Adaptive design of fixture for thin-walled shell/cylindrical components

A technology for cylindrical parts and fixtures, which is used in the testing of machine/structural parts, measuring/indicating equipment, drilling/drilling equipment, etc., and can solve problems such as no metal sleeve and no explanation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

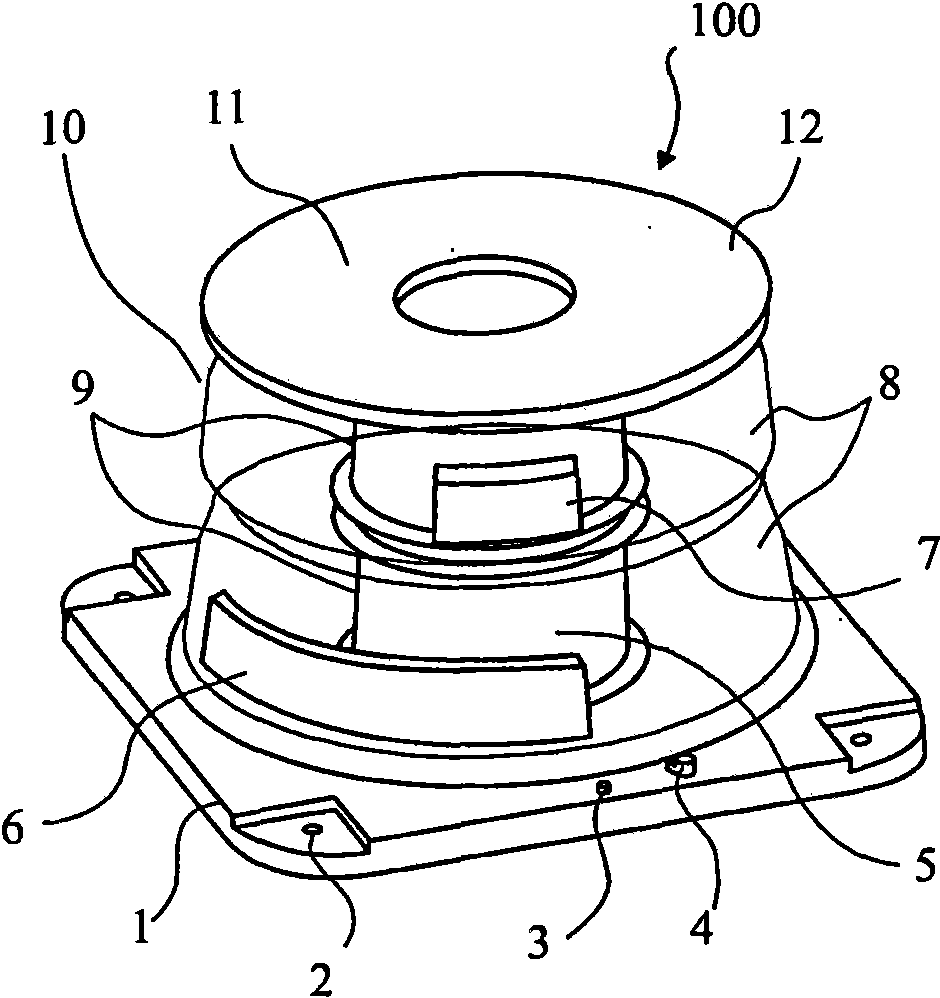

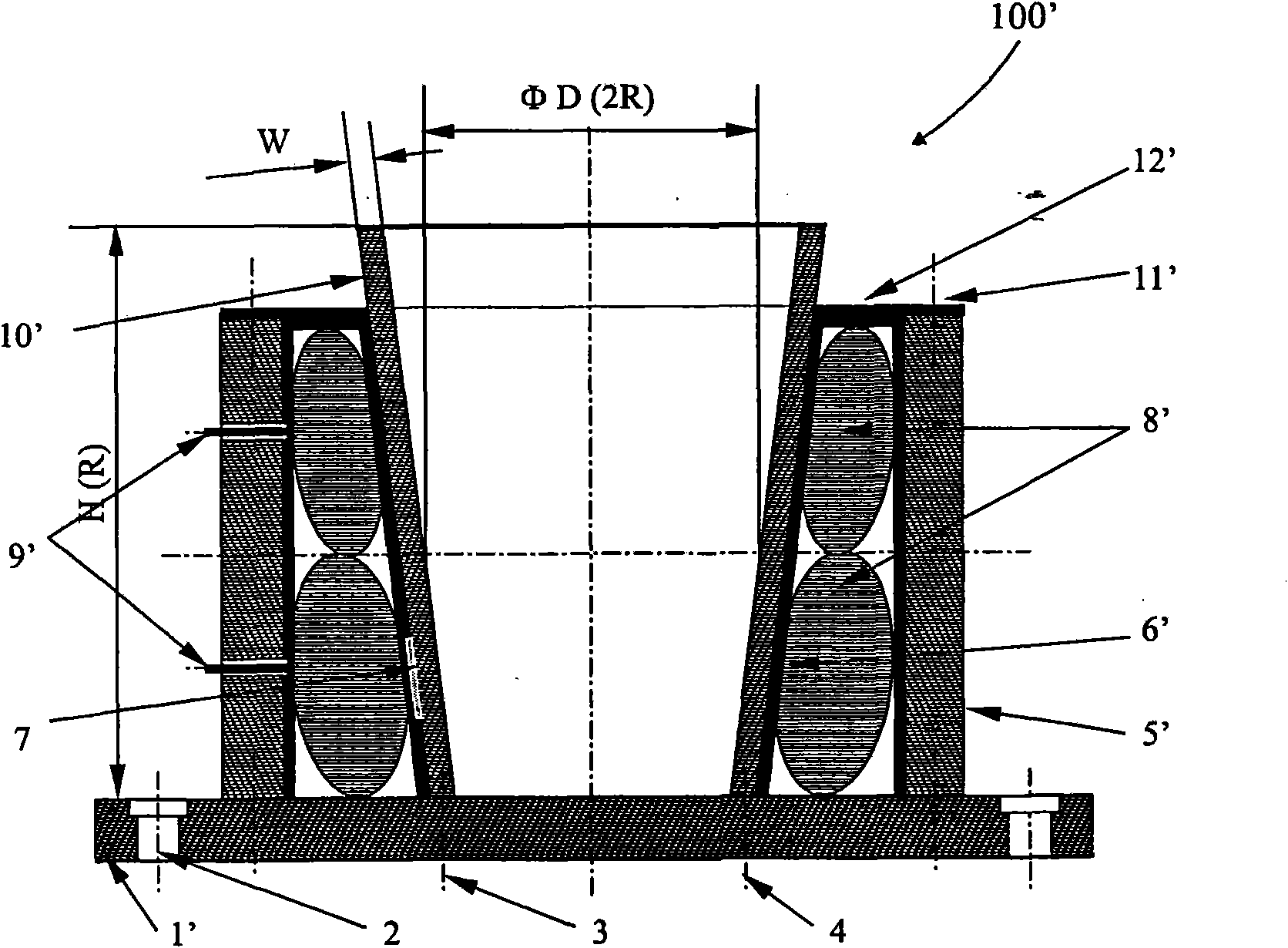

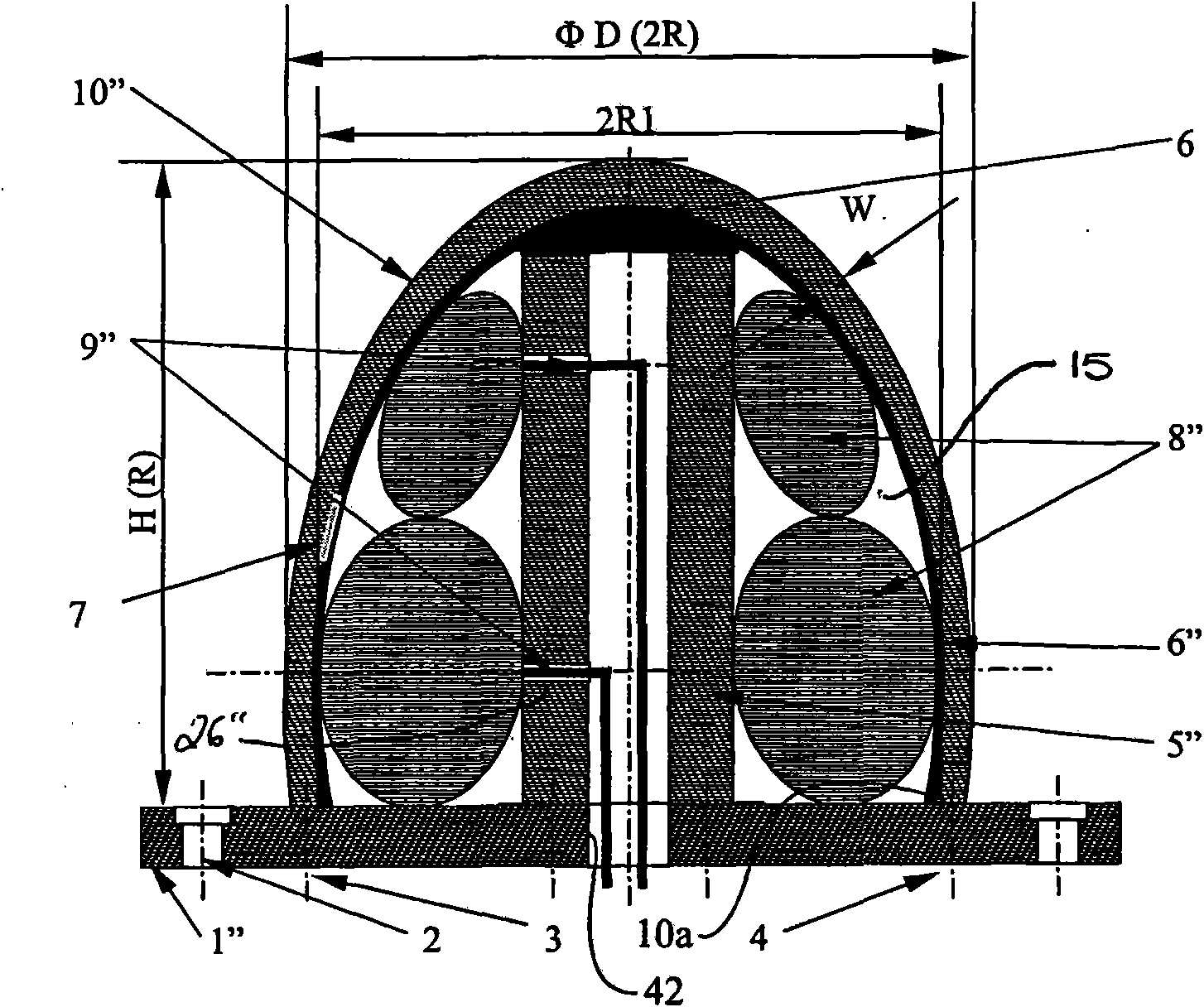

[0045] figure 1 Among them, an internal self-adjusting fixture 100 for internal machining of a thin-walled cylindrical part 10 includes a mounting base 1 in the form of a thick-walled plate having a table ( Not shown) the mounting hole 2 for connection. The positioning pin 3 and the clip 4 position and fix the component 10 on the base 1 .

[0046] The thick-walled rigid mandrel and column 5 are fixed at the center of the base 1 by bolts (not shown). The end of the mandrel 5 is a flange connected with the thick-walled cover 12 . Mounted on the arbor are two modified wheel inner tubes 8 having an inner radius R corresponding to the radius of the arbor 5 . The inner tube 8 is made of synthetic rubber (elastomeric material), which can be inflated to fit the contents confined in the cylindrical part 10 , the supporting mandrel 5 , the mounting base 1 and the cover 12 . Each inner tube 8 has its own inlet valve 9 on its inner surface and is mounted through a corresponding eyele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com