Sweet potato dreg type fermented feed and production method thereof

A technology of fermented feed and sweet potato dregs, applied in animal feed, animal feed, application, etc., can solve problems such as processing difficulties, achieve the effects of reducing costs, improving various indicators, and increasing value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

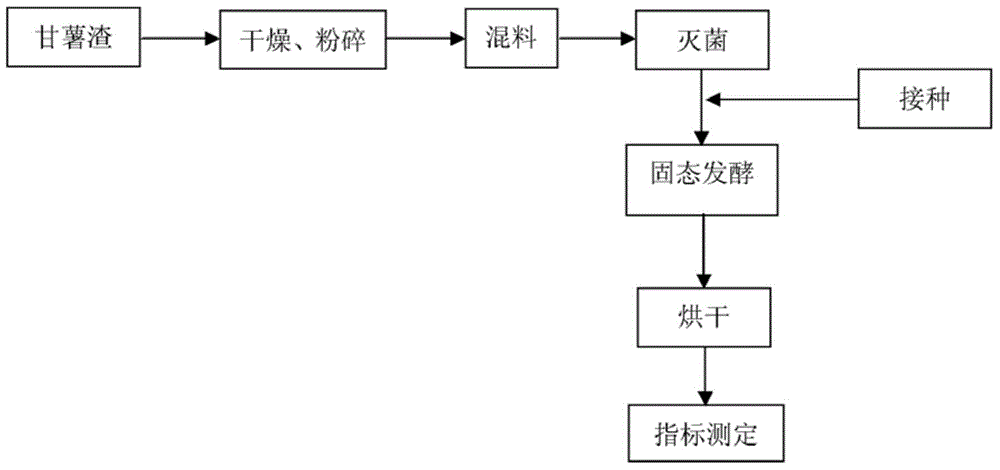

Image

Examples

Embodiment

[0041] Unless otherwise specified, the following examples are carried out according to conventional methods known to those skilled in the art, and the reagents used are those commonly used in corresponding analyzes and preparations in the art.

[0042] In the present embodiment, a kind of sweet potato dregs type fermented feed is prepared, and the specific preparation method is as follows:

[0043] 1. Material selection

[0044] The sweet potato residue used in this example comes from the sweet potato residue produced by Shandong Shengqi Biological Co., Ltd. after processing sweet potatoes to produce starch. The storage time is no more than 2 hours, dried at 90°C until the moisture content is less than 10%, and crushed to pass through a 60-mesh sieve. The fermenting bacteria preparation is active dry yeast produced by Shandong Shengqi Biological Co., Ltd.

[0045] 2. Preparation steps

[0046] (1) Drying and crushing of sweet potato dregs: 1.2 kg of fresh sweet potato dregs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com