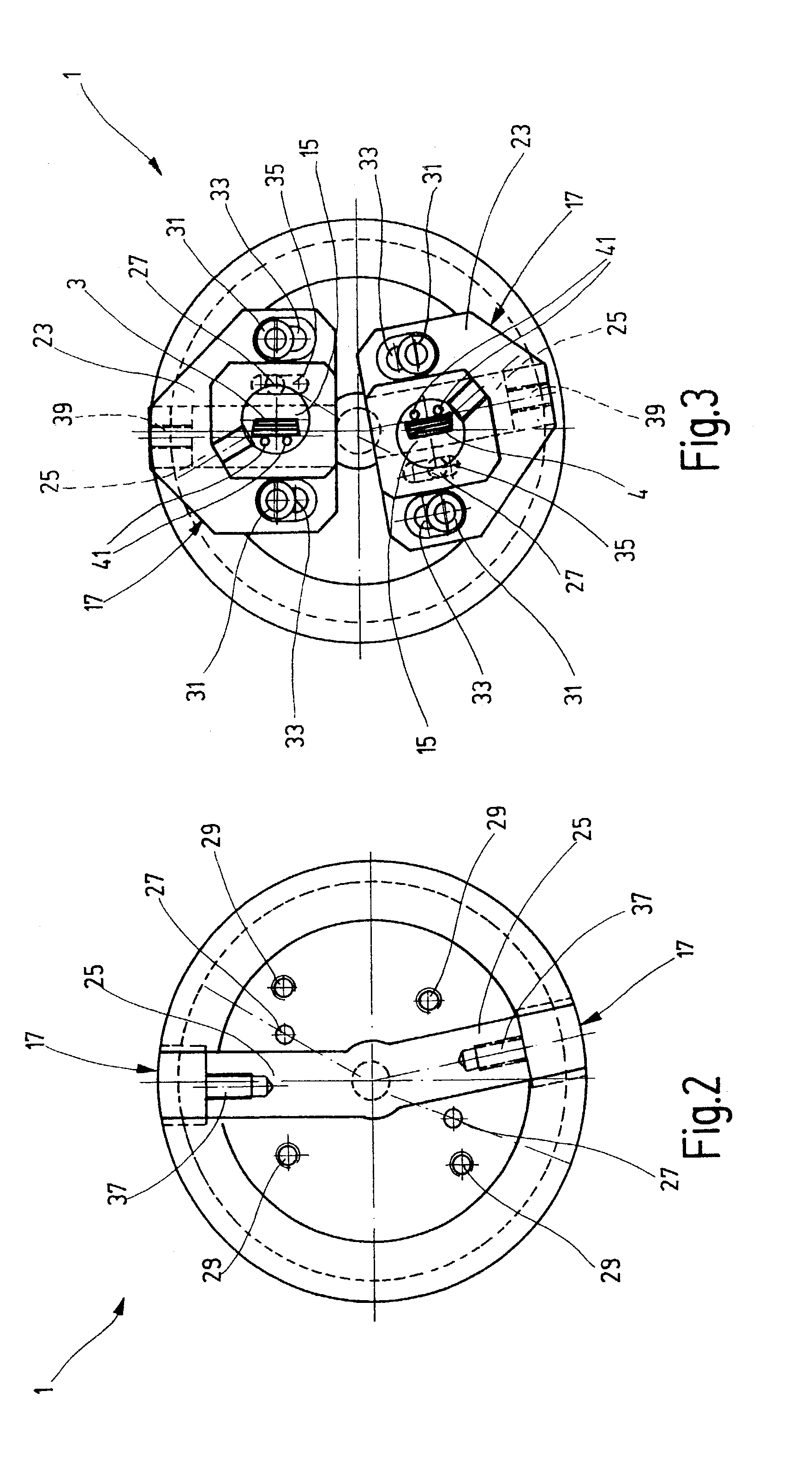

Tool for machining pipe ends

InactiveUS6957936B2Avoid disadvantagesIncrease valueThread cutting toolsTransportation and packagingBlade plateEngineering

A tool for removing material or machining the end of a pipe. The tool having at least one and preferably two blade plates. Each blade plate includes a first cutter for machining an end surface of the pipe, a second cutter adjacent the first cutter for producing an internal chamfer in the pipe end and a third cutter adjacent the first cutter positioned for producing an external chamfer adjoining the end surface of the pipe end. Devices guide and permit movement of the cutters either radially or axially. The shaping of the cutter is disclosed.

