Lignite-drying and quality-improving process for preparing superheated steam from waste heat steam

A superheated steam and hot steam technology, applied in the direction of steam superheating, heating to dry solid materials, steam generation, etc., can solve the problems of hidden danger of fire or explosion, uneconomical heat source, etc. Effects of explosion hazard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

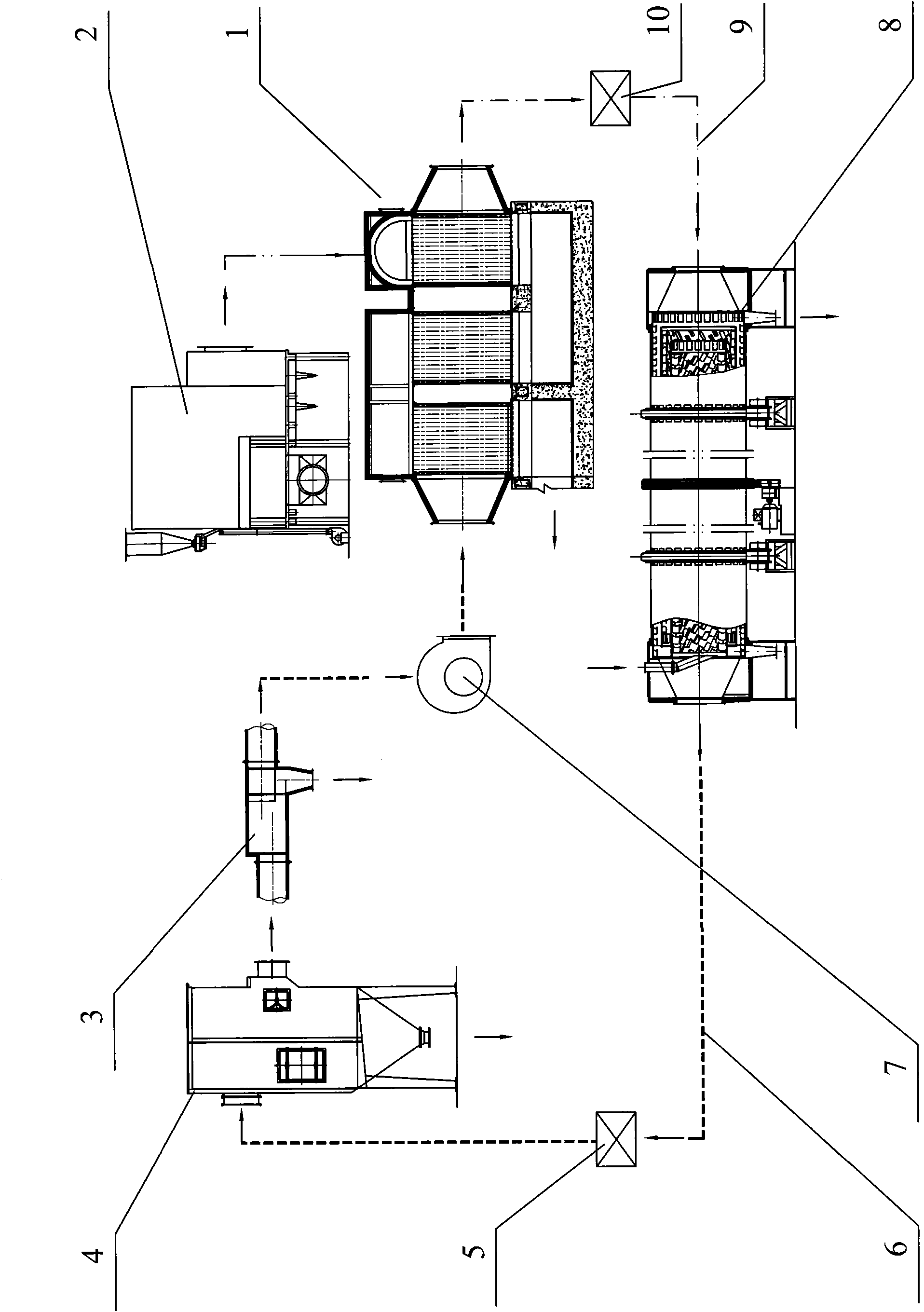

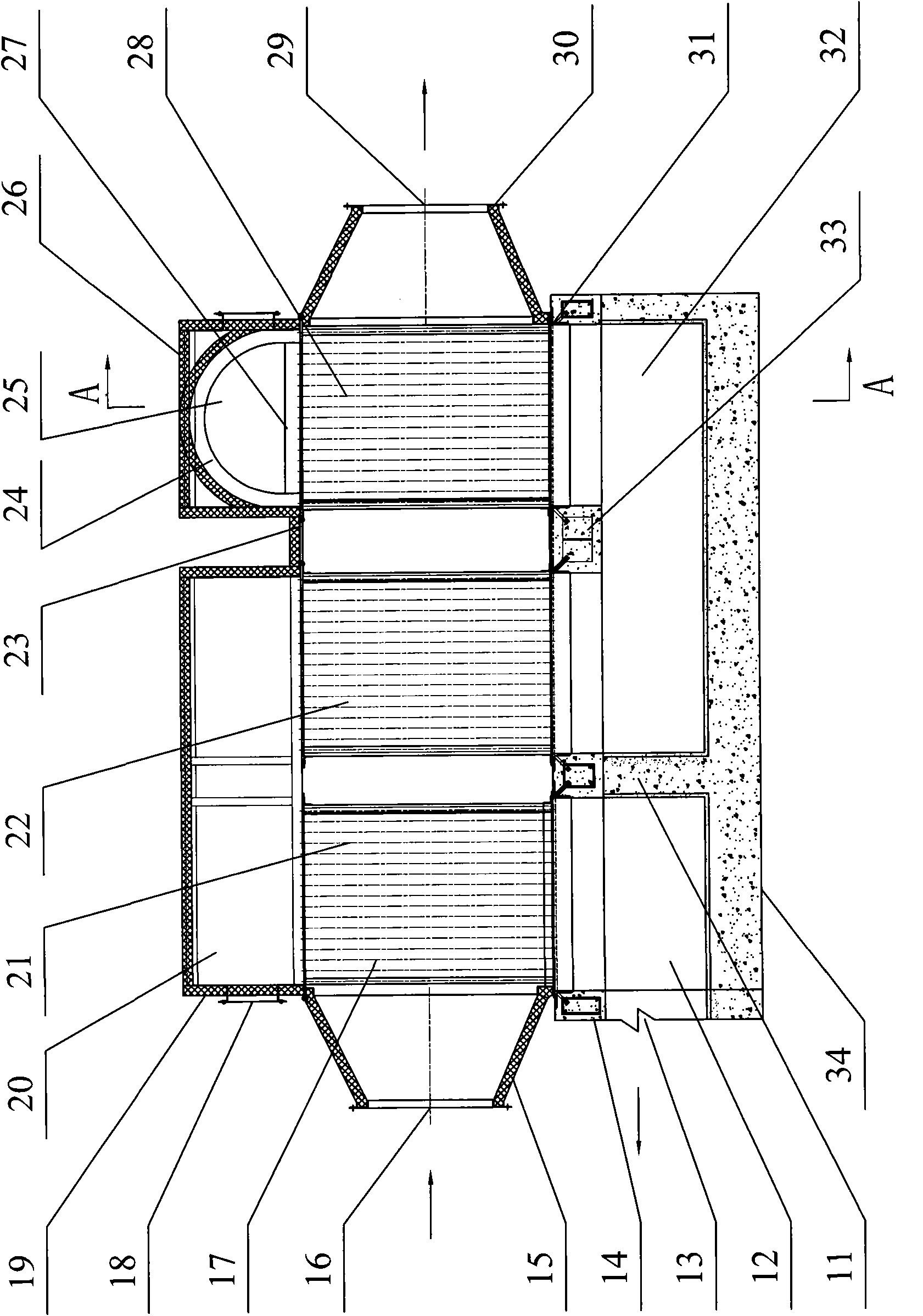

