Polyamide aerogel fibers and preparation method and application thereof

A polyamide gel fiber and aerogel fiber technology, which is applied in the directions of single-component polyamide rayon, fiber processing, filament/thread forming, etc., can solve the problem of few types and limited application fields of aerogel fibers, etc. problem, to achieve the effect of high porosity, excellent spinnability, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Another aspect of the embodiments of the present invention also provides a method for preparing the aforementioned polyamide airgel fiber, which includes:

[0035] (1) Provide polyamide spinning solution;

[0036] (2) prepare polyamide gel fiber with polyamide spinning solution;

[0037] (3) performing special drying treatment on the polyamide gel fiber to obtain polyamide airgel fiber.

[0038] Wherein, in a more specific typical implementation case, the preparation method includes:

[0039] (1) Select a suitable polyamide material, synthesize or dissolve it to prepare a spinning solution, preferably, the polyamide material used can be dissolved in a certain solvent;

[0040] (2) obtaining the polyamide gel fiber by the polyamide spinning solution through spinning technology;

[0041] (3) The polyamide gel fiber is placed in a solvent of a certain proportion, and the solvent is replaced with an alcohol gel fiber or a hydrogel fiber; the above polyamide gel fiber is ...

Embodiment 1

[0066] (1) Select poly-p-phenylene terephthalamide fibers and an equal amount of KOH to be dissolved in DMSO as spinning solution;

[0067] (2) Extruding the spinning solution into a 30% DMSO aqueous solution through a syringe pump to form a polyamide gel fiber, the spinneret hole diameter is 300 μm, and the draft ratio is 0.9;

[0068] (3) Carry out solvent replacement to above-mentioned polyamide gel fiber, replacement solvent is deionized water;