Owner:MAPAL FAB FUR PRAZIONSWERKZEUGE DR KRESS KG

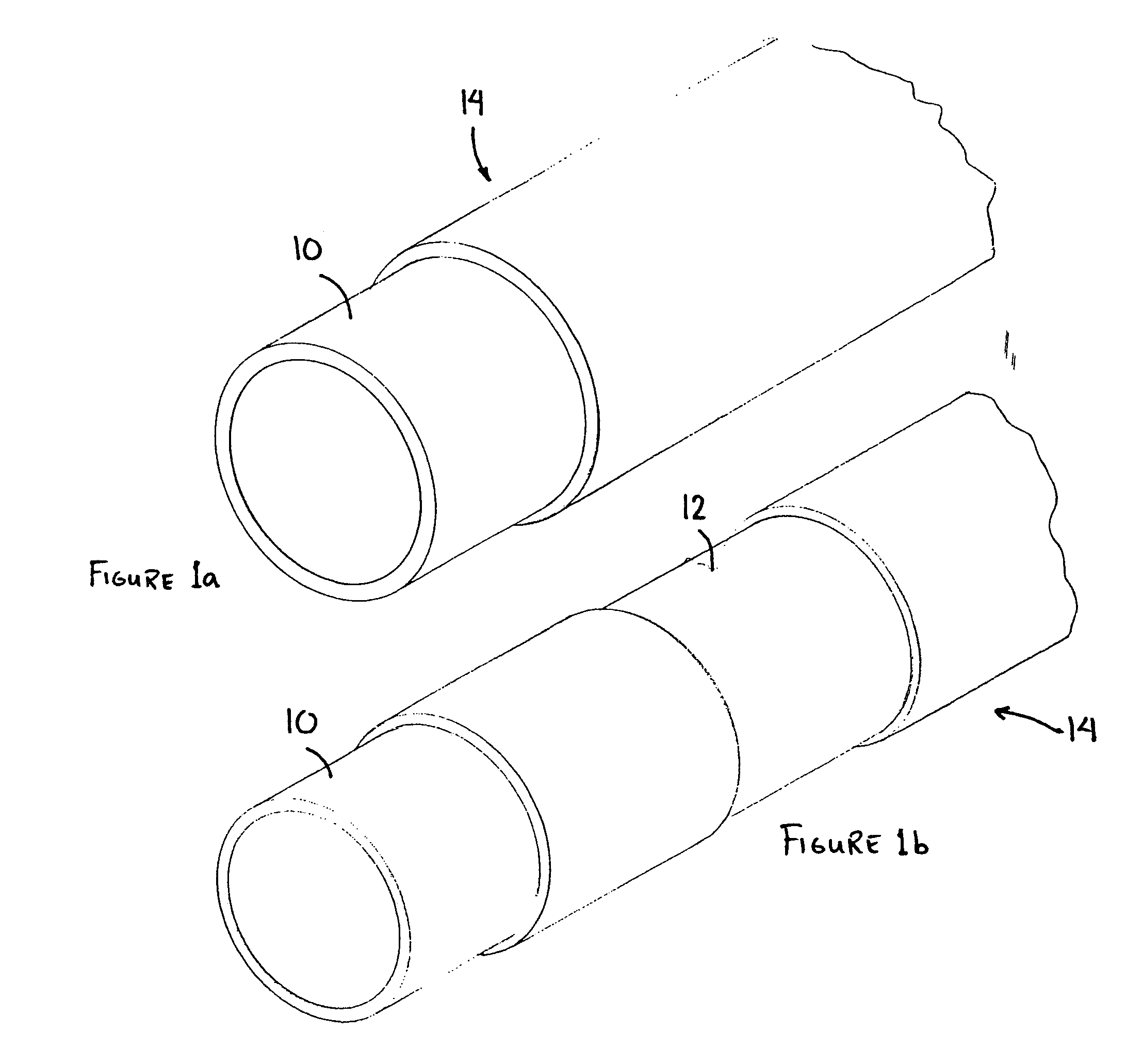

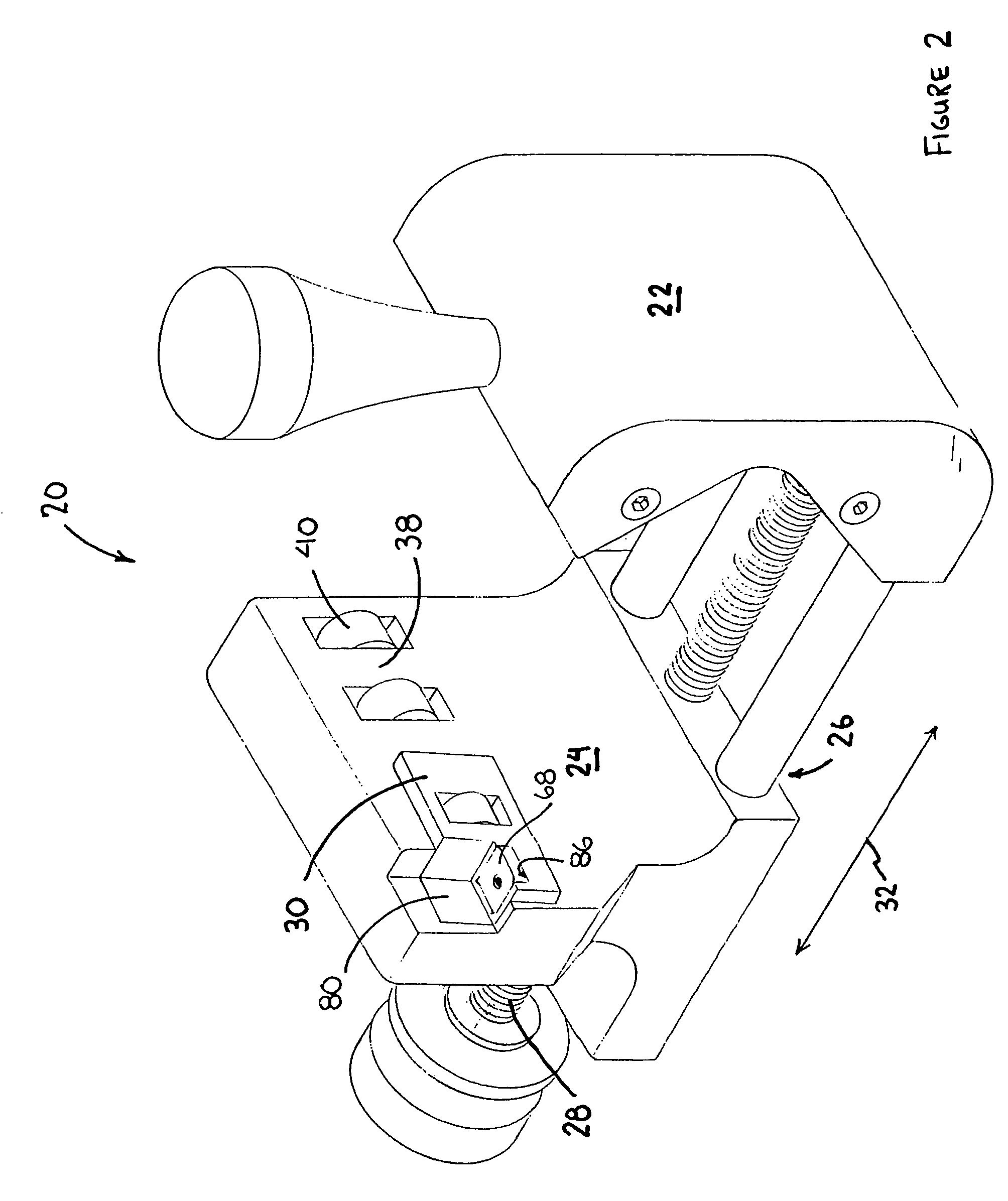

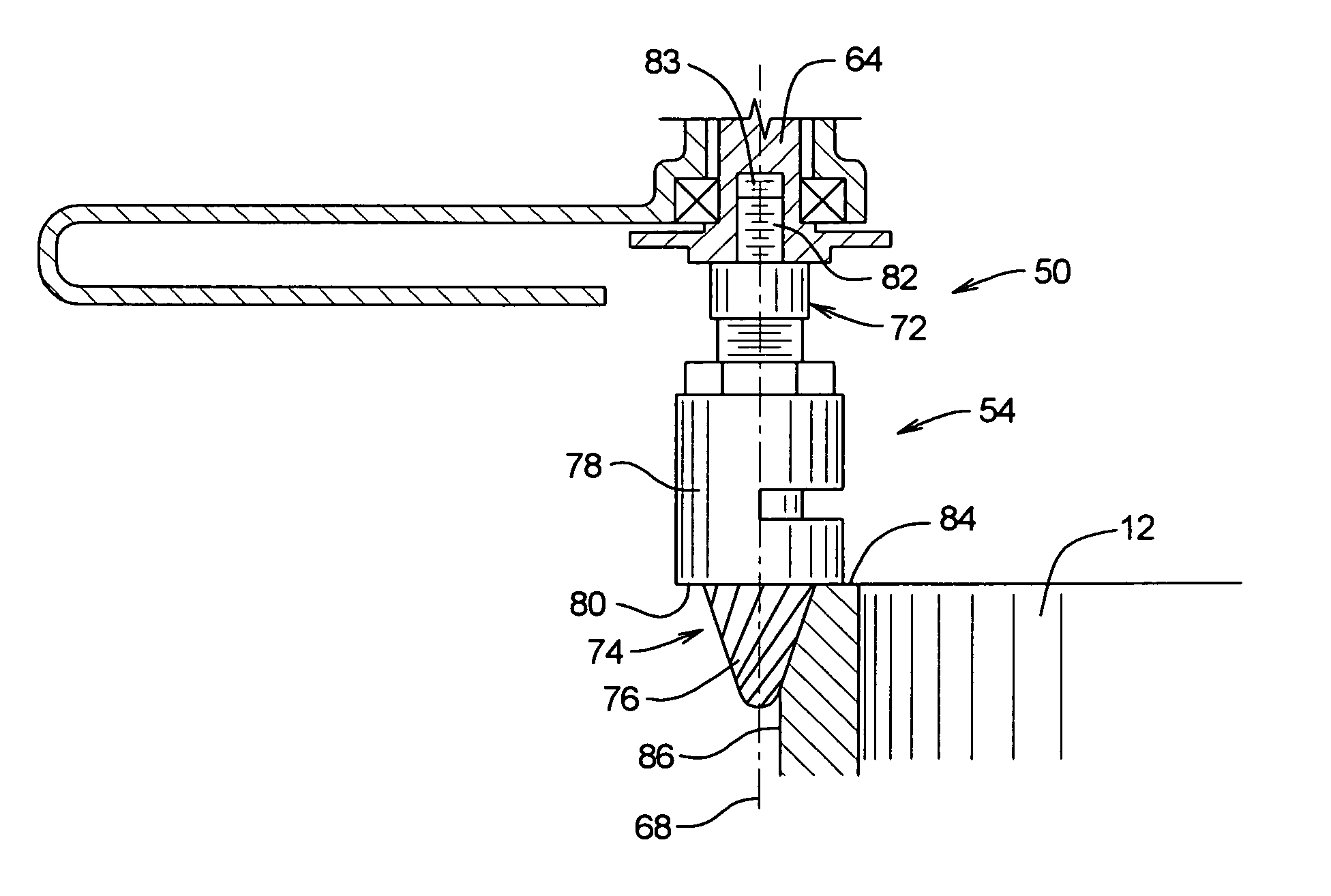

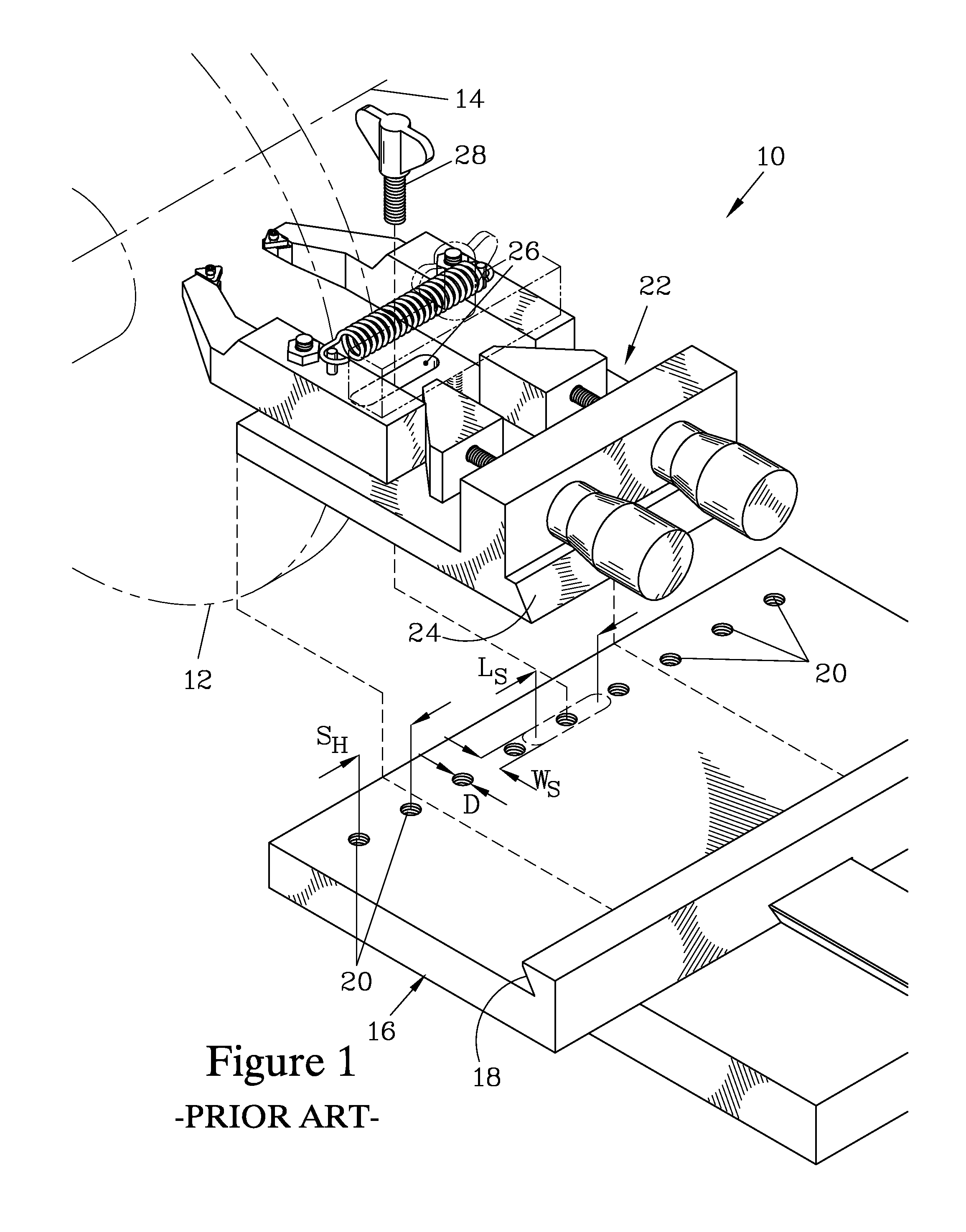

Adjustable pipe shaving device

A pipe shaving device for removing a uniform layer of material from the outer circumference of a pipe is provided. The device comprises a first frame member providing at least two support surfaces for the pipe, a second frame member slidable with respect to the first frame member so as to allow the device to engage and support a pipe, and a cutting platform mounted on the second frame member, the cutting platform providing a cutting blade for removing a uniform thickness of material from the outer diameter of the pipe when the pipe and the device are rotated relative to one another.

Owner:S & D MACHINE & TOOL

Pipe beveling tool and method

InactiveUS7103950B1Edge grinding machinesRevolution surface grinding machinesEngineeringMechanical engineering

A tool assembly which is adapted to perform a cutting operation and also a beveling operation on a pipe. There is a rotary power saw which has rotary drive member to which a saw blade can be mounted. There is a bevel section having a mounting member that connects to the rotary drive member, and a bevel member. There is a locating surface portion around the axis of rotation of the bevel member, and an end lateral locating section and an apex end of the bevel member. The bevel section can be removably connected to the drive member of the power saw.

