Self-stabilizing cervical interbody fusion cage and manufacturing die and method thereof

An intervertebral fusion device and a technology for manufacturing molds are applied in the field of intervertebral fusion devices to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

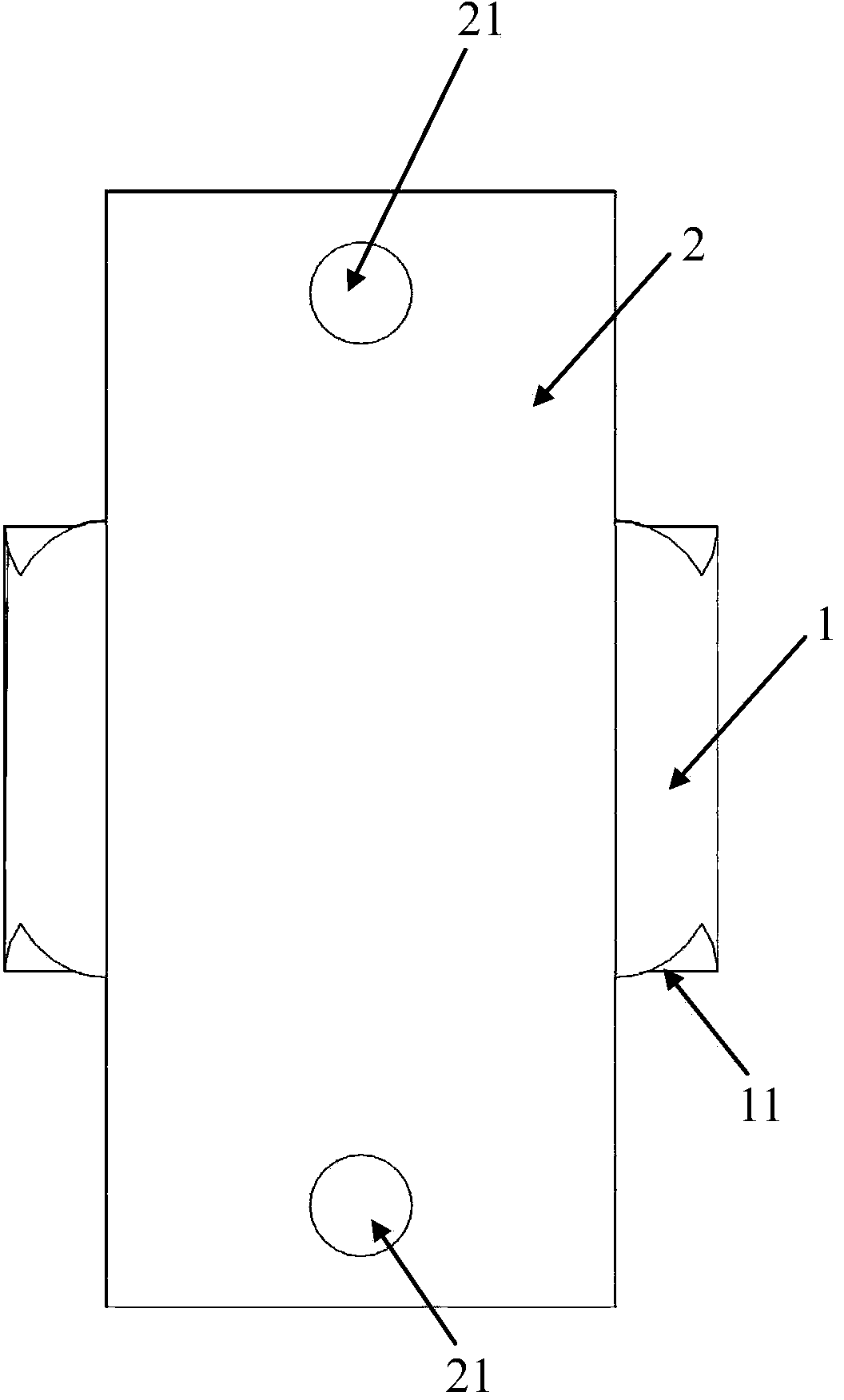

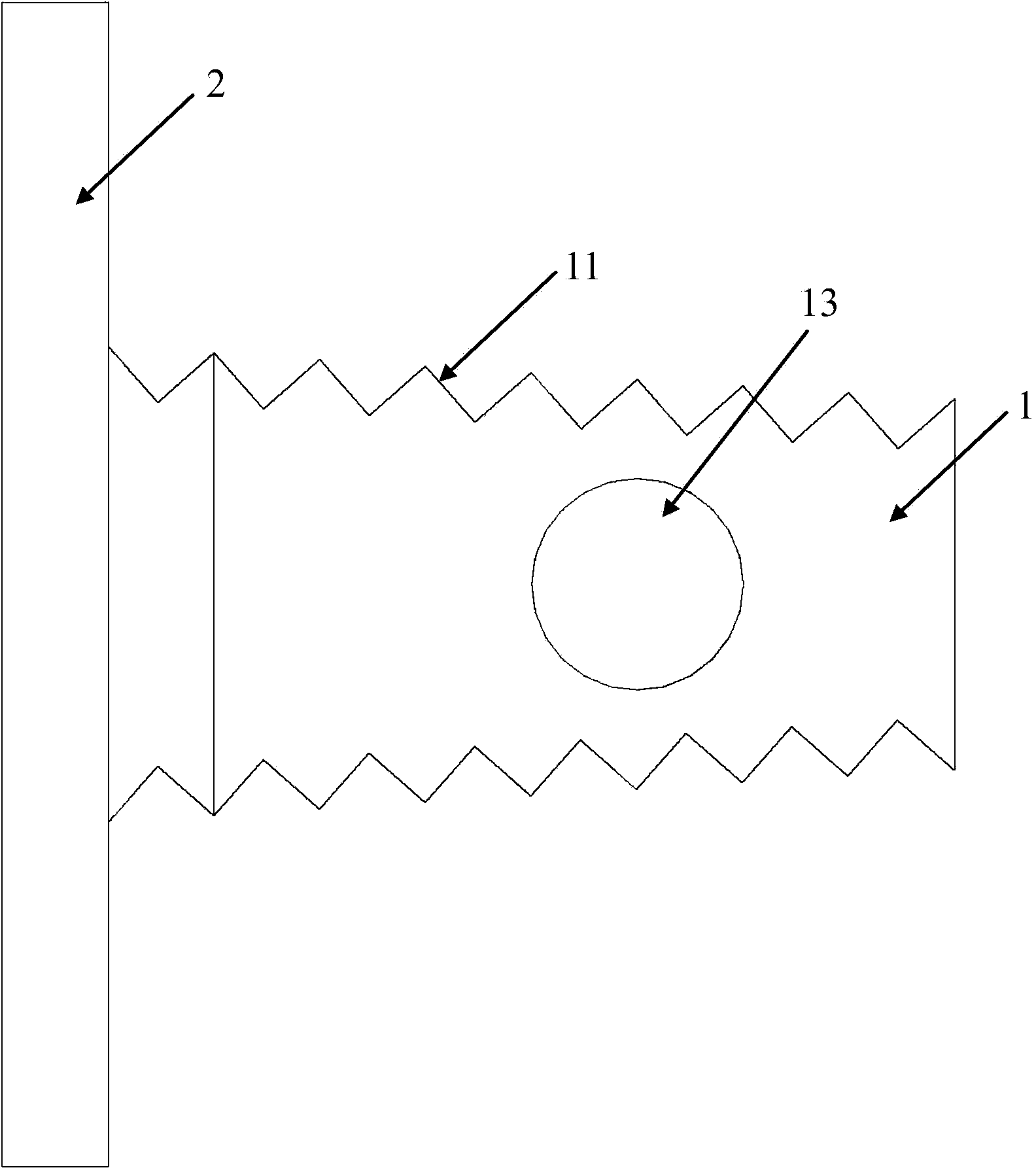

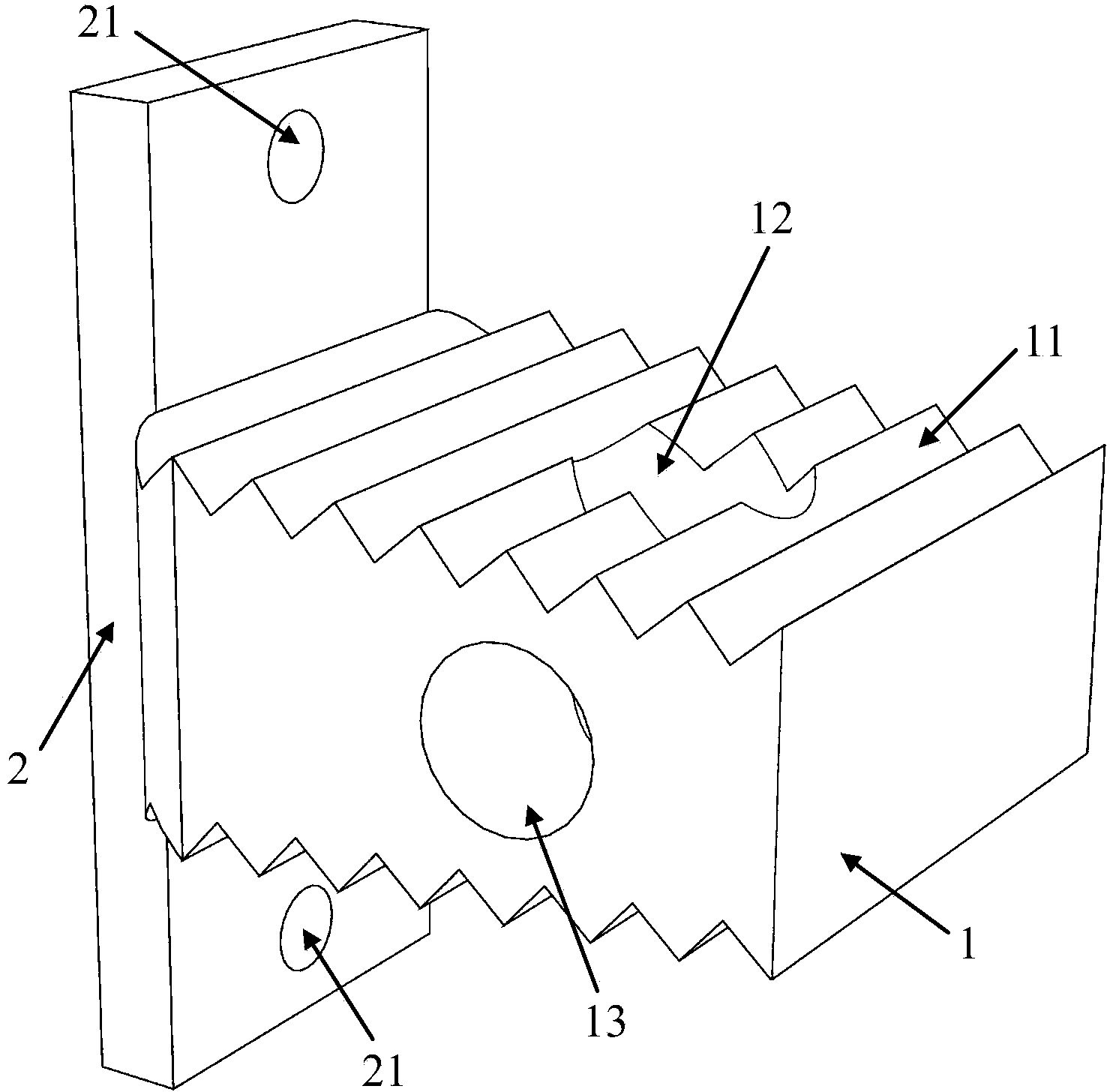

[0102] The main body 1 of the fusion device is made of mineralized collagen material; the size of the main body 1 of the fusion device is 14.0 mm in length, 12.5 mm in width, the height of the front end is 7.0 mm, and the height of the rear end is 6.0 mm; the upper and lower end surfaces of the fusion device body 1 have a depth of 0.35 mm. mm, a tooth-like structure with a spacing of 2.0mm; the left and right sides of the fuser body 1 are centered near the back with a cylindrical vertical through-hole 12 with a diameter of 4.6mm, and the distance from the center of the vertical through-hole 12 to the rear end surface of the fuser body 1 is 6.3mm . During the manufacturing process, it is necessary to accurately weigh 1.93g (accurate to 0.01g) of