Jig for holding thin cylindrical work, method for processing thin cylindrical work, and sheet film forming roll

A thin-walled cylinder and holding fixture technology, applied in workpiece clamping devices, workpieces, manufacturing tools, etc., can solve problems such as difficulty in maintaining machining accuracy, deformation of elastic parts, and inability to meet machining expectations, and achieve the effect of improving cylindricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

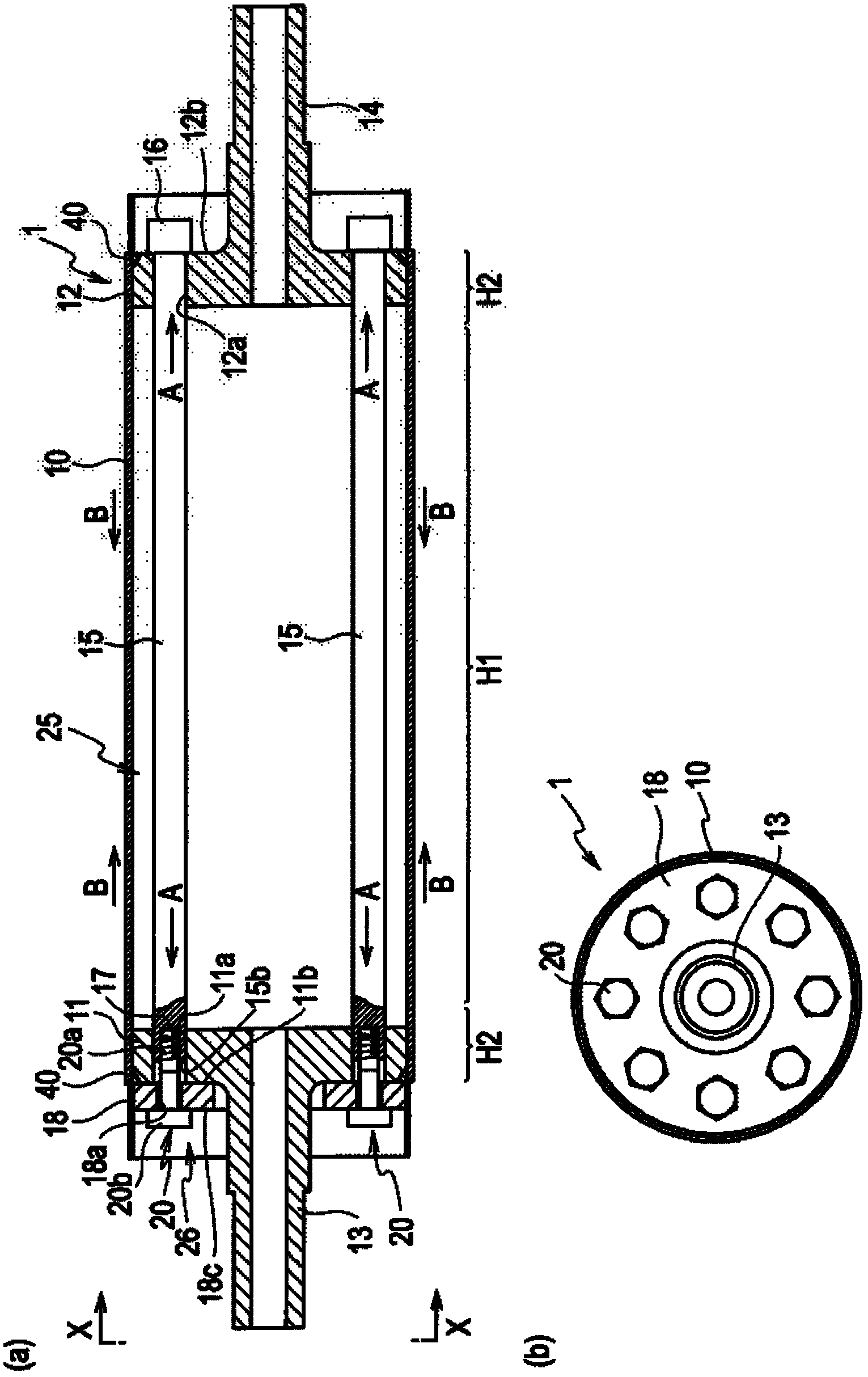

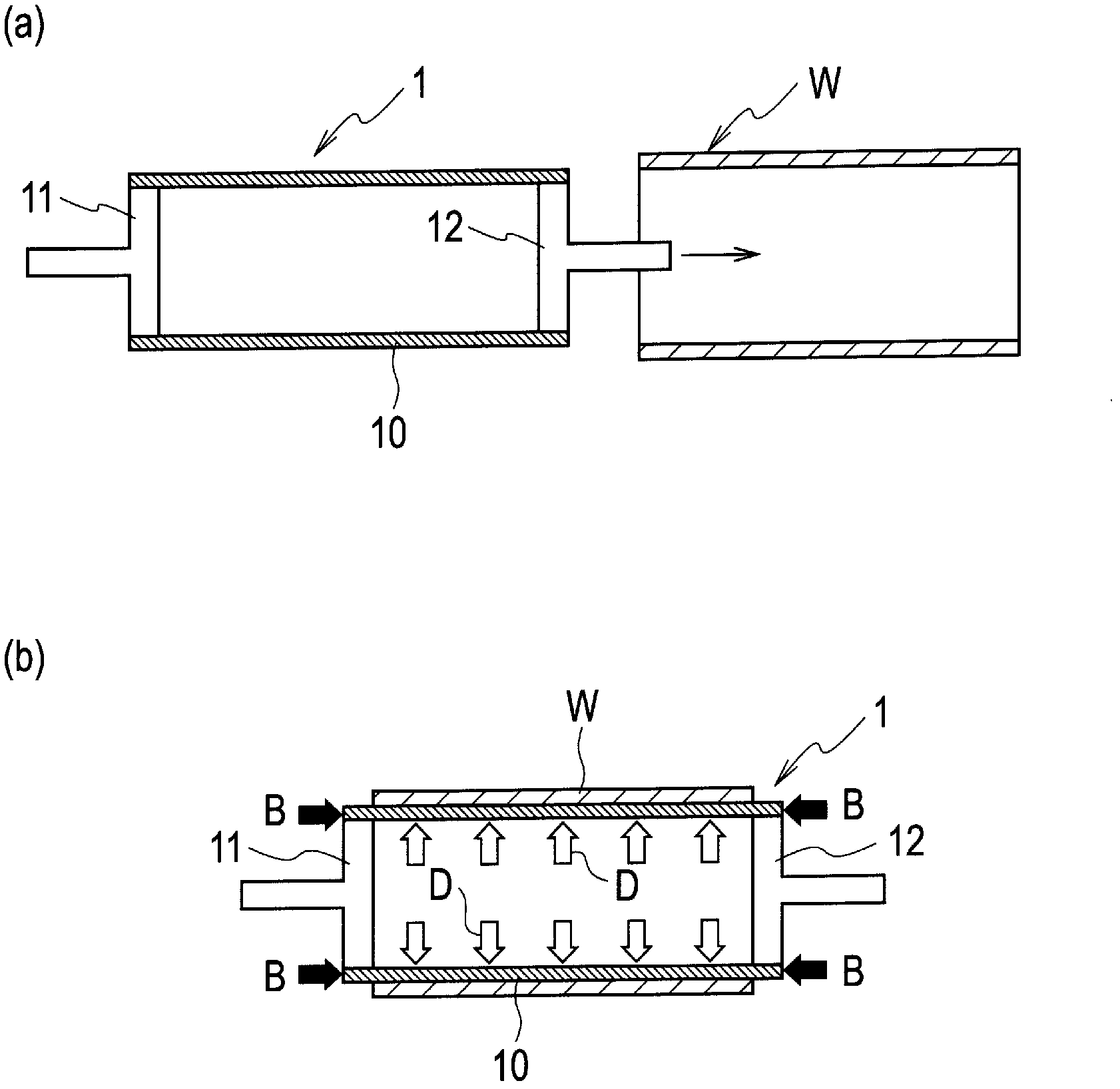

[0047] figure 1 The holding jig 1 shown in (a) and (b) is used for thin-walled cylindrical workpiece W (refer to figure 2 ) is mainly inserted into the inner circumference of the workpiece W when the outer peripheral surface is machined, and the workpiece W is held from the inner peripheral side.

[0048] The workpiece W assumed here is, for example, a sleeve (metal outer cylinder) for forming rolls such as plastic films, and is processed so that the thickness (wall thickness) of the surrounding wall is 2mm or less (more precisely, less than 2mm), and the cylindricity Workpieces of products whose maximum roughness Rmax of the outer peripheral surface is below 50 μm and below 1 μm. The form of use is to use the workpiece W as an outer cylinder, arrange an inner cylinder member coaxially on the inner peripheral side, and ensure a space for the heat medium to flow between the inner cylinder member and the outer cylinder. A forming roll with a double cylinder structure, as requi...

