Method for manufacturing polyamide resin laminated film roll

A polyamide-based, manufacturing method technology that is applied to the field of manufacturing polyamide-based resin laminated film rolls, and can solve problems such as inability to exhibit sliding properties and inconsequential processing characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

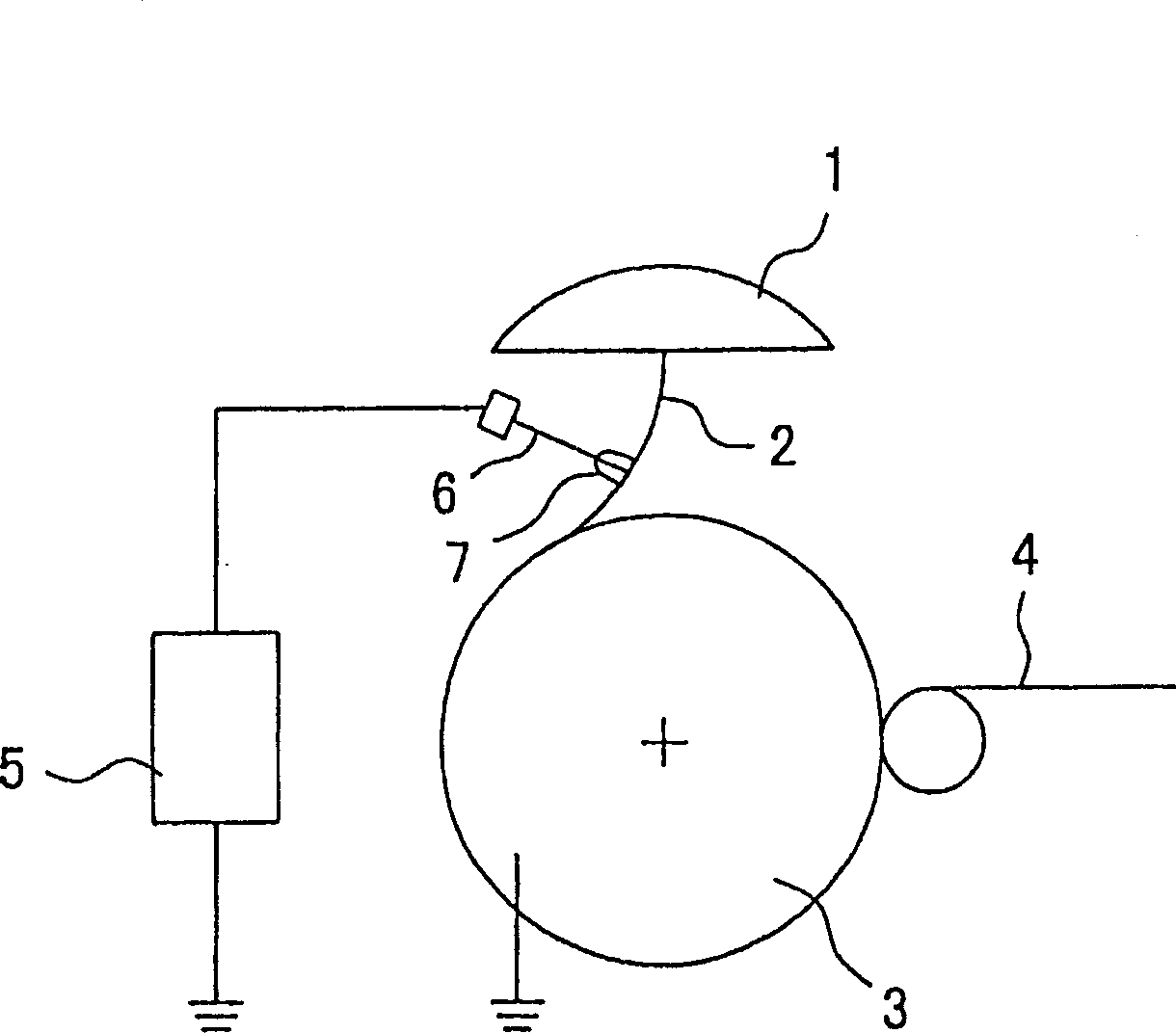

[0057] The preferred mode of the method for producing the polyamide resin laminated film roll of the present invention will be described below. According to the manufacturing method of the present invention, an unstretched sheet (unstretched laminate sheet) obtained by melt-extruding a polyamide resin by a co-extrusion method along the longitudinal direction (length direction) and the transverse direction ( Width direction) After biaxial stretching, it is wound into a roll shape to produce a polyamide resin laminated film roll.

[0058] As the polyamide resin used in the present invention, for example, nylon 6 using ε-caprolactam as a main raw material can be cited. In addition, examples of other polyamide resins include polyamide resins obtained by polycondensation of three-membered ring or more lactam, ω-amino acid, dibasic acid, and diamine. Specifically, as the lactam, in addition to the ε-caprolactam exemplified above, for example, enantholactam (oenantholactam), capryrolacta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com