Production method and routing method of routing art work sheet

A technology of process drawings and production methods, applied in the direction of manufacturing wiring harnesses, circuit layout on support structures, etc., can solve problems such as irregularities, non-uniform wiring harnesses, product quality and production efficiency effects, etc., to ensure product quality and improve production efficiency. , the effect of facilitating work guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

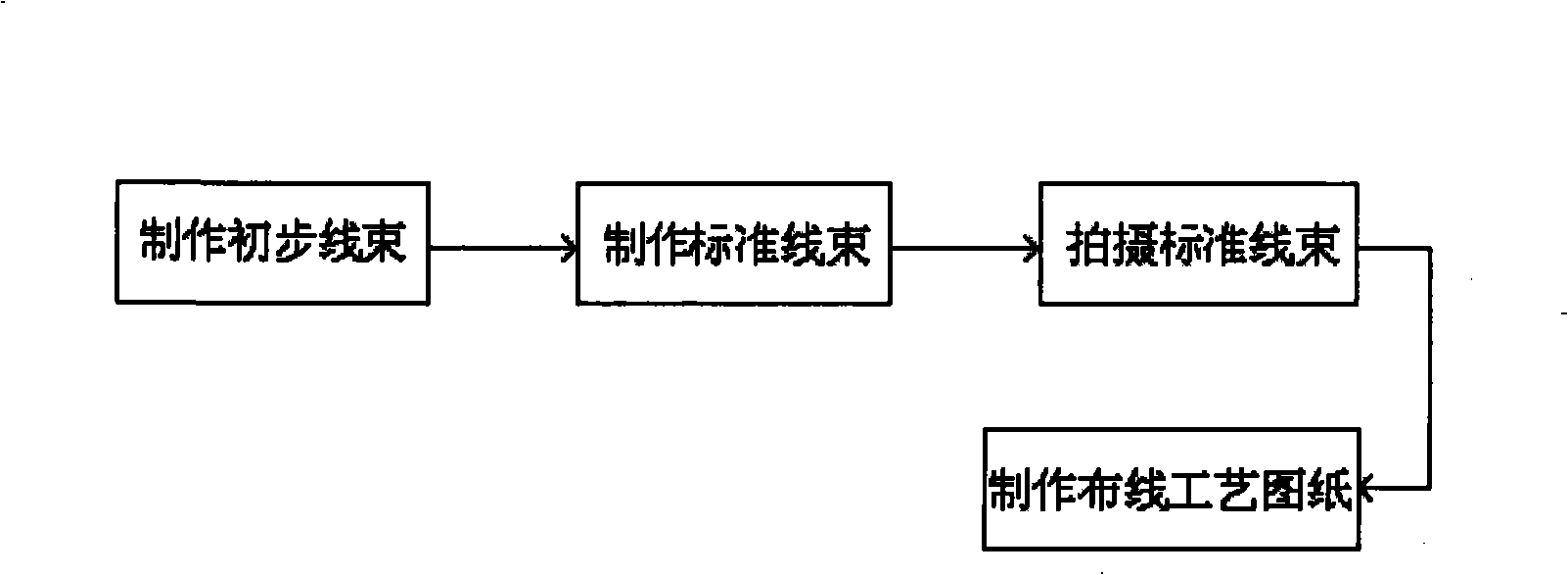

[0026] For the production process of wiring process drawings, see figure 1 , including the following steps:

[0027] There are about 120 wires connected to the existing wiring product,

[0028] The first step is to make a preliminary wiring harness: make a rough wiring harness for the wires of the product to become a preliminary wiring harness. During production, a rough wiring harness production process table can be drawn up based on the actual product, and then the preliminary wiring harness production can be carried out according to the process table;

