Vanadium-titanium oxide catalyst, and preparation method and application thereof

A vanadium-titanium oxide and catalyst technology, which is applied in the field of cerium-doped vanadium-titanium oxide catalyst and vanadium-titanium oxide catalyst, can solve the problems of being easily affected by alkali metal poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Ce-doped V 2 o 5 / WO 3 -TiO 2 Catalyst, where V 2 o 5 The loading amount was 1%, and the Ce / V molar ratio was 4. After each precursor salt is dissolved into an aqueous solution and mixed uniformly, commercial titanium tungsten powder (WO 3 Content 5wt%), the solution volume to titanium tungsten powder mass ratio is 10:1 (mL / g), continuously stirred at 30°C for 2h, after rotary evaporation, put the obtained catalyst into an oven and dry at 100°C overnight, Finally, the powder catalyst was obtained by calcining in air at 500°C for 5 hours in a muffle furnace. Grind and sieve the prepared catalyst, take 40-60 mesh for later use, and call it catalyst Ce4VWTi.

Embodiment 2

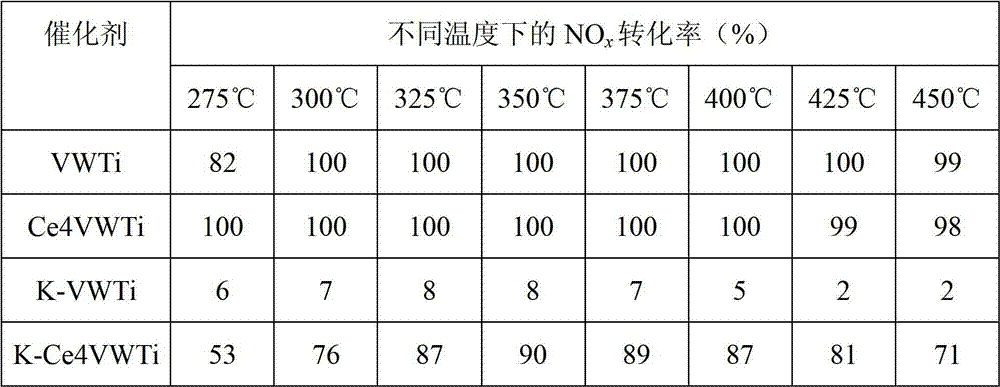

[0069] The Ce4VWTi in Example 1 and the VWTi catalyst powder in Comparative Example 1 were poisoned with K element. KNO 3 Soluble in aqueous solution according to KNO 3 The solution volume and catalyst powder mass ratio were 2:1 for impregnation, and the K addition amount was K / V with a molar ratio of 4. Catalyst powder impregnated in KNO 3 After 12 hours of solution, it was dried in an oven at 100°C, and then calcined in air at 500°C for 3 hours in a muffle furnace to obtain a powdered poisoned catalyst. Grind and sieve the prepared poisoned catalysts, and take 40-60 meshes for later use, which are called catalysts K-Ce4VWTi and K-VWTi.

Embodiment 3

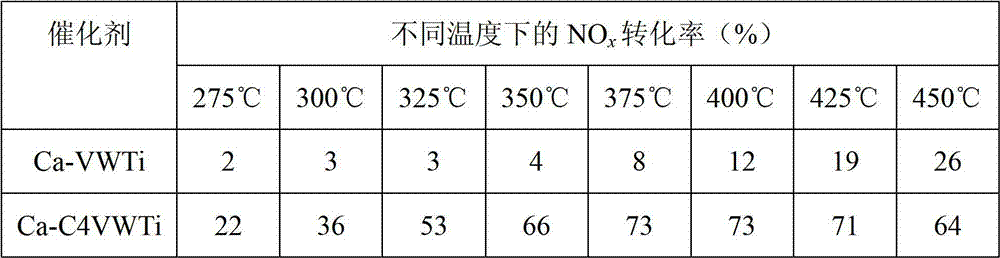

[0071] The Ce4VWTi in Example 1 and the VWTi catalyst powder in Comparative Example 1 were poisoned with Ca. Ca(NO 3 ) 2 4H 2 O was dissolved in the aqueous solution, impregnated according to the volume ratio of calcium nitrate solution to catalyst powder mass ratio of 2:1, and the Ca addition amount was Ca / V molar ratio of 8. The catalyst powder was soaked in calcium nitrate solution for 12 hours, dried in an oven at 100°C, and calcined in air at 500°C for 5 hours in a muffle furnace to obtain a powdered poisoned catalyst. Grind and sieve the prepared poisoned catalyst, and take 40-60 mesh for later use, called catalysts Ca-Ce4VWTi and Ca-VWTi.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com