Refining method of cyclohexane dicarboxylates plasticizer

A technology of cyclohexanedicarboxylic acid and ester plasticizers, which is applied in the direction of carboxylate preparation, carboxylate separation/purification, chemical instruments and methods, etc., and can solve high energy consumption, large alkali washing wastewater, process To solve problems such as long process, achieve the effect of increasing purity, improving acid value and chroma, and shortening the refining process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

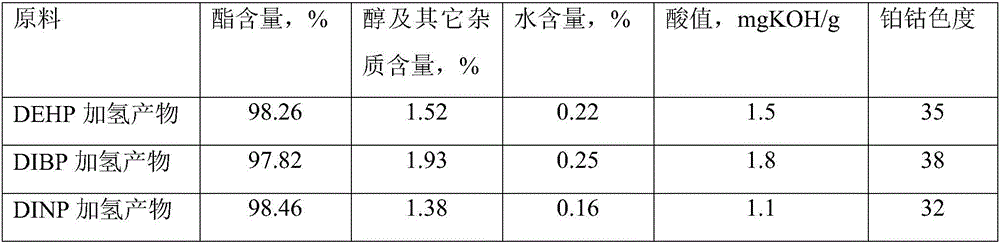

[0015] The raw material properties are shown in Table 1:

[0016] Table 1 Composition of hydrogenation products of phthalate plasticizers

[0017]

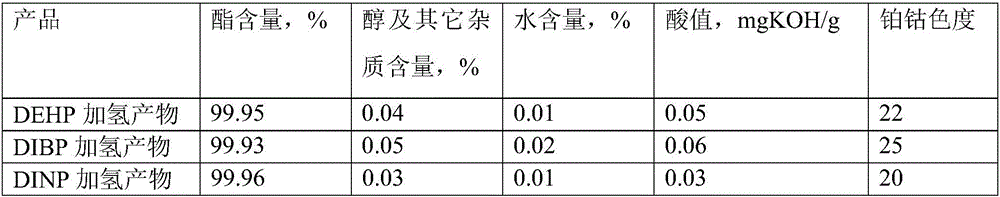

Embodiment 1

[0019] The raw material is the direct hydrogenation product of DEHP, the content of diisooctyl 1,2-cyclohexanedicarboxylate is 98.26%, the content of alcohol and other impurities is 1.52%, the content of water is 0.22%, the acid value is 1.5mgKOH / g, and the color of platinum-cobalt 35. The DEHP hydrogenation product is heated to 150°C and then enters the dealcoholization tower, and steam stripping is used. The steam stripping temperature is 150°C, the ratio of steam volume to material volume is 1:10, and the pressure at the top of the tower is 15kPaA. The bottom of the tower is extracted into the dehydration tower, the material inlet temperature is 143°C, and the pressure at the top of the dehydration tower is 12kPaA. After flash dehydration, the material enters the refining reactor. The upper part of the refining reactor is filled with modified alkaline clay; the lower part is filled with shell-type activated carbon. The operating conditions of the refining reactor are: react...

Embodiment 2

[0021] The raw material is the direct hydrogenation product of DIBP, the content of diisobutyl 1,2-cyclohexanedicarboxylate is 97.82%, the content of alcohol and other impurities is 1.93%, the content of water is 0.25%, the acid value is 1.8mgKOH / g, and the color of platinum-cobalt 38. The DIBP hydrogenation product is heated to 140°C and then enters the dealcoholization tower, and steam stripping is used. The steam stripping temperature is 150°C, the ratio of steam volume to material volume is 1:12, and the pressure at the top of the tower is 15kPaA. The bottom of the tower is extracted into the dehydration tower, the material inlet temperature is 137°C, and the pressure at the top of the dehydration tower is 12kPaA. After flash dehydration, the material enters the refining reactor. The upper part of the refining reactor is filled with modified alkaline clay, and the lower part is filled with shell-type activated carbon. The operating conditions of the refining reactor are: r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com