Method for raising intensity of long periodic optical-fibre grating and reducing tape width and optical-fibre grating

A fiber grating and long-period technology, which is applied in cladding optical fiber, optical waveguide light guide, optical waveguide coupling, etc., can solve the problems of LPFG intensity and bandwidth indicators that cannot be achieved, and achieve easy batching, high grating strength, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further elaborated below in conjunction with accompanying drawing:

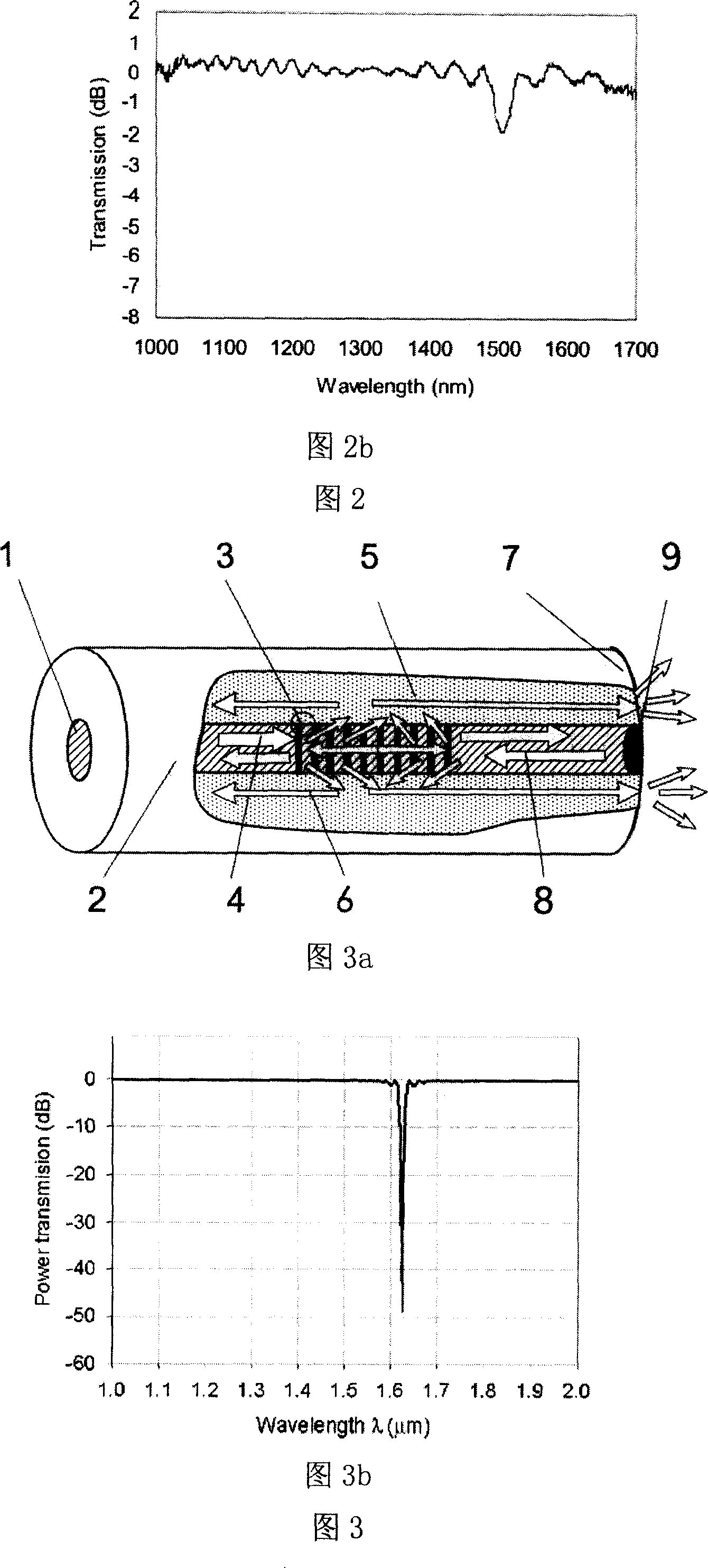

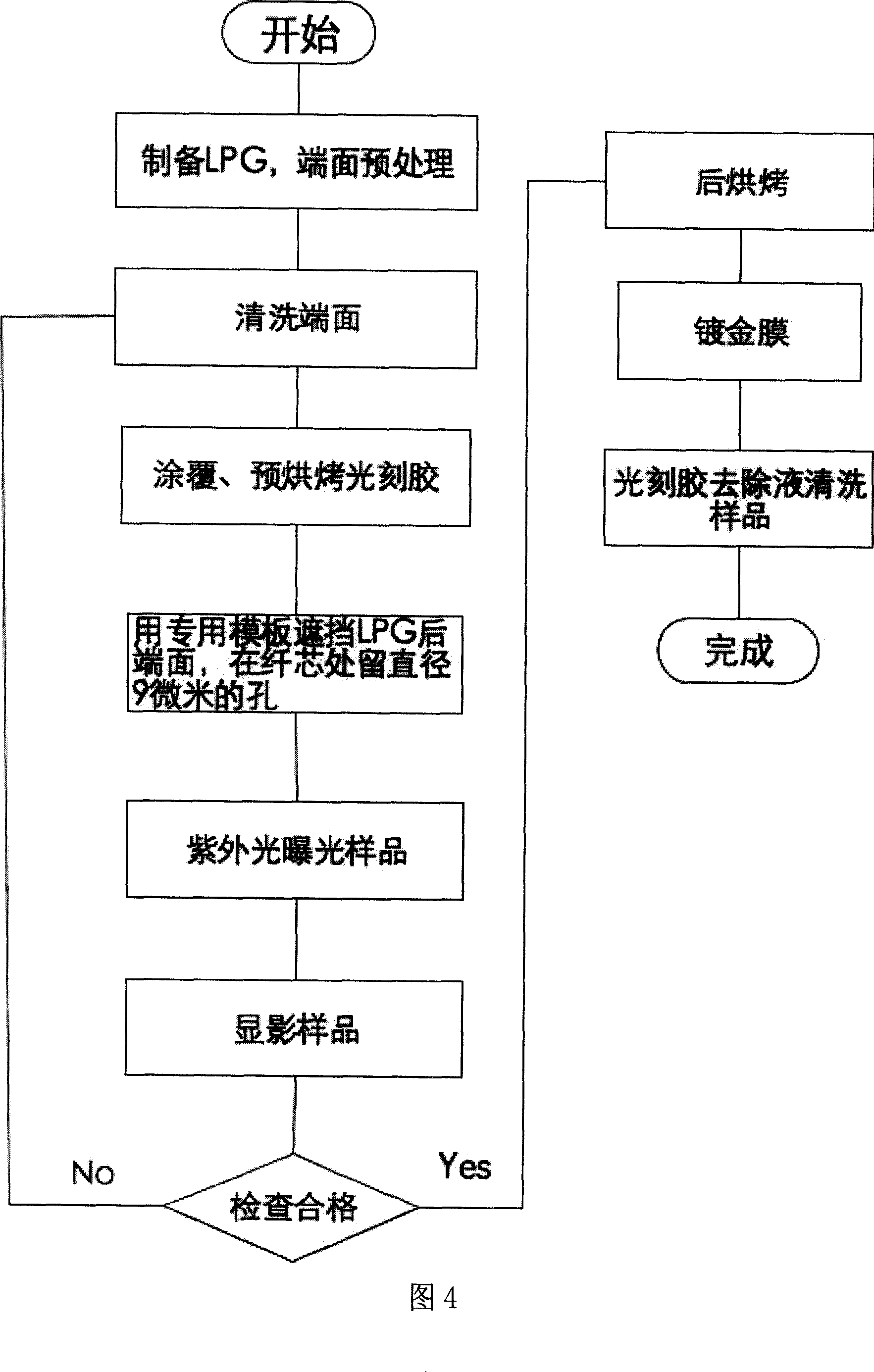

[0045] Referring to Fig. 3a, a long period fiber grating is composed of a core 1, a cladding 2, a grating region 3, a grating rear end face 7, a core mode reflector 9 and the like. The core mode reflector 9 is a gold-plated reflective surface, which is made at the end of the fiber core on the rear end face 7 of the grating, and has a diameter of 9 microns, which is the same as the diameter of the fiber core 1 . The production adopts micro-electromechanical system (MEMS) and micro-nano manufacturing technology, see Figure 4, the process flow is as follows:

[0046] 1) Preprocessing:

[0047] Prepare a well-made LPFG, and process its rear end surface into a mirror surface;

[0048] 2) Cleaning:

[0049] Soak in sulfuric acid solution for 10 minutes, rinse with distilled water, and dry with nitrogen; put in acetone solution, ultrasonically clean for 3 minutes, rinse with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com