Phosphorus-nitrogen-boron synergistic efficient flame retardant flexible curing agent and synthesis method thereof

A synthesis method and high flame retardant technology are applied in the field of phosphorus-nitrogen-boron synergistic high flame-retardant flexible curing agent and its synthesis field, which can solve the problem that the synthesis reaction temperature and flame retardant efficiency of polyester with low acid value cannot be synthesized. To solve the problems of synergistic flame retardant, inability to synthesize high acid value curing agent, etc., to achieve the effect of optimization of curing agent index parameters, strong adjustability, and obvious synergistic flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

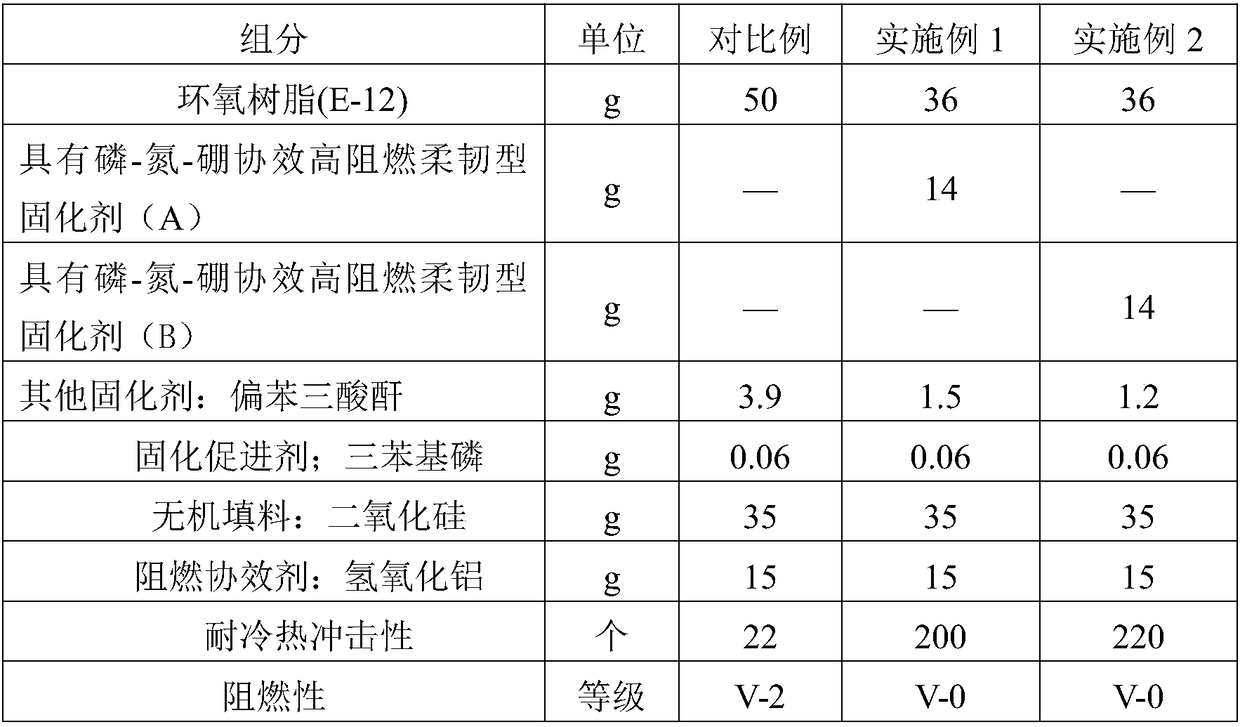

Examples

Embodiment 1

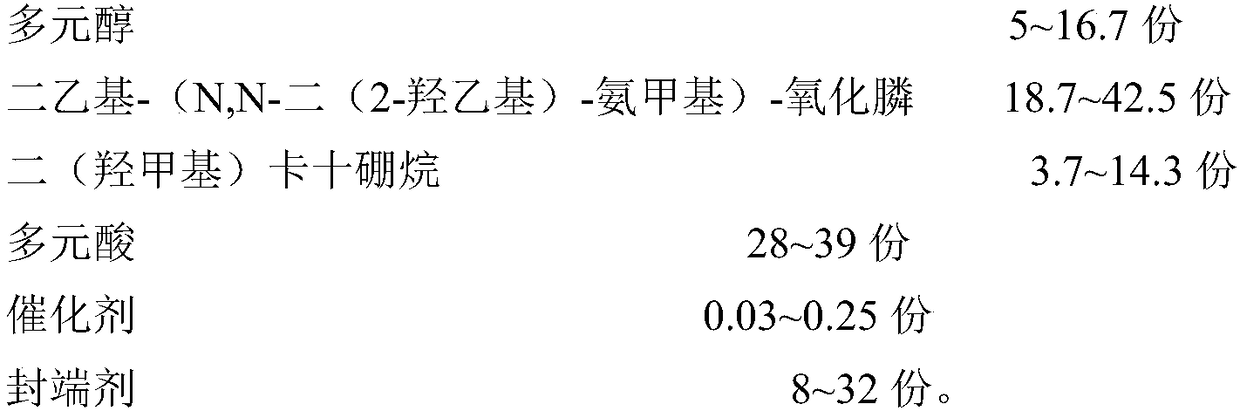

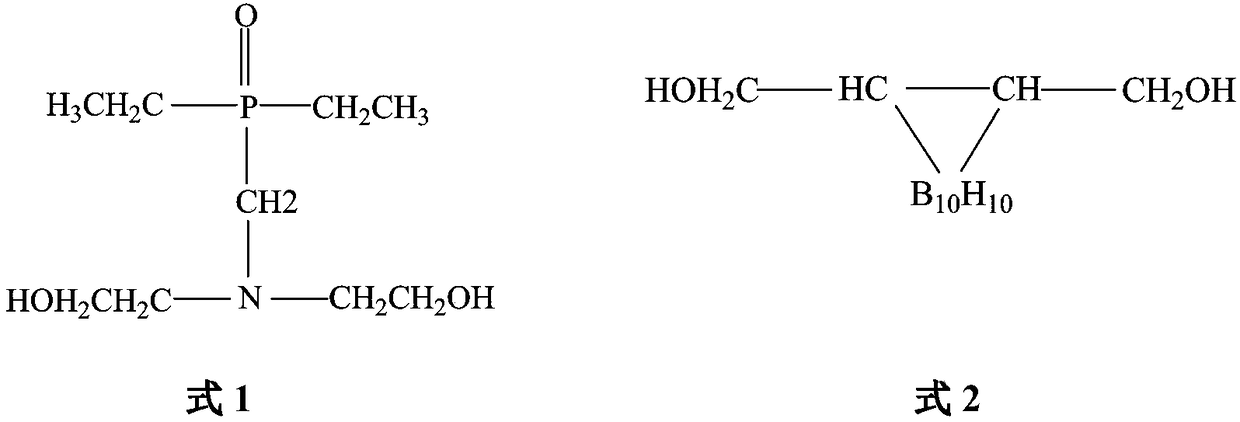

[0032] A kind of synthetic method with phosphorus-nitrogen-boron synergistic highly flame-retardant flexible curing agent (A), the steps are as follows:

[0033] (1) After the four-neck flask, stirrer, distillation column, condenser tube and temperature-controlled heating mantle are finished, add 95g of neopentyl glycol, raise the temperature to 110-130°C, stir and melt, add 244.4g of diethyl-(N, N-bis(2-hydroxyethyl)-aminomethyl)-phosphine oxide, 56.5g bis(hydroxymethyl)cadecaborane, after stirring evenly, the temperature was raised to 140°C;

