In-situ hydrophobic modified aramid nano aerogel fiber as well as preparation method and application thereof

A nano-airgel and hydrophobic modification technology, applied in fiber treatment, fiber type, physical treatment, etc., can solve the problems of fluorocarbon easy to fall off, skeleton shrinkage and collapse, complex preparation, etc., to achieve good hydrophobic performance and reaction conditions Mild, easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] An aspect of the embodiments of the present invention provides a method for preparing in-situ hydrophobically modified aramid nano-airgel fibers during the spinning process, including:

[0030] Provide aramid nano spinning solution;

[0031] Hydrophobic modified aramid nanogel fibers are prepared by spinning technology, the coagulation bath used in the spinning technology includes a combination of the first organic solvent and a halogenation reagent, and the halogenation reagent includes monobrominated alkane, monochlorinated Any one or a combination of two or more of alkanes, dibromoalkanes, dichloroalkanes, and trichloroalkanes;

[0032] The hydrophobically modified aramid nano-gel fiber is dried to obtain the in-situ hydrophobically modified aramid nano-airgel fiber.

[0033] In some implementation cases, the preparation method specifically includes the following steps:

[0034] (1) Provide aramid fiber nano spinning solution;

[0035] (2) Select and adjust the ch...

Embodiment 1

[0083] (1) Select poly-p-phenylene terephthalamide fibers, add an equal amount of KOH, dissolve in DMSO, and form a 1% spinning solution;

[0084] (2) The spinning solution is extruded into a monobromobutane by a syringe pump: in the coagulation bath of ethanol (volume ratio)=1:3, the reaction forms a hydrophobic modified aramid fiber nanogel fiber, wherein the extrusion needle diameter is 250μm;

[0085] (3) Carry out multiple solvent replacements to the above-mentioned hydrophobically modified aramid nanogel fibers, and the replacement solvent is ethanol;