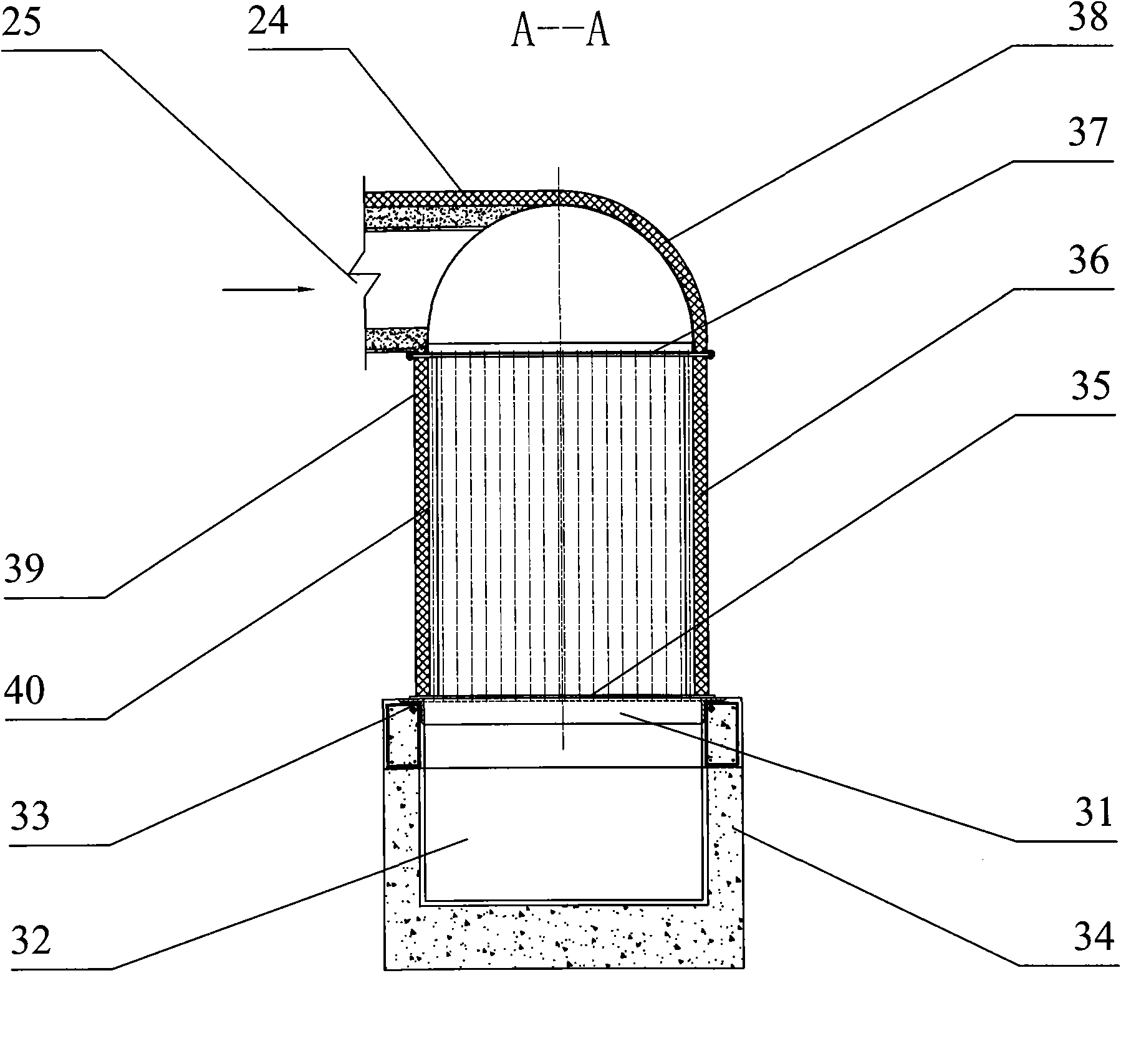

[0034] according to Figure 1-8The specific process steps of the present invention are described in detail. In order to achieve the ideal drying and upgrading effect, the lignite drying and upgrading process using waste heat gas to prepare superheated steam adopts a thermal energy device that provides heat exchange medium and uses waste heat gas to prepare superheated steam according to actual use requirements and may be specially designed 1 And the energy-saving cylinder type lignite drying and upgrading device improved on the structure basis of the "double return drum dryer" with the notification number CN100573003C and the "three return drum dryer" with the notification number CN100570253C originally designed by the inventor 8. Therefore, it can ensure that the process design of the present invention is reasonable, and the route is simple and smooth. Of course, other thermal energy devices and drying devices with similar functions can also be used to replace the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com