Out of round tool bit holder assembly

a technology of round tool bit holder and assembly, which is applied in the direction of turning machine accessories, manufacturing tools, portable lathes, etc., can solve the problems of special challenges for out-of-round work pieces and out-of-round work pieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention represents broadly applicable improvements to a tool slide assembly, which holds a tool bit for use in a clamshell lathe assembly. The embodiments detailed herein are intended to be taken as representative or exemplary of those in which the improvements of the invention may be incorporated and are not intended to be limiting. For purposes of discussion, and without any limitation intended, the tool slide assembly of the present invention will be described in conjunction with a clamshell lathe assembly of known suitable construction. Those skilled in the art will appreciate that the tool slide assembly of the present invention may be utilized with a variety of other available lathes for machining work pieces.

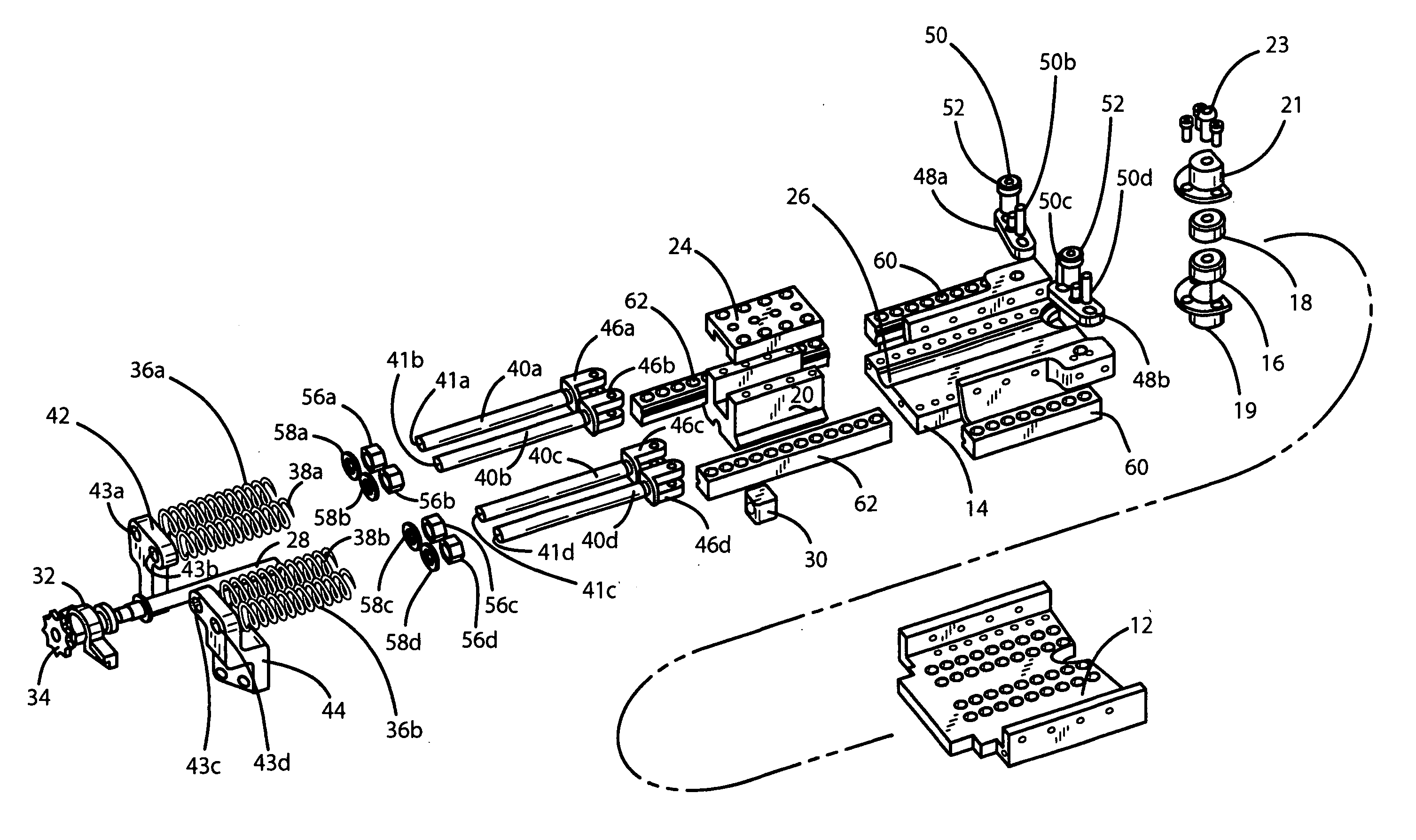

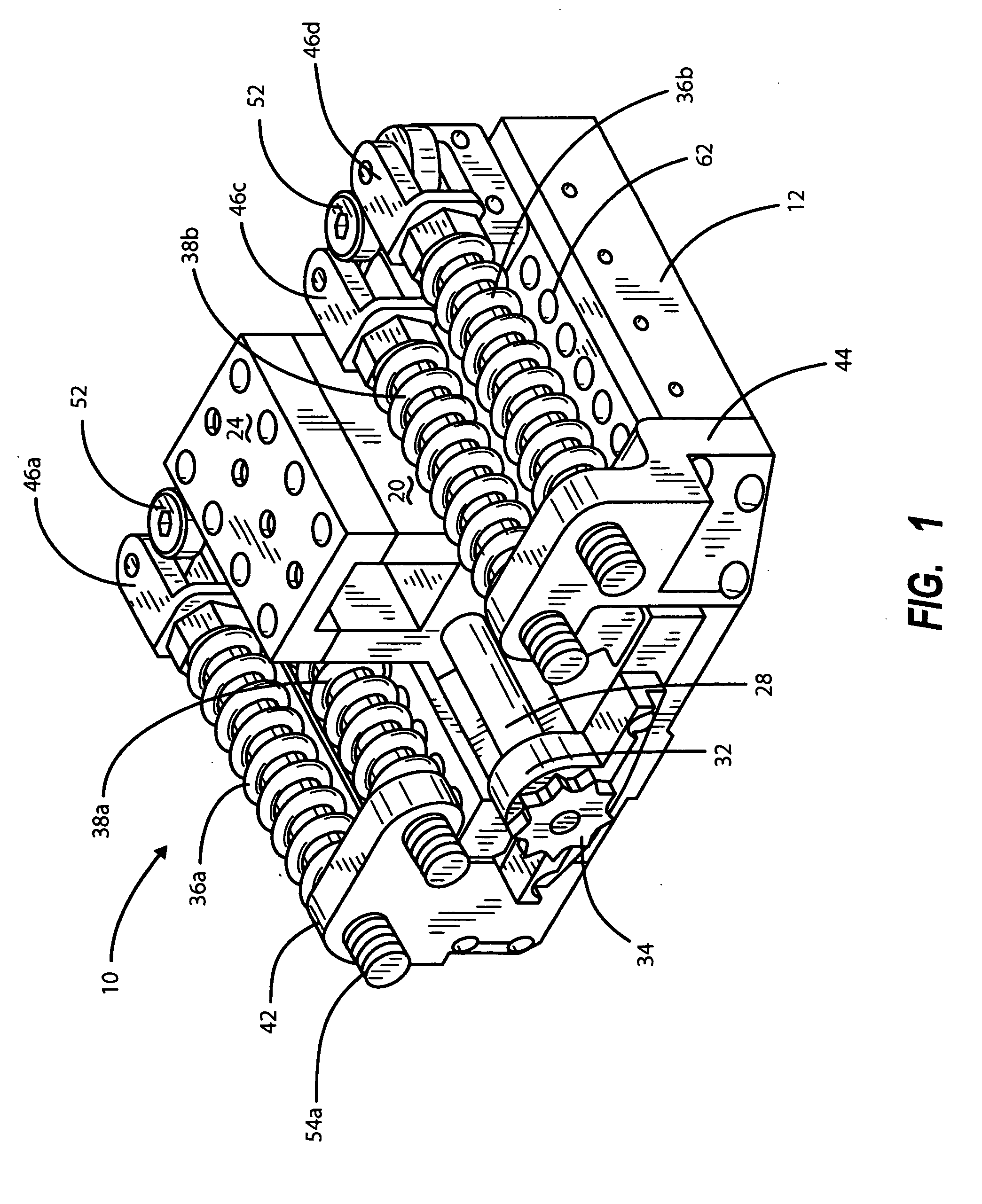

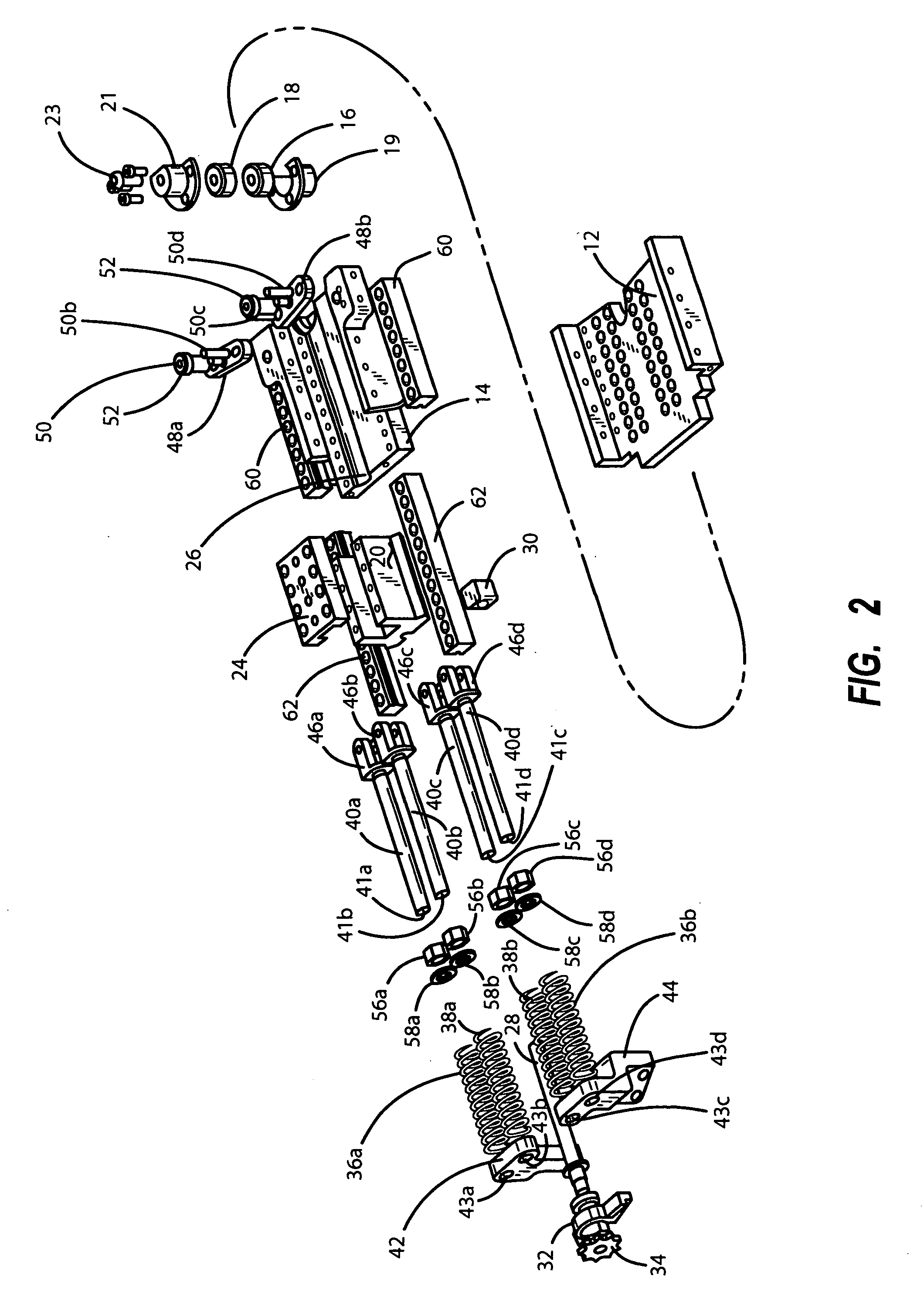

[0014]FIG. 1 shows a perspective view of the slide bit assembly 10. The exploded view in FIG. 2 shows that the tool bit assembly generally comprises a base 12 and a tool bit holder. The tool bit holder comprises a slide plate 14, which includes two r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com