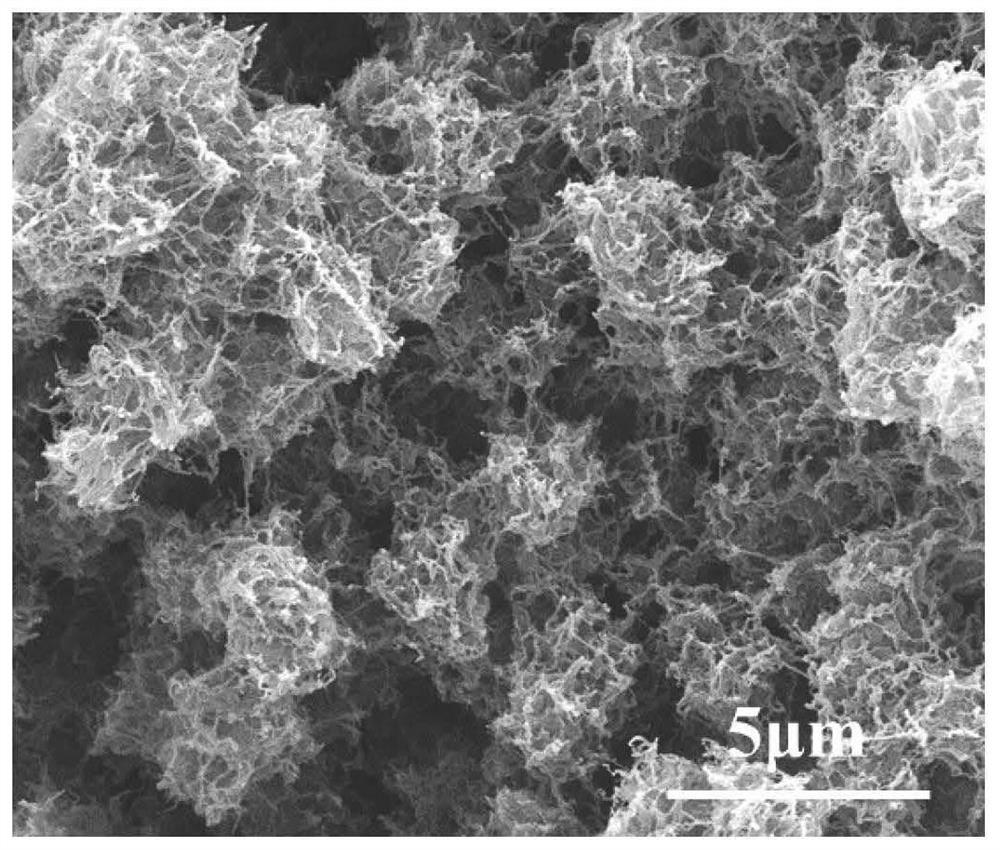

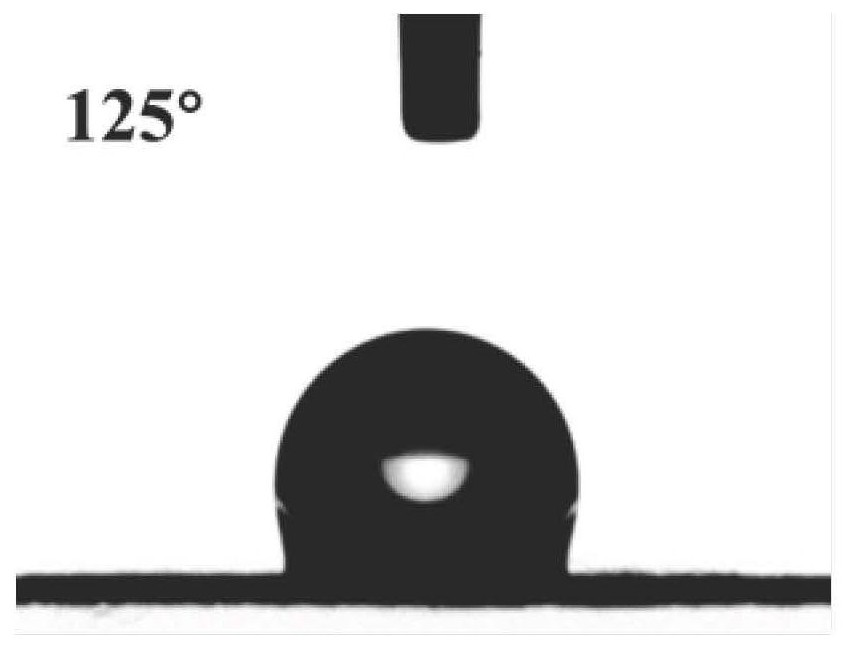

[0086] (4) Put the replaced alcogel fiber into supercritical CO 2 In a dryer, dry until the fibers are free of solvent components. figure 1 The SEM photo of the aramid nano-airgel fiber after the hydrophobic modification of the obtained embodiment is shown, figure 2 The contact angle of the aramid nano-airgel fiber after hydrophobic modification obtained in this example is shown. For other parameters of the hydrophob...

Embodiment 2

[0088] (1) Select poly-p-phenylene terephthalamide fibers, add an equal amount of KOH, dissolve in DMSO, and form a 2% spinning solution;

[0089] (2) spinning solution is extruded into dibromobutane by syringe pump: in the coagulation bath of ethanol (volume ratio)=2:1, reaction forms hydrophobically modified aramid fiber nano gel fiber, wherein extruding needle diameter is 250μm;

[0090] (3) Carry out multiple solvent replacements to the above-mentioned hydrophobically modified aramid nanogel fibers, and the replacement solvent is ethanol;

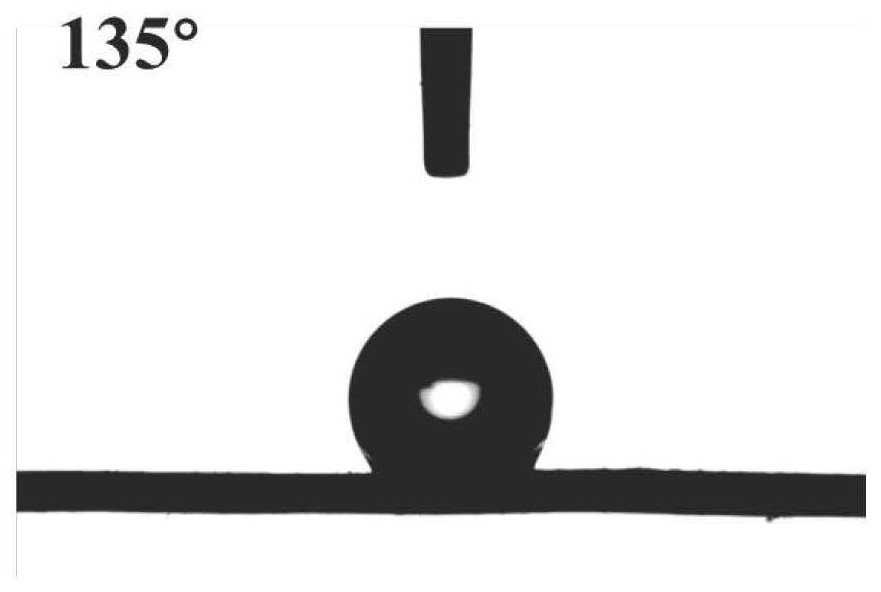

[0091] (4) Put the replaced alcogel fiber into supercritical CO 2 In a dryer, dry until the fibers are free of solvent components. image 3 The contact angle of the aramid nano-airgel fiber after hydrophobic modification obtained in this example is shown. For other parameters of the hydrophobically modified aramid nano-airgel fibers obtained in this example, please refer to Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com