mineralized collagen powder, put it into the first forming mold 31, hold the pressure for 90 seconds under a pressure of 1000MPa, and carry out the cold pressing molding of the cage body. After testing, the material density of the fuser...

Embodiment 2

[0106] The main body 1 of the fusion device is made of mineralized collagen material; the size of the main body 1 of the fusion device is 15.0 mm in length, 12.0 mm in width, the height of the front end is 8.0 mm, and the height of the rear end is 7.0 mm; the upper and lower end surfaces of the fusion device body 1 have a depth of 0.5 mm, a tooth-like structure with a spacing of 2.0mm; the left and right sides of the fuser body 1 are centered near the back, and there is a square vertical through hole 12 with a side length of 5.5mm, and the distance from the center of the vertical through hole 12 to the rear end surface of the fuser body 1 is 7.0mm . During the manufacturing process, 2.27g (accurate to 0.01g) of mineralized collagen powder needs to be accurately weighed, loaded into the first molding die 31, and held at a pressure of 900MPa for 120 seconds to cold-press the main body of the cage. After testing, the material density of the fuser main body 1 of this embodiment is...

Embodiment 3

[0110] The main body 1 of the fusion device is made of mineralized collagen material; the size of the main body 1 of the fusion device is 16.0 mm in length, 14.0 mm in width, 9.0 mm in height at the front end, and 7.5 mm in height at the rear end; the upper and lower end surfaces of the fusion device body 1 have a depth of 0.6 mm, a tooth-like structure with a spacing of 2.2mm; the center of the fuser body 1 has a cylindrical vertical through-hole 12 with a diameter of 6.0mm near the back, and the distance from the center of the vertical through-hole 12 to the rear end surface of the fuser body 1 is 8.0mm . During the manufacturing process, it is necessary to accurately weigh 3.18g (accurate to 0.01g) of mineralized collagen powder, put it into the first forming mold 31, hold the pressure at 1100MPa for 80 seconds, and carry out the cold-press molding of the cage body. After testing, the material density of the fuser main body 1 of this embodiment is 1.72g / cm 3 , The axial co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com