Hotpot condiment capable of effectively preventing grease oxidation and preparation method thereof

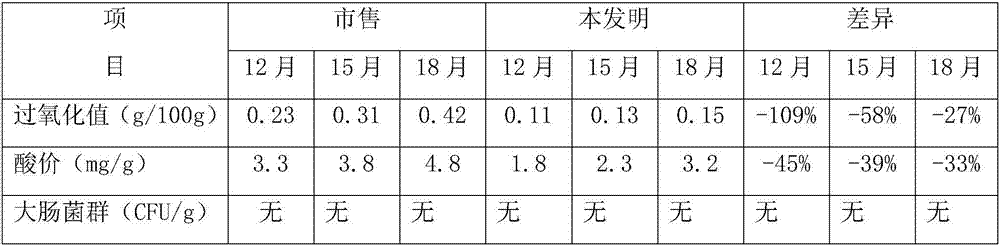

A technology for hot pot base material and oil oxidation, which is applied in the direction of food ingredients as antioxidants, bacteria used in food preparation, and the function of food ingredients. It can solve problems such as oxidation and rancidity, prevent oxidation, reduce acid value, and prolong The effect of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] A hot pot bottom material that effectively prevents oil oxidation, mainly prepared from the following raw materials in parts by weight: 33 parts of butter, 27 parts of bean paste, 11 parts of tempeh, 11 parts of basic sauce, 8 parts of rapeseed oil, and 8 parts of Chaotian pepper , 8 parts of ginger, 7 parts of seasoning sauce, 5 parts of sugar, 4 parts of peppercorns, 4 parts of salt, 2 parts of garlic, 2 parts of monosodium glutamate, 0.4 parts of spices, 0.3 parts of compound enzyme, 0.3 parts of I+G, 0.08 parts of scallops share;

[0060] The butter is crude butter extracted from cows slaughtered in accordance with halal slaughter standards, and is refined into butter meeting the requirements of the food industry through hydration, alkali refining, decolorization, deodorization and other treatments.

[0061] The preparation method of the basic sauce comprises the following steps: take a 4cm×4cm×1cm beef block, wash it, marinate it in 35% honey solution for 4 minutes, ...

Embodiment 2

[0084] A hot pot bottom material that effectively prevents oil oxidation, mainly prepared from the following raw materials in parts by weight: 32 parts of butter, 26 parts of bean paste, 10 parts of tempeh, 10 parts of basic sauce, 7 parts of rapeseed oil, and 7 parts of Chaotian pepper , 7 parts of ginger, 6 parts of seasoning sauce, 4.5 parts of sugar, 3.5 parts of peppercorns, 3.5 parts of salt, 1.5 parts of garlic, 1.5 parts of monosodium glutamate, 0.35 parts of spices, 0.25 parts of compound enzyme, 0.25 parts of I+G, 0.07 parts of scallops share;

[0085] The butter is crude butter extracted from cows slaughtered in accordance with halal slaughter standards, and is refined into butter meeting the requirements of the food industry through hydration, alkali refining, decolorization, deodorization and other treatments.

[0086] The preparation method of the basic sauce comprises the following steps: take a 4cm×4cm×1cm beef block, wash it, marinate it in 30% honey solution ...

Embodiment 3

[0109] A hot pot bottom material that effectively prevents oil oxidation, mainly prepared from the following raw materials in parts by weight: 34 parts of butter, 28 parts of bean paste, 12 parts of tempeh, 12 parts of basic sauce, 9 parts of rapeseed oil, and 9 parts of Chaotian pepper , 9 parts of ginger, 8 parts of seasoning sauce, 5.5 parts of sugar, 4.5 parts of peppercorns, 4.5 parts of salt, 2.5 parts of garlic, 2.5 parts of monosodium glutamate, 0.45 parts of spices, 0.35 parts of compound enzyme, 0.35 parts of I+G, 00.09 parts of scallops share;

[0110] The butter is crude butter extracted from cows slaughtered in accordance with halal slaughter standards, and is refined into butter meeting the requirements of the food industry through hydration, alkali refining, decolorization, deodorization and other treatments.

[0111] The preparation method of the basic sauce includes the following steps: take a 4cm×4cm×1cm beef block, wash it, marinate it in 40% honey solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com