[0034] (2) Add 40g of adipic acid, 257.8g of isophthalic acid and 0.69g of ethyl triphenylphosphine bromide, under the protection of nitrogen, slowly raise the temperature to 140°C for esterification reaction and by-product water flows out, and control distillation The column temperature is not higher than 100°C;

[0035] (3) Then carry out a segmented esterification reaction, 140~170°C for 1.5~3h, 170~200°C for 2~3h, 200~230°C for 1~...

Embodiment 2

[0040] A kind of synthetic method with phosphorus-nitrogen-boron synergistic highly flame-retardant flexible curing agent (B), the steps are as follows:

[0041] (1) After the four-necked flask, stirrer, distillation column, condenser tube and temperature-controlled heating mantle are finished, add 85g of neopentyl glycol, raise the temperature to 110-130°C, stir and melt, add 246.01g of diethyl-(N, N-bis(2-hydroxyethyl)-aminomethyl)-phosphine oxide, 37.36g bis(hydroxymethyl)cadecaborane, after stirring evenly, the temperature was raised to 140°C;

[0042] (2) Add 55.21g of adipic acid, 188.3g of isophthalic acid and 0.61g of ethyl triphenylphosphine bromide, under the protection of nitrogen, slowly raise the temperature to 140°C for esterification reaction and by-product water flows out, control The temperature of the distillation column is not higher than 100°C;

[0043] (3) Then carry out a segmented esterification reaction, 140~170°C for 1.5~3h, 170~200°C for 2~3h, 200~23...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com