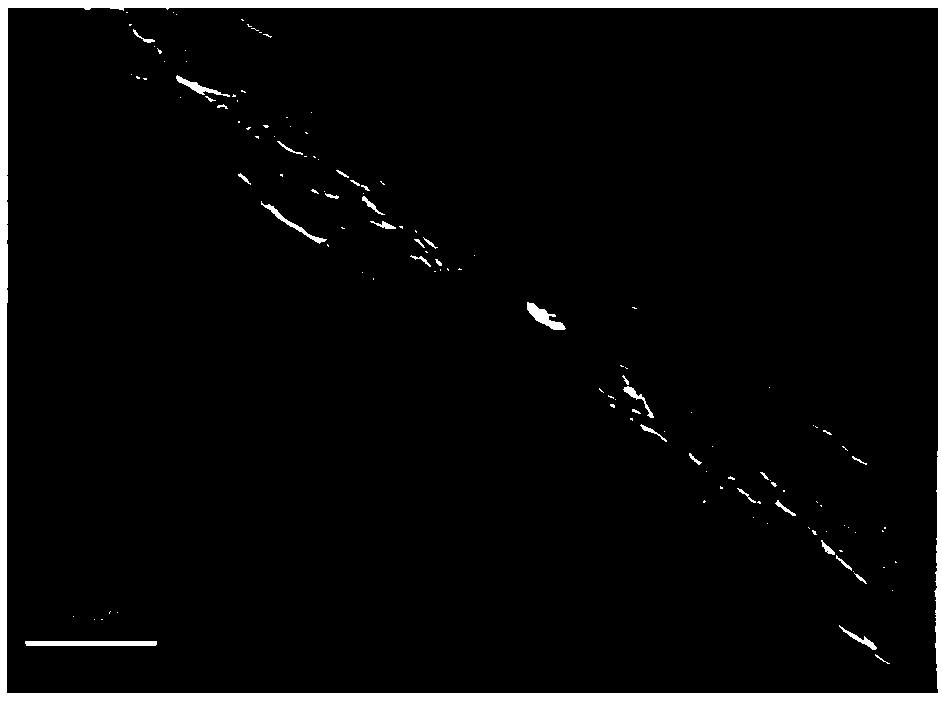

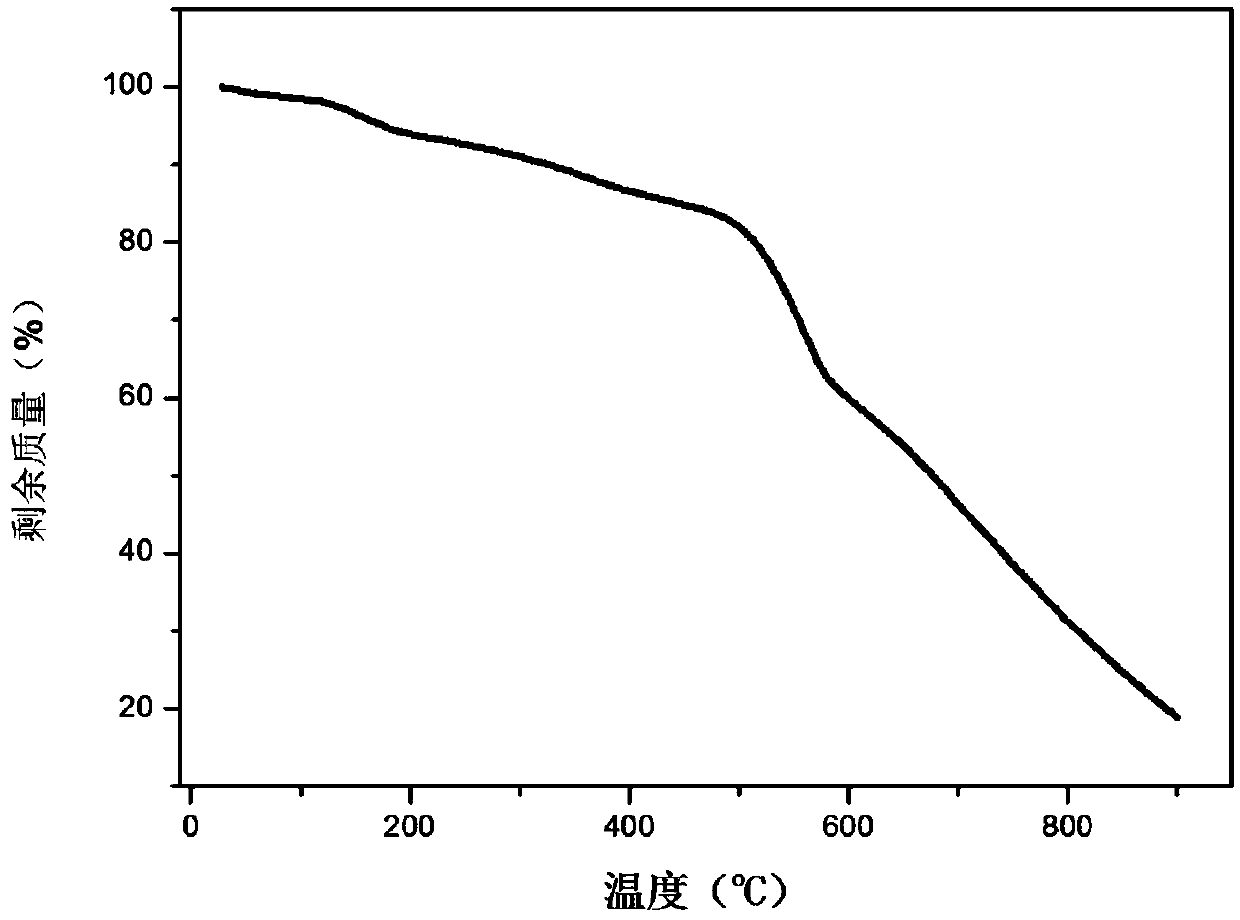

[0069] (4) After the above-mentioned hydrogel fibers were frozen at -12°C for 8 hours, they were placed in a vacuum freeze dryer and dried until no solvent components existed in the fibers. figure 1 Show the SEM photo of the polyamide airgel fiber gained in the present embodiment, figure 2 The TG curve of the polyamide airgel fiber obtained in this example is shown. For other parameters, please refer to Table 1.

Embodiment 2

[0071] (1) Select poly-p-phenylene terephthalamide fibers and an equal amount of KOH to be dissolved in DMSO as spinning solution;

[0072] (2) Extruding the spinning solution into a 30% DMSO aqueous solution through a syringe pump to form a polyamide gel fiber, the spinneret hole diameter is 300 μm, and the draft ratio is 0.9;

[0073] (3) Carry out solvent replacement to above-mentioned polyamide gel fiber, replacement solvent is cyclohexane;

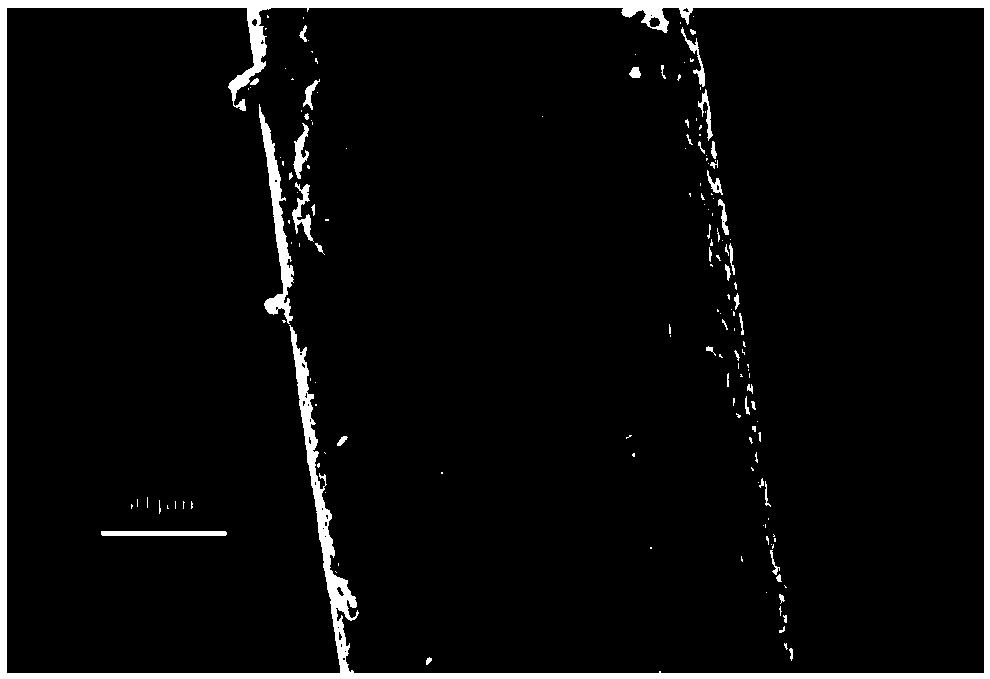

[0074] (4) After freezing the above-mentioned hydrogel fibers at -12° C. for 8 hours, put them into a vacuum freeze dryer, and dry them until no solvent component exists in the fibers. image 3 The SEM photos of the polyamide airgel fibers obtained in this example are shown, and other parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com