Processing mechanism and processing method of main body component of bicycle

A technology for processing mechanisms and bicycles, which is applied to bicycle accessories, bicycle frames, household components, etc., can solve the problems that the productivity cannot be effectively improved, the cost and productivity are not solved, and the labor cost is increased, so as to save the pressure holding and cooling procedures. , The effect of improving shape accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

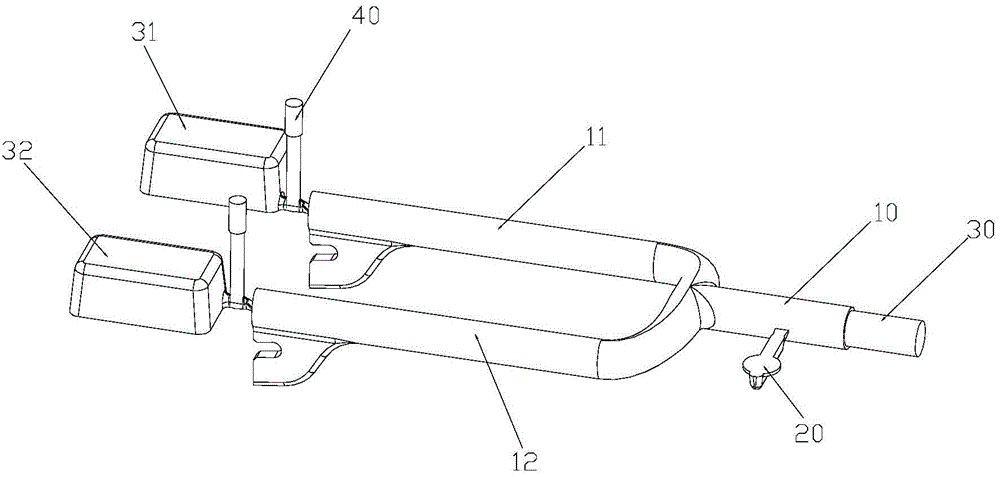

[0041] The specific content of the invention will be described in detail below in conjunction with the accompanying drawings.

[0042]The core innovation of the invention is to introduce the water-assisted molding process into the injection molding process, and organically combine the two, so that all the main components of the bicycle are integrally formed, and the processing time is greatly shortened.

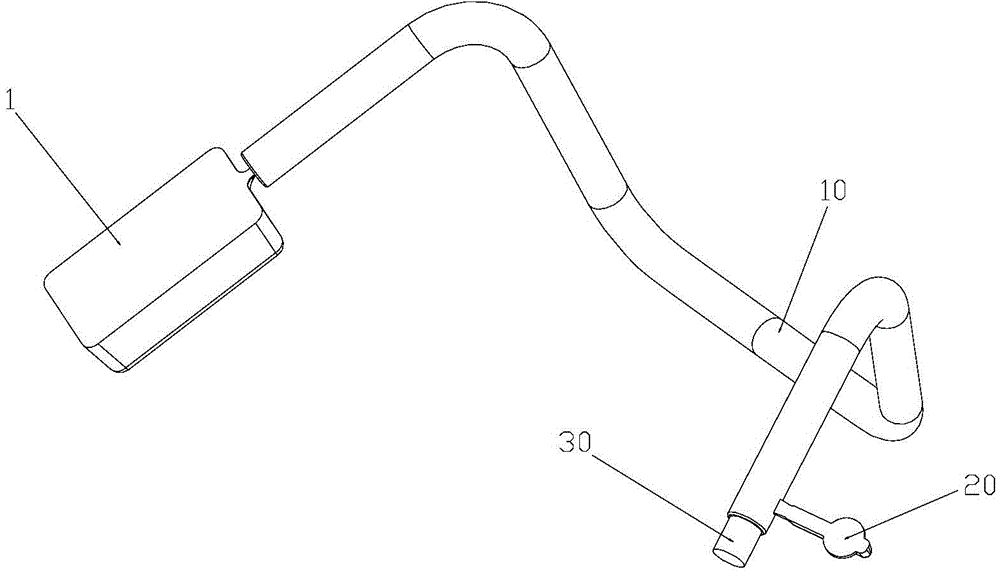

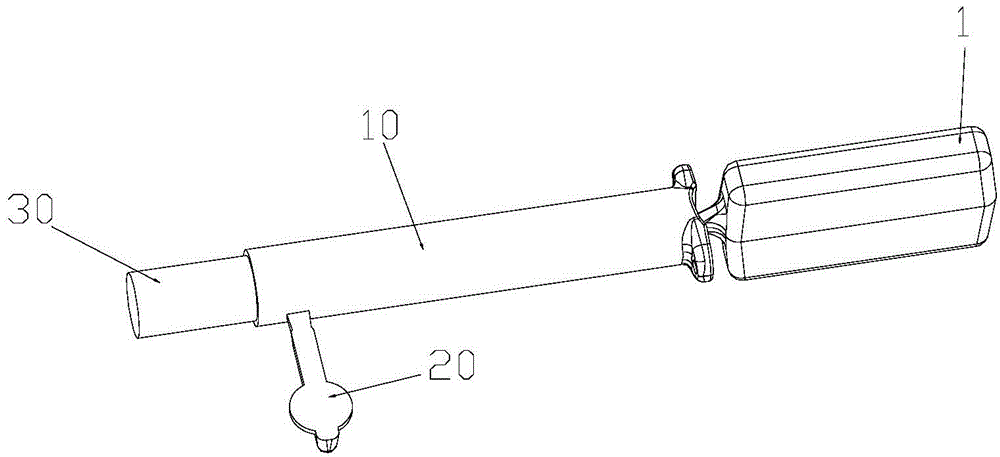

[0043] Through the analysis of the structural characteristics of the main components of the bicycle, such as the frame, front fork, handlebar, and seat tube, it can be seen that the common point is that each has a main pipe. For example, the main pipe of the frame is the seat used to connect the seat tube. Tube connection pipe, and the main pipe of the seat tube and the handlebar is its body; Multiple legs support the rear wheels, while the front fork extends from its main leg with two legs that connect to support the front wheels.

[0044] In view of the above-mentioned str...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com