Owner:SCHEFFER DOUGLAS

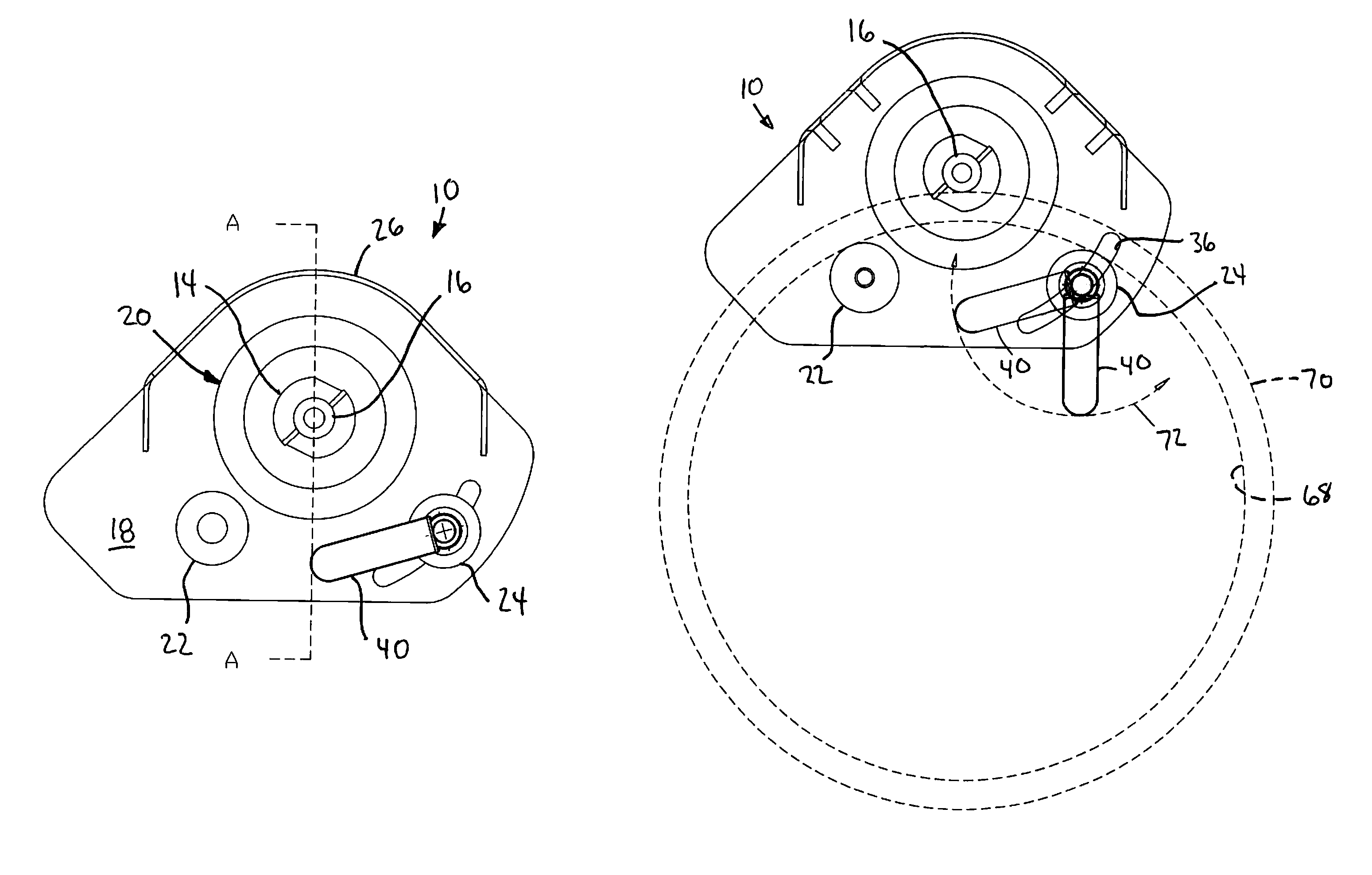

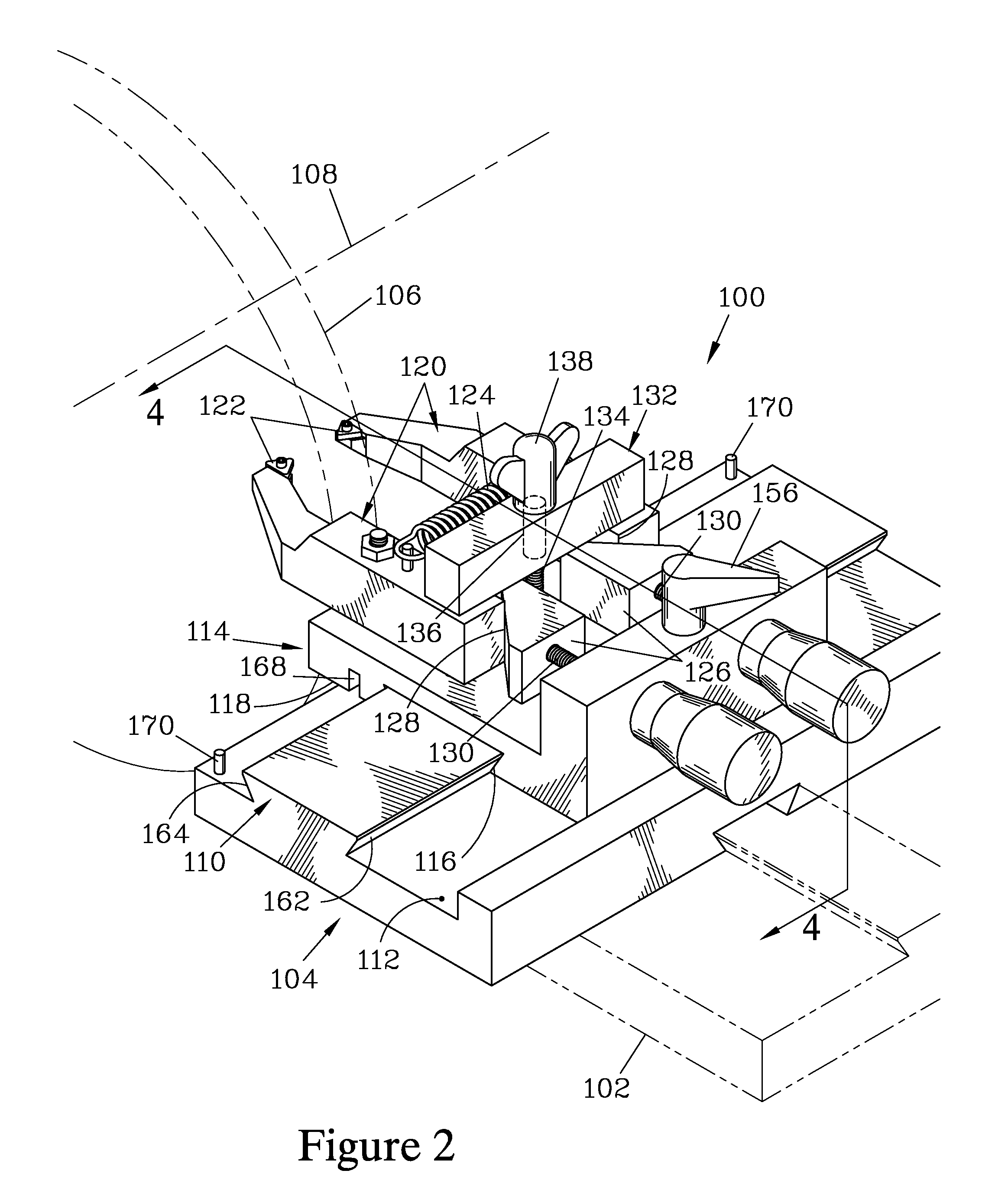

Portable machining apparatus tool module

A tool module for a machining apparatus including a rotatable portion. The tool module includes at least one adjustment clamp supported by the rotatable portion. A module base is supported by the at least one adjustment clamp and defines a linear movement track. A tool slide is configured to support a cutting tool and is movable along the linear movement track. The at least one adjustment clamp is movable from a release position to a locking position and vice versa, and in both the release position and the locking position the at least one adjustment clamp is connected to the rotatable portion. In the release position the at least one adjustment clamp permits the module base to translate relative thereto, and in the locking position the at least one adjustment clamp engages the module base to inhibit the module base from moving relative thereto.

