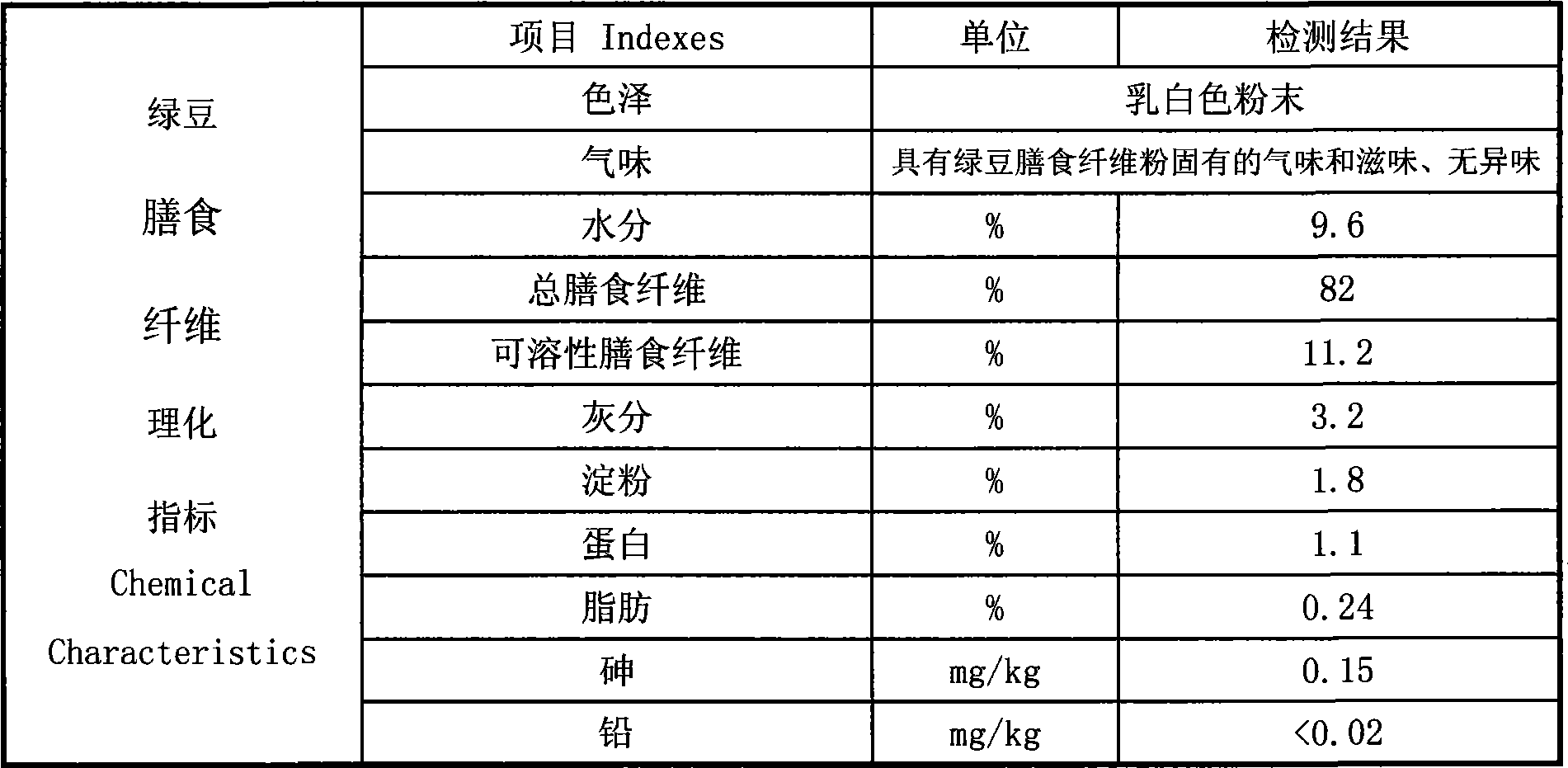

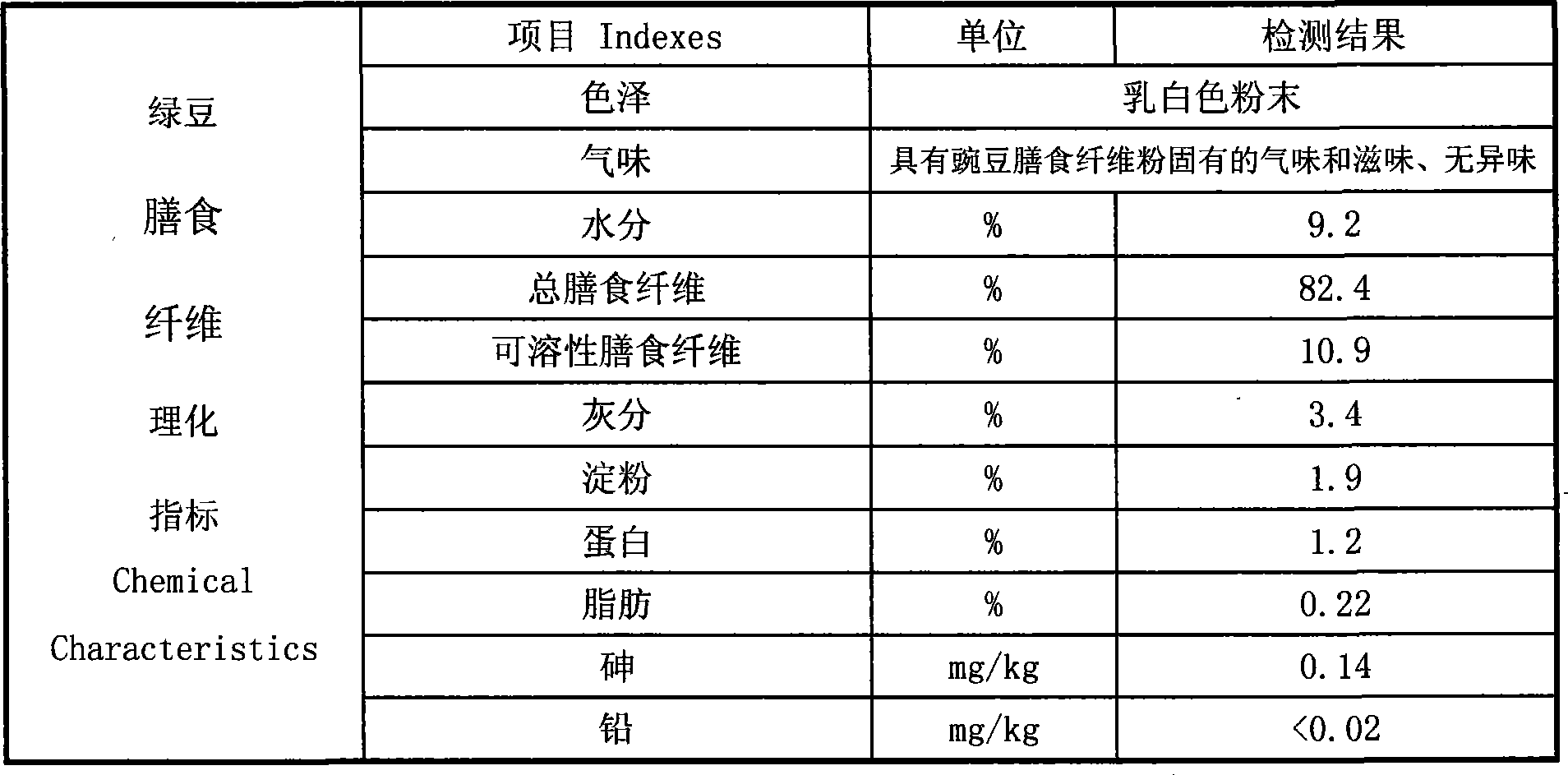

Mung bean or pea dietary fiber and method for producing the same

A dietary fiber and production method technology, applied in the field of dietary fiber and its production, can solve the problems of food quality influence, rough taste, poor appearance, etc., and achieve the effects of improving food color and flavor, delicate taste, and short material residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a kind of production method of mung bean or pea dietary fiber, weigh 100kg of bean dregs after processing mung bean or pea starch, send it to a separator for separation, and remove the non-dietary fiber part; then the separated dietary fiber is transported to the plate frame The filter press removes part of the water; adjust the flash drying temperature to 145°C, and then transport the dietary fiber to the flash dryer for drying; the dried dietary fiber enters the microwave sterilization equipment for processing; the microwave sterilization temperature is controlled at 80°C, and the time 3 minutes; adjust the fineness of the sieve of the superfine pulverizer to be 200 mesh, then input the dietary fiber into the superfine pulverizer for final treatment, and obtain the finished dietary fiber product.

Embodiment 2

[0026] Embodiment 2, a kind of mung bean or pea dietary fiber production method, weigh 100kg of bean dregs after processing mung bean or pea starch, send it to the separator for separation, remove the non-dietary fiber part; then transport the separated dietary