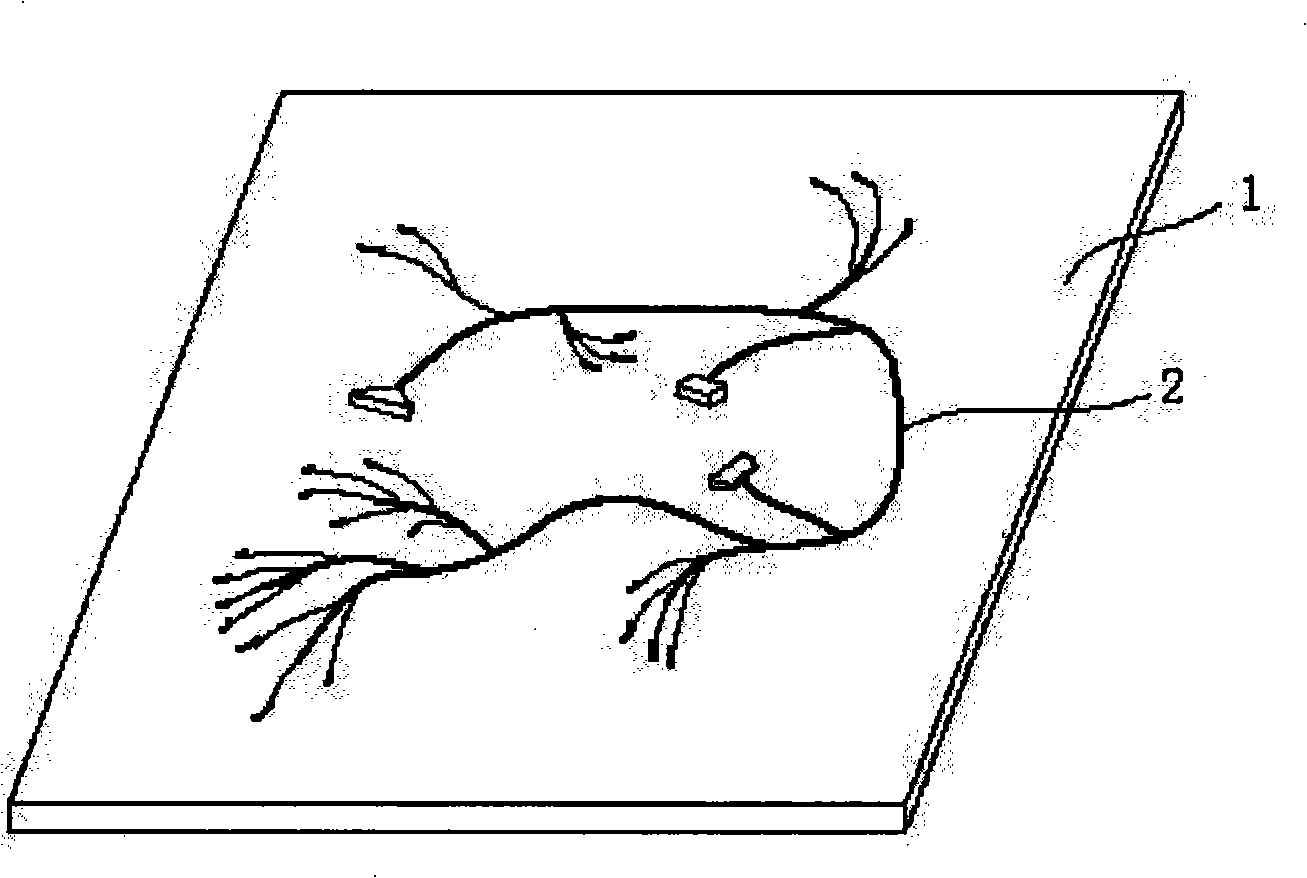

[0029] The second step is to make a standard harness: see image 3 , carry out standard wiring in the product 1 according to the process requirements to form the standard wire harness 2. Since the standard wire harness 2 will be a sample for taking photos, the forming, binding, and fixing of the wire harness must meet various process requirements. ;

[0030] The third step is to shoot the standard harness: see Figure 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com