Owner:ACTUANT CORP

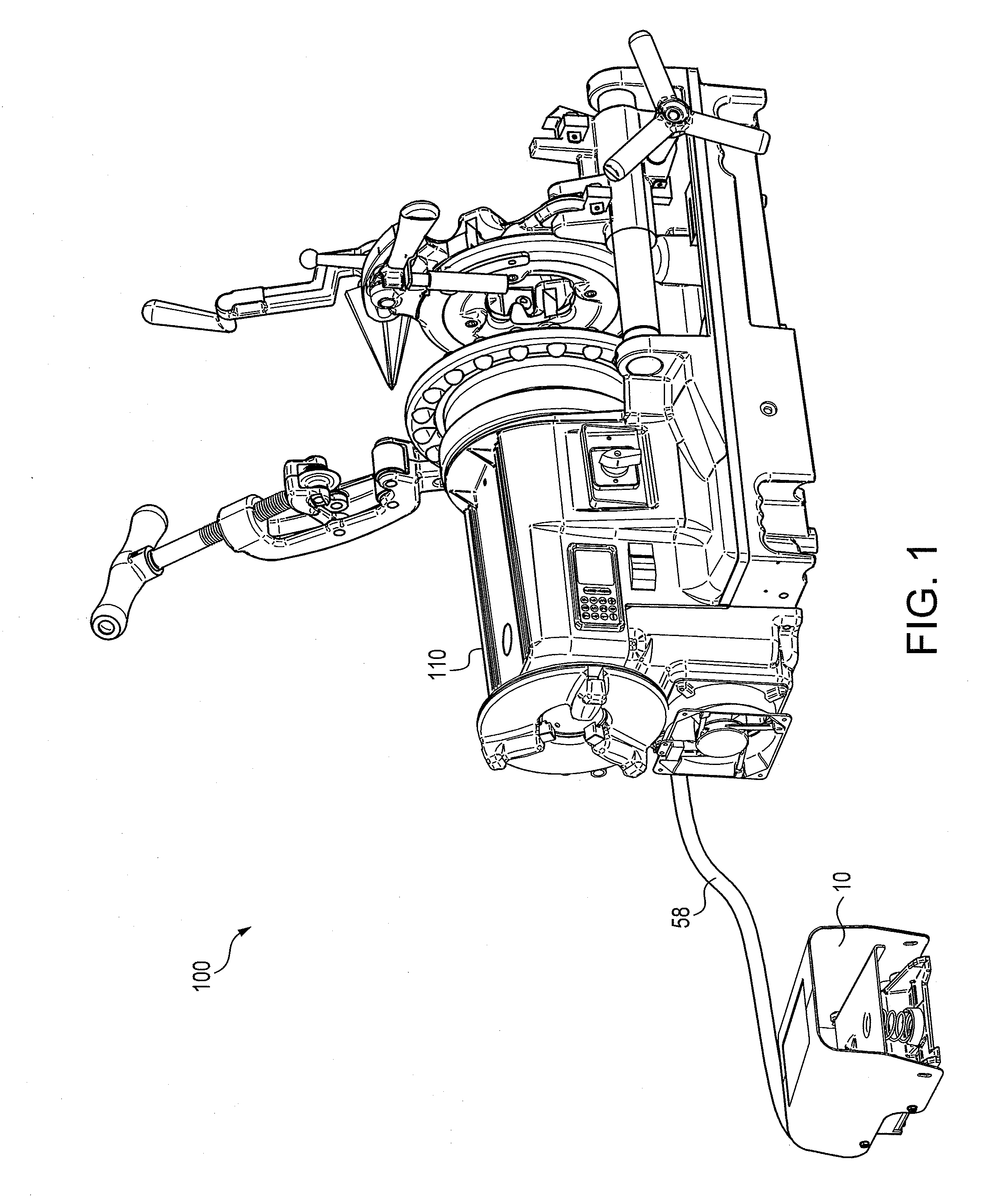

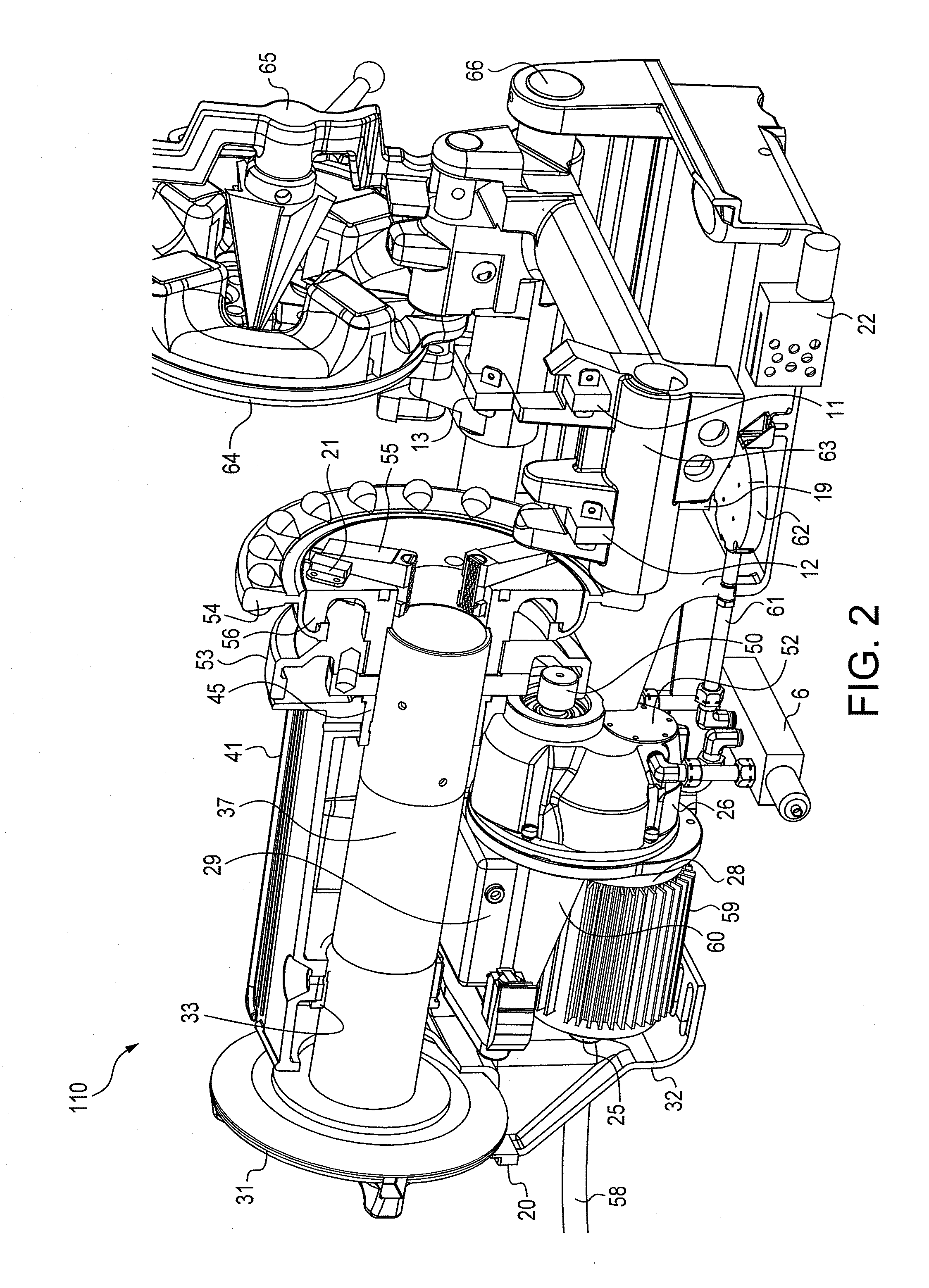

Systems and devices for performing powered threading operations

ActiveUS20120039679A1Turning machine accessoriesThread cutting machinesOperator interfaceBrushless DC electric motor

A device and associated system for threading, cutting, and reaming pipe ends are described. The device and system utilizes a brushless DC electric motor. The devices also include on-board electronics and operator interface(s) to provide sophisticated control and information as to the various operations. Also described are methods of operating the devices and several different modes for performing various operations.

