Preparation method of epoxy group-terminated styrene-butadiene-styrene (SBS) ternary block copolymer

An epoxy-terminated styrene and ternary block technology, which is applied in the field of preparation of end-group functional styrene-butadiene-styrene tertiary block copolymers, can solve the problem of unreported epoxy-terminated, inability to Then switch the brand, equipment pollution and other problems, to achieve the effect of superior performance, high end capping rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

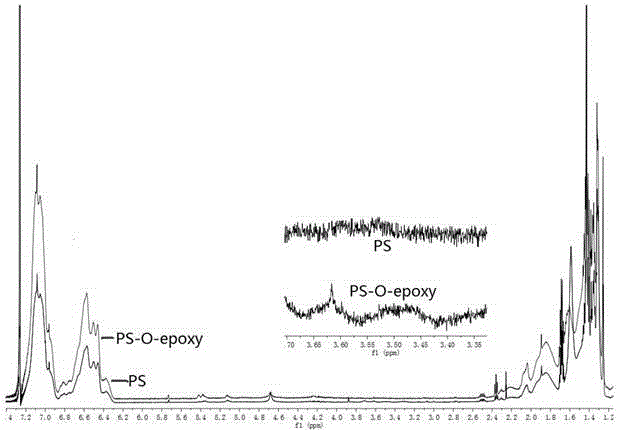

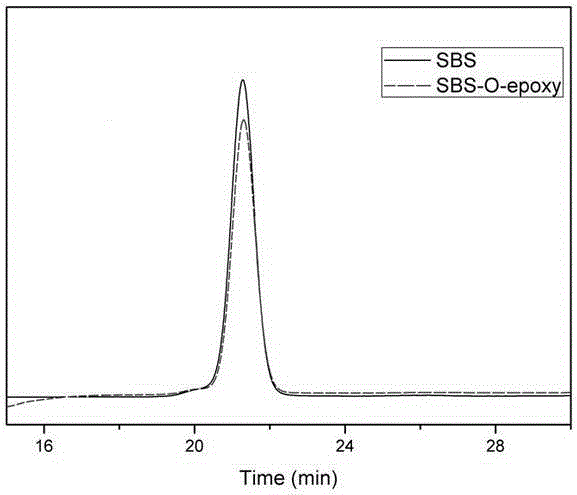

Embodiment 1

[0026] In a 10L polymerization kettle, 4.42kg of cyclohexane, 125g of styrene and tetrahydrofuran were injected with nitrogen pressure, and the molar ratio of tetrahydrofuran to effective n-butyllithium was 0.15. Heating to raise the temperature, adding n-butyllithium to break the impurity, when the system changes from colorless to pale yellow, the impurity in the system has been removed. Then add 3.6ml of effective n-butyllithium solution rapidly at 60°C, the molar concentration of n-butyllithium solution is 2.43mol / L, and initiate polymerization for 30min; In the polymerization kettle, react for 35min; press nitrogen into 125g styrene at the same temperature, continue to react for 30min, then add 1.4ml propylene oxide, react for 15min, then add 2ml epichlorohydrin, react for 15min, use 1.5ml ethanol Termination, adding 0.6% of anti-aging agent 2,6-di-tert-butyl p-cresol according to the mass of the final polymerization product. After the polymerization is completed, the rea...

Embodiment 2

[0030]In a 10L polymerization kettle, 4.42kg of cyclohexane, 125g of styrene and tetrahydrofuran were injected with nitrogen pressure, and the molar ratio of tetrahydrofuran to effective lithium was 0.2. Heating to raise the temperature, adding n-butyllithium to break the impurity, when the system changes from colorless to pale yellow, the impurity in the system has been removed. Then add 4.1ml of effective n-butyllithium solution rapidly at 60°C, the molar concentration of n-butyllithium solution is 2.43mol / L, and initiate polymerization for 30min; In the polymerization kettle, react for 25min; press nitrogen into 125g styrene at the same temperature, continue to react for 30min, then add 1.5ml propylene oxide, react for 15 minutes, then add 2.2ml epichlorohydrin, react for 15min, use 1.6 ml of ethanol to terminate, add anti-aging agent 2,6-di-tert-butyl p-cresol with a mass percentage of 0.3% based on the mass of the final polymerization product. After the polymerization is...

Embodiment 3

[0032] In a 10L polymerization kettle, 4.42kg of cyclohexane, 125g of styrene and tetrahydrofuran were injected with nitrogen pressure, and the molar ratio of tetrahydrofuran to effective lithium was 0.15. Heating to raise the temperature, adding n-butyllithium to break the impurity, when the system changes from colorless to pale yellow, the impurity in the system has been removed. Then add 3.2ml of effective n-butyllithium solution rapidly at 60°C, the molar concentration of n-butyllithium solution is 2.43mol / L, and initiate polymerization for 30min; In the polymerization kettle, react for 35 minutes; pressurize 125g styrene with nitrogen at the same temperature, continue to react for 30 minutes, then add 1.3ml propylene oxide, react for 15 minutes, then add 2ml epichlorohydrin, react for 10min, use 1.5ml Ethanol is terminated, and the amount of 1% anti-aging agent 2,6-di-tert-butyl-p-cresol is added according to the mass of the final polymerization product. After the polyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com