Refrigerator oil and refrigeration compressor and system

A refrigeration compressor and refrigeration machine oil technology, which is applied in the field of refrigeration compressors and refrigeration compressor systems, can solve the problems of low viscosity index and flash point, poor low-temperature fluidity, easy to block capillary tubes, etc., and achieve high flash point and good mutual solubility , the effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

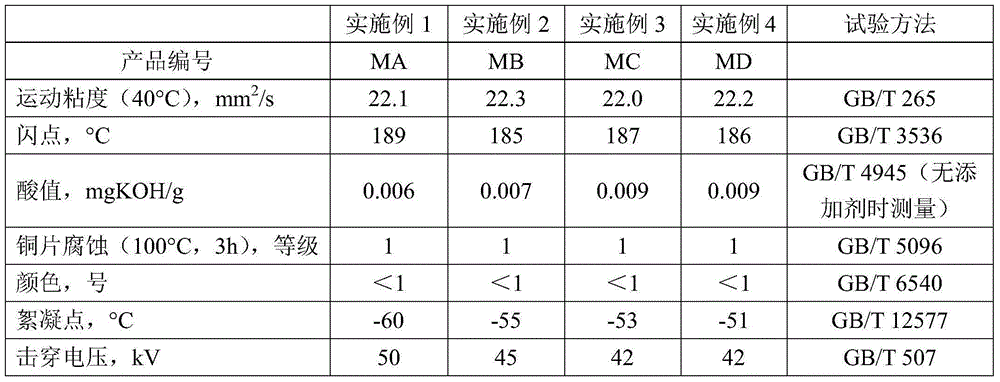

[0033] Blend 5 g of detergent and dispersant, 1 g of antioxidant, and 2 g of antiwear agent first, and then blend with 100 g of alkylbenzene oil A to obtain refrigerating machine oil MA, whose properties are shown in Table 1.

Embodiment 2

[0035] Blend 7 grams of detergent and dispersant, 1 gram of antioxidant, and 2 grams of antiwear agent first, and then blend with 100 grams of alkylbenzene oil B to obtain refrigerating machine oil MB, whose properties are shown in Table 1.

Embodiment 3

[0037] Blend 0.7 g of detergent and dispersant, 0.5 g of antioxidant, and 2 g of antiwear agent first, and then blend with 100 g of alkylbenzene oil A to obtain refrigerating machine oil MC, whose properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com