Owner:EMERSON ELECTRIC CO

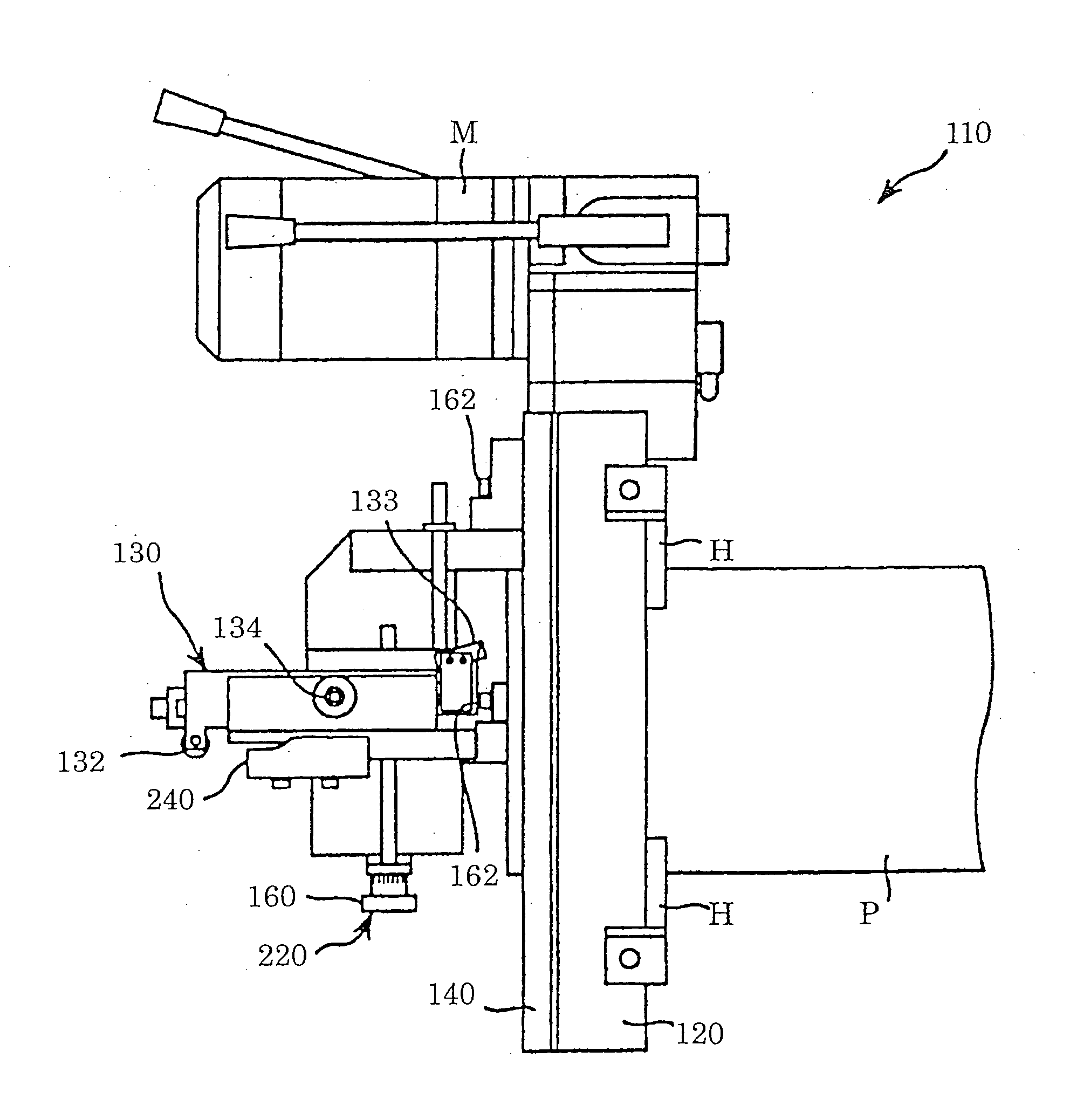

Cutting head assembly for on-vehicle brake lathe

ActiveUS7712401B1Limit motionEasy to separatePortable latheTool holdersTool bitMechanical engineering

A cutting head assembly holds a pair of tool bits for an on-vehicle brake disk lathe having a platform. The cutting head assembly has a platform key fixed to the platform and extending parallel to a brake disk axis of rotation. The cutting head assembly also has a plate having a plate keyway that slidably engages the platform key. Tool bit arms are adjustably mounted to the plate and support the tool bits. A locking structure connected to the plate locks the platform key with respect to the plate keyway, and the interaction of the locking structure with the plate and the platform key creates a compressive load between the plate and the platform as the platform key is locked with respect to the plate keyway.

Owner:BONITA IP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com