Welding anti-spattering agent for galvanized steel plate and galvanized oil-coated steel plate

An anti-spatter agent, galvanized steel technology, applied in welding media, welding equipment, welding/welding/cutting items, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

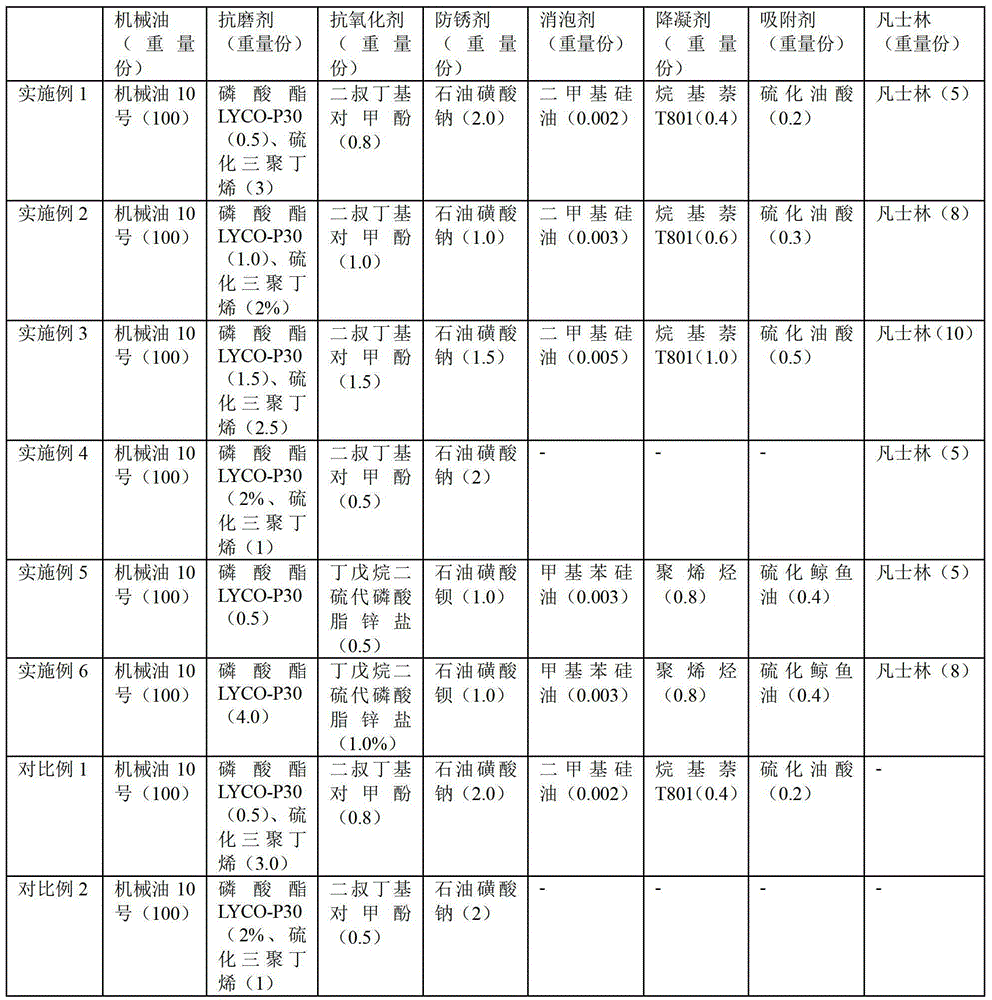

[0036] The ingredients were mixed according to the ingredients and contents in Table 1. When mixing, the vaseline was first melted and then mixed with other ingredients, and then stirred for 5 minutes to obtain the welding anti-spatter agent.

[0037] It will be injected into the oil tank of the electrostatic oiling unit. When the lead of the galvanized steel coil enters the electrostatic oiling unit, the electrostatic oiling unit will be started to apply oil normally. 2 ~4g / m 2 (wherein, embodiment 1 is 1g / m 2 , Example 2 is 2g / m 2 , Example 3 is 3g / m 2 , embodiment 4 is 4g / m 2 , Example 5 is 2g / m 2, Example 6 is 2g / m 2 ), the galvanized steel coil passes through the electrostatic coating room at a set speed to form a mixed oil film evenly coated with anti-rust oil and Vaseline. Coil normally after passing through the electrostatic oiling unit to obtain galvanized oiled steel sheets A1-A6 resistant to welding spatter.

Embodiment 7

[0047] The corrosion resistance test of the galvanized and oiled steel sheets A1-A6 and B1-B2 obtained above was carried out according to the neutral salt spray test in GB / T10125-1997 "Corrosion Tests in Artificial Atmosphere-Salt Spray Test".

[0048] The specific method is as follows: after cutting the galvanized oil-coated steel sheets A1-A6 and B1-B2 into sizes of 150mm×75mm×1.0mm, seal the edges with transparent tape to obtain the pattern. The sample is placed in the salt spray test chamber, and the test surface is at an angle of 15° to 30° to the vertical direction. The test temperature is 35±2°C, the test medium is NaCl aqueous solution with a concentration of 50g / L, the pH value is 6.5, and the amount of salt spray settlement: 1~2ml / h.80cm 2 . Open the test chamber every 2 hours to take out the samples for observation, and compare the changes in the corrosion of the samples. By comparison, it can be seen that the corrosion of the galvanized and oiled steel sheets A1 ...

Embodiment 8

[0050] Welding spatter resistance tests were carried out on the galvanized and oiled steel sheets A1-A6 and B1-B2 obtained above.

[0051] The anti-welding spatter test adopts CO with severe welding spatter 2 Shielded welding is tested (carbon dioxide gas shielded welding is the welding method with the most serious spatter, and the amount of molten metal particles spatter is large, and the spatter adheres to the surface of the weldment, and even metallurgically combines with the surface of the weldment). Specific test process: the galvanized oiled steel plate is placed in CO 2 On the edge of the weld bead of the shielded welding test plate (horizontal distance is about 10mm), during the welding process, it can be observed that the molten metal particles splash on the galvanized and oiled steel sheets A1-A6 and roll without sticking, while the molten metal particles splash on the plated steel sheets. The zinc-oiled steel sheets B1-B2 stop sticking together immediately after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com