Polyamide airgel fiber, its preparation method and application

A technology of polyamide gel fiber and airgel fiber, which is applied in the direction of single-component polyamide rayon, fiber treatment, bulk chemical production, etc., and can solve the problems of limited application fields and few types of airgel fiber , to achieve the effects of excellent spinnability, high porosity, and simple preparation process

Active Publication Date: 2022-05-31

SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Airgel fibers that have appeared at present include graphene oxide airgel fibers, graphene airgel fibers, titanium oxide airgel fibers, cellulose airgel fibers and polyvinylidene fluoride airgel fibers, etc., but the types Still relatively few, and the application fields of obtained airgel fibers are still limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0037] (3) The polyamide gel fiber is specially dried to obtain a polyamide aerogel fiber.

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Login to View More

Abstract

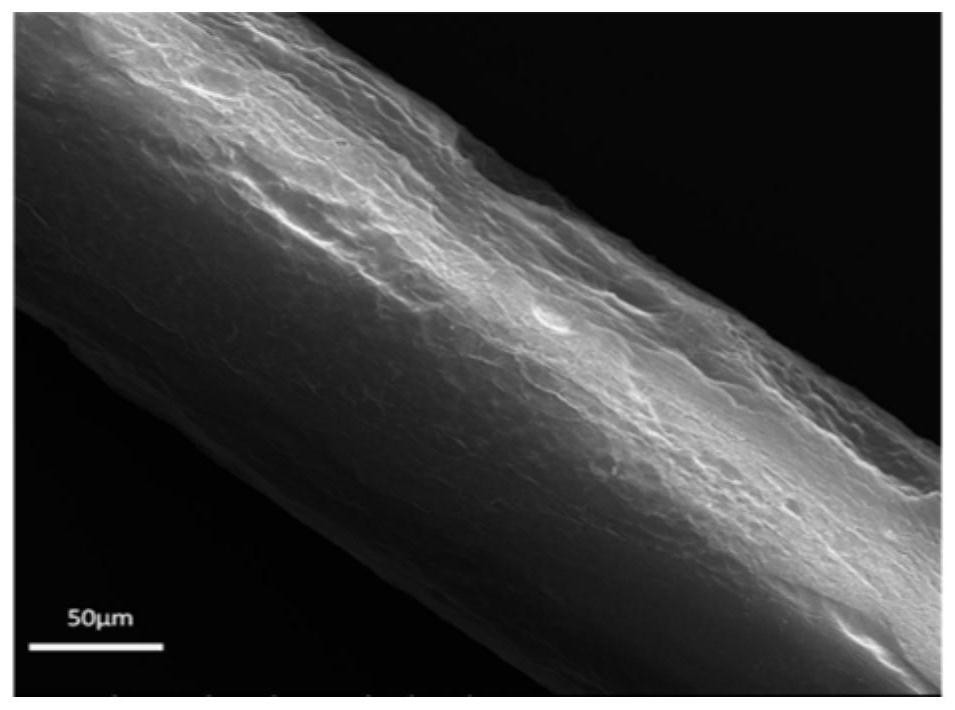

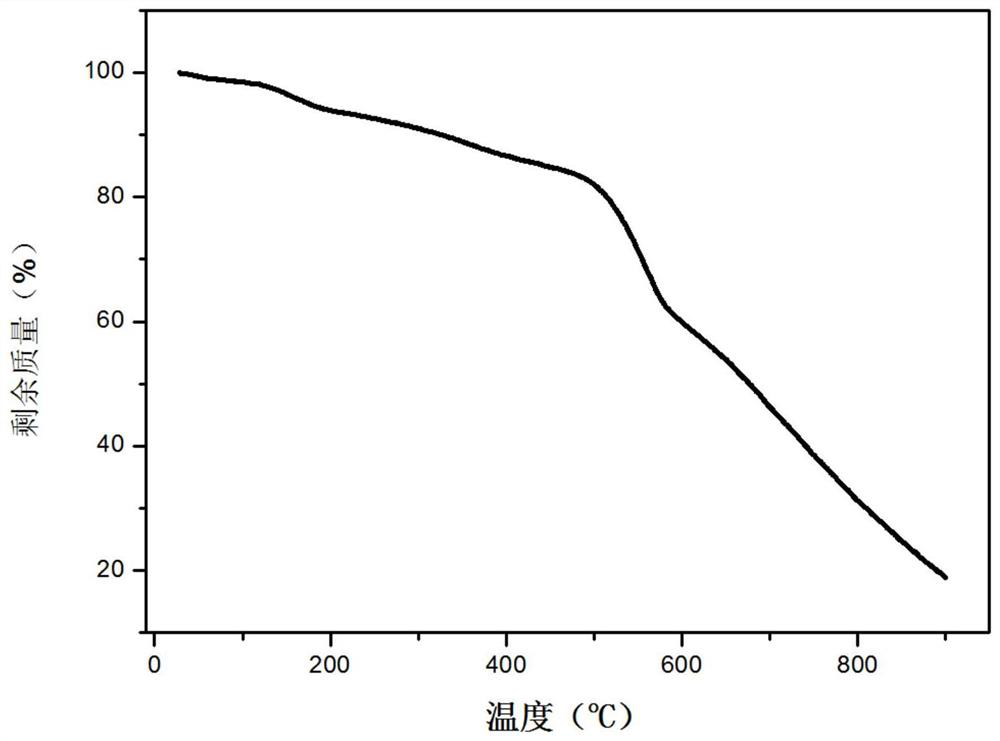

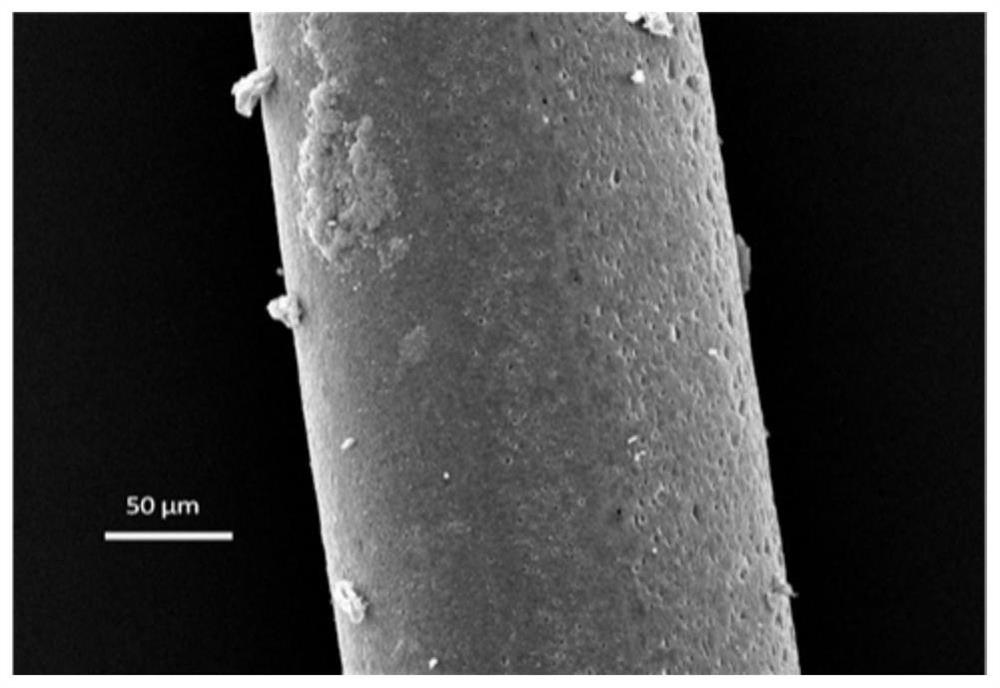

The invention discloses a polyamide airgel fiber, its preparation method and application. The polyamide airgel fiber has a connected three-dimensional porous network structure, and the three-dimensional porous network structure is formed by overlapping polyamide nanostructures. The preparation method includes: providing a polyamide spinning solution, preparing polyamide gel fibers by using gel spinning method, wet spinning method, dry spinning method and 3D printing method, and preparing the polyamide gel fiber The fibers are dried to obtain polyamide airgel fibers. The polyamide airgel fiber of the present invention has a unique three-dimensional porous network structure, extremely low thermal conductivity, relatively high porosity, certain spinnability and excellent skeleton structure stability, and can be applied in fields such as textiles. In addition, the obtained polyamide airgel fibers can be filled with different functional materials without affecting the stability of the skeleton material, which has great application prospects.

Description

Polyamide aerogel fiber, its preparation method and application technical field The present invention relates to a kind of novel functional fiber, relate in particular to a kind of polyamide aerogel fiber and preparation method thereof The invention relates to a method and application, and belongs to the technical field of nanoporous materials and functional fibers. Background technique [0002] Fiber materials have a long history. Since the fifth millennium BC, human beings have begun to use natural fibers such as cotton and linen. since the nineteenth century Since the birth of synthetic fibers in the early 1990s, the development of fiber materials has been greatly promoted due to the advantages of controllable components and designable structures. The types of fibers continue to increase, and different types of fibers such as differentiated fibers, high-performance fibers, functional fibers and smart fibers have been developed. types of fibers. After decades of de...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D01F6/90D01D5/247

CPCD01F6/90D01D5/247Y02P20/54

Inventor 张学同刘增伟

Owner SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com