fiber to the plate frame The filter press removes part of the water; adjust the flash drying temperature to 165°C, and then transport the dietary fiber to the flash dryer for drying; the dried dietary fiber enters the microwave sterilization equipment for processing; the temperature is controlled at 85°C for 5 minutes Adjust the fineness of the sieve of the superfine pulverizer to be 400 meshes, and then input the dietary fiber into the superfine pulverizer for final treatment to obtain the finished dietary fiber product.

Embodiment 3

[0027] Embodiment 3, a kind of mung bean or pea dietary fiber production method, weigh 100kg of bean dregs after processing mung bean or pea starch, send it to the separator for separation, remove the non-dietary fiber part; then transport the separated dietary fiber to the plate frame The filter press removes part of the water; adjust the flash drying temperature to 185°C, and then transport the dietary fiber to the flash dryer for drying; the dried dietary fiber enters the microwave sterilization equipment for processing; the temperature is controlled at 90°C for 6 minutes ; adjust the fineness of the sieve of the superfine pulverizer to be 800 meshes, then input the dietary fiber into the superfine pulverizer for final treatment, and obtain the finished dietary fiber product.

[0028] In the above embodiments, "deep processing" is carried out on the bean dregs produced by starch processing, and the existing coarse crushing processing and extraction method is changed, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com