no. 2 approach

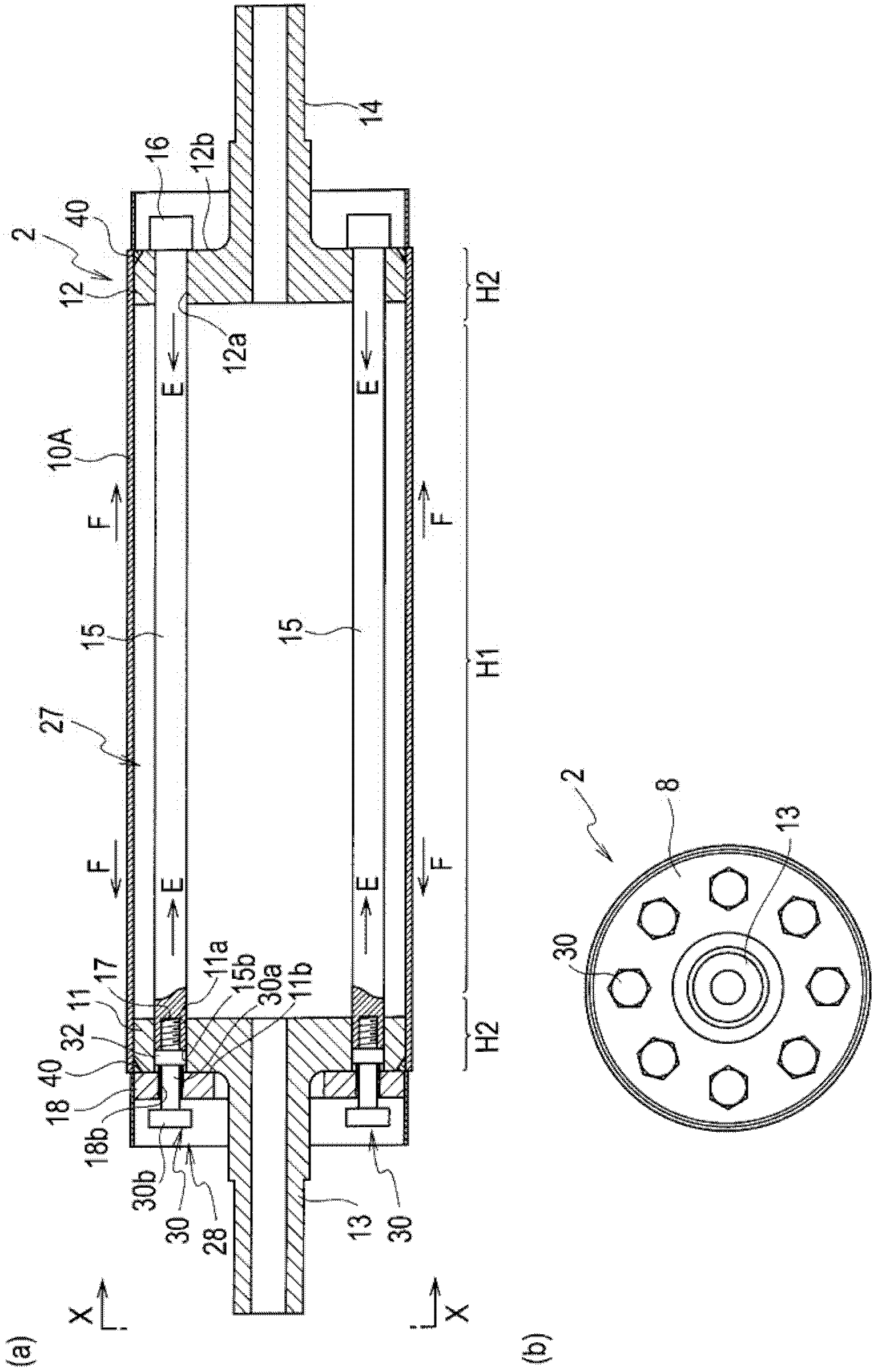

[0064] image 3 The holding jig 2 according to the second embodiment shown in (a) and (b) is also the same as the first embodiment, and is used for thin-walled cylindrical workpiece W (refer to Figure 4 ) is mainly a holding jig 2 that is inserted into the inner periphery of the workpiece W and holds the workpiece W from the inner peripheral side when the outer peripheral surface is machined.

[0065] The holding jig 2 includes a hollow cylindrical metal cylindrical holding member 10A (holding member) whose diameter can be slightly elastically expanded and contracted, and whose wall thickness is set thin. There are shaft portions 13, 14 concentric with the metal cylinder holding member 10A, and a pair of left and right circular side plates 11, 12 that fasten the outer peripheries to both axial ends of the metal cylinder holding member 10A , is disposed between these pair of side plates 11, 12, and the metal cylinder is made A diameter reduction mechanism (diameter changing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com