Low-temperature spread jet nitrogen charge refreshing method for maize germ oil

A technology of corn germ oil and fresh-keeping method, which is applied in the field of nitrogen flushing and fresh-keeping, and low temperature field of corn germ oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Use a single diatomaceous earth sand filter rod nitrogen dispersion injector whose geometric dimensions are: Long cylindrical body with a pore size ranging from 16 to 30 microns.

[0039] It is installed in parallel in the center of the oil pipeline before filling, so that the nitrogen gas will form a fine airflow after passing through the dispersing injector under the pressure of 0.8MPa, and form a turbulent mixing with the oil liquid, so as to eliminate the oxygen that is miscible in the oil and prevent corn The purpose of oil oxidation deterioration.

[0040] The oxygen content in the corn germ oil processed by the nitrogen-filled fresh-keeping method of this embodiment is less than 0.008%;

[0041] The acid value in the bottled corn germ oil processed by the nitrogen-filling fresh-keeping method of this embodiment increased from 0.12 (mgKOH / g) to 0.18 (mgKOH / g) within 18 months, only an increase of 0.5 times.

Embodiment 2

[0043] Nitrogen dispersion injectors using three diatomaceous earth sand filter rods, each geometrically dimensioned as: Long cylindrical body with a pore size of 16-30 microns, installed in series in the oil pipeline before canning, the centerline of each diatomite sand filter rod coincides with the centerline of the oil pipeline, so that the nitrogen gas is under 0.6MPa pressure , After passing through the dispersing injector, a fine airflow is formed, and it forms a turbulent mixing with the oil liquid, so as to eliminate the oxygen miscible in the oil and achieve the purpose of preventing the corn oil from oxidative deterioration.

[0044] The oxygen content in the corn germ oil processed by the nitrogen-filled fresh-keeping method of this embodiment is less than 0.008%;

[0045] The acid value in the bottled corn germ oil processed by the nitrogen flushing preservation method of this embodiment increased from 0.12 (mgKOH / g) to 0.18 (mgKOH / g) within 18 months, only an i...

Embodiment 3

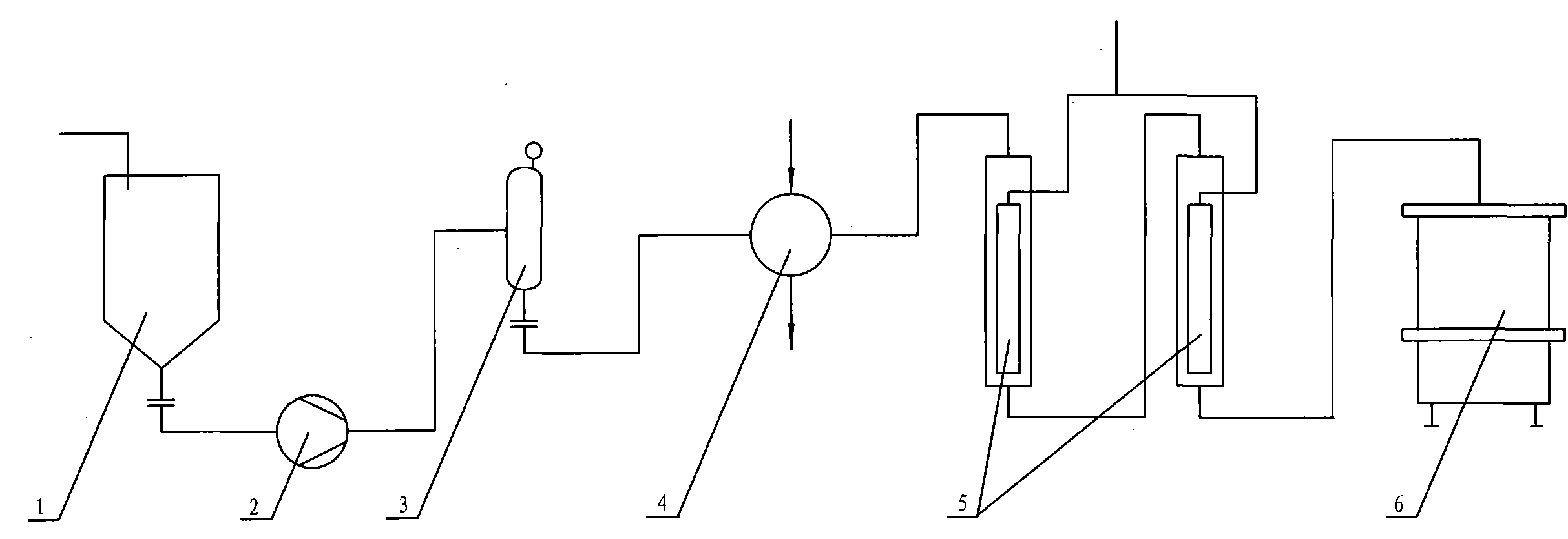

[0047] In the corn germ oil production system, the processing process example of the nitrogen-filling fresh-keeping method of the present invention is adopted

[0048] During the production process, the nitrogen-filled fresh-keeping mainly grasps the following points:

[0049] The corn oil from refining is covered with nitrogen under negative pressure; cooled to 7-15°C; nitrogen dispersive jet is used to disperse and inject nitrogen at a pressure of 0.5-0.8 MPa.

[0050] See the attached flow chart figure 1 , the specific steps are:

[0051]With the corn germ oil from the refining process, under a certain negative pressure (133-266Pa, the oxygen content is the lowest at this time), immediately carry out nitrogen filling by covering method, and send it into a 30-ton refined oil storage tank; use oil pump 2 as power , after being filtered by the precision filter 3, it is sent to the cooling cooler device 4 to cool down, and reaches the set temperature between 7 and 15° C; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com