Self-centering clamp for thin-walled part

A technology for self-centering fixtures and thin-walled parts, which is applied in the direction of metal processing machinery parts, clamping, and workpieces. It can solve problems such as clamping and processing deformation of thin-walled parts, and achieve improved processing accuracy, small deformation, and easy loading and unloading. The effect of machining parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

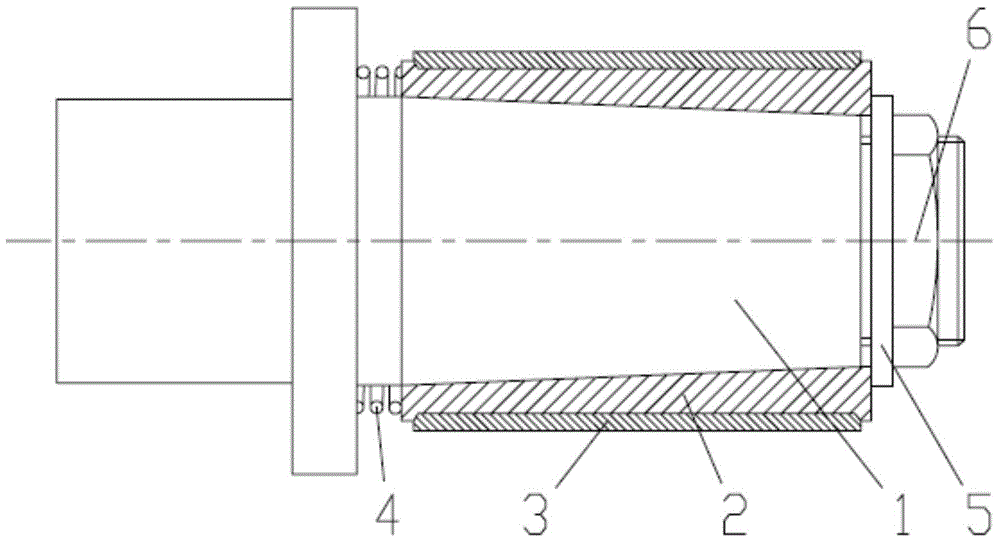

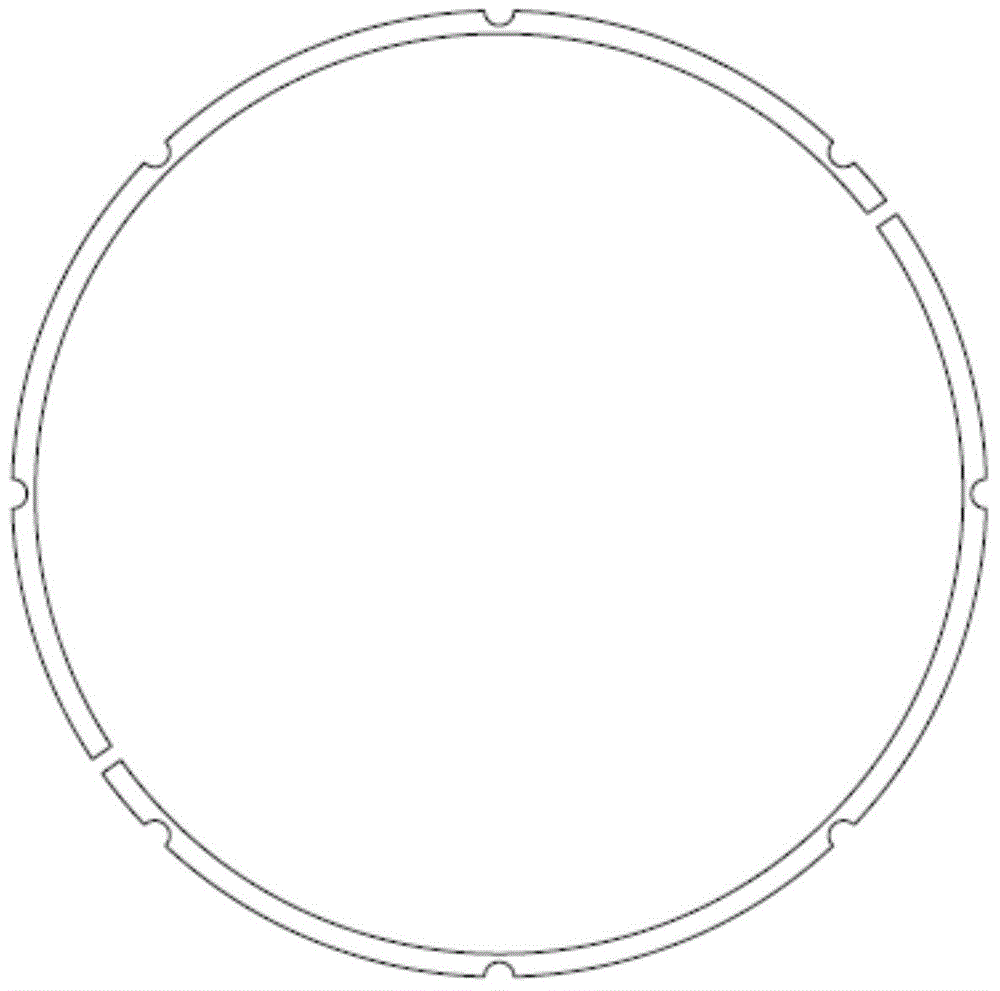

[0012] Such as figure 1 , Shown in 4, a self-centering fixture for thin-walled parts, including a mandrel 1, expansion sleeve 2, flexible positioning sleeve 3, spring 4, retaining ring 5, adjustment nut 6.

[0013] The mandrel 1 is in the shape of a cone, the inner wall of the expansion sleeve 2 is a conical surface matching the outer wall of the mandrel, and the outer wall is a cylindrical surface, and the expansion sleeve 2 is matched with the cone of the mandrel 1 through the conical surface of the inner wall. The front end of the sleeve 2 is connected to the stepped end face of the rear end of the mandrel 1 through the spring 4, the rear end of the expansion sleeve 2 is in contact with the adjusting nut 6 screwed on the threaded end of the mandrel through the stop ring 5, and the expansion sleeve 2 is externally